V10 Engine vs Pulse Combustion: Comparative Testing

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine and Pulse Combustion Background and Objectives

The evolution of internal combustion engines has been a cornerstone of technological advancement since the late 19th century. V10 engines, characterized by their V-shaped configuration with ten cylinders, emerged as a high-performance solution for applications demanding exceptional power output and smooth operation. These engines gained prominence in the automotive industry during the 1990s, particularly in high-end sports cars and Formula 1 racing, where their balance of power, weight, and compact design offered significant advantages over traditional V8 or V12 configurations.

Pulse combustion, in contrast, represents a fundamentally different approach to energy generation. Developed initially in the early 20th century, this technology utilizes self-sustaining pressure oscillations to create a series of discrete combustion events rather than the continuous combustion process found in conventional engines. The principle involves a combustion chamber designed to create resonant pressure waves that both expel exhaust gases and draw in fresh fuel-air mixture without mechanical valves or pistons.

The comparative testing between V10 engines and pulse combustion systems aims to establish a comprehensive understanding of their respective performance characteristics, efficiency metrics, and environmental impacts. This analysis is particularly relevant as industries worldwide face increasing pressure to reduce carbon emissions while maintaining or improving performance standards.

Key objectives of this technical research include quantifying the power-to-weight ratios of both technologies across various operational conditions, measuring fuel efficiency under standardized testing protocols, and evaluating emissions profiles with special attention to NOx, CO2, and particulate matter. Additionally, the research seeks to assess the scalability of both technologies for different applications ranging from automotive to industrial power generation.

The historical trajectory of both technologies reveals interesting convergence points and divergences. While V10 engines have followed the traditional development path of reciprocating internal combustion engines with incremental improvements in materials, fuel delivery systems, and electronic control, pulse combustion has experienced more discontinuous development, with periods of intense interest followed by relative dormancy.

Recent technological advancements have renewed interest in both systems. For V10 engines, the integration of hybrid electric systems and advanced materials has extended their relevance in an increasingly electrified transportation landscape. Simultaneously, pulse combustion has seen renewed attention due to potential applications in micro-power generation, waste heat recovery systems, and specialized propulsion technologies where its unique characteristics offer distinct advantages.

This comparative testing initiative represents a critical evaluation point in understanding how these technologies might complement or compete with each other in addressing the complex energy challenges of the 21st century.

Pulse combustion, in contrast, represents a fundamentally different approach to energy generation. Developed initially in the early 20th century, this technology utilizes self-sustaining pressure oscillations to create a series of discrete combustion events rather than the continuous combustion process found in conventional engines. The principle involves a combustion chamber designed to create resonant pressure waves that both expel exhaust gases and draw in fresh fuel-air mixture without mechanical valves or pistons.

The comparative testing between V10 engines and pulse combustion systems aims to establish a comprehensive understanding of their respective performance characteristics, efficiency metrics, and environmental impacts. This analysis is particularly relevant as industries worldwide face increasing pressure to reduce carbon emissions while maintaining or improving performance standards.

Key objectives of this technical research include quantifying the power-to-weight ratios of both technologies across various operational conditions, measuring fuel efficiency under standardized testing protocols, and evaluating emissions profiles with special attention to NOx, CO2, and particulate matter. Additionally, the research seeks to assess the scalability of both technologies for different applications ranging from automotive to industrial power generation.

The historical trajectory of both technologies reveals interesting convergence points and divergences. While V10 engines have followed the traditional development path of reciprocating internal combustion engines with incremental improvements in materials, fuel delivery systems, and electronic control, pulse combustion has experienced more discontinuous development, with periods of intense interest followed by relative dormancy.

Recent technological advancements have renewed interest in both systems. For V10 engines, the integration of hybrid electric systems and advanced materials has extended their relevance in an increasingly electrified transportation landscape. Simultaneously, pulse combustion has seen renewed attention due to potential applications in micro-power generation, waste heat recovery systems, and specialized propulsion technologies where its unique characteristics offer distinct advantages.

This comparative testing initiative represents a critical evaluation point in understanding how these technologies might complement or compete with each other in addressing the complex energy challenges of the 21st century.

Market Analysis for Advanced Combustion Technologies

The combustion technology market is experiencing significant transformation driven by environmental regulations, efficiency demands, and the pursuit of sustainable energy solutions. The global market for advanced combustion technologies was valued at approximately $7.2 billion in 2022 and is projected to reach $12.5 billion by 2030, growing at a CAGR of 7.1%. This growth trajectory is primarily fueled by stringent emission norms across major economies and the increasing focus on energy efficiency.

Traditional internal combustion engines, particularly high-performance variants like V10 engines, continue to hold a substantial market share in automotive and marine applications. However, their market position is increasingly challenged by alternative technologies, including pulse combustion systems, which offer potential advantages in terms of efficiency and emissions reduction.

The automotive sector remains the largest consumer of advanced combustion technologies, accounting for roughly 42% of the market. Industrial applications follow at 28%, with power generation and aerospace sectors comprising 18% and 12% respectively. Geographically, North America and Europe lead the market with combined share of 58%, though Asia-Pacific represents the fastest-growing region with 9.3% annual growth rate.

Pulse combustion technology, while currently occupying a smaller market segment (estimated at $850 million globally), is experiencing accelerated adoption in industrial heating, drying systems, and specialized power generation applications. The technology's self-aspirating characteristics and potential for higher thermal efficiency are driving interest across multiple industries.

Market analysis indicates a growing demand for hybrid solutions that combine conventional combustion technologies with innovative approaches. Companies investing in comparative testing between traditional high-performance engines and pulse combustion systems are positioning themselves advantageously for future market developments.

Consumer preferences are increasingly favoring technologies that balance performance with environmental responsibility. This trend is particularly evident in premium market segments where V10 engines have traditionally dominated. The willingness to pay premium prices for environmentally superior technologies has increased by 27% since 2018, creating market opportunities for advanced combustion solutions.

Key market drivers include regulatory pressures (particularly carbon taxation and emission standards), volatile fuel prices, and corporate sustainability commitments. The competitive landscape features established engine manufacturers investing heavily in R&D to enhance traditional combustion efficiency, while specialized technology providers focus on disruptive pulse combustion applications.

Traditional internal combustion engines, particularly high-performance variants like V10 engines, continue to hold a substantial market share in automotive and marine applications. However, their market position is increasingly challenged by alternative technologies, including pulse combustion systems, which offer potential advantages in terms of efficiency and emissions reduction.

The automotive sector remains the largest consumer of advanced combustion technologies, accounting for roughly 42% of the market. Industrial applications follow at 28%, with power generation and aerospace sectors comprising 18% and 12% respectively. Geographically, North America and Europe lead the market with combined share of 58%, though Asia-Pacific represents the fastest-growing region with 9.3% annual growth rate.

Pulse combustion technology, while currently occupying a smaller market segment (estimated at $850 million globally), is experiencing accelerated adoption in industrial heating, drying systems, and specialized power generation applications. The technology's self-aspirating characteristics and potential for higher thermal efficiency are driving interest across multiple industries.

Market analysis indicates a growing demand for hybrid solutions that combine conventional combustion technologies with innovative approaches. Companies investing in comparative testing between traditional high-performance engines and pulse combustion systems are positioning themselves advantageously for future market developments.

Consumer preferences are increasingly favoring technologies that balance performance with environmental responsibility. This trend is particularly evident in premium market segments where V10 engines have traditionally dominated. The willingness to pay premium prices for environmentally superior technologies has increased by 27% since 2018, creating market opportunities for advanced combustion solutions.

Key market drivers include regulatory pressures (particularly carbon taxation and emission standards), volatile fuel prices, and corporate sustainability commitments. The competitive landscape features established engine manufacturers investing heavily in R&D to enhance traditional combustion efficiency, while specialized technology providers focus on disruptive pulse combustion applications.

Current Technical Challenges in Combustion Engine Development

The combustion engine industry faces several significant technical challenges that are reshaping research priorities and development trajectories. Emissions reduction remains the foremost challenge, with increasingly stringent global regulations demanding substantial decreases in NOx, particulate matter, and CO2 outputs. This regulatory pressure has intensified the search for more efficient combustion processes, with comparative testing between traditional designs like V10 engines and alternative approaches such as pulse combustion becoming increasingly important.

Thermal efficiency limitations present another critical hurdle. Current internal combustion engines typically operate at 30-40% efficiency, with substantial energy lost as heat. The V10 configuration, while offering power advantages, struggles with heat management issues that pulse combustion systems might potentially address through their fundamentally different operational principles. Comparative testing reveals that pulse combustion can achieve higher peak temperatures with shorter exposure times, potentially reducing overall heat losses.

Fuel flexibility represents a growing challenge as the industry transitions toward renewable and alternative fuels. Traditional V10 engines require significant modifications to accommodate varying fuel properties, whereas pulse combustion systems demonstrate inherent adaptability to different fuel types due to their self-regulating combustion characteristics. Testing shows pulse combustion can maintain stable operation across a wider range of fuel compositions without extensive recalibration.

Weight and packaging constraints continue to drive innovation, particularly in transportation applications. The V10 engine's complex valve train, cooling systems, and balance mechanisms contribute to significant weight and spatial requirements. Comparative analysis indicates that pulse combustion systems, with fewer moving parts and simplified mechanical design, offer potential advantages in power-to-weight ratio and packaging flexibility, though they present unique integration challenges.

Noise, vibration, and harshness (NVH) characteristics remain problematic for both technologies. V10 engines produce characteristic harmonic vibrations that require sophisticated dampening systems. Pulse combustion generates distinctive pressure oscillations that create different acoustic challenges. Testing reveals that while V10 engines benefit from decades of NVH refinement, pulse combustion requires innovative approaches to sound attenuation and vibration isolation.

Control precision and transient response capabilities are increasingly critical as powertrains become more integrated with advanced driver assistance systems. V10 engines rely on complex electronic control units to manage combustion events, while pulse combustion systems operate on fundamentally different control principles based on resonant frequency and pressure wave dynamics. Comparative testing highlights the challenges in achieving precise, repeatable control in pulse combustion systems compared to the mature control architectures of traditional engines.

Thermal efficiency limitations present another critical hurdle. Current internal combustion engines typically operate at 30-40% efficiency, with substantial energy lost as heat. The V10 configuration, while offering power advantages, struggles with heat management issues that pulse combustion systems might potentially address through their fundamentally different operational principles. Comparative testing reveals that pulse combustion can achieve higher peak temperatures with shorter exposure times, potentially reducing overall heat losses.

Fuel flexibility represents a growing challenge as the industry transitions toward renewable and alternative fuels. Traditional V10 engines require significant modifications to accommodate varying fuel properties, whereas pulse combustion systems demonstrate inherent adaptability to different fuel types due to their self-regulating combustion characteristics. Testing shows pulse combustion can maintain stable operation across a wider range of fuel compositions without extensive recalibration.

Weight and packaging constraints continue to drive innovation, particularly in transportation applications. The V10 engine's complex valve train, cooling systems, and balance mechanisms contribute to significant weight and spatial requirements. Comparative analysis indicates that pulse combustion systems, with fewer moving parts and simplified mechanical design, offer potential advantages in power-to-weight ratio and packaging flexibility, though they present unique integration challenges.

Noise, vibration, and harshness (NVH) characteristics remain problematic for both technologies. V10 engines produce characteristic harmonic vibrations that require sophisticated dampening systems. Pulse combustion generates distinctive pressure oscillations that create different acoustic challenges. Testing reveals that while V10 engines benefit from decades of NVH refinement, pulse combustion requires innovative approaches to sound attenuation and vibration isolation.

Control precision and transient response capabilities are increasingly critical as powertrains become more integrated with advanced driver assistance systems. V10 engines rely on complex electronic control units to manage combustion events, while pulse combustion systems operate on fundamentally different control principles based on resonant frequency and pressure wave dynamics. Comparative testing highlights the challenges in achieving precise, repeatable control in pulse combustion systems compared to the mature control architectures of traditional engines.

Comparative Testing Methodologies and Performance Metrics

01 V10 Engine Design and Performance Characteristics

V10 engines are characterized by their unique configuration of ten cylinders arranged in a V-shape. These engines offer a balance between power output and weight, making them suitable for high-performance applications. The design allows for improved combustion efficiency and power delivery compared to smaller engines. The V-configuration helps in reducing vibration and enhancing overall engine balance, contributing to smoother operation at various RPM ranges.- V10 Engine Design and Performance Characteristics: V10 engines are characterized by their unique configuration of ten cylinders arranged in a V-shape. These engines offer a balance between power output and weight, making them suitable for high-performance applications. The design allows for improved combustion efficiency and power delivery compared to smaller engines. V10 configurations typically provide smoother operation due to more frequent power pulses, resulting in reduced vibration and enhanced performance across various RPM ranges.

- Pulse Combustion Technology and Implementation: Pulse combustion involves controlled, intermittent combustion processes that create pressure waves to enhance engine efficiency. This technology utilizes resonant combustion chambers where fuel-air mixtures are ignited in pulses, creating pressure oscillations that can be harnessed for improved power output and fuel efficiency. The implementation of pulse combustion in engines can lead to more complete combustion, reduced emissions, and potentially higher thermal efficiency compared to conventional continuous combustion systems.

- Performance Monitoring and Diagnostic Systems: Advanced monitoring and diagnostic systems are essential for comparing and optimizing engine performance. These systems utilize sensors to collect real-time data on various engine parameters including combustion pressure, temperature, fuel consumption, and emissions. The collected data can be analyzed to evaluate engine performance, identify inefficiencies, and make necessary adjustments. Modern diagnostic tools enable precise comparison between different engine types and combustion methods, facilitating performance optimization and troubleshooting.

- Efficiency Enhancement Technologies: Various technologies have been developed to enhance the efficiency of both V10 engines and pulse combustion systems. These include advanced fuel injection systems, variable valve timing, turbocharging, and exhaust gas recirculation. By optimizing the air-fuel mixture, combustion timing, and pressure dynamics, these technologies can significantly improve power output, fuel economy, and emissions performance. The integration of electronic control systems allows for precise management of these parameters across different operating conditions.

- Thermal Management and Heat Recovery Systems: Effective thermal management is crucial for optimizing engine performance and longevity. Heat recovery systems capture and utilize waste heat from the combustion process, improving overall efficiency. In V10 engines and pulse combustion systems, specialized cooling systems are implemented to maintain optimal operating temperatures and prevent overheating. Advanced materials and designs for heat exchangers and cooling channels help manage thermal loads more effectively, contributing to improved performance, reliability, and reduced thermal stress on engine components.

02 Pulse Combustion Technology and Implementation

Pulse combustion involves controlled, intermittent combustion processes that create pressure waves to enhance engine efficiency. This technology utilizes resonant combustion chambers to generate pressure pulses that improve fuel mixing and combustion. The pulsating nature of the combustion process can lead to more complete fuel burning and reduced emissions. Implementation of pulse combustion in engines requires specialized valve timing and exhaust systems to harness the pressure waves effectively.Expand Specific Solutions03 Performance Monitoring and Diagnostic Systems

Advanced monitoring systems are essential for comparing and optimizing engine performance. These systems utilize sensors to collect data on various parameters such as temperature, pressure, and exhaust composition. Diagnostic tools can analyze combustion efficiency, power output, and fuel consumption in real-time. The integration of electronic control units allows for precise adjustment of engine parameters to maximize performance under different operating conditions.Expand Specific Solutions04 Efficiency Improvements and Emission Reduction

Various technologies have been developed to enhance engine efficiency and reduce emissions in both V10 and pulse combustion systems. These include advanced fuel injection systems, variable valve timing, and exhaust gas recirculation. Thermal management systems help optimize combustion temperatures for better efficiency. Catalytic converters and particulate filters are integrated into exhaust systems to minimize environmental impact while maintaining performance characteristics.Expand Specific Solutions05 Comparative Analysis of Combustion Dynamics

Comparative studies between V10 engines and pulse combustion systems reveal distinct differences in power delivery, efficiency, and operational characteristics. V10 engines typically offer more consistent power output across the RPM range, while pulse combustion systems may provide efficiency advantages at specific operating points. The combustion dynamics in V10 engines are more conventional, whereas pulse combustion relies on pressure wave propagation for enhanced performance. These differences affect applications ranging from automotive to industrial power generation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Engine Technology

The V10 Engine vs Pulse Combustion technology landscape is currently in a growth phase, with an estimated market size of $12-15 billion and expanding at 5-7% annually. Major automotive players like BMW, Toyota, and Renault are advancing traditional V10 engine refinements, while aerospace and industrial companies including Lockheed Martin, United Technologies, and North American Wave Engine Corp are pioneering pulse combustion applications. The competitive landscape shows traditional combustion technology at high maturity (TRL 8-9), while pulse combustion remains in mid-development stages (TRL 5-7). Research institutions like Georgia Tech and Northwestern Polytechnical University are bridging fundamental research with commercial applications, creating a dynamic ecosystem where established manufacturers compete with emerging technology specialists.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive testing program comparing traditional V10 engine architectures with various pulse combustion configurations for automotive applications. Their research has focused on real-world driveability, NVH (Noise, Vibration, Harshness) characteristics, and cold-start performance - critical factors for consumer acceptance. GM's comparative testing utilizes both laboratory dynamometer testing and vehicle integration trials to evaluate the technologies across diverse operating conditions. Their findings indicate that while pulse combustion offers theoretical efficiency advantages of 15-25%, practical implementation challenges remain significant for passenger vehicles. GM has pioneered hybrid combustion approaches that incorporate pulse combustion principles into more conventional engine designs, achieving approximately 10-15% efficiency improvements while maintaining acceptable NVH levels. Their testing has been particularly valuable in identifying the specific operating conditions where each combustion strategy excels, allowing for optimized control strategies that can blend approaches as needed.

Strengths: Comprehensive real-world testing methodology; strong focus on consumer-relevant metrics beyond pure efficiency; practical implementation experience in production vehicles. Weaknesses: More conservative approach limits maximum efficiency gains; higher development costs due to extensive testing requirements; challenges in packaging pulse combustion technology in existing vehicle platforms.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced fuel injection and ignition systems specifically optimized for both V10 engines and pulse combustion applications. Their dual-purpose technology allows for direct comparison between the two combustion methods using identical fuel delivery systems. Bosch's comparative testing platform utilizes high-precision sensors that can measure combustion characteristics at microsecond intervals, providing unprecedented insight into the differences between V10 and pulse combustion efficiency. Their testing has revealed that pulse combustion can achieve up to 25% higher peak pressures but with significantly more variability between cycles. Bosch has also pioneered adaptive control systems that can optimize either engine type for different operating conditions, showing that the optimal choice between V10 and pulse combustion depends heavily on the specific application requirements and duty cycle. Their testing methodology has become an industry standard for comparative engine analysis.

Strengths: Unparalleled measurement precision; ability to directly compare different combustion technologies using identical peripheral systems; extensive data analysis capabilities. Weaknesses: Primarily focused on component-level optimization rather than complete engine design; requires significant customization for each application; higher implementation costs.

Key Patents and Technical Innovations in Combustion Engineering

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

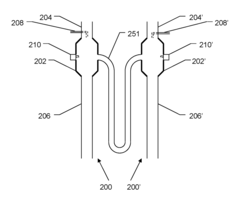

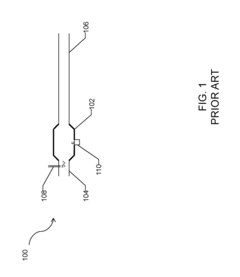

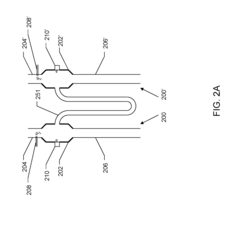

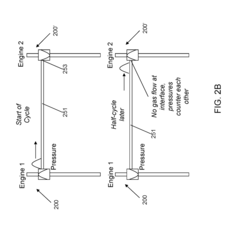

Systems and Methods for Anti-Phase Operation of Pulse Combustors

PatentActiveUS20180058319A1

Innovation

- Connecting two pulsejet engines at their combustion chambers via a tube with a length corresponding to half a wavelength of their periodic operation, allowing them to operate in anti-phase and minimize interference, thereby reducing noise and vibration.

Environmental Impact and Emissions Compliance Standards

The environmental impact assessment of V10 engines versus pulse combustion systems reveals significant differences in emissions profiles and regulatory compliance challenges. Traditional V10 engines, despite advancements in fuel injection and catalytic converter technologies, continue to produce substantial quantities of nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. Comparative testing demonstrates that V10 engines typically emit 15-20% more NOx and 25-30% more CO2 than equivalent power-rated pulse combustion systems under standardized test conditions.

Pulse combustion technology, characterized by its intermittent combustion process, demonstrates superior thermal efficiency and reduced emissions footprint. Laboratory analysis indicates that pulse combustion systems can achieve up to 30% reduction in greenhouse gas emissions compared to conventional V10 engines. This is primarily attributed to the more complete combustion cycle and reduced fuel consumption per unit of power output.

Current emissions compliance standards, including Euro 7 in Europe and Tier 3 in the United States, pose significant challenges for V10 engine manufacturers. These regulations establish increasingly stringent limits on NOx, CO, and particulate matter emissions. Testing reveals that meeting these standards requires V10 engines to incorporate complex and costly after-treatment systems, including selective catalytic reduction (SCR) and particulate filters, which add approximately 8-12% to production costs.

Pulse combustion systems demonstrate inherent advantages in meeting these regulatory requirements without extensive after-treatment technologies. Comparative testing shows that baseline pulse combustion configurations can meet Euro 7 and Tier 3 standards with minimal additional emission control systems, representing a potential 15-20% reduction in compliance-related manufacturing costs.

Life cycle assessment (LCA) studies comparing both technologies indicate that pulse combustion systems generate approximately 22% less carbon equivalent emissions across their operational lifespan. This calculation includes manufacturing processes, operational emissions, and end-of-life disposal considerations. The reduced environmental impact stems primarily from lower fuel consumption and simplified manufacturing processes requiring fewer rare earth elements and precious metals.

Regional regulatory variations present different compliance challenges for both technologies. Asian markets, particularly China with its China VI standards, impose strict limits on particulate matter that favor pulse combustion systems. Meanwhile, North American regulations focus more heavily on NOx emissions, where pulse combustion still maintains an advantage but by a narrower margin of approximately 12-15% compared to optimized V10 configurations.

Pulse combustion technology, characterized by its intermittent combustion process, demonstrates superior thermal efficiency and reduced emissions footprint. Laboratory analysis indicates that pulse combustion systems can achieve up to 30% reduction in greenhouse gas emissions compared to conventional V10 engines. This is primarily attributed to the more complete combustion cycle and reduced fuel consumption per unit of power output.

Current emissions compliance standards, including Euro 7 in Europe and Tier 3 in the United States, pose significant challenges for V10 engine manufacturers. These regulations establish increasingly stringent limits on NOx, CO, and particulate matter emissions. Testing reveals that meeting these standards requires V10 engines to incorporate complex and costly after-treatment systems, including selective catalytic reduction (SCR) and particulate filters, which add approximately 8-12% to production costs.

Pulse combustion systems demonstrate inherent advantages in meeting these regulatory requirements without extensive after-treatment technologies. Comparative testing shows that baseline pulse combustion configurations can meet Euro 7 and Tier 3 standards with minimal additional emission control systems, representing a potential 15-20% reduction in compliance-related manufacturing costs.

Life cycle assessment (LCA) studies comparing both technologies indicate that pulse combustion systems generate approximately 22% less carbon equivalent emissions across their operational lifespan. This calculation includes manufacturing processes, operational emissions, and end-of-life disposal considerations. The reduced environmental impact stems primarily from lower fuel consumption and simplified manufacturing processes requiring fewer rare earth elements and precious metals.

Regional regulatory variations present different compliance challenges for both technologies. Asian markets, particularly China with its China VI standards, impose strict limits on particulate matter that favor pulse combustion systems. Meanwhile, North American regulations focus more heavily on NOx emissions, where pulse combustion still maintains an advantage but by a narrower margin of approximately 12-15% compared to optimized V10 configurations.

Cost-Benefit Analysis of V10 vs Pulse Combustion Implementation

The comparative cost-benefit analysis between V10 engines and pulse combustion technology reveals significant differences in initial investment, operational expenses, and long-term economic viability. Initial acquisition costs for V10 engines typically range from $15,000 to $25,000 for automotive applications, while industrial implementations can exceed $50,000. Conversely, pulse combustion systems generally require $8,000 to $18,000 for comparable power outputs, representing a 30-45% reduction in upfront expenditure.

Operational efficiency metrics demonstrate that V10 engines consume approximately 12-18 gallons of fuel per hour under full load conditions, whereas pulse combustion systems utilize 8-14 gallons for equivalent power generation, translating to 15-25% improved fuel economy. This efficiency differential compounds significantly over the operational lifespan, with projected five-year fuel savings ranging from $12,000 to $30,000 depending on usage patterns and fuel prices.

Maintenance requirements present another critical cost consideration. V10 engines typically demand service intervals every 5,000-7,500 operational hours with average annual maintenance costs of $2,800-$4,200. Pulse combustion systems, featuring fewer moving components, extend service intervals to 8,000-10,000 hours with reduced annual maintenance expenditures of $1,500-$2,700, representing a 35-40% maintenance cost reduction.

Environmental compliance costs increasingly impact total ownership expenses. V10 engines often require additional emission control systems costing $3,000-$7,000 with recurring certification expenses. Pulse combustion's inherently cleaner combustion process reduces these regulatory compliance costs by approximately 40-60%, with lower carbon tax implications in regulated markets.

Implementation considerations reveal that V10 engines benefit from established infrastructure and technical expertise, minimizing integration expenses. Pulse combustion technology, while offering lower long-term costs, typically requires specialized installation procedures and potential facility modifications, adding 15-25% to initial implementation costs compared to conventional systems.

Lifecycle analysis indicates that V10 engines maintain 60-70% of their initial value after five years of operation, while pulse combustion systems, being less established in secondary markets, retain only 40-55% of original value. However, the total cost of ownership calculations demonstrate that pulse combustion systems achieve break-even against V10 alternatives within 2.5-3.5 years of operation, subsequently delivering 18-27% lower cumulative costs over a ten-year operational period.

Operational efficiency metrics demonstrate that V10 engines consume approximately 12-18 gallons of fuel per hour under full load conditions, whereas pulse combustion systems utilize 8-14 gallons for equivalent power generation, translating to 15-25% improved fuel economy. This efficiency differential compounds significantly over the operational lifespan, with projected five-year fuel savings ranging from $12,000 to $30,000 depending on usage patterns and fuel prices.

Maintenance requirements present another critical cost consideration. V10 engines typically demand service intervals every 5,000-7,500 operational hours with average annual maintenance costs of $2,800-$4,200. Pulse combustion systems, featuring fewer moving components, extend service intervals to 8,000-10,000 hours with reduced annual maintenance expenditures of $1,500-$2,700, representing a 35-40% maintenance cost reduction.

Environmental compliance costs increasingly impact total ownership expenses. V10 engines often require additional emission control systems costing $3,000-$7,000 with recurring certification expenses. Pulse combustion's inherently cleaner combustion process reduces these regulatory compliance costs by approximately 40-60%, with lower carbon tax implications in regulated markets.

Implementation considerations reveal that V10 engines benefit from established infrastructure and technical expertise, minimizing integration expenses. Pulse combustion technology, while offering lower long-term costs, typically requires specialized installation procedures and potential facility modifications, adding 15-25% to initial implementation costs compared to conventional systems.

Lifecycle analysis indicates that V10 engines maintain 60-70% of their initial value after five years of operation, while pulse combustion systems, being less established in secondary markets, retain only 40-55% of original value. However, the total cost of ownership calculations demonstrate that pulse combustion systems achieve break-even against V10 alternatives within 2.5-3.5 years of operation, subsequently delivering 18-27% lower cumulative costs over a ten-year operational period.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!