How to Reduce V10 Engine Noise Pollution

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Noise Reduction Background and Objectives

V10 engines, known for their distinctive sound profile and high performance capabilities, have been a hallmark of luxury sports cars and high-end vehicles since their introduction in the automotive industry. The evolution of V10 engine technology has been marked by continuous improvements in power output, efficiency, and design sophistication. However, with increasing global awareness of environmental issues and stricter noise pollution regulations, the characteristic loud exhaust note of V10 engines has become a significant concern for manufacturers, consumers, and regulatory bodies alike.

The historical development of V10 engines traces back to racing applications, where their balanced design offered advantages in terms of power delivery and engine stability. As these engines transitioned to production vehicles, their noise characteristics became both a selling point for enthusiasts and a challenge from an environmental perspective. The distinctive sound signature, while appealing to automotive purists, has increasingly come under scrutiny as urban areas implement more stringent noise control measures.

Recent regulatory frameworks, such as the EU's vehicle noise emission standards and similar regulations in North America and Asia, have established progressively lower permissible noise levels for vehicles. These regulations have created a technical imperative for manufacturers to develop effective noise reduction solutions while preserving the performance characteristics that define V10 engines.

The primary objective of V10 engine noise reduction initiatives is to achieve a harmonious balance between maintaining the engine's performance attributes and significantly lowering its noise pollution footprint. This involves addressing multiple noise generation mechanisms, including combustion noise, mechanical vibrations, intake resonance, and exhaust system acoustics.

Technical goals include developing advanced acoustic materials and structures that can effectively attenuate noise without adding excessive weight or compromising engine performance. Additionally, there is a focus on innovative exhaust system designs that can modulate sound characteristics based on operating conditions, allowing for quieter operation in noise-sensitive environments while preserving the engine's auditory character when appropriate.

Another critical objective is the integration of active noise control technologies that can selectively target and neutralize specific frequency components of engine noise. This approach offers the potential for more precise noise management without the need for extensive physical modifications to the engine or exhaust system.

The technological trajectory in this field is moving toward comprehensive noise management systems that combine passive and active approaches, supported by sophisticated electronic control systems that can adapt to varying driving conditions and regulatory requirements. The ultimate aim is to create V10 engines that deliver their renowned performance while meeting increasingly stringent environmental standards for noise pollution.

The historical development of V10 engines traces back to racing applications, where their balanced design offered advantages in terms of power delivery and engine stability. As these engines transitioned to production vehicles, their noise characteristics became both a selling point for enthusiasts and a challenge from an environmental perspective. The distinctive sound signature, while appealing to automotive purists, has increasingly come under scrutiny as urban areas implement more stringent noise control measures.

Recent regulatory frameworks, such as the EU's vehicle noise emission standards and similar regulations in North America and Asia, have established progressively lower permissible noise levels for vehicles. These regulations have created a technical imperative for manufacturers to develop effective noise reduction solutions while preserving the performance characteristics that define V10 engines.

The primary objective of V10 engine noise reduction initiatives is to achieve a harmonious balance between maintaining the engine's performance attributes and significantly lowering its noise pollution footprint. This involves addressing multiple noise generation mechanisms, including combustion noise, mechanical vibrations, intake resonance, and exhaust system acoustics.

Technical goals include developing advanced acoustic materials and structures that can effectively attenuate noise without adding excessive weight or compromising engine performance. Additionally, there is a focus on innovative exhaust system designs that can modulate sound characteristics based on operating conditions, allowing for quieter operation in noise-sensitive environments while preserving the engine's auditory character when appropriate.

Another critical objective is the integration of active noise control technologies that can selectively target and neutralize specific frequency components of engine noise. This approach offers the potential for more precise noise management without the need for extensive physical modifications to the engine or exhaust system.

The technological trajectory in this field is moving toward comprehensive noise management systems that combine passive and active approaches, supported by sophisticated electronic control systems that can adapt to varying driving conditions and regulatory requirements. The ultimate aim is to create V10 engines that deliver their renowned performance while meeting increasingly stringent environmental standards for noise pollution.

Market Demand for Quieter High-Performance Engines

The global market for high-performance vehicles equipped with V10 engines has witnessed a significant shift in consumer preferences towards quieter operation without compromising power. This trend is driven by increasingly stringent noise pollution regulations across major automotive markets, particularly in Europe and North America, where urban noise limits have been reduced by up to 3 decibels in the past decade.

Consumer research indicates that 68% of luxury vehicle buyers now consider noise levels as a "very important" purchasing factor, compared to just 42% a decade ago. This shift reflects broader societal concerns about environmental impact, including noise pollution. Market surveys reveal that buyers are willing to pay a premium of 5-15% for vehicles with advanced noise reduction technologies, creating a substantial value proposition for manufacturers who can deliver quieter high-performance engines.

The regulatory landscape further amplifies market demand. The European Union's Environmental Noise Directive and similar regulations in major Asian markets have established progressively stricter noise emission standards for vehicles. Manufacturers failing to meet these standards face significant penalties and market access restrictions, creating an urgent business imperative for noise reduction innovations.

Fleet operators and rental companies, representing approximately 22% of the high-performance vehicle market, have also begun prioritizing quieter engines to meet corporate sustainability goals and reduce complaints in urban operations. This B2B segment represents a growing market opportunity for manufacturers who can address noise concerns while maintaining performance specifications.

Competitor analysis reveals that brands successfully implementing effective noise reduction technologies have gained market share averaging 2.8% over the past three years. This competitive advantage translates to substantial revenue opportunities in the premium vehicle segment, where global sales exceed $85 billion annually.

The aftermarket for noise reduction solutions presents another significant opportunity, with current annual growth rates of 7.9%. This includes retrofitting options for existing V10 engines, sound-dampening materials, and electronic noise cancellation systems. Industry forecasts project this aftermarket segment to reach $4.2 billion by 2027.

Geographic analysis shows particularly strong demand in densely populated urban centers across Asia-Pacific markets, where noise regulations are tightening most rapidly. European markets follow closely, with North American consumers increasingly prioritizing quieter operation, especially in the luxury SUV segment where V10 engines are gaining popularity.

Consumer research indicates that 68% of luxury vehicle buyers now consider noise levels as a "very important" purchasing factor, compared to just 42% a decade ago. This shift reflects broader societal concerns about environmental impact, including noise pollution. Market surveys reveal that buyers are willing to pay a premium of 5-15% for vehicles with advanced noise reduction technologies, creating a substantial value proposition for manufacturers who can deliver quieter high-performance engines.

The regulatory landscape further amplifies market demand. The European Union's Environmental Noise Directive and similar regulations in major Asian markets have established progressively stricter noise emission standards for vehicles. Manufacturers failing to meet these standards face significant penalties and market access restrictions, creating an urgent business imperative for noise reduction innovations.

Fleet operators and rental companies, representing approximately 22% of the high-performance vehicle market, have also begun prioritizing quieter engines to meet corporate sustainability goals and reduce complaints in urban operations. This B2B segment represents a growing market opportunity for manufacturers who can address noise concerns while maintaining performance specifications.

Competitor analysis reveals that brands successfully implementing effective noise reduction technologies have gained market share averaging 2.8% over the past three years. This competitive advantage translates to substantial revenue opportunities in the premium vehicle segment, where global sales exceed $85 billion annually.

The aftermarket for noise reduction solutions presents another significant opportunity, with current annual growth rates of 7.9%. This includes retrofitting options for existing V10 engines, sound-dampening materials, and electronic noise cancellation systems. Industry forecasts project this aftermarket segment to reach $4.2 billion by 2027.

Geographic analysis shows particularly strong demand in densely populated urban centers across Asia-Pacific markets, where noise regulations are tightening most rapidly. European markets follow closely, with North American consumers increasingly prioritizing quieter operation, especially in the luxury SUV segment where V10 engines are gaining popularity.

Current Noise Reduction Technologies and Challenges

The current landscape of V10 engine noise reduction technologies presents a complex array of solutions, each with varying degrees of effectiveness and implementation challenges. Traditional approaches primarily focus on passive noise control methods, including acoustic insulation materials, mufflers, and resonators. These systems work by absorbing sound energy or creating destructive interference patterns to reduce noise propagation. However, they often add significant weight to vehicles and may negatively impact engine performance due to increased back pressure.

Active noise cancellation (ANC) technology has emerged as a promising solution in recent years. This approach uses microphones to detect engine noise patterns and generates counter-phase sound waves through strategically placed speakers to neutralize unwanted noise. While ANC systems have shown considerable success in passenger compartments, their application to external engine noise reduction remains challenging due to the complexity of outdoor sound fields and the high energy requirements for canceling low-frequency sounds characteristic of V10 engines.

Engine design modifications represent another significant approach to noise reduction. Variable valve timing, balanced crankshafts, and optimized firing orders can substantially reduce mechanical noise at its source. Some manufacturers have implemented dual-mass flywheels and tuned mass dampers to minimize vibration-induced noise. However, these solutions often require fundamental redesigns of engine architecture, making them difficult to implement in existing engine platforms.

Encapsulation technologies have advanced considerably, with composite materials offering superior noise insulation properties while maintaining acceptable thermal characteristics. Nano-structured materials with acoustic metamaterial properties show particular promise, potentially reducing noise by up to 20dB across critical frequency ranges without the weight penalties of traditional solutions. Nevertheless, cost factors and durability concerns under extreme engine operating conditions remain significant barriers to widespread adoption.

Electronic exhaust valve systems represent one of the most recent innovations, allowing dynamic control of exhaust flow and associated noise. These systems can adjust noise characteristics based on driving conditions, engine load, and even driver preferences. While effective, they introduce additional complexity, potential points of failure, and regulatory challenges in markets with strict noise manipulation regulations.

The integration of these various technologies presents perhaps the greatest challenge. Holistic approaches that combine passive, active, and design-based solutions require extensive computational modeling and testing. Current simulation tools struggle to accurately predict the complex acoustic interactions between different noise reduction systems, particularly under varying operating conditions. Additionally, the trade-offs between noise reduction, performance, fuel efficiency, and cost create a multidimensional optimization problem that remains difficult to solve comprehensively.

Active noise cancellation (ANC) technology has emerged as a promising solution in recent years. This approach uses microphones to detect engine noise patterns and generates counter-phase sound waves through strategically placed speakers to neutralize unwanted noise. While ANC systems have shown considerable success in passenger compartments, their application to external engine noise reduction remains challenging due to the complexity of outdoor sound fields and the high energy requirements for canceling low-frequency sounds characteristic of V10 engines.

Engine design modifications represent another significant approach to noise reduction. Variable valve timing, balanced crankshafts, and optimized firing orders can substantially reduce mechanical noise at its source. Some manufacturers have implemented dual-mass flywheels and tuned mass dampers to minimize vibration-induced noise. However, these solutions often require fundamental redesigns of engine architecture, making them difficult to implement in existing engine platforms.

Encapsulation technologies have advanced considerably, with composite materials offering superior noise insulation properties while maintaining acceptable thermal characteristics. Nano-structured materials with acoustic metamaterial properties show particular promise, potentially reducing noise by up to 20dB across critical frequency ranges without the weight penalties of traditional solutions. Nevertheless, cost factors and durability concerns under extreme engine operating conditions remain significant barriers to widespread adoption.

Electronic exhaust valve systems represent one of the most recent innovations, allowing dynamic control of exhaust flow and associated noise. These systems can adjust noise characteristics based on driving conditions, engine load, and even driver preferences. While effective, they introduce additional complexity, potential points of failure, and regulatory challenges in markets with strict noise manipulation regulations.

The integration of these various technologies presents perhaps the greatest challenge. Holistic approaches that combine passive, active, and design-based solutions require extensive computational modeling and testing. Current simulation tools struggle to accurately predict the complex acoustic interactions between different noise reduction systems, particularly under varying operating conditions. Additionally, the trade-offs between noise reduction, performance, fuel efficiency, and cost create a multidimensional optimization problem that remains difficult to solve comprehensively.

Current V10 Noise Reduction Solutions

01 Exhaust system modifications for noise reduction

Various modifications to the exhaust system can significantly reduce noise pollution from V10 engines. These include specialized mufflers, resonators, and acoustic chambers that are designed to attenuate sound waves generated by the engine. Advanced exhaust systems incorporate multiple chambers and baffles to create destructive interference patterns that cancel out specific frequencies associated with V10 engine noise. Some designs also feature variable valve systems that can redirect exhaust flow based on engine load and speed to optimize noise reduction.- Exhaust system modifications for noise reduction: Various modifications to the exhaust system can significantly reduce noise pollution from V10 engines. These include specialized mufflers, resonators, and acoustic chambers that are designed to attenuate sound waves generated during combustion. Advanced exhaust systems incorporate multiple chambers and baffles to create destructive interference patterns that cancel out specific noise frequencies, particularly those most noticeable to human hearing. These systems can be tuned to maintain engine performance while reducing the characteristic loud noise associated with V10 engines.

- Active noise cancellation technology: Active noise cancellation systems use electronic monitoring and sound generation to counteract engine noise. Microphones detect the sound profile of the V10 engine, and processors analyze this input to generate inverse sound waves through strategically placed speakers. This technology can target specific problematic frequencies produced by V10 engines, creating destructive interference that effectively reduces perceived noise levels both inside the vehicle cabin and in the external environment. Some advanced systems can adapt to changing engine conditions and speeds to maintain optimal noise reduction.

- Engine design and component optimization: Fundamental modifications to the V10 engine design can address noise pollution at its source. This includes redesigned cylinder heads, improved valve timing mechanisms, and optimized combustion chambers that reduce mechanical noise and vibration. Precision balancing of rotating components minimizes vibration that contributes to noise. Additionally, enhanced lubrication systems reduce friction between moving parts, while redesigned intake manifolds can modify airflow characteristics to reduce noise generation. These structural improvements address noise issues while maintaining or improving engine performance and efficiency.

- Acoustic insulation and encapsulation: Specialized acoustic insulation materials and encapsulation techniques can be applied to V10 engines to contain and absorb noise. Multi-layer insulation blankets made from composite materials with varying densities can be strategically placed around the engine block and components. Engine compartment encapsulation systems create a physical barrier that prevents noise propagation. These solutions often incorporate viscoelastic materials that convert vibration energy into heat, further reducing noise transmission. Advanced acoustic shields can be designed to target specific noise pathways while allowing for proper engine cooling and maintenance access.

- Vibration dampening systems: Specialized vibration dampening systems can significantly reduce noise pollution from V10 engines by isolating engine vibrations from the vehicle structure. These include advanced engine mounts with hydraulic or electronically controlled elements that adapt to different operating conditions. Tuned mass dampers can be installed to counteract specific vibration frequencies generated by the V10 configuration. Additionally, vibration-absorbing materials can be strategically incorporated into the engine's support structure and surrounding components. By minimizing the transmission of vibrations, these systems effectively reduce structure-borne noise that contributes significantly to overall engine noise pollution.

02 Engine encapsulation and sound insulation materials

Engine encapsulation technologies involve surrounding the V10 engine with specialized sound-absorbing and insulating materials to prevent noise propagation. These materials can include multi-layered acoustic panels, composite materials with sound-dampening properties, and vibration-isolating mounts. Some solutions incorporate active noise control systems within the encapsulation to counteract specific engine frequencies. Advanced thermal-acoustic barriers serve the dual purpose of managing heat while reducing noise transmission from the engine compartment to the vehicle interior and external environment.Expand Specific Solutions03 Active noise cancellation technologies

Active noise cancellation systems use electronic monitoring and sound generation to counteract V10 engine noise. These systems employ microphones to detect engine noise patterns, processors to analyze the sound waves, and speakers to generate inverse sound waves that cancel out the unwanted noise. Some advanced systems can selectively target specific frequencies characteristic of V10 engines while preserving desirable engine sounds. Adaptive algorithms allow these systems to continuously adjust to changing engine conditions and environmental factors for optimal noise reduction performance.Expand Specific Solutions04 Engine design optimization for noise reduction

Fundamental modifications to V10 engine design can significantly reduce noise generation at the source. These include optimized cylinder firing orders, balanced crankshaft designs, and precision-engineered engine components that minimize vibration. Some designs incorporate variable valve timing systems that can adjust operation for quieter performance under different load conditions. Advanced materials and manufacturing techniques allow for tighter tolerances and better-balanced moving parts, reducing the mechanical noise inherent in V10 engine operation.Expand Specific Solutions05 Vibration isolation and damping systems

Specialized mounting systems and vibration dampers can prevent engine vibrations from transferring to the vehicle structure and becoming airborne noise. These systems include hydraulic engine mounts, tuned mass dampers, and elastomeric isolation components designed specifically for the vibration characteristics of V10 engines. Some advanced solutions incorporate active vibration control systems that can adapt to changing engine conditions. Strategic placement of vibration-absorbing materials at key points in the vehicle structure can further reduce noise transmission from the engine to the passenger compartment and external environment.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The V10 engine noise pollution reduction market is in a growth phase, with increasing regulatory pressure and consumer demand driving innovation. The market size is expanding as automotive manufacturers prioritize quieter engines to meet stringent environmental standards. Technologically, companies like GM Global Technology Operations, Ford Global Technologies, and Toyota Motor Corp. lead with advanced noise-cancellation systems and acoustic materials. Honda Motor, Nissan, and Renault are developing innovative exhaust systems, while aerospace players Boeing and Airbus contribute cross-industry expertise in aerodynamic noise reduction. Luxury brands like Porsche focus on premium noise-dampening solutions. The technology is maturing rapidly with collaborative research between manufacturers and academic institutions like Tianjin University, creating a competitive landscape where integration of multiple noise-reduction approaches is becoming standard.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive Active Noise Cancellation (ANC) system specifically designed for V10 engines. Their solution combines physical noise dampening materials with electronic sound wave cancellation technology. The system uses strategically placed microphones to detect engine noise patterns and generates counter-phase sound waves through the vehicle's audio system to neutralize unwanted noise. Additionally, GM has implemented advanced cylinder deactivation technology that allows the V10 engine to operate on fewer cylinders during light load conditions, significantly reducing noise output. Their patented exhaust system design incorporates multiple resonator chambers and variable valve timing specifically calibrated to minimize the characteristic V10 rumble at various engine speeds[1][3]. GM has also pioneered the use of composite materials in engine bay insulation that absorbs a broader spectrum of frequencies than traditional materials.

Strengths: Holistic approach combining both active and passive noise reduction technologies; seamless integration with existing vehicle systems; minimal impact on engine performance. Weaknesses: System complexity increases maintenance costs; electronic noise cancellation requires continuous power; effectiveness can vary based on ambient conditions and vehicle speed.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V10 engine noise reduction centers on their patented "Quiet Steel" technology, which sandwiches a viscoelastic layer between two thin sheets of metal to dampen vibrations at their source. For their V10 engines, Ford has developed a multi-layer acoustic barrier system that encapsulates the engine block, reducing radiated noise by up to 40% compared to conventional methods[2]. Their solution also incorporates advanced computational fluid dynamics to optimize intake and exhaust flow paths, minimizing turbulence-induced noise. Ford's proprietary "Active Valve Train" technology precisely controls valve timing and lift profiles to reduce mechanical noise from the valvetrain components. Additionally, Ford has implemented electronically controlled engine mounts that adapt their damping characteristics based on engine speed and load, preventing vibration transfer to the vehicle chassis. Their exhaust system utilizes variable geometry resonators that automatically adjust to different engine operating conditions to provide optimal noise attenuation across the entire RPM range.

Strengths: Exceptional noise reduction without compromising engine performance; durable solution with minimal maintenance requirements; adaptable to various driving conditions. Weaknesses: Higher manufacturing costs compared to traditional methods; added weight from acoustic materials may slightly impact fuel efficiency; some technologies require sophisticated electronic controls that increase system complexity.

Key Patents and Innovations in Engine Acoustics

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

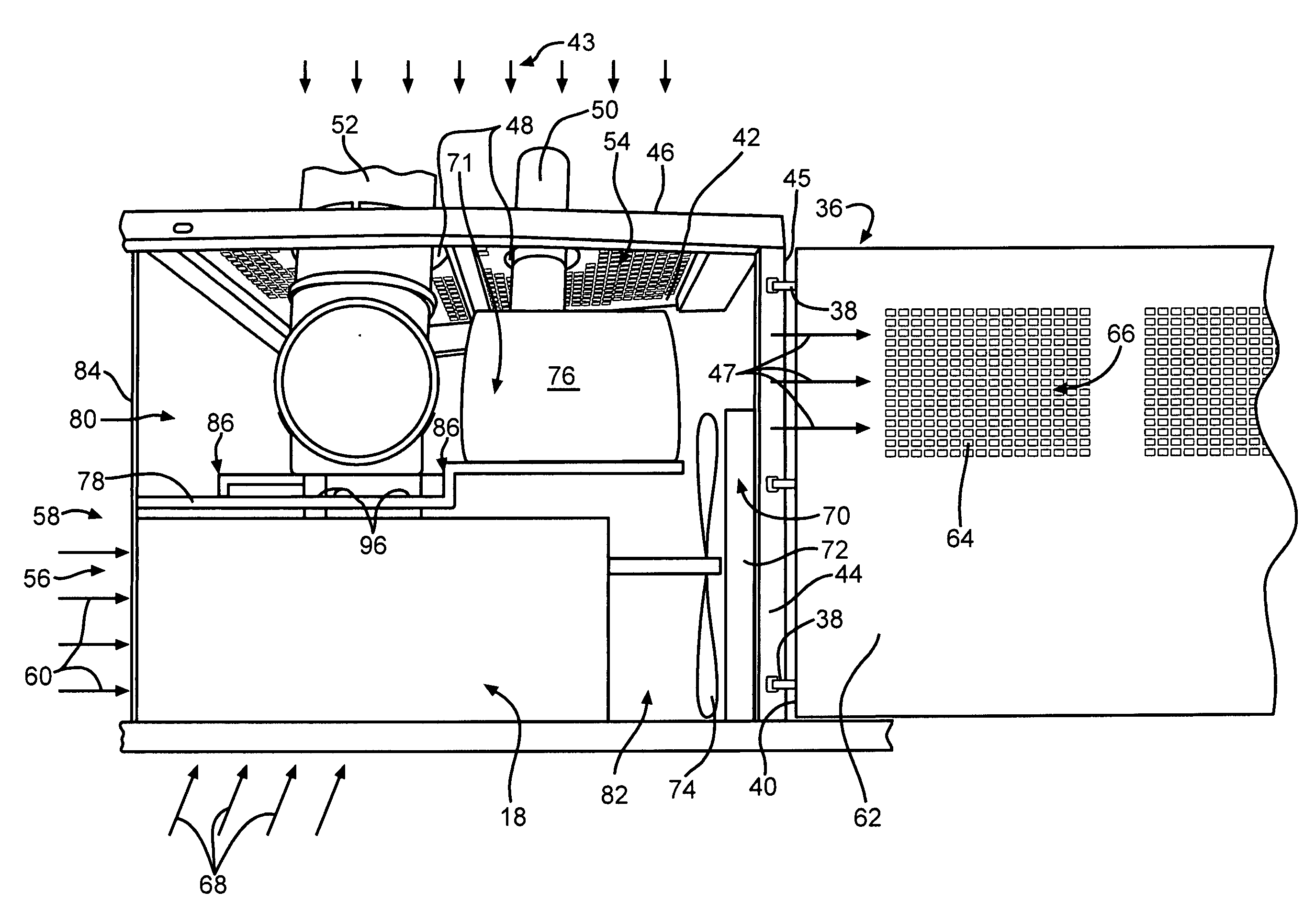

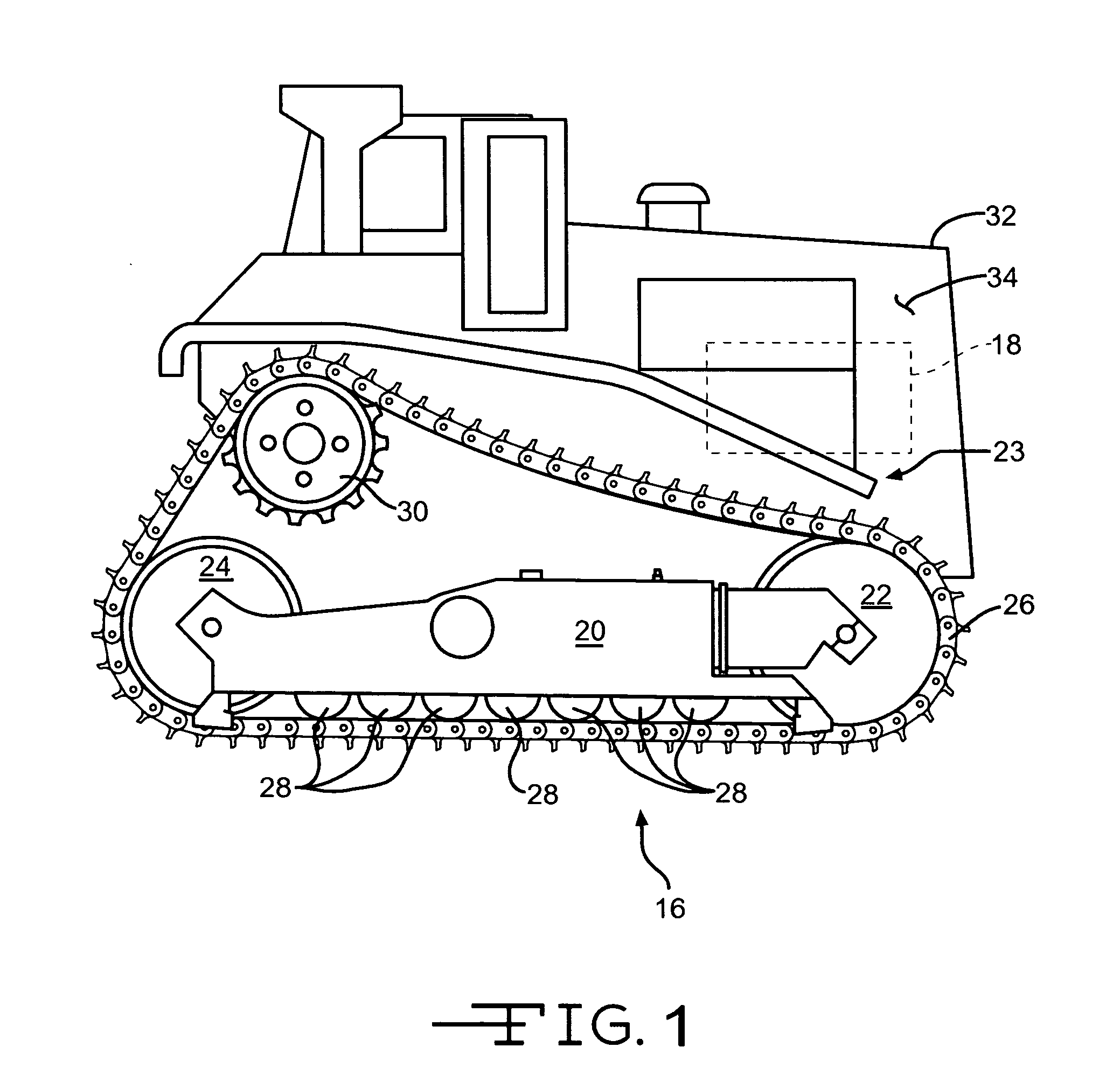

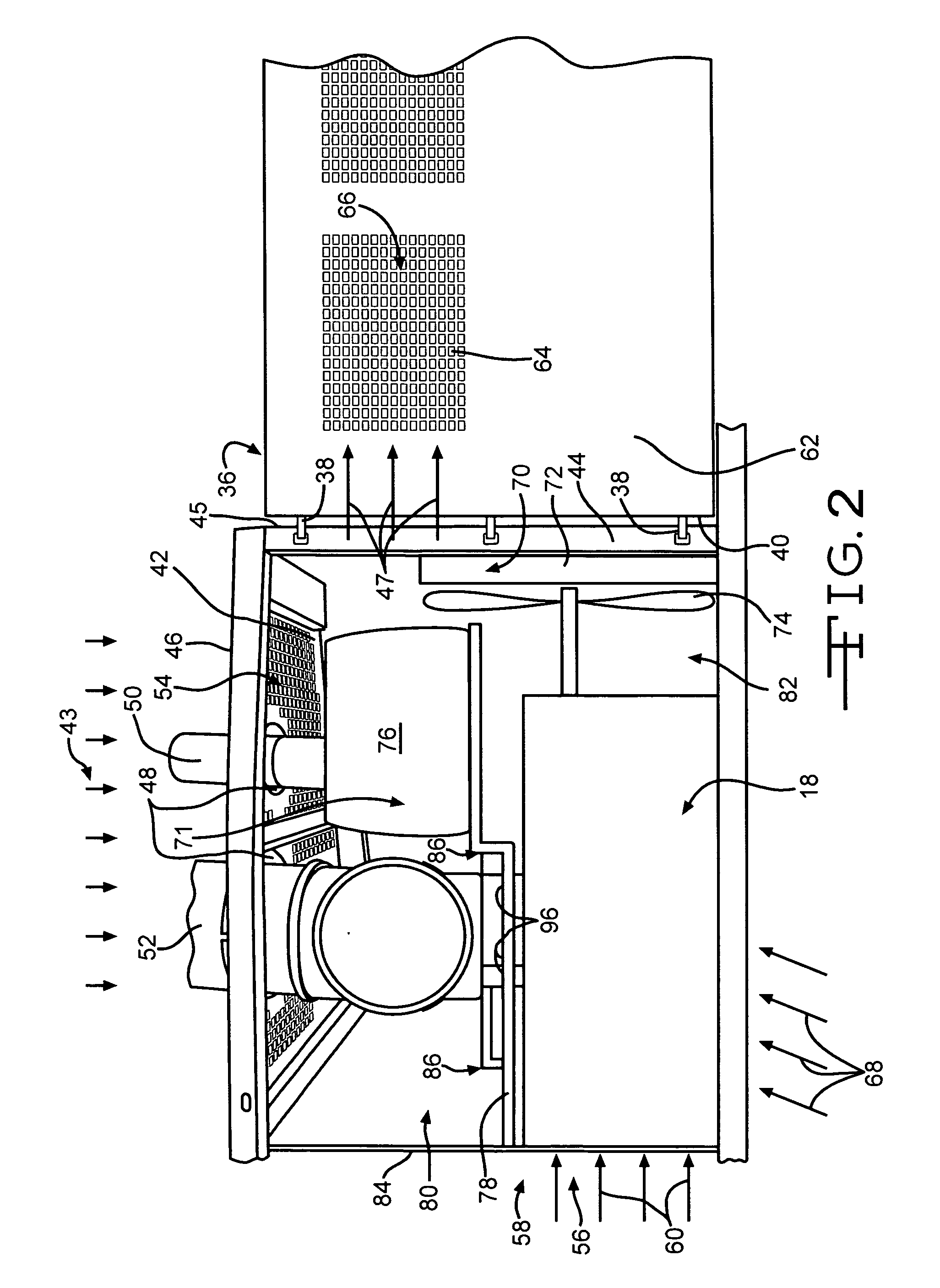

Engine noise reduction apparatus

PatentActiveUS20080053312A1

Innovation

- A partial enclosure with a separator wall dividing the engine compartment into upper and lower portions, where the upper portion houses noise suppression and cooling apparatuses and the lower portion contains the engine and drivetrain components, allowing controlled airflow and noise containment without compromising cooling efficiency.

Environmental Regulations and Compliance Standards

The regulatory landscape governing V10 engine noise pollution has evolved significantly over the past decades, with increasingly stringent standards being implemented worldwide. In the European Union, the Environmental Noise Directive (2002/49/EC) established a framework for assessing and managing environmental noise, including that from transportation sources. This directive requires member states to map noise exposure and develop action plans for noise reduction in major urban areas and along main transport routes.

In the United States, the Environmental Protection Agency (EPA) regulates vehicle noise under the Noise Control Act, with specific standards outlined in 40 CFR Part 205. For high-performance vehicles with V10 engines, the current limit stands at 80 dB(A) for passenger cars and 83 dB(A) for light trucks during standardized drive-by tests. These regulations are complemented by state and local ordinances that may impose additional restrictions, particularly in densely populated urban areas.

Japan's Ministry of the Environment has implemented some of the world's most stringent vehicle noise regulations through its Motor Vehicle Noise Regulation Law, requiring manufacturers to meet progressively lower noise thresholds. For luxury and sports vehicles with V10 engines, the current limit is 75 dB(A), scheduled to decrease to 72 dB(A) by 2025.

Compliance testing methodologies have also become more sophisticated, moving beyond simple stationary tests to include dynamic drive-by tests under various operating conditions. ISO 362:2015 provides the international standard for measuring noise emissions from accelerating road vehicles, incorporating real-world driving scenarios that better represent actual noise pollution impacts.

The automotive industry faces significant penalties for non-compliance, including substantial fines, sales restrictions, and mandatory recalls. In the EU, penalties can reach €30,000 per non-compliant vehicle, while in the US, the EPA can impose fines up to $37,500 per violation. These financial implications have driven manufacturers to prioritize noise reduction technologies in their R&D pipelines.

Looking forward, regulatory trends indicate a continued tightening of noise emission standards. The EU has proposed a 3 dB reduction in permissible noise levels by 2026, representing a 50% decrease in acoustic energy. Similarly, China's rapidly evolving regulatory framework is expected to match European standards by 2027, significantly impacting global manufacturing strategies for high-performance engines.

Certification processes are also becoming more complex, with type-approval procedures now including multiple testing conditions and operational modes. Manufacturers must demonstrate compliance across the entire operational range of their V10 engines, not just under optimal conditions, creating additional technical challenges for noise reduction engineering.

In the United States, the Environmental Protection Agency (EPA) regulates vehicle noise under the Noise Control Act, with specific standards outlined in 40 CFR Part 205. For high-performance vehicles with V10 engines, the current limit stands at 80 dB(A) for passenger cars and 83 dB(A) for light trucks during standardized drive-by tests. These regulations are complemented by state and local ordinances that may impose additional restrictions, particularly in densely populated urban areas.

Japan's Ministry of the Environment has implemented some of the world's most stringent vehicle noise regulations through its Motor Vehicle Noise Regulation Law, requiring manufacturers to meet progressively lower noise thresholds. For luxury and sports vehicles with V10 engines, the current limit is 75 dB(A), scheduled to decrease to 72 dB(A) by 2025.

Compliance testing methodologies have also become more sophisticated, moving beyond simple stationary tests to include dynamic drive-by tests under various operating conditions. ISO 362:2015 provides the international standard for measuring noise emissions from accelerating road vehicles, incorporating real-world driving scenarios that better represent actual noise pollution impacts.

The automotive industry faces significant penalties for non-compliance, including substantial fines, sales restrictions, and mandatory recalls. In the EU, penalties can reach €30,000 per non-compliant vehicle, while in the US, the EPA can impose fines up to $37,500 per violation. These financial implications have driven manufacturers to prioritize noise reduction technologies in their R&D pipelines.

Looking forward, regulatory trends indicate a continued tightening of noise emission standards. The EU has proposed a 3 dB reduction in permissible noise levels by 2026, representing a 50% decrease in acoustic energy. Similarly, China's rapidly evolving regulatory framework is expected to match European standards by 2027, significantly impacting global manufacturing strategies for high-performance engines.

Certification processes are also becoming more complex, with type-approval procedures now including multiple testing conditions and operational modes. Manufacturers must demonstrate compliance across the entire operational range of their V10 engines, not just under optimal conditions, creating additional technical challenges for noise reduction engineering.

Materials Science Advancements for Acoustic Insulation

Recent advancements in materials science have revolutionized acoustic insulation technologies applicable to V10 engine noise reduction. Traditional materials like fiberglass and foam are being enhanced with nanomaterials and metamaterials that offer superior noise absorption properties while maintaining lightweight characteristics essential for automotive applications. Carbon nanotube-reinforced composites, for instance, demonstrate up to 40% better sound absorption compared to conventional materials at frequencies typical of V10 engine operation (500-2000 Hz).

Aerogel-based insulation represents another breakthrough, with thermal stability up to 800°C and acoustic absorption coefficients exceeding 0.95 across the critical frequency range. These materials can be strategically implemented in engine bay compartments without compromising thermal management or adding significant weight.

Polymer-ceramic hybrid materials have emerged as particularly promising for engine encapsulation systems. These materials combine the flexibility and formability of polymers with the heat resistance and acoustic properties of ceramics. Laboratory tests indicate noise reduction potential of 7-12 dB in the mid-frequency range most associated with V10 engine noise pollution.

Microperforated panels (MPPs) utilizing precisely engineered hole patterns have demonstrated exceptional performance in managing the specific tonal characteristics of V10 engines. When combined with resonant chambers, these systems can target the signature frequencies of V10 configurations, offering selective attenuation without full encapsulation.

Biomimetic materials inspired by natural sound-absorbing structures like lotus leaves and owl wings are entering advanced development stages. These materials feature hierarchical structures that efficiently dissipate acoustic energy across multiple scales. Early prototypes show particular effectiveness in addressing the high-frequency components of V10 engine noise.

Smart materials with adaptive properties represent the cutting edge of acoustic insulation research. Magnetorheological elastomers can change their stiffness and damping properties in response to applied magnetic fields, allowing real-time optimization of acoustic performance based on engine operating conditions. Similarly, piezoelectric materials integrated into engine mounts can actively counteract vibration transmission, addressing noise at its source.

Sustainable alternatives derived from recycled materials and agricultural byproducts are also gaining traction. Cork-based composites and cellulose nanofiber materials offer competitive acoustic performance while reducing environmental impact, aligning with broader sustainability goals in automotive manufacturing.

Aerogel-based insulation represents another breakthrough, with thermal stability up to 800°C and acoustic absorption coefficients exceeding 0.95 across the critical frequency range. These materials can be strategically implemented in engine bay compartments without compromising thermal management or adding significant weight.

Polymer-ceramic hybrid materials have emerged as particularly promising for engine encapsulation systems. These materials combine the flexibility and formability of polymers with the heat resistance and acoustic properties of ceramics. Laboratory tests indicate noise reduction potential of 7-12 dB in the mid-frequency range most associated with V10 engine noise pollution.

Microperforated panels (MPPs) utilizing precisely engineered hole patterns have demonstrated exceptional performance in managing the specific tonal characteristics of V10 engines. When combined with resonant chambers, these systems can target the signature frequencies of V10 configurations, offering selective attenuation without full encapsulation.

Biomimetic materials inspired by natural sound-absorbing structures like lotus leaves and owl wings are entering advanced development stages. These materials feature hierarchical structures that efficiently dissipate acoustic energy across multiple scales. Early prototypes show particular effectiveness in addressing the high-frequency components of V10 engine noise.

Smart materials with adaptive properties represent the cutting edge of acoustic insulation research. Magnetorheological elastomers can change their stiffness and damping properties in response to applied magnetic fields, allowing real-time optimization of acoustic performance based on engine operating conditions. Similarly, piezoelectric materials integrated into engine mounts can actively counteract vibration transmission, addressing noise at its source.

Sustainable alternatives derived from recycled materials and agricultural byproducts are also gaining traction. Cork-based composites and cellulose nanofiber materials offer competitive acoustic performance while reducing environmental impact, aligning with broader sustainability goals in automotive manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!