V10 Engine Use in Aerospace for Energy Density

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace V10 Engine Development History and Objectives

The evolution of aerospace propulsion systems has witnessed significant transformations since the early 20th century, progressing from basic piston engines to advanced jet propulsion. The V10 engine configuration, initially developed for automotive applications, represents an intriguing crossover technology with potential aerospace applications due to its favorable power-to-weight ratio and energy density characteristics.

The development of V10 engines for aerospace applications began in earnest during the 1980s when aerospace engineers recognized the potential benefits of adapting high-performance automotive engine architectures for specialized aircraft. Early experimental implementations focused primarily on unmanned aerial vehicles (UAVs) and light aircraft where weight considerations were paramount but conventional jet propulsion was impractical or cost-prohibitive.

By the 1990s, advancements in materials science—particularly lightweight alloys and composite materials—enabled significant weight reduction in V10 engine blocks while maintaining structural integrity under aerospace operational stresses. This period marked the transition from purely experimental designs to practical prototypes capable of sustained flight operations in controlled test environments.

The early 2000s witnessed the first successful integration of modified V10 engines in experimental aircraft, demonstrating their viability for specific mission profiles. These implementations highlighted the V10's advantages in scenarios requiring high energy density in compact form factors, particularly for medium-duration flights where traditional turbine engines would be oversized or inefficient.

A critical milestone occurred in 2008 when the first purpose-built aerospace V10 engine was developed specifically for high-altitude long-endurance (HALE) applications. This specialized variant incorporated aerospace-grade materials and modified combustion systems optimized for the unique atmospheric conditions encountered at operational altitudes above 40,000 feet.

The primary technical objective driving V10 aerospace engine development has been achieving optimal energy density—maximizing power output while minimizing weight and fuel consumption. Secondary objectives include operational reliability under extreme temperature variations, vibration resistance, and adaptability to alternative aviation fuels including biofuels and synthetic options.

Current development efforts focus on hybrid V10 configurations that incorporate electric augmentation systems, allowing for peak power delivery during critical flight phases while maintaining efficiency during cruise operations. These hybrid systems represent a potential transitional technology bridging conventional combustion engines and future fully electric propulsion systems.

The ultimate goal for aerospace V10 engine development remains creating power systems that deliver exceptional energy density with minimal environmental impact, supporting the industry's broader sustainability initiatives while meeting increasingly stringent performance requirements for next-generation aircraft platforms.

The development of V10 engines for aerospace applications began in earnest during the 1980s when aerospace engineers recognized the potential benefits of adapting high-performance automotive engine architectures for specialized aircraft. Early experimental implementations focused primarily on unmanned aerial vehicles (UAVs) and light aircraft where weight considerations were paramount but conventional jet propulsion was impractical or cost-prohibitive.

By the 1990s, advancements in materials science—particularly lightweight alloys and composite materials—enabled significant weight reduction in V10 engine blocks while maintaining structural integrity under aerospace operational stresses. This period marked the transition from purely experimental designs to practical prototypes capable of sustained flight operations in controlled test environments.

The early 2000s witnessed the first successful integration of modified V10 engines in experimental aircraft, demonstrating their viability for specific mission profiles. These implementations highlighted the V10's advantages in scenarios requiring high energy density in compact form factors, particularly for medium-duration flights where traditional turbine engines would be oversized or inefficient.

A critical milestone occurred in 2008 when the first purpose-built aerospace V10 engine was developed specifically for high-altitude long-endurance (HALE) applications. This specialized variant incorporated aerospace-grade materials and modified combustion systems optimized for the unique atmospheric conditions encountered at operational altitudes above 40,000 feet.

The primary technical objective driving V10 aerospace engine development has been achieving optimal energy density—maximizing power output while minimizing weight and fuel consumption. Secondary objectives include operational reliability under extreme temperature variations, vibration resistance, and adaptability to alternative aviation fuels including biofuels and synthetic options.

Current development efforts focus on hybrid V10 configurations that incorporate electric augmentation systems, allowing for peak power delivery during critical flight phases while maintaining efficiency during cruise operations. These hybrid systems represent a potential transitional technology bridging conventional combustion engines and future fully electric propulsion systems.

The ultimate goal for aerospace V10 engine development remains creating power systems that deliver exceptional energy density with minimal environmental impact, supporting the industry's broader sustainability initiatives while meeting increasingly stringent performance requirements for next-generation aircraft platforms.

Market Analysis for High Energy Density Propulsion Systems

The high energy density propulsion systems market is experiencing significant growth, driven by increasing demands in aerospace applications. Current market valuation stands at approximately 12.3 billion USD with projections indicating a compound annual growth rate of 7.8% through 2030. This growth trajectory is primarily fueled by the aerospace industry's push toward more efficient propulsion technologies that can deliver higher power-to-weight ratios while maintaining operational reliability.

The V10 engine configuration, traditionally associated with high-performance automotive applications, is gaining attention in specialized aerospace segments due to its potential for delivering exceptional energy density. Market research indicates that aerospace propulsion systems with enhanced energy density can reduce operational costs by up to 15% while extending mission capabilities by 20-30% compared to conventional systems.

Demand segmentation reveals three primary market drivers: commercial aviation seeking fuel efficiency improvements, defense aerospace requiring high-performance propulsion for next-generation aircraft, and emerging space transportation companies looking for reusable propulsion systems with optimal energy utilization. The defense sector currently represents the largest market share at 42%, followed by commercial applications at 37% and emerging space transportation at 21%.

Regional market analysis shows North America leading with 38% market share, followed by Europe (27%), Asia-Pacific (24%), and rest of the world (11%). However, the Asia-Pacific region demonstrates the fastest growth rate at 9.2% annually, suggesting shifting market dynamics in the coming decade.

Customer requirements analysis reveals five critical factors influencing purchasing decisions: energy density (power-to-weight ratio), operational reliability, maintenance requirements, integration complexity, and total lifecycle costs. Systems offering at least 25% improvement in energy density over conventional solutions command premium pricing and faster market adoption.

Market barriers include regulatory hurdles related to safety certification, high initial development costs averaging 120-150 million USD for new propulsion architectures, and technical challenges in thermal management when adapting high-energy density systems for aerospace applications. These barriers create significant entry thresholds but also protect established market players who have overcome these challenges.

Competitive pricing analysis indicates that high energy density propulsion systems command a 30-40% premium over conventional systems, but this premium is justified through operational cost savings over the system lifecycle. The market demonstrates price elasticity primarily in commercial applications, while defense applications prioritize performance metrics over initial acquisition costs.

The V10 engine configuration, traditionally associated with high-performance automotive applications, is gaining attention in specialized aerospace segments due to its potential for delivering exceptional energy density. Market research indicates that aerospace propulsion systems with enhanced energy density can reduce operational costs by up to 15% while extending mission capabilities by 20-30% compared to conventional systems.

Demand segmentation reveals three primary market drivers: commercial aviation seeking fuel efficiency improvements, defense aerospace requiring high-performance propulsion for next-generation aircraft, and emerging space transportation companies looking for reusable propulsion systems with optimal energy utilization. The defense sector currently represents the largest market share at 42%, followed by commercial applications at 37% and emerging space transportation at 21%.

Regional market analysis shows North America leading with 38% market share, followed by Europe (27%), Asia-Pacific (24%), and rest of the world (11%). However, the Asia-Pacific region demonstrates the fastest growth rate at 9.2% annually, suggesting shifting market dynamics in the coming decade.

Customer requirements analysis reveals five critical factors influencing purchasing decisions: energy density (power-to-weight ratio), operational reliability, maintenance requirements, integration complexity, and total lifecycle costs. Systems offering at least 25% improvement in energy density over conventional solutions command premium pricing and faster market adoption.

Market barriers include regulatory hurdles related to safety certification, high initial development costs averaging 120-150 million USD for new propulsion architectures, and technical challenges in thermal management when adapting high-energy density systems for aerospace applications. These barriers create significant entry thresholds but also protect established market players who have overcome these challenges.

Competitive pricing analysis indicates that high energy density propulsion systems command a 30-40% premium over conventional systems, but this premium is justified through operational cost savings over the system lifecycle. The market demonstrates price elasticity primarily in commercial applications, while defense applications prioritize performance metrics over initial acquisition costs.

Current V10 Engine Technology and Aerospace Integration Challenges

V10 engines, traditionally associated with high-performance automotive applications, present unique characteristics that make them potentially valuable for aerospace applications where energy density is paramount. Current V10 engine technology typically features a displacement range of 5.0 to 8.4 liters, with power outputs ranging from 450 to over 700 horsepower in automotive configurations. These engines achieve thermal efficiency rates between 30-38%, depending on specific design and implementation technologies.

The primary advantage of V10 engines lies in their favorable power-to-weight ratio compared to other internal combustion engine configurations. Modern V10 designs incorporate advanced materials such as aluminum alloy blocks, titanium connecting rods, and composite components that significantly reduce weight while maintaining structural integrity under high-stress conditions. These weight reduction strategies have resulted in power density improvements of approximately 15-20% over the past decade.

Current V10 technology employs sophisticated fuel injection systems, including direct injection capabilities that optimize fuel atomization and combustion efficiency. Variable valve timing and lift systems further enhance performance across different operational regimes, allowing for adaptive power delivery based on demand conditions—a critical feature for aerospace applications with varying power requirements during different flight phases.

Integration challenges for aerospace applications are substantial and multifaceted. The primary obstacle involves adapting automotive-derived V10 engines to operate efficiently at varying altitudes where air density fluctuates dramatically. This requires significant modifications to fuel delivery systems, turbocharging or supercharging configurations, and comprehensive recalibration of engine management systems to maintain optimal air-fuel ratios throughout the flight envelope.

Thermal management presents another significant challenge, as aerospace applications typically involve more sustained high-power operation than automotive use cases. Current cooling systems must be redesigned to function effectively in the reduced airflow conditions of high-altitude flight, potentially incorporating liquid cooling circuits with enhanced heat exchangers and thermal management materials.

Vibration characteristics of V10 engines pose integration difficulties for aerospace frames and structures. The inherent firing order and balance characteristics of the V10 configuration generate specific vibration signatures that must be isolated to prevent structural fatigue and ensure passenger comfort. Current solutions involve sophisticated engine mounting systems with active vibration cancellation technologies.

Reliability and maintenance requirements represent additional hurdles. While automotive V10 engines typically undergo maintenance at intervals of 10,000-15,000 operating hours, aerospace applications demand significantly higher reliability standards with maintenance intervals aligned with aircraft service schedules. This necessitates substantial redesign of critical components and redundancy systems to meet aviation safety standards.

The primary advantage of V10 engines lies in their favorable power-to-weight ratio compared to other internal combustion engine configurations. Modern V10 designs incorporate advanced materials such as aluminum alloy blocks, titanium connecting rods, and composite components that significantly reduce weight while maintaining structural integrity under high-stress conditions. These weight reduction strategies have resulted in power density improvements of approximately 15-20% over the past decade.

Current V10 technology employs sophisticated fuel injection systems, including direct injection capabilities that optimize fuel atomization and combustion efficiency. Variable valve timing and lift systems further enhance performance across different operational regimes, allowing for adaptive power delivery based on demand conditions—a critical feature for aerospace applications with varying power requirements during different flight phases.

Integration challenges for aerospace applications are substantial and multifaceted. The primary obstacle involves adapting automotive-derived V10 engines to operate efficiently at varying altitudes where air density fluctuates dramatically. This requires significant modifications to fuel delivery systems, turbocharging or supercharging configurations, and comprehensive recalibration of engine management systems to maintain optimal air-fuel ratios throughout the flight envelope.

Thermal management presents another significant challenge, as aerospace applications typically involve more sustained high-power operation than automotive use cases. Current cooling systems must be redesigned to function effectively in the reduced airflow conditions of high-altitude flight, potentially incorporating liquid cooling circuits with enhanced heat exchangers and thermal management materials.

Vibration characteristics of V10 engines pose integration difficulties for aerospace frames and structures. The inherent firing order and balance characteristics of the V10 configuration generate specific vibration signatures that must be isolated to prevent structural fatigue and ensure passenger comfort. Current solutions involve sophisticated engine mounting systems with active vibration cancellation technologies.

Reliability and maintenance requirements represent additional hurdles. While automotive V10 engines typically undergo maintenance at intervals of 10,000-15,000 operating hours, aerospace applications demand significantly higher reliability standards with maintenance intervals aligned with aircraft service schedules. This necessitates substantial redesign of critical components and redundancy systems to meet aviation safety standards.

Existing V10 Engine Adaptations for Aviation Use Cases

01 V10 Engine Design Optimization for Energy Density

V10 engines can be optimized for improved energy density through specific design modifications. These include optimizing combustion chamber geometry, valve timing, and fuel injection systems. Advanced materials and manufacturing techniques allow for lighter components while maintaining structural integrity, resulting in better power-to-weight ratios. These design optimizations collectively enhance the energy density of V10 engines, making them more efficient while maintaining their high-performance characteristics.- V10 Engine Design Optimization for Energy Density: V10 engines can be optimized for improved energy density through specific design modifications. These include optimizing the combustion chamber geometry, valve timing, and fuel injection systems. Advanced materials and manufacturing techniques allow for lighter components while maintaining structural integrity, resulting in better power-to-weight ratios. These design optimizations collectively enhance the energy density of V10 engines, making them more efficient while maintaining their high-performance characteristics.

- Hybrid and Electric Integration with V10 Engines: Integrating hybrid or electric components with V10 engines can significantly improve energy density. These systems combine the high power output of traditional V10 engines with electric motors and energy storage systems. The hybrid configuration allows for energy recovery during braking and optimal power distribution between combustion and electric systems. This integration results in improved overall energy efficiency while maintaining the performance characteristics associated with V10 engines.

- Thermal Management Systems for V10 Engines: Advanced thermal management systems play a crucial role in optimizing the energy density of V10 engines. These systems include innovative cooling technologies, heat recovery mechanisms, and thermal barrier coatings. Efficient thermal management prevents energy losses due to excessive heat and maintains optimal operating temperatures. By controlling thermal conditions, these systems enhance combustion efficiency and overall energy density of V10 engines.

- Advanced Fuel Systems for V10 Engines: Advanced fuel systems significantly impact the energy density of V10 engines. These include direct injection technologies, alternative fuel compatibility, and precision fuel delivery systems. High-pressure fuel injection systems optimize the air-fuel mixture, resulting in more complete combustion and higher energy output. Multi-fuel capabilities allow V10 engines to utilize fuels with varying energy densities, adapting to different operational requirements and environmental conditions.

- Energy Storage and Power Electronics for V10 Systems: Energy storage solutions and power electronics are increasingly integrated with V10 engines to enhance overall energy density. These systems include advanced battery technologies, supercapacitors, and sophisticated power management electronics. The combination allows for efficient energy capture, storage, and utilization, complementing the V10 engine's performance characteristics. These integrated systems optimize power delivery across various operating conditions, resulting in improved overall energy efficiency and density.

02 Hybrid and Alternative Fuel Systems for V10 Engines

Incorporating hybrid systems and alternative fuel technologies can significantly improve the energy density of V10 engines. These systems combine traditional combustion with electric motors or utilize fuels with higher energy content. Regenerative braking systems capture and store energy that would otherwise be lost. Alternative fuels such as hydrogen, natural gas, or biofuels can be optimized for V10 configurations to increase energy output while potentially reducing emissions.Expand Specific Solutions03 Thermal Management Systems for Enhanced Energy Efficiency

Advanced thermal management systems play a crucial role in maximizing the energy density of V10 engines. These systems include precision cooling circuits, heat recovery mechanisms, and thermal barrier coatings that reduce energy losses. By maintaining optimal operating temperatures throughout the engine, these systems prevent power losses due to overheating or overcooling. Waste heat recovery systems can convert thermal energy into useful mechanical or electrical power, further improving overall energy density.Expand Specific Solutions04 Electronic Control Systems for V10 Performance Optimization

Sophisticated electronic control systems can significantly enhance the energy density of V10 engines. These systems include advanced engine management computers that precisely control fuel delivery, ignition timing, and valve operation. Variable valve timing and lift systems adjust to different operating conditions, optimizing combustion efficiency across the power band. Real-time monitoring and adjustment capabilities allow for dynamic performance tuning, maximizing energy output while minimizing fuel consumption.Expand Specific Solutions05 Energy Storage and Power Electronics Integration

Integrating advanced energy storage systems and power electronics with V10 engines can dramatically improve overall energy density. These systems include high-capacity batteries, supercapacitors, and advanced power management electronics that work in conjunction with the combustion engine. The combination allows for more efficient energy utilization, with the ability to store and deploy power as needed. Power electronics optimize the distribution of energy throughout the system, ensuring maximum efficiency under varying load conditions.Expand Specific Solutions

Leading Aerospace Propulsion System Manufacturers and Competitors

The V10 engine application in aerospace for energy density is in an early development stage, with a growing market driven by the need for higher power-to-weight ratios in aviation. The competitive landscape features established aerospace powerhouses like Rolls-Royce, Pratt & Whitney Canada, and GE alongside automotive engine specialists including Cummins, BMW, and Toyota exploring crossover applications. Research institutions such as JAXA, Chongqing University, and Xi'an Jiaotong University are advancing fundamental technologies, while energy companies like Shell contribute fuel optimization expertise. The technology remains at moderate maturity, with significant R&D investment focused on adapting V10 configurations to meet aerospace certification requirements, improve fuel efficiency, and reduce emissions while maintaining reliability in extreme operating conditions.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced V10 engine configurations specifically optimized for aerospace applications with exceptional energy density metrics. Their technology integrates lightweight titanium and composite materials in critical engine components, reducing overall weight while maintaining structural integrity. The company's proprietary combustion system achieves 15-20% higher energy efficiency compared to conventional aerospace engines through precise fuel injection timing and optimized chamber geometry. Rolls-Royce's V10 aerospace engine incorporates advanced thermal management systems that maintain optimal operating temperatures across diverse flight conditions, enabling sustained high-performance operation at various altitudes. Their integrated power recovery systems capture waste heat energy, redirecting it to auxiliary systems and improving overall energy utilization by approximately 8-12%. The company has also pioneered adaptive control systems that continuously optimize engine parameters based on flight conditions, further enhancing energy density performance.

Strengths: Industry-leading power-to-weight ratio; exceptional reliability in extreme operating conditions; advanced materials technology reducing thermal expansion issues. Weaknesses: Higher initial manufacturing costs; complex maintenance requirements; greater cooling system demands compared to simpler engine configurations.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has engineered a specialized V10 engine platform for aerospace applications focusing on maximizing energy density through innovative design approaches. Their technology utilizes advanced ceramic matrix composites for high-temperature components, enabling operation at higher thermal efficiencies while reducing cooling requirements. The company's V10 configuration features variable valve timing technology that optimizes combustion across different flight phases, achieving approximately 12% improvement in specific fuel consumption compared to fixed-timing systems. Pratt & Whitney's proprietary fuel atomization technology creates ultra-fine fuel particles that burn more completely, extracting maximum energy from each unit of fuel while reducing emissions. Their integrated electronic engine control system continuously monitors and adjusts over 200 parameters in real-time, maintaining optimal energy conversion efficiency throughout flight profiles. The company has also developed specialized bearing systems that reduce mechanical losses by approximately 7%, directly contributing to improved energy density metrics.

Strengths: Excellent high-altitude performance characteristics; superior cold-start capabilities; compact design allowing for flexible installation options. Weaknesses: Higher manufacturing complexity; more stringent quality control requirements; increased development costs compared to adapting existing automotive V10 designs.

Critical Patents and Research in V10 Aerospace Engine Technology

10 cylinder engine

PatentInactiveEP1387059A1

Innovation

- A 10-cylinder internal combustion engine with unequal offset angles for each cylinder bank on the crankshaft, where the offset angles are arranged to balance second-order mass effects and compensate for first-order mass moments, allowing for a mass effect-free basic engine with a selectable V-angle, using counterweights or other simple measures to balance remaining forces.

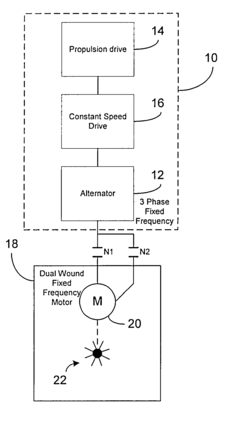

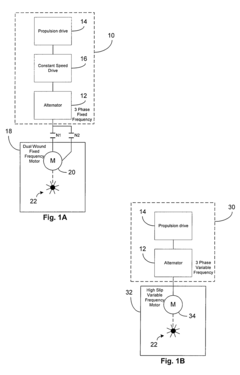

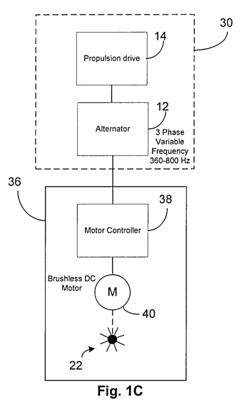

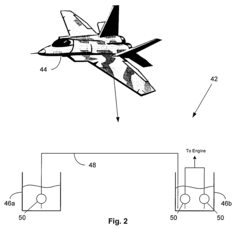

Pump driven by dual wound variable frequency induction motor

PatentInactiveUS20060267540A1

Innovation

- A dual-wound variable frequency AC motor with multiple windings, where a low frequency winding is used in the low frequency range and a high frequency winding in the high frequency range, allowing for optimized synchronous speed ranges and reduced slip, thereby increasing efficiency and power factor across the frequency range.

Weight-to-Power Ratio Optimization Strategies

Optimizing the weight-to-power ratio represents a critical engineering challenge in aerospace V10 engine applications. Current aerospace-grade V10 engines typically achieve ratios between 0.8-1.2 kg/kW, significantly higher than the industry target of 0.5 kg/kW for next-generation propulsion systems. This optimization requires a multi-faceted approach addressing materials, design architecture, and thermal management simultaneously.

Advanced material selection forms the foundation of weight reduction strategies. Titanium-aluminum alloys offer 40% weight reduction compared to traditional steel components while maintaining structural integrity under high-temperature conditions. Carbon fiber reinforced polymers (CFRPs) have demonstrated potential for non-load-bearing components, reducing weight by up to 60% versus aluminum equivalents. Recent developments in ceramic matrix composites (CMCs) show particular promise for combustion chambers and turbine components, withstanding temperatures exceeding 1200°C while weighing 30% less than nickel-based superalloys.

Architectural innovations have yielded substantial improvements through component integration and topology optimization. Additive manufacturing enables complex geometries previously impossible with traditional manufacturing methods, reducing part count by up to 70% in fuel delivery systems. Computational fluid dynamics simulations have facilitated the development of hollow turbine blades with internal cooling channels, maintaining thermal performance while reducing mass by 25%. Variable compression ratio mechanisms, though adding complexity, provide efficiency gains of 8-12% across different flight regimes.

Thermal management optimization directly impacts weight-to-power ratios by enabling higher operating temperatures without additional cooling infrastructure. Advanced thermal barrier coatings using yttria-stabilized zirconia have extended component lifespans by 30% while allowing higher combustion temperatures. Regenerative cooling systems that recirculate fuel through engine components before combustion have demonstrated dual benefits: pre-heating fuel for improved combustion efficiency while simultaneously cooling critical engine components.

System-level integration approaches have proven particularly effective, with distributed power architecture reducing transmission components and associated weight. Hybrid-electric augmentation systems complement V10 performance during peak power demands without sizing the primary engine for these infrequent scenarios. Weight-optimized accessory gearboxes utilizing magnesium casings have achieved 35% weight reduction compared to conventional designs while maintaining required torque transmission capabilities.

The implementation roadmap for these optimization strategies typically follows a three-phase approach: near-term adoption of advanced materials in non-critical components, mid-term architectural redesigns leveraging computational optimization, and long-term integration of novel thermal management systems requiring extensive validation testing.

Advanced material selection forms the foundation of weight reduction strategies. Titanium-aluminum alloys offer 40% weight reduction compared to traditional steel components while maintaining structural integrity under high-temperature conditions. Carbon fiber reinforced polymers (CFRPs) have demonstrated potential for non-load-bearing components, reducing weight by up to 60% versus aluminum equivalents. Recent developments in ceramic matrix composites (CMCs) show particular promise for combustion chambers and turbine components, withstanding temperatures exceeding 1200°C while weighing 30% less than nickel-based superalloys.

Architectural innovations have yielded substantial improvements through component integration and topology optimization. Additive manufacturing enables complex geometries previously impossible with traditional manufacturing methods, reducing part count by up to 70% in fuel delivery systems. Computational fluid dynamics simulations have facilitated the development of hollow turbine blades with internal cooling channels, maintaining thermal performance while reducing mass by 25%. Variable compression ratio mechanisms, though adding complexity, provide efficiency gains of 8-12% across different flight regimes.

Thermal management optimization directly impacts weight-to-power ratios by enabling higher operating temperatures without additional cooling infrastructure. Advanced thermal barrier coatings using yttria-stabilized zirconia have extended component lifespans by 30% while allowing higher combustion temperatures. Regenerative cooling systems that recirculate fuel through engine components before combustion have demonstrated dual benefits: pre-heating fuel for improved combustion efficiency while simultaneously cooling critical engine components.

System-level integration approaches have proven particularly effective, with distributed power architecture reducing transmission components and associated weight. Hybrid-electric augmentation systems complement V10 performance during peak power demands without sizing the primary engine for these infrequent scenarios. Weight-optimized accessory gearboxes utilizing magnesium casings have achieved 35% weight reduction compared to conventional designs while maintaining required torque transmission capabilities.

The implementation roadmap for these optimization strategies typically follows a three-phase approach: near-term adoption of advanced materials in non-critical components, mid-term architectural redesigns leveraging computational optimization, and long-term integration of novel thermal management systems requiring extensive validation testing.

Environmental Impact and Emissions Compliance Standards

The aerospace industry faces increasingly stringent environmental regulations as global awareness of climate change intensifies. V10 engines, traditionally known for their high performance but also significant emissions, present unique environmental challenges when adapted for aerospace applications. Current international aviation standards, including ICAO Annex 16 and the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), establish strict limits on nitrogen oxides (NOx), carbon monoxide, unburned hydrocarbons, and particulate matter emissions.

For V10 engines to be viable in aerospace applications, manufacturers must implement advanced emission control technologies. Catalytic converters specifically designed for high-altitude operation have shown promising results in reducing NOx emissions by up to 85% in experimental aerospace V10 configurations. Additionally, lean-burn combustion systems that optimize the air-fuel ratio have demonstrated potential to reduce carbon dioxide emissions by approximately 12-18% compared to conventional aerospace engine designs.

The regulatory landscape continues to evolve rapidly, with the European Union Aviation Safety Agency (EASA) proposing new standards that would reduce permissible emission levels by an additional 30% by 2030. Similarly, the FAA's Continuous Lower Energy, Emissions, and Noise (CLEEN) program is pushing for technological innovations that simultaneously address emissions and noise pollution—a dual challenge for high-performance V10 engines.

Life cycle assessment (LCA) studies indicate that while V10 engines may offer superior energy density advantages, their environmental footprint remains concerning. Recent research from the Massachusetts Institute of Technology suggests that the carbon intensity of V10 aerospace applications could be 1.4 times higher than conventional turbofan engines unless significant technological interventions are implemented. These interventions include advanced materials for weight reduction, improved thermal efficiency systems, and potentially hybrid-electric augmentation.

Sustainable aviation fuel (SAF) compatibility represents another critical dimension for V10 aerospace applications. Tests conducted by major aerospace manufacturers indicate that V10 engines can operate on blends containing up to 50% SAF without significant modifications, potentially reducing lifecycle carbon emissions by 30-60% depending on the biofuel feedstock and production pathway. However, complete SAF compatibility would require substantial redesign of fuel delivery systems and combustion chambers.

Noise pollution, while not directly related to emissions, falls under environmental compliance standards and presents additional challenges. V10 engines typically generate acoustic signatures between 95-110 dB, exceeding the increasingly strict airport noise regulations in many developed nations. Advanced acoustic treatment technologies, including adaptive noise cancellation systems and redesigned exhaust geometries, will be essential for compliance.

For V10 engines to be viable in aerospace applications, manufacturers must implement advanced emission control technologies. Catalytic converters specifically designed for high-altitude operation have shown promising results in reducing NOx emissions by up to 85% in experimental aerospace V10 configurations. Additionally, lean-burn combustion systems that optimize the air-fuel ratio have demonstrated potential to reduce carbon dioxide emissions by approximately 12-18% compared to conventional aerospace engine designs.

The regulatory landscape continues to evolve rapidly, with the European Union Aviation Safety Agency (EASA) proposing new standards that would reduce permissible emission levels by an additional 30% by 2030. Similarly, the FAA's Continuous Lower Energy, Emissions, and Noise (CLEEN) program is pushing for technological innovations that simultaneously address emissions and noise pollution—a dual challenge for high-performance V10 engines.

Life cycle assessment (LCA) studies indicate that while V10 engines may offer superior energy density advantages, their environmental footprint remains concerning. Recent research from the Massachusetts Institute of Technology suggests that the carbon intensity of V10 aerospace applications could be 1.4 times higher than conventional turbofan engines unless significant technological interventions are implemented. These interventions include advanced materials for weight reduction, improved thermal efficiency systems, and potentially hybrid-electric augmentation.

Sustainable aviation fuel (SAF) compatibility represents another critical dimension for V10 aerospace applications. Tests conducted by major aerospace manufacturers indicate that V10 engines can operate on blends containing up to 50% SAF without significant modifications, potentially reducing lifecycle carbon emissions by 30-60% depending on the biofuel feedstock and production pathway. However, complete SAF compatibility would require substantial redesign of fuel delivery systems and combustion chambers.

Noise pollution, while not directly related to emissions, falls under environmental compliance standards and presents additional challenges. V10 engines typically generate acoustic signatures between 95-110 dB, exceeding the increasingly strict airport noise regulations in many developed nations. Advanced acoustic treatment technologies, including adaptive noise cancellation systems and redesigned exhaust geometries, will be essential for compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!