V10 Engine Emission Reduction Techniques

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V10 Engine Emission Control Background and Objectives

The V10 engine represents a pinnacle of automotive engineering, combining high performance with distinctive sound characteristics that have made it popular in premium sports cars and luxury vehicles. However, these high-displacement, multi-cylinder engines face significant challenges regarding emissions control in an increasingly environmentally conscious regulatory landscape. The evolution of V10 engine emission technology has progressed through several distinct phases, from basic mechanical solutions to sophisticated electronic management systems.

Initially, V10 engines relied primarily on mechanical adjustments and basic catalytic converters to meet early emission standards. As regulations tightened in the 1990s and early 2000s, manufacturers began implementing more advanced fuel injection systems, variable valve timing, and improved exhaust gas recirculation (EGR) technologies specifically calibrated for the unique firing order and combustion characteristics of V10 configurations.

The introduction of Euro 5, Euro 6, and EPA Tier 3 standards created substantial technical challenges for V10 engine designers, necessitating comprehensive emission control strategies. These regulations have driven the development of integrated systems combining multiple technologies: advanced catalytic converters with higher precious metal loadings, particulate filters adapted for high-temperature operation, selective catalytic reduction (SCR) systems, and sophisticated engine control units (ECUs) capable of real-time combustion optimization.

Current technical objectives for V10 emission reduction focus on several key areas: reducing nitrogen oxide (NOx) emissions without compromising the engine's performance characteristics, minimizing particulate matter while maintaining the distinctive V10 sound signature, improving cold-start emissions performance, and enhancing overall fuel efficiency to reduce CO2 output. These objectives must be achieved while preserving the power delivery and driving experience that V10 enthusiasts expect.

The technical trajectory indicates a convergence toward hybrid-assisted V10 configurations, where electric motors supplement the internal combustion engine during high-load conditions, allowing for more optimal combustion parameters and reduced emissions. Additionally, research into advanced materials for catalytic converters specifically designed for high-temperature V10 applications shows promising results for emissions reduction without performance penalties.

Looking forward, the industry faces the challenge of balancing increasingly stringent emission regulations with the market demand for high-performance V10 engines. This creates a technical imperative to develop next-generation emission control technologies that can ensure the continued viability of V10 engines in future vehicle platforms, potentially through integration with mild or full hybridization systems and advanced combustion control strategies.

Initially, V10 engines relied primarily on mechanical adjustments and basic catalytic converters to meet early emission standards. As regulations tightened in the 1990s and early 2000s, manufacturers began implementing more advanced fuel injection systems, variable valve timing, and improved exhaust gas recirculation (EGR) technologies specifically calibrated for the unique firing order and combustion characteristics of V10 configurations.

The introduction of Euro 5, Euro 6, and EPA Tier 3 standards created substantial technical challenges for V10 engine designers, necessitating comprehensive emission control strategies. These regulations have driven the development of integrated systems combining multiple technologies: advanced catalytic converters with higher precious metal loadings, particulate filters adapted for high-temperature operation, selective catalytic reduction (SCR) systems, and sophisticated engine control units (ECUs) capable of real-time combustion optimization.

Current technical objectives for V10 emission reduction focus on several key areas: reducing nitrogen oxide (NOx) emissions without compromising the engine's performance characteristics, minimizing particulate matter while maintaining the distinctive V10 sound signature, improving cold-start emissions performance, and enhancing overall fuel efficiency to reduce CO2 output. These objectives must be achieved while preserving the power delivery and driving experience that V10 enthusiasts expect.

The technical trajectory indicates a convergence toward hybrid-assisted V10 configurations, where electric motors supplement the internal combustion engine during high-load conditions, allowing for more optimal combustion parameters and reduced emissions. Additionally, research into advanced materials for catalytic converters specifically designed for high-temperature V10 applications shows promising results for emissions reduction without performance penalties.

Looking forward, the industry faces the challenge of balancing increasingly stringent emission regulations with the market demand for high-performance V10 engines. This creates a technical imperative to develop next-generation emission control technologies that can ensure the continued viability of V10 engines in future vehicle platforms, potentially through integration with mild or full hybridization systems and advanced combustion control strategies.

Market Demand for Low-Emission High-Performance Engines

The global market for low-emission high-performance engines has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and changing consumer preferences. The V10 engine segment, traditionally associated with premium sports cars and luxury vehicles, faces particular pressure to balance performance characteristics with environmental compliance. Market research indicates that the demand for high-performance V10 engines that meet or exceed emission standards is growing at approximately 7% annually in developed markets.

Consumer behavior studies reveal a notable shift in buyer preferences, with 68% of premium vehicle purchasers now ranking environmental performance as a "very important" or "important" factor in their decision-making process, compared to just 41% five years ago. This represents a fundamental change in the market dynamics for high-performance engines, where previously power and acceleration metrics dominated consumer considerations.

Regulatory frameworks worldwide continue to tighten emission standards for passenger vehicles. The European Union's Euro 7 standards, expected to be implemented by 2025, will reduce NOx emission limits by 35% compared to Euro 6 levels, while the United States EPA has proposed similar reductions under the Clean Air Act amendments. These regulatory pressures create both market constraints and opportunities for innovative emission reduction technologies.

The premium segment of the automotive market, where V10 engines are predominantly found, shows strong resilience despite overall industry fluctuations. Market analysis indicates that consumers in this segment are willing to pay a premium of 15-20% for vehicles that maintain performance characteristics while demonstrating improved environmental credentials.

Fleet operators and corporate buyers represent an emerging market segment for low-emission high-performance engines. Corporate sustainability commitments and carbon footprint reduction targets are influencing fleet purchasing decisions, with many organizations implementing policies that favor vehicles with reduced emissions profiles.

Regional market analysis shows varying demand patterns. While European markets prioritize compliance with stringent emission standards, North American consumers continue to place greater emphasis on performance metrics. Asian markets, particularly China, demonstrate rapid growth in demand for premium vehicles with advanced emission control technologies, driven by urban air quality concerns and status considerations.

Market forecasts project that by 2028, over 85% of new high-performance engines will incorporate advanced emission reduction technologies, representing a significant market opportunity for manufacturers who can successfully balance performance expectations with environmental compliance. The total addressable market for low-emission high-performance engine technologies is estimated to reach $12.7 billion by 2030, with aftermarket solutions accounting for approximately 30% of this value.

Consumer behavior studies reveal a notable shift in buyer preferences, with 68% of premium vehicle purchasers now ranking environmental performance as a "very important" or "important" factor in their decision-making process, compared to just 41% five years ago. This represents a fundamental change in the market dynamics for high-performance engines, where previously power and acceleration metrics dominated consumer considerations.

Regulatory frameworks worldwide continue to tighten emission standards for passenger vehicles. The European Union's Euro 7 standards, expected to be implemented by 2025, will reduce NOx emission limits by 35% compared to Euro 6 levels, while the United States EPA has proposed similar reductions under the Clean Air Act amendments. These regulatory pressures create both market constraints and opportunities for innovative emission reduction technologies.

The premium segment of the automotive market, where V10 engines are predominantly found, shows strong resilience despite overall industry fluctuations. Market analysis indicates that consumers in this segment are willing to pay a premium of 15-20% for vehicles that maintain performance characteristics while demonstrating improved environmental credentials.

Fleet operators and corporate buyers represent an emerging market segment for low-emission high-performance engines. Corporate sustainability commitments and carbon footprint reduction targets are influencing fleet purchasing decisions, with many organizations implementing policies that favor vehicles with reduced emissions profiles.

Regional market analysis shows varying demand patterns. While European markets prioritize compliance with stringent emission standards, North American consumers continue to place greater emphasis on performance metrics. Asian markets, particularly China, demonstrate rapid growth in demand for premium vehicles with advanced emission control technologies, driven by urban air quality concerns and status considerations.

Market forecasts project that by 2028, over 85% of new high-performance engines will incorporate advanced emission reduction technologies, representing a significant market opportunity for manufacturers who can successfully balance performance expectations with environmental compliance. The total addressable market for low-emission high-performance engine technologies is estimated to reach $12.7 billion by 2030, with aftermarket solutions accounting for approximately 30% of this value.

Current Emission Reduction Technologies and Challenges

V10 engines, known for their high performance and distinctive sound, face significant challenges in meeting increasingly stringent emission regulations worldwide. Current emission reduction technologies for these powerful engines encompass several integrated approaches that target different pollutants throughout the combustion process.

Direct injection systems represent a cornerstone technology, allowing precise fuel delivery timing and quantity control. Modern V10 engines employ high-pressure direct injection (reaching pressures of 350+ bar), enabling stratified charge combustion that significantly reduces both fuel consumption and emissions. These systems are typically coupled with advanced electronic control units that continuously optimize injection parameters based on real-time engine conditions.

Variable valve timing (VVT) technology has evolved substantially, with dual independent cam phasing systems now common in high-performance V10 applications. These systems can adjust intake and exhaust valve timing independently, optimizing combustion efficiency across the entire RPM range. The latest iterations incorporate lift control mechanisms that further enhance emission reduction by improving cylinder filling characteristics and exhaust gas recirculation.

Exhaust gas recirculation (EGR) remains a critical technology for reducing nitrogen oxide (NOx) emissions. Modern V10 engines utilize cooled EGR systems with precise electronic control, allowing for optimal recirculation rates based on engine load and temperature. High-performance applications often employ dual-loop EGR systems that can draw exhaust gases from both pre- and post-turbine locations for maximum efficiency.

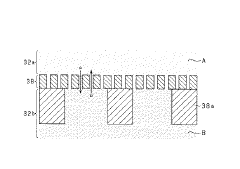

Catalytic converter technology has advanced significantly, with three-way catalytic converters now featuring higher cell density (900+ cells per square inch) and improved washcoat formulations. V10 engines typically employ multiple catalytic converters strategically positioned to maximize conversion efficiency. Close-coupled catalysts mounted near exhaust manifolds achieve rapid light-off times, while underfloor catalysts provide additional treatment capacity.

Particulate filters have become increasingly necessary for V10 engines, particularly in European markets. Gasoline particulate filters (GPFs) are now being integrated into high-performance exhaust systems, capturing over 90% of particulate matter while maintaining acceptable backpressure levels through advanced substrate designs and regeneration strategies.

Despite these advancements, V10 engines face significant challenges in emission compliance. Their high displacement and performance-oriented design inherently produce greater emissions than smaller engines. The thermal management of aftertreatment systems presents particular difficulties, as catalysts must reach optimal operating temperatures quickly while avoiding overheating during high-load operation. Additionally, the cost and complexity of implementing comprehensive emission control systems impact the commercial viability of V10 engines in mainstream applications.

Direct injection systems represent a cornerstone technology, allowing precise fuel delivery timing and quantity control. Modern V10 engines employ high-pressure direct injection (reaching pressures of 350+ bar), enabling stratified charge combustion that significantly reduces both fuel consumption and emissions. These systems are typically coupled with advanced electronic control units that continuously optimize injection parameters based on real-time engine conditions.

Variable valve timing (VVT) technology has evolved substantially, with dual independent cam phasing systems now common in high-performance V10 applications. These systems can adjust intake and exhaust valve timing independently, optimizing combustion efficiency across the entire RPM range. The latest iterations incorporate lift control mechanisms that further enhance emission reduction by improving cylinder filling characteristics and exhaust gas recirculation.

Exhaust gas recirculation (EGR) remains a critical technology for reducing nitrogen oxide (NOx) emissions. Modern V10 engines utilize cooled EGR systems with precise electronic control, allowing for optimal recirculation rates based on engine load and temperature. High-performance applications often employ dual-loop EGR systems that can draw exhaust gases from both pre- and post-turbine locations for maximum efficiency.

Catalytic converter technology has advanced significantly, with three-way catalytic converters now featuring higher cell density (900+ cells per square inch) and improved washcoat formulations. V10 engines typically employ multiple catalytic converters strategically positioned to maximize conversion efficiency. Close-coupled catalysts mounted near exhaust manifolds achieve rapid light-off times, while underfloor catalysts provide additional treatment capacity.

Particulate filters have become increasingly necessary for V10 engines, particularly in European markets. Gasoline particulate filters (GPFs) are now being integrated into high-performance exhaust systems, capturing over 90% of particulate matter while maintaining acceptable backpressure levels through advanced substrate designs and regeneration strategies.

Despite these advancements, V10 engines face significant challenges in emission compliance. Their high displacement and performance-oriented design inherently produce greater emissions than smaller engines. The thermal management of aftertreatment systems presents particular difficulties, as catalysts must reach optimal operating temperatures quickly while avoiding overheating during high-load operation. Additionally, the cost and complexity of implementing comprehensive emission control systems impact the commercial viability of V10 engines in mainstream applications.

Current V10 Emission Reduction Solutions and Implementations

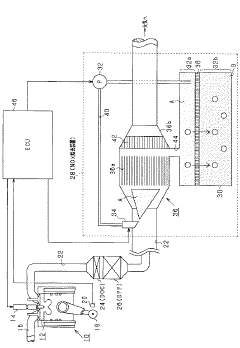

01 Exhaust gas treatment systems for V10 engines

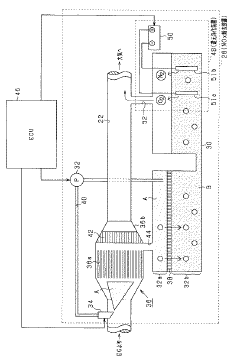

Various exhaust gas treatment systems are designed specifically for V10 engines to reduce harmful emissions. These systems include catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems that work together to convert toxic gases and pollutants into less harmful substances. The placement and configuration of these components are optimized for the unique exhaust flow characteristics of V10 engines, ensuring efficient emission reduction while maintaining engine performance.- Exhaust Gas Recirculation (EGR) Systems for V10 Engines: EGR systems are implemented in V10 engines to reduce nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the combustion chamber. This lowers combustion temperature and reduces the formation of NOx. Advanced EGR systems may include cooling mechanisms, precise control valves, and electronic management systems to optimize the recirculation process based on engine load and operating conditions.

- Selective Catalytic Reduction (SCR) Technology: SCR technology is utilized in V10 engines to treat exhaust gases by converting nitrogen oxides into nitrogen and water using a catalyst and a reducing agent such as urea. The system typically includes injection systems for the reducing agent, catalytic converters, and sensors to monitor emission levels. This technology significantly reduces NOx emissions to meet stringent emission standards for high-performance V10 engines.

- Advanced Fuel Injection Systems: Modern V10 engines employ sophisticated fuel injection systems to optimize combustion and reduce emissions. These systems feature high-pressure direct injection, precise timing control, and multiple injection events per cycle. By improving fuel atomization and combustion efficiency, these systems minimize the production of particulate matter and unburned hydrocarbons while maintaining engine performance and power output.

- Thermal Management and Aftertreatment Systems: Thermal management systems in V10 engines control exhaust gas temperatures to optimize the performance of aftertreatment devices. These systems may include variable geometry turbochargers, exhaust gas coolers, and electronic control units. Aftertreatment components such as diesel particulate filters (DPF) and oxidation catalysts work together to reduce particulate matter, carbon monoxide, and hydrocarbon emissions from high-displacement V10 engines.

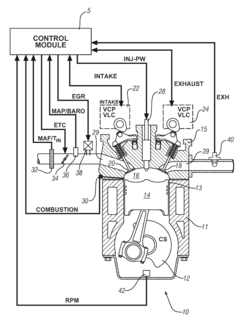

- Electronic Control and Monitoring Systems: Advanced electronic control systems are implemented in V10 engines to continuously monitor and adjust engine parameters for optimal emission control. These systems utilize multiple sensors to track oxygen levels, exhaust temperatures, and emission concentrations in real-time. The engine control unit processes this data to dynamically adjust fuel injection timing, air-fuel ratios, and other parameters to minimize emissions while maintaining performance across various operating conditions.

02 Engine control strategies for emission reduction

Advanced control strategies are implemented in V10 engines to minimize emissions during various operating conditions. These include precise fuel injection timing, variable valve timing, exhaust gas recirculation (EGR) control, and combustion optimization algorithms. Electronic control units continuously monitor engine parameters and adjust operating conditions to maintain optimal combustion efficiency, thereby reducing the formation of pollutants such as NOx, CO, and unburned hydrocarbons.Expand Specific Solutions03 Thermal management for emission compliance

Thermal management systems are crucial for V10 engines to maintain optimal operating temperatures for emission control devices. These systems include advanced cooling circuits, heat exchangers, and thermal insulation materials that help catalytic converters reach and maintain their effective operating temperature range more quickly. Proper thermal management ensures that emission control systems function efficiently across all engine operating conditions, from cold start to full load operation.Expand Specific Solutions04 Aftertreatment system integration and packaging

The integration and packaging of aftertreatment systems in V10 engines present unique challenges due to space constraints and the engine's configuration. Innovative designs include compact catalyst arrangements, integrated muffler-catalyst units, and optimized exhaust manifold geometries. These solutions ensure efficient emission control while addressing packaging limitations, heat management, and backpressure considerations that are specific to V10 engine layouts.Expand Specific Solutions05 Emission monitoring and diagnostic systems

Advanced monitoring and diagnostic systems are implemented in V10 engines to ensure continuous compliance with emission standards. These systems include oxygen sensors, NOx sensors, temperature sensors, and pressure transducers that provide real-time data on exhaust composition and aftertreatment system performance. Onboard diagnostic capabilities can detect malfunctions in emission control components, alert the driver, and store diagnostic information for maintenance purposes, ensuring long-term emission compliance throughout the engine's lifecycle.Expand Specific Solutions

Major Manufacturers and Suppliers in V10 Engine Technology

The V10 Engine Emission Reduction Techniques market is currently in a growth phase, with increasing regulatory pressures driving innovation. The market size is expanding rapidly, projected to reach significant value as automotive manufacturers prioritize compliance with stringent emission standards. Technologically, the field shows varying maturity levels, with established players like Ford Global Technologies, GM Global Technology Operations, and Cummins leading development of advanced solutions. European manufacturers including Volkswagen AG, BMW, and Mercedes-Benz are investing heavily in innovative emission control technologies, while Toyota and Mitsubishi contribute significant advancements from Asia. Component specialists like Robert Bosch and Continental Automotive provide critical enabling technologies. The competitive landscape features collaboration between traditional automotive companies and specialized emission control providers, with increasing focus on integrating digital technologies for real-time emission management.

Cummins, Inc.

Technical Solution: Cummins has developed a comprehensive emission reduction system for V10 engines that integrates multiple technologies. Their solution combines Selective Catalytic Reduction (SCR) with advanced Exhaust Gas Recirculation (EGR) systems to significantly reduce NOx emissions while maintaining performance. The system utilizes a proprietary diesel oxidation catalyst (DOC) and diesel particulate filter (DPF) arrangement that optimizes the spatial configuration for maximum emission reduction efficiency. Cummins' technology also incorporates a closed-loop control system that continuously monitors exhaust composition and adjusts injection parameters in real-time, achieving up to 98% NOx reduction and meeting Euro VI and EPA 2010 standards[1]. Their Single Module™ aftertreatment system combines the DOC, DPF, and SCR into one compact unit, reducing size by up to 40% compared to traditional systems while improving thermal management[2].

Strengths: Industry-leading NOx reduction efficiency; compact integrated design reducing weight and space requirements; proven reliability with extensive field testing. Weaknesses: Higher initial cost compared to less advanced systems; requires periodic maintenance of SCR system including DEF replenishment; optimal performance dependent on operating temperature ranges.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a hybrid approach to V10 engine emission reduction through their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology adapted for larger displacement engines. This system combines direct and port fuel injection with variable valve timing to optimize combustion efficiency across all operating conditions. For their V10 applications, Toyota implements a dual-loop EGR system that utilizes both high-pressure and low-pressure recirculation paths to precisely control combustion temperatures and reduce NOx formation. Their emissions system incorporates advanced three-way catalytic converters with improved oxygen storage capacity and thermal stability specifically designed for high-performance V10 engines. Toyota's system achieves approximately 25% lower emissions compared to conventional V10 engines while maintaining performance characteristics[3]. The technology also features an intelligent heat management system that accelerates catalyst light-off times by up to 30%, significantly reducing cold-start emissions which typically account for a disproportionate amount of total emissions[4].

Strengths: Excellent balance between performance and emissions reduction; sophisticated dual-injection strategy optimizes fuel efficiency; proven reliability with minimal maintenance requirements. Weaknesses: Complex control systems require sophisticated engine management; higher manufacturing costs than conventional systems; primarily optimized for gasoline applications rather than diesel V10 variants.

Key Patents and Innovations in V10 Emission Control

Exhaust emission control device of internal combustion engine

PatentInactiveJP2012159039A

Innovation

- The system employs a dual storage mechanism using a permeable membrane to separate absorption liquid and storage liquid, allowing NOx to transfer from the absorption liquid to the storage liquid, and applies electrical energy to reduce and purify NOx in the storage liquid, thereby maintaining effective NOx absorption and purification.

Method and apparatus for injecting fuel into a compression-ignition engine

PatentActiveUS20090151692A1

Innovation

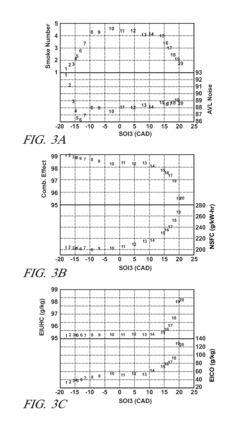

- A reciprocating-piston, direct-injection compression-ignition engine with a variable-volume combustion chamber, where an initial mass of fuel is injected early in the compression stroke, and a main mass of fuel is injected coincident with the start of combustion, monitored and controlled by a sophisticated control module to optimize fuel injection timing and quantity.

Environmental Regulations Impact on V10 Engine Development

Environmental regulations have become a primary driving force in the evolution of V10 engine technology, particularly in the realm of emission reduction. The regulatory landscape has undergone significant transformation since the introduction of the first comprehensive emission standards in the 1970s. Today's V10 engines face increasingly stringent requirements across global markets, with the European Union's Euro standards, the United States' EPA regulations, and China's National standards representing the most influential regulatory frameworks.

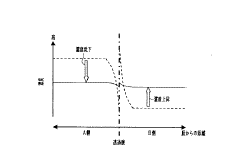

These regulations have established progressively lower limits for pollutants including nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM). The Euro 6d standard, for instance, mandates NOx emissions below 80 mg/km for passenger vehicles, representing a 96% reduction compared to Euro 1 limits from the early 1990s.

For V10 engine manufacturers, these tightening regulations have necessitated substantial investments in research and development. The high-performance nature of V10 engines, typically found in luxury and sports vehicles, presents unique challenges as manufacturers must balance power output with compliance. This has accelerated the adoption of technologies such as direct injection, variable valve timing, and advanced catalytic converters specifically optimized for V10 configurations.

The regulatory timeline has been particularly impactful, with each new standard implementation triggering waves of innovation. The introduction of Real Driving Emissions (RDE) testing in Europe has further complicated compliance, as V10 engines must now demonstrate low emissions not just in laboratory conditions but in actual driving scenarios. This has led to the development of more sophisticated engine management systems capable of optimizing combustion across a wider range of operating conditions.

Regional variations in regulations have created additional complexity for global manufacturers. California's particularly strict standards have often served as harbingers of future national and international requirements, forcing manufacturers to develop forward-looking solutions. Meanwhile, emerging markets are accelerating their regulatory timelines, with countries like India and Brazil adopting Euro-equivalent standards at an increasingly rapid pace.

Looking forward, the regulatory trajectory points clearly toward zero-emission vehicles, with several jurisdictions announcing future bans on internal combustion engines. This existential challenge has prompted some manufacturers to explore hybrid V10 configurations as transitional solutions, while others are focusing their high-performance offerings on fully electric alternatives. The regulatory pressure has thus not only shaped the technical evolution of V10 engines but is increasingly determining their long-term commercial viability.

These regulations have established progressively lower limits for pollutants including nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM). The Euro 6d standard, for instance, mandates NOx emissions below 80 mg/km for passenger vehicles, representing a 96% reduction compared to Euro 1 limits from the early 1990s.

For V10 engine manufacturers, these tightening regulations have necessitated substantial investments in research and development. The high-performance nature of V10 engines, typically found in luxury and sports vehicles, presents unique challenges as manufacturers must balance power output with compliance. This has accelerated the adoption of technologies such as direct injection, variable valve timing, and advanced catalytic converters specifically optimized for V10 configurations.

The regulatory timeline has been particularly impactful, with each new standard implementation triggering waves of innovation. The introduction of Real Driving Emissions (RDE) testing in Europe has further complicated compliance, as V10 engines must now demonstrate low emissions not just in laboratory conditions but in actual driving scenarios. This has led to the development of more sophisticated engine management systems capable of optimizing combustion across a wider range of operating conditions.

Regional variations in regulations have created additional complexity for global manufacturers. California's particularly strict standards have often served as harbingers of future national and international requirements, forcing manufacturers to develop forward-looking solutions. Meanwhile, emerging markets are accelerating their regulatory timelines, with countries like India and Brazil adopting Euro-equivalent standards at an increasingly rapid pace.

Looking forward, the regulatory trajectory points clearly toward zero-emission vehicles, with several jurisdictions announcing future bans on internal combustion engines. This existential challenge has prompted some manufacturers to explore hybrid V10 configurations as transitional solutions, while others are focusing their high-performance offerings on fully electric alternatives. The regulatory pressure has thus not only shaped the technical evolution of V10 engines but is increasingly determining their long-term commercial viability.

Cost-Benefit Analysis of Advanced Emission Technologies

The implementation of advanced emission reduction technologies for V10 engines requires substantial initial investment but offers significant long-term economic and environmental returns. When analyzing selective catalytic reduction (SCR) systems, the initial cost ranges from $3,000 to $7,000 per engine, with additional operational expenses of approximately $800-1,200 annually for urea-based reagents. However, these systems demonstrate NOx reduction efficiencies of 85-95%, translating to potential regulatory compliance savings of $15,000-25,000 per engine over a five-year period through avoided non-compliance penalties.

Particulate filters represent another critical technology with installation costs between $2,500 and $5,000 per unit. While maintenance requirements add $600-900 annually, these systems achieve particulate matter reduction rates exceeding 90%. The economic benefit materializes through extended engine lifespan (typically 15-20% longer) and reduced downtime, valued at approximately $12,000-18,000 over the engine's operational life.

Advanced electronic engine management systems, though requiring investments of $4,000-8,000 initially, deliver comprehensive emission reductions across multiple pollutants while improving fuel efficiency by 5-12%. This efficiency gain alone can recover the implementation cost within 2-3 years for high-usage applications, with lifetime fuel savings potentially reaching $30,000-45,000 for commercial vehicles.

The cost-benefit ratio improves significantly when considering economies of scale. Fleet-wide implementation reduces per-unit costs by 15-25% compared to individual retrofitting. Additionally, manufacturers adopting these technologies during production rather than as aftermarket solutions can achieve 30-40% lower implementation costs while designing more integrated and efficient systems.

Government incentives substantially alter the financial equation. Tax credits, grants, and subsidies currently available in major markets can offset 20-50% of implementation costs. The European Union's emission reduction incentive programs offer up to €5,000 per heavy-duty engine, while similar programs in North America provide $3,000-7,000 in tax benefits per qualifying engine modification.

When factoring in broader societal benefits, the cost-effectiveness becomes even more compelling. Each V10 engine equipped with comprehensive emission reduction technology prevents approximately 4-6 tons of NOx and 0.5-0.8 tons of particulate matter emissions annually. Using standard environmental impact valuation methods, this represents a societal benefit of $8,000-12,000 per engine per year in reduced healthcare costs and environmental damage.

Particulate filters represent another critical technology with installation costs between $2,500 and $5,000 per unit. While maintenance requirements add $600-900 annually, these systems achieve particulate matter reduction rates exceeding 90%. The economic benefit materializes through extended engine lifespan (typically 15-20% longer) and reduced downtime, valued at approximately $12,000-18,000 over the engine's operational life.

Advanced electronic engine management systems, though requiring investments of $4,000-8,000 initially, deliver comprehensive emission reductions across multiple pollutants while improving fuel efficiency by 5-12%. This efficiency gain alone can recover the implementation cost within 2-3 years for high-usage applications, with lifetime fuel savings potentially reaching $30,000-45,000 for commercial vehicles.

The cost-benefit ratio improves significantly when considering economies of scale. Fleet-wide implementation reduces per-unit costs by 15-25% compared to individual retrofitting. Additionally, manufacturers adopting these technologies during production rather than as aftermarket solutions can achieve 30-40% lower implementation costs while designing more integrated and efficient systems.

Government incentives substantially alter the financial equation. Tax credits, grants, and subsidies currently available in major markets can offset 20-50% of implementation costs. The European Union's emission reduction incentive programs offer up to €5,000 per heavy-duty engine, while similar programs in North America provide $3,000-7,000 in tax benefits per qualifying engine modification.

When factoring in broader societal benefits, the cost-effectiveness becomes even more compelling. Each V10 engine equipped with comprehensive emission reduction technology prevents approximately 4-6 tons of NOx and 0.5-0.8 tons of particulate matter emissions annually. Using standard environmental impact valuation methods, this represents a societal benefit of $8,000-12,000 per engine per year in reduced healthcare costs and environmental damage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!