How to Enhance LDPE Products with Nanotechnology?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Nanotech Evolution

The evolution of nanotechnology in LDPE (Low-Density Polyethylene) products represents a significant advancement in polymer science and materials engineering. This progression can be traced through several key stages, each marked by notable technological breakthroughs and innovative applications.

In the early 2000s, researchers began exploring the potential of nanoparticles to enhance the properties of LDPE. Initial efforts focused on incorporating inorganic nanofillers such as silica and clay to improve mechanical strength and barrier properties. These early experiments laid the groundwork for more sophisticated nanocomposite materials.

By the mid-2000s, carbon-based nanomaterials, particularly carbon nanotubes and graphene, emerged as promising additives for LDPE. These materials offered exceptional mechanical and electrical properties, opening up new possibilities for conductive and high-strength LDPE composites. This period saw increased research into dispersion techniques and surface functionalization to improve compatibility between nanofillers and the LDPE matrix.

The late 2000s and early 2010s witnessed a shift towards more complex nanostructures. Multi-walled carbon nanotubes and graphene oxide became popular due to their enhanced dispersibility and interaction with the polymer matrix. Researchers also began exploring hybrid nanocomposites, combining different types of nanofillers to achieve synergistic effects.

From 2010 to 2015, there was a growing focus on sustainable and bio-based nanofillers. Cellulose nanocrystals and nanofibrils derived from plant sources gained attention as eco-friendly alternatives to synthetic nanoparticles. This trend aligned with increasing environmental concerns and the push for more sustainable materials in various industries.

The period from 2015 to 2020 saw advancements in nanoparticle functionalization and surface modification techniques. These improvements allowed for better control over the interface between nanofillers and the LDPE matrix, resulting in enhanced property improvements and more consistent performance across different applications.

Most recently, from 2020 onwards, the focus has shifted towards smart and responsive LDPE nanocomposites. Researchers are exploring nanoparticles that can respond to external stimuli such as temperature, light, or electrical fields, enabling the development of LDPE products with adaptive properties. Additionally, there is growing interest in using nanotechnology to enhance the recyclability and biodegradability of LDPE, addressing long-standing environmental concerns associated with plastic waste.

Throughout this evolution, the primary goal has remained consistent: to leverage nanotechnology to overcome the inherent limitations of LDPE, such as low strength, poor barrier properties, and limited functionality. The ongoing research continues to push the boundaries of what is possible with LDPE, promising new applications and improved performance in existing ones.

In the early 2000s, researchers began exploring the potential of nanoparticles to enhance the properties of LDPE. Initial efforts focused on incorporating inorganic nanofillers such as silica and clay to improve mechanical strength and barrier properties. These early experiments laid the groundwork for more sophisticated nanocomposite materials.

By the mid-2000s, carbon-based nanomaterials, particularly carbon nanotubes and graphene, emerged as promising additives for LDPE. These materials offered exceptional mechanical and electrical properties, opening up new possibilities for conductive and high-strength LDPE composites. This period saw increased research into dispersion techniques and surface functionalization to improve compatibility between nanofillers and the LDPE matrix.

The late 2000s and early 2010s witnessed a shift towards more complex nanostructures. Multi-walled carbon nanotubes and graphene oxide became popular due to their enhanced dispersibility and interaction with the polymer matrix. Researchers also began exploring hybrid nanocomposites, combining different types of nanofillers to achieve synergistic effects.

From 2010 to 2015, there was a growing focus on sustainable and bio-based nanofillers. Cellulose nanocrystals and nanofibrils derived from plant sources gained attention as eco-friendly alternatives to synthetic nanoparticles. This trend aligned with increasing environmental concerns and the push for more sustainable materials in various industries.

The period from 2015 to 2020 saw advancements in nanoparticle functionalization and surface modification techniques. These improvements allowed for better control over the interface between nanofillers and the LDPE matrix, resulting in enhanced property improvements and more consistent performance across different applications.

Most recently, from 2020 onwards, the focus has shifted towards smart and responsive LDPE nanocomposites. Researchers are exploring nanoparticles that can respond to external stimuli such as temperature, light, or electrical fields, enabling the development of LDPE products with adaptive properties. Additionally, there is growing interest in using nanotechnology to enhance the recyclability and biodegradability of LDPE, addressing long-standing environmental concerns associated with plastic waste.

Throughout this evolution, the primary goal has remained consistent: to leverage nanotechnology to overcome the inherent limitations of LDPE, such as low strength, poor barrier properties, and limited functionality. The ongoing research continues to push the boundaries of what is possible with LDPE, promising new applications and improved performance in existing ones.

Market Demand Analysis

The market demand for enhanced LDPE products using nanotechnology has been steadily growing in recent years. This surge is primarily driven by the increasing need for high-performance packaging materials across various industries, including food and beverage, pharmaceuticals, and consumer goods. The global LDPE market, valued at approximately $33 billion in 2020, is projected to reach $50 billion by 2027, with a significant portion of this growth attributed to nano-enhanced products.

Nanotechnology offers several advantages in enhancing LDPE properties, addressing key market demands. Improved barrier properties against moisture, gases, and UV radiation are particularly sought after in the food packaging industry. This sector alone accounts for over 40% of the LDPE market and is experiencing rapid growth due to changing consumer lifestyles and increased demand for packaged foods.

The automotive and construction industries are also showing increased interest in nano-enhanced LDPE products. These sectors require materials with enhanced mechanical strength, thermal stability, and chemical resistance. Nano-enhanced LDPE offers potential solutions to these demands, driving market growth in these areas. The automotive industry, in particular, is projected to increase its use of nano-enhanced polymers by 15% annually over the next five years.

Environmental concerns and sustainability initiatives are shaping market demands as well. Consumers and regulatory bodies are pushing for more eco-friendly packaging solutions. Nanotechnology in LDPE can potentially reduce material usage while maintaining or improving performance, aligning with these sustainability goals. This trend is expected to drive significant market growth, with eco-friendly packaging solutions projected to grow at a CAGR of 6% through 2025.

The healthcare sector presents another significant market opportunity for nano-enhanced LDPE products. The demand for advanced medical packaging with improved barrier properties and antimicrobial characteristics has been amplified by recent global health events. This sector is expected to be a key driver of market growth, with an estimated annual growth rate of 8% for specialized medical packaging materials.

Geographically, Asia-Pacific is emerging as the fastest-growing market for nano-enhanced LDPE products, driven by rapid industrialization, population growth, and increasing disposable incomes. North America and Europe continue to be significant markets, with a focus on high-value applications in aerospace, healthcare, and advanced packaging solutions.

In conclusion, the market demand for nano-enhanced LDPE products is robust and diverse, spanning multiple industries and geographical regions. The ability of nanotechnology to address specific performance requirements while potentially offering sustainability benefits positions it as a key driver in the evolution of LDPE products. As research and development in this field continue to advance, the market is expected to see further expansion and diversification of applications.

Nanotechnology offers several advantages in enhancing LDPE properties, addressing key market demands. Improved barrier properties against moisture, gases, and UV radiation are particularly sought after in the food packaging industry. This sector alone accounts for over 40% of the LDPE market and is experiencing rapid growth due to changing consumer lifestyles and increased demand for packaged foods.

The automotive and construction industries are also showing increased interest in nano-enhanced LDPE products. These sectors require materials with enhanced mechanical strength, thermal stability, and chemical resistance. Nano-enhanced LDPE offers potential solutions to these demands, driving market growth in these areas. The automotive industry, in particular, is projected to increase its use of nano-enhanced polymers by 15% annually over the next five years.

Environmental concerns and sustainability initiatives are shaping market demands as well. Consumers and regulatory bodies are pushing for more eco-friendly packaging solutions. Nanotechnology in LDPE can potentially reduce material usage while maintaining or improving performance, aligning with these sustainability goals. This trend is expected to drive significant market growth, with eco-friendly packaging solutions projected to grow at a CAGR of 6% through 2025.

The healthcare sector presents another significant market opportunity for nano-enhanced LDPE products. The demand for advanced medical packaging with improved barrier properties and antimicrobial characteristics has been amplified by recent global health events. This sector is expected to be a key driver of market growth, with an estimated annual growth rate of 8% for specialized medical packaging materials.

Geographically, Asia-Pacific is emerging as the fastest-growing market for nano-enhanced LDPE products, driven by rapid industrialization, population growth, and increasing disposable incomes. North America and Europe continue to be significant markets, with a focus on high-value applications in aerospace, healthcare, and advanced packaging solutions.

In conclusion, the market demand for nano-enhanced LDPE products is robust and diverse, spanning multiple industries and geographical regions. The ability of nanotechnology to address specific performance requirements while potentially offering sustainability benefits positions it as a key driver in the evolution of LDPE products. As research and development in this field continue to advance, the market is expected to see further expansion and diversification of applications.

Current Challenges

The enhancement of Low-Density Polyethylene (LDPE) products through nanotechnology faces several significant challenges that require innovative solutions. One of the primary obstacles is achieving uniform dispersion of nanoparticles within the LDPE matrix. The high viscosity of LDPE and the tendency of nanoparticles to agglomerate make it difficult to obtain a homogeneous distribution, which is crucial for realizing the full potential of nanocomposites.

Another major challenge lies in maintaining the desirable properties of LDPE while incorporating nanoparticles. The addition of nanofillers can sometimes lead to unexpected changes in mechanical properties, such as reduced flexibility or decreased impact strength. Balancing the enhancement of certain properties without compromising others remains a complex task that demands careful material engineering.

The scalability of nanotechnology-enhanced LDPE production presents a significant hurdle. While laboratory-scale experiments may yield promising results, translating these into large-scale industrial processes without compromising quality or increasing costs substantially is a formidable challenge. This includes developing efficient mixing techniques and ensuring consistent quality across large production batches.

Environmental concerns and regulatory compliance pose additional challenges. The potential release of nanoparticles during the product lifecycle, including production, use, and disposal, raises questions about environmental impact and human health. Addressing these concerns requires comprehensive studies on the long-term effects of nanoparticles and developing strategies to mitigate any potential risks.

The cost-effectiveness of incorporating nanotechnology into LDPE products is another critical challenge. The high cost of nanoparticles and the potential need for specialized equipment or processes can significantly increase production costs. Justifying these increased costs through enhanced performance or new functionalities is essential for market acceptance and commercial viability.

Furthermore, the characterization and quality control of nanocomposite LDPE products present technical difficulties. Existing methods may not be sufficient to accurately assess the dispersion of nanoparticles or predict the long-term stability of the enhanced properties. Developing new analytical techniques and standards specific to nanocomposite materials is necessary to ensure consistent product quality and performance.

Lastly, the challenge of compatibility between nanoparticles and LDPE matrices remains a significant area of research. Improving the interfacial adhesion between nanofillers and the polymer matrix is crucial for enhancing mechanical and barrier properties. This often requires surface modification of nanoparticles or the development of novel compatibilizers, adding complexity to the material design and production process.

Another major challenge lies in maintaining the desirable properties of LDPE while incorporating nanoparticles. The addition of nanofillers can sometimes lead to unexpected changes in mechanical properties, such as reduced flexibility or decreased impact strength. Balancing the enhancement of certain properties without compromising others remains a complex task that demands careful material engineering.

The scalability of nanotechnology-enhanced LDPE production presents a significant hurdle. While laboratory-scale experiments may yield promising results, translating these into large-scale industrial processes without compromising quality or increasing costs substantially is a formidable challenge. This includes developing efficient mixing techniques and ensuring consistent quality across large production batches.

Environmental concerns and regulatory compliance pose additional challenges. The potential release of nanoparticles during the product lifecycle, including production, use, and disposal, raises questions about environmental impact and human health. Addressing these concerns requires comprehensive studies on the long-term effects of nanoparticles and developing strategies to mitigate any potential risks.

The cost-effectiveness of incorporating nanotechnology into LDPE products is another critical challenge. The high cost of nanoparticles and the potential need for specialized equipment or processes can significantly increase production costs. Justifying these increased costs through enhanced performance or new functionalities is essential for market acceptance and commercial viability.

Furthermore, the characterization and quality control of nanocomposite LDPE products present technical difficulties. Existing methods may not be sufficient to accurately assess the dispersion of nanoparticles or predict the long-term stability of the enhanced properties. Developing new analytical techniques and standards specific to nanocomposite materials is necessary to ensure consistent product quality and performance.

Lastly, the challenge of compatibility between nanoparticles and LDPE matrices remains a significant area of research. Improving the interfacial adhesion between nanofillers and the polymer matrix is crucial for enhancing mechanical and barrier properties. This often requires surface modification of nanoparticles or the development of novel compatibilizers, adding complexity to the material design and production process.

Existing Nanotech Solutions

01 LDPE product manufacturing processes

Various manufacturing processes for Low-Density Polyethylene (LDPE) products, including extrusion, injection molding, and blow molding techniques. These processes involve melting LDPE resin and shaping it into different forms such as films, sheets, and containers.- LDPE product manufacturing processes: Various manufacturing processes for Low-Density Polyethylene (LDPE) products, including extrusion, injection molding, and film blowing. These processes involve different techniques to shape LDPE into various forms such as films, sheets, and molded parts.

- LDPE product applications: Wide range of applications for LDPE products, including packaging materials, agricultural films, consumer goods, and industrial components. LDPE's flexibility, chemical resistance, and low cost make it suitable for diverse uses across multiple industries.

- LDPE blends and composites: Development of LDPE blends and composites to enhance material properties. These formulations may include other polymers, additives, or fillers to improve strength, durability, or specific functional characteristics of the final product.

- Recycling and sustainability of LDPE products: Techniques and processes for recycling LDPE products to promote sustainability. This includes methods for collecting, sorting, and reprocessing LDPE waste into new products or raw materials, addressing environmental concerns associated with plastic waste.

- LDPE product modifications and enhancements: Methods to modify and enhance LDPE products, such as surface treatments, crosslinking, or the incorporation of specific additives. These modifications aim to improve properties like barrier performance, printability, or UV resistance for specialized applications.

02 LDPE product applications

Wide range of applications for LDPE products, including packaging materials, agricultural films, consumer goods, and industrial components. LDPE's flexibility, chemical resistance, and low cost make it suitable for various uses across different industries.Expand Specific Solutions03 LDPE blends and composites

Development of LDPE blends and composites to enhance material properties. These formulations may include other polymers, additives, or fillers to improve strength, durability, or specific functional characteristics of the final product.Expand Specific Solutions04 Recycling and sustainability of LDPE products

Techniques and processes for recycling LDPE products to promote sustainability. This includes collection methods, sorting technologies, and reprocessing techniques to convert used LDPE products into new materials or energy sources.Expand Specific Solutions05 LDPE product quality control and testing

Methods and equipment for quality control and testing of LDPE products. This involves assessing physical properties, chemical composition, and performance characteristics to ensure consistency and compliance with industry standards.Expand Specific Solutions

Key Industry Players

The nanotechnology enhancement of LDPE products is in a nascent stage, with significant growth potential in the global plastics market. The industry is transitioning from research to early commercialization, driven by increasing demand for high-performance materials. Key players like Dow Global Technologies, PetroChina, and SABIC are investing heavily in R&D, while universities such as Northwestern and King Fahd University of Petroleum & Minerals contribute to fundamental research. The technology's maturity varies, with some companies like Nanoco Technologies and Mitsui Chemicals leading in nanoparticle integration, while others are still in the experimental phase. The competitive landscape is diverse, including petrochemical giants, specialized nanotechnology firms, and academic institutions, indicating a dynamic and evolving market.

Dow Global Technologies LLC

Technical Solution: Dow has developed a nanocomposite technology for enhancing LDPE products. Their approach involves incorporating nanoscale fillers, such as nanoclay or nanosilica, into the LDPE matrix. This results in improved mechanical properties, barrier performance, and thermal stability[1]. The company has also explored the use of graphene nanoplatelets to enhance the electrical conductivity and mechanical strength of LDPE[3]. Additionally, Dow has developed a proprietary process for creating nanostructured LDPE films with enhanced optical properties and improved tear resistance[5].

Strengths: Improved mechanical properties, enhanced barrier performance, and increased thermal stability. Weaknesses: Potential challenges in achieving uniform dispersion of nanofillers and increased production costs.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a novel approach to enhance LDPE products using nanotechnology. Their method involves the incorporation of nanosilica particles into LDPE through a melt-compounding process[2]. This technique results in improved mechanical properties, such as tensile strength and elongation at break. SABIC has also explored the use of carbon nanotubes (CNTs) to enhance the electrical conductivity of LDPE, making it suitable for antistatic applications[4]. Furthermore, the company has developed a patented process for creating nanocomposite LDPE films with enhanced gas barrier properties, which is particularly useful for packaging applications[6].

Strengths: Enhanced mechanical properties, improved electrical conductivity, and better gas barrier performance. Weaknesses: Potential issues with nanoparticle agglomeration and increased production complexity.

Core Nanotech Innovations

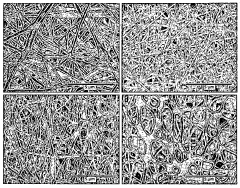

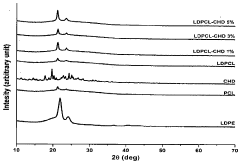

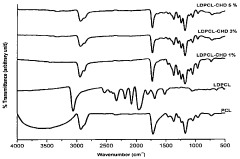

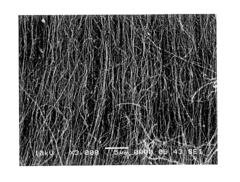

Method of LDPE/PCL nanofibers production and uses thereof

PatentActiveIN202241067511A

Innovation

- Development of LDPE/PCL nanofibers with a 40/60 blending ratio and incorporation of chlorhexidine diacetate (CHD) using a solution electrospinning method, which results in smooth, randomly aligned nanofibers with improved cytocompatibility, hydrophilicity, and controlled drug release, while exhibiting strong antibacterial and antibiofilm properties.

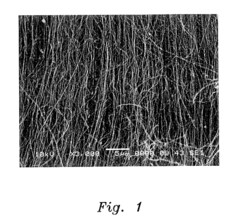

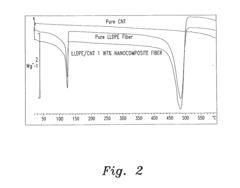

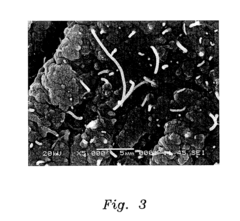

Linear low density polyethylene nanocomposite fibers and method of making the same

PatentInactiveUS20130190442A1

Innovation

- Formation of linear low density polyethylene nanocomposite fibers by embedding carbon nanotubes within a LLDPE matrix, which are then extruded and spun to produce fibers with enhanced tensile strength, elasticity, and ductility, with optimal toughness achieved at 0.3 wt% carbon nanotube concentration.

Environmental Impact

The integration of nanotechnology into LDPE products presents both opportunities and challenges from an environmental perspective. Nanoparticles can significantly enhance the properties of LDPE, potentially leading to more durable and efficient products. This increased longevity could reduce waste and the need for frequent replacements, thereby minimizing the overall environmental footprint of LDPE-based items.

However, the environmental impact of nanoparticles in LDPE products is a complex issue that requires careful consideration. One primary concern is the potential release of nanoparticles into the environment during the product's lifecycle or disposal. These particles, due to their small size, may have unforeseen effects on ecosystems and organisms. Studies have shown that some nanoparticles can accumulate in aquatic environments and potentially enter the food chain, raising questions about long-term ecological consequences.

The production process of nano-enhanced LDPE also warrants attention. While nanotechnology may improve the efficiency of manufacturing, it could potentially increase energy consumption or require additional resources, offsetting some of the environmental benefits. Furthermore, the synthesis of certain nanoparticles may involve the use of toxic chemicals or generate hazardous waste, necessitating stringent control measures to prevent environmental contamination.

On the positive side, nano-enhanced LDPE products could contribute to sustainability efforts through improved recyclability and biodegradability. Some nanoparticles have shown promise in enhancing the breakdown of plastics under specific conditions, potentially addressing the persistent issue of plastic pollution. Additionally, the improved barrier properties of nano-enhanced LDPE could lead to better food preservation and reduced food waste, indirectly benefiting the environment.

The end-of-life management of nano-enhanced LDPE products is a critical aspect to consider. Current recycling systems may not be equipped to handle these advanced materials, potentially leading to improper disposal or contamination of recycling streams. Research into specialized recycling processes for nano-enhanced plastics is ongoing, aiming to maximize material recovery while minimizing environmental risks.

As the field progresses, lifecycle assessments and environmental impact studies specific to nano-enhanced LDPE products are essential. These evaluations will help quantify the net environmental effects, balancing the benefits of improved product performance against potential risks. Regulatory frameworks and industry standards must evolve to address the unique challenges posed by nanomaterials in consumer products, ensuring responsible development and application of this technology in LDPE enhancement.

However, the environmental impact of nanoparticles in LDPE products is a complex issue that requires careful consideration. One primary concern is the potential release of nanoparticles into the environment during the product's lifecycle or disposal. These particles, due to their small size, may have unforeseen effects on ecosystems and organisms. Studies have shown that some nanoparticles can accumulate in aquatic environments and potentially enter the food chain, raising questions about long-term ecological consequences.

The production process of nano-enhanced LDPE also warrants attention. While nanotechnology may improve the efficiency of manufacturing, it could potentially increase energy consumption or require additional resources, offsetting some of the environmental benefits. Furthermore, the synthesis of certain nanoparticles may involve the use of toxic chemicals or generate hazardous waste, necessitating stringent control measures to prevent environmental contamination.

On the positive side, nano-enhanced LDPE products could contribute to sustainability efforts through improved recyclability and biodegradability. Some nanoparticles have shown promise in enhancing the breakdown of plastics under specific conditions, potentially addressing the persistent issue of plastic pollution. Additionally, the improved barrier properties of nano-enhanced LDPE could lead to better food preservation and reduced food waste, indirectly benefiting the environment.

The end-of-life management of nano-enhanced LDPE products is a critical aspect to consider. Current recycling systems may not be equipped to handle these advanced materials, potentially leading to improper disposal or contamination of recycling streams. Research into specialized recycling processes for nano-enhanced plastics is ongoing, aiming to maximize material recovery while minimizing environmental risks.

As the field progresses, lifecycle assessments and environmental impact studies specific to nano-enhanced LDPE products are essential. These evaluations will help quantify the net environmental effects, balancing the benefits of improved product performance against potential risks. Regulatory frameworks and industry standards must evolve to address the unique challenges posed by nanomaterials in consumer products, ensuring responsible development and application of this technology in LDPE enhancement.

Regulatory Considerations

The integration of nanotechnology into LDPE products necessitates careful consideration of regulatory frameworks to ensure compliance, safety, and market acceptance. Various regulatory bodies worldwide have established guidelines and standards for nanomaterials in consumer products, including those used in packaging and plastic applications.

In the United States, the Food and Drug Administration (FDA) oversees the use of nanomaterials in food contact materials, including LDPE products. Manufacturers must demonstrate that their nano-enhanced LDPE products are safe for intended use and comply with existing regulations. The FDA's approach to nanotechnology is based on the product-specific and science-based regulatory assessment, requiring companies to provide detailed information on the nanomaterials used, their properties, and potential migration into food.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to nanomaterials used in LDPE products. Under REACH, manufacturers must register nanomaterials and provide safety data, including potential risks to human health and the environment. Additionally, the EU has specific regulations for food contact materials, requiring thorough risk assessments for nano-enhanced packaging materials.

Environmental regulations also play a crucial role in the development of nano-enhanced LDPE products. Many countries have implemented or are developing regulations to address the potential environmental impacts of nanomaterials. These regulations often focus on waste management, recycling, and the potential release of nanoparticles into the environment during the product lifecycle.

Labeling requirements for products containing nanomaterials vary across jurisdictions. Some regions require explicit labeling of nano-content, while others do not have specific requirements. Manufacturers must stay informed about labeling regulations in their target markets to ensure compliance and transparency.

Occupational health and safety regulations are another critical aspect to consider. Workers involved in the production of nano-enhanced LDPE products may be exposed to nanomaterials, necessitating appropriate safety measures and monitoring protocols. Regulatory bodies such as OSHA in the United States and EU-OSHA in Europe provide guidelines for handling nanomaterials in the workplace.

As nanotechnology continues to evolve, regulatory frameworks are likely to adapt and become more specific. Companies developing nano-enhanced LDPE products must maintain ongoing dialogue with regulatory authorities and stay abreast of emerging guidelines. Proactive engagement in regulatory discussions and participation in industry standards development can help shape future regulations and ensure long-term compliance.

Ultimately, navigating the regulatory landscape for nano-enhanced LDPE products requires a comprehensive understanding of diverse regulatory requirements, ongoing monitoring of regulatory changes, and a commitment to safety and transparency throughout the product development and commercialization process.

In the United States, the Food and Drug Administration (FDA) oversees the use of nanomaterials in food contact materials, including LDPE products. Manufacturers must demonstrate that their nano-enhanced LDPE products are safe for intended use and comply with existing regulations. The FDA's approach to nanotechnology is based on the product-specific and science-based regulatory assessment, requiring companies to provide detailed information on the nanomaterials used, their properties, and potential migration into food.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to nanomaterials used in LDPE products. Under REACH, manufacturers must register nanomaterials and provide safety data, including potential risks to human health and the environment. Additionally, the EU has specific regulations for food contact materials, requiring thorough risk assessments for nano-enhanced packaging materials.

Environmental regulations also play a crucial role in the development of nano-enhanced LDPE products. Many countries have implemented or are developing regulations to address the potential environmental impacts of nanomaterials. These regulations often focus on waste management, recycling, and the potential release of nanoparticles into the environment during the product lifecycle.

Labeling requirements for products containing nanomaterials vary across jurisdictions. Some regions require explicit labeling of nano-content, while others do not have specific requirements. Manufacturers must stay informed about labeling regulations in their target markets to ensure compliance and transparency.

Occupational health and safety regulations are another critical aspect to consider. Workers involved in the production of nano-enhanced LDPE products may be exposed to nanomaterials, necessitating appropriate safety measures and monitoring protocols. Regulatory bodies such as OSHA in the United States and EU-OSHA in Europe provide guidelines for handling nanomaterials in the workplace.

As nanotechnology continues to evolve, regulatory frameworks are likely to adapt and become more specific. Companies developing nano-enhanced LDPE products must maintain ongoing dialogue with regulatory authorities and stay abreast of emerging guidelines. Proactive engagement in regulatory discussions and participation in industry standards development can help shape future regulations and ensure long-term compliance.

Ultimately, navigating the regulatory landscape for nano-enhanced LDPE products requires a comprehensive understanding of diverse regulatory requirements, ongoing monitoring of regulatory changes, and a commitment to safety and transparency throughout the product development and commercialization process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!