How to Mitigate Signal Drift in Piezoelectric Devices

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Drift Background and Objectives

Piezoelectric devices have been integral to numerous technological applications since their discovery in the late 19th century. These devices, which convert mechanical stress into electrical charge and vice versa, have found widespread use in sensors, actuators, and energy harvesting systems. However, a persistent challenge in their implementation has been the phenomenon of signal drift, which can significantly impact the accuracy and reliability of piezoelectric-based measurements over time.

The evolution of piezoelectric technology has been marked by continuous efforts to enhance performance and mitigate inherent limitations. From the early use of natural crystals like quartz to the development of synthetic materials such as lead zirconate titanate (PZT), researchers have sought to improve the stability and efficiency of piezoelectric devices. Despite these advancements, signal drift remains a critical issue that demands innovative solutions.

Signal drift in piezoelectric devices manifests as a gradual change in the output signal over time, even when the input remains constant. This drift can be attributed to various factors, including temperature fluctuations, mechanical stress, and material aging. The consequences of unaddressed drift are far-reaching, potentially leading to inaccurate measurements, false alarms in sensing applications, and reduced efficiency in energy harvesting systems.

The primary objective in addressing piezoelectric drift is to develop robust mitigation strategies that can ensure long-term stability and reliability of these devices across diverse operating conditions. This goal encompasses several key areas of focus, including material science innovations, advanced signal processing techniques, and novel device architectures.

Researchers aim to create piezoelectric materials with inherently lower drift characteristics, explore compensation algorithms that can dynamically adjust for drift in real-time, and design self-calibrating systems that maintain accuracy over extended periods. Additionally, there is a growing interest in leveraging emerging technologies such as machine learning and artificial intelligence to predict and correct drift patterns.

Understanding the underlying mechanisms of piezoelectric drift is crucial for developing effective mitigation strategies. This involves comprehensive studies of material properties at the molecular level, analysis of environmental factors influencing drift, and the development of sophisticated modeling techniques to predict drift behavior under various conditions.

As we delve deeper into the background and objectives of piezoelectric drift mitigation, it becomes clear that this challenge presents both significant obstacles and exciting opportunities for innovation. The quest for stable, drift-resistant piezoelectric devices not only promises to enhance existing applications but also opens doors to new possibilities in fields ranging from medical diagnostics to aerospace engineering.

The evolution of piezoelectric technology has been marked by continuous efforts to enhance performance and mitigate inherent limitations. From the early use of natural crystals like quartz to the development of synthetic materials such as lead zirconate titanate (PZT), researchers have sought to improve the stability and efficiency of piezoelectric devices. Despite these advancements, signal drift remains a critical issue that demands innovative solutions.

Signal drift in piezoelectric devices manifests as a gradual change in the output signal over time, even when the input remains constant. This drift can be attributed to various factors, including temperature fluctuations, mechanical stress, and material aging. The consequences of unaddressed drift are far-reaching, potentially leading to inaccurate measurements, false alarms in sensing applications, and reduced efficiency in energy harvesting systems.

The primary objective in addressing piezoelectric drift is to develop robust mitigation strategies that can ensure long-term stability and reliability of these devices across diverse operating conditions. This goal encompasses several key areas of focus, including material science innovations, advanced signal processing techniques, and novel device architectures.

Researchers aim to create piezoelectric materials with inherently lower drift characteristics, explore compensation algorithms that can dynamically adjust for drift in real-time, and design self-calibrating systems that maintain accuracy over extended periods. Additionally, there is a growing interest in leveraging emerging technologies such as machine learning and artificial intelligence to predict and correct drift patterns.

Understanding the underlying mechanisms of piezoelectric drift is crucial for developing effective mitigation strategies. This involves comprehensive studies of material properties at the molecular level, analysis of environmental factors influencing drift, and the development of sophisticated modeling techniques to predict drift behavior under various conditions.

As we delve deeper into the background and objectives of piezoelectric drift mitigation, it becomes clear that this challenge presents both significant obstacles and exciting opportunities for innovation. The quest for stable, drift-resistant piezoelectric devices not only promises to enhance existing applications but also opens doors to new possibilities in fields ranging from medical diagnostics to aerospace engineering.

Market Demand Analysis for Stable Piezoelectric Devices

The market demand for stable piezoelectric devices has been steadily increasing across various industries due to their unique properties and versatile applications. These devices, which convert mechanical stress into electrical signals and vice versa, are crucial components in numerous high-precision systems and sensors. However, the issue of signal drift has been a persistent challenge, limiting their widespread adoption and long-term reliability.

In the automotive sector, piezoelectric sensors are extensively used in engine management systems, tire pressure monitoring, and advanced driver assistance systems (ADAS). The growing trend towards electric and autonomous vehicles has further amplified the need for stable piezoelectric devices, as these vehicles rely heavily on precise sensor data for optimal performance and safety.

The aerospace industry represents another significant market for stable piezoelectric devices. Aircraft manufacturers and defense contractors require highly reliable sensors for structural health monitoring, vibration control, and fuel management systems. The ability to mitigate signal drift in these applications is critical for ensuring flight safety and operational efficiency.

In the medical field, piezoelectric devices play a vital role in ultrasound imaging, surgical tools, and implantable medical devices. The demand for more accurate and stable diagnostic and therapeutic equipment is driving the need for improved piezoelectric technologies that can maintain signal integrity over extended periods.

The industrial sector, particularly in manufacturing and process control, has shown a growing interest in stable piezoelectric devices for applications such as precision machining, quality control, and predictive maintenance. The ability to accurately measure and monitor vibrations, pressures, and forces over time is essential for optimizing production processes and reducing downtime.

Consumer electronics represent a rapidly expanding market for piezoelectric devices, with applications in smartphones, wearables, and smart home devices. As these products become more sophisticated and feature-rich, the demand for stable, long-lasting sensors increases. Manufacturers are seeking solutions to signal drift to enhance user experience and product longevity.

The energy sector, particularly in oil and gas exploration and renewable energy systems, relies on piezoelectric sensors for seismic monitoring, structural health assessment of wind turbines, and wave energy harvesting. Stable, drift-free sensors are crucial for accurate data collection and efficient energy production.

As the Internet of Things (IoT) and smart city initiatives continue to grow, the demand for reliable, low-power sensors is expected to surge. Piezoelectric devices that can maintain stable signals over long periods are ideal for these applications, where frequent maintenance or replacement is impractical.

The market for stable piezoelectric devices is further driven by stringent regulatory requirements in industries such as automotive, aerospace, and healthcare. Compliance with safety standards and performance specifications necessitates the development of more reliable and accurate sensing technologies.

In the automotive sector, piezoelectric sensors are extensively used in engine management systems, tire pressure monitoring, and advanced driver assistance systems (ADAS). The growing trend towards electric and autonomous vehicles has further amplified the need for stable piezoelectric devices, as these vehicles rely heavily on precise sensor data for optimal performance and safety.

The aerospace industry represents another significant market for stable piezoelectric devices. Aircraft manufacturers and defense contractors require highly reliable sensors for structural health monitoring, vibration control, and fuel management systems. The ability to mitigate signal drift in these applications is critical for ensuring flight safety and operational efficiency.

In the medical field, piezoelectric devices play a vital role in ultrasound imaging, surgical tools, and implantable medical devices. The demand for more accurate and stable diagnostic and therapeutic equipment is driving the need for improved piezoelectric technologies that can maintain signal integrity over extended periods.

The industrial sector, particularly in manufacturing and process control, has shown a growing interest in stable piezoelectric devices for applications such as precision machining, quality control, and predictive maintenance. The ability to accurately measure and monitor vibrations, pressures, and forces over time is essential for optimizing production processes and reducing downtime.

Consumer electronics represent a rapidly expanding market for piezoelectric devices, with applications in smartphones, wearables, and smart home devices. As these products become more sophisticated and feature-rich, the demand for stable, long-lasting sensors increases. Manufacturers are seeking solutions to signal drift to enhance user experience and product longevity.

The energy sector, particularly in oil and gas exploration and renewable energy systems, relies on piezoelectric sensors for seismic monitoring, structural health assessment of wind turbines, and wave energy harvesting. Stable, drift-free sensors are crucial for accurate data collection and efficient energy production.

As the Internet of Things (IoT) and smart city initiatives continue to grow, the demand for reliable, low-power sensors is expected to surge. Piezoelectric devices that can maintain stable signals over long periods are ideal for these applications, where frequent maintenance or replacement is impractical.

The market for stable piezoelectric devices is further driven by stringent regulatory requirements in industries such as automotive, aerospace, and healthcare. Compliance with safety standards and performance specifications necessitates the development of more reliable and accurate sensing technologies.

Signal Drift Challenges in Piezoelectric Technology

Signal drift in piezoelectric devices presents a significant challenge in maintaining the accuracy and reliability of measurements over time. This phenomenon, characterized by the gradual change in the output signal of a piezoelectric sensor or actuator without a corresponding change in the input, can lead to erroneous readings and compromised system performance. The causes of signal drift are multifaceted, stemming from both intrinsic and extrinsic factors.

Intrinsic factors contributing to signal drift include the inherent properties of piezoelectric materials, such as aging effects and crystal structure changes over time. These materials may experience slow relaxation processes or gradual depolarization, leading to a reduction in their piezoelectric response. Additionally, microscopic defects within the crystal lattice can migrate or evolve, altering the material's electromechanical properties.

Extrinsic factors play a significant role in signal drift as well. Environmental conditions, particularly temperature fluctuations and humidity changes, can dramatically affect the performance of piezoelectric devices. Thermal expansion and contraction of components can induce mechanical stresses, while moisture ingress may alter the electrical properties of the device. Moreover, mechanical fatigue from repeated stress cycles can lead to gradual degradation of the piezoelectric element.

The impact of signal drift varies across applications but is particularly critical in high-precision measurement systems, such as accelerometers, pressure sensors, and ultrasonic transducers. In these contexts, even small deviations can lead to significant errors in data interpretation and system control. For instance, in structural health monitoring, undetected signal drift could mask early signs of material fatigue or damage.

Addressing signal drift requires a multifaceted approach. Compensation techniques, such as real-time calibration and adaptive filtering algorithms, can help mitigate the effects of drift in software. Hardware solutions may involve improved packaging and isolation to minimize environmental influences, or the use of more stable piezoelectric materials. Some advanced approaches include the development of self-calibrating sensors and the implementation of redundant sensing elements for cross-validation.

Research in this area continues to evolve, with emerging strategies focusing on nanoscale engineering of piezoelectric materials to enhance their long-term stability. Additionally, machine learning algorithms are being explored to predict and correct for drift based on historical data and environmental parameters. The challenge of signal drift remains a key focus in the ongoing development and refinement of piezoelectric technology, driving innovation in both materials science and signal processing domains.

Intrinsic factors contributing to signal drift include the inherent properties of piezoelectric materials, such as aging effects and crystal structure changes over time. These materials may experience slow relaxation processes or gradual depolarization, leading to a reduction in their piezoelectric response. Additionally, microscopic defects within the crystal lattice can migrate or evolve, altering the material's electromechanical properties.

Extrinsic factors play a significant role in signal drift as well. Environmental conditions, particularly temperature fluctuations and humidity changes, can dramatically affect the performance of piezoelectric devices. Thermal expansion and contraction of components can induce mechanical stresses, while moisture ingress may alter the electrical properties of the device. Moreover, mechanical fatigue from repeated stress cycles can lead to gradual degradation of the piezoelectric element.

The impact of signal drift varies across applications but is particularly critical in high-precision measurement systems, such as accelerometers, pressure sensors, and ultrasonic transducers. In these contexts, even small deviations can lead to significant errors in data interpretation and system control. For instance, in structural health monitoring, undetected signal drift could mask early signs of material fatigue or damage.

Addressing signal drift requires a multifaceted approach. Compensation techniques, such as real-time calibration and adaptive filtering algorithms, can help mitigate the effects of drift in software. Hardware solutions may involve improved packaging and isolation to minimize environmental influences, or the use of more stable piezoelectric materials. Some advanced approaches include the development of self-calibrating sensors and the implementation of redundant sensing elements for cross-validation.

Research in this area continues to evolve, with emerging strategies focusing on nanoscale engineering of piezoelectric materials to enhance their long-term stability. Additionally, machine learning algorithms are being explored to predict and correct for drift based on historical data and environmental parameters. The challenge of signal drift remains a key focus in the ongoing development and refinement of piezoelectric technology, driving innovation in both materials science and signal processing domains.

Current Drift Compensation Methods

01 Temperature compensation techniques

Various temperature compensation techniques are employed to mitigate signal drift in piezoelectric devices. These methods involve using temperature sensors, implementing temperature-dependent correction algorithms, or designing temperature-insensitive structures. By compensating for temperature variations, the stability and accuracy of piezoelectric device outputs can be significantly improved.- Temperature compensation techniques: Various temperature compensation techniques are employed to mitigate signal drift in piezoelectric devices. These methods involve using temperature sensors, implementing temperature-dependent correction algorithms, or designing temperature-insensitive circuits. By accounting for temperature variations, these techniques help maintain signal stability and accuracy across different operating conditions.

- Signal processing and filtering: Advanced signal processing and filtering techniques are utilized to reduce signal drift in piezoelectric devices. These methods may include digital filtering, adaptive algorithms, or frequency domain analysis to separate the desired signal from drift components. By implementing these techniques, the overall signal quality and stability can be improved, leading to more reliable measurements.

- Mechanical design optimization: Optimizing the mechanical design of piezoelectric devices can help minimize signal drift. This may involve using specific materials, improving mounting techniques, or implementing stress-relief structures. By addressing mechanical factors that contribute to drift, such as creep or hysteresis, the long-term stability of the device can be enhanced.

- Feedback and self-calibration systems: Implementing feedback loops and self-calibration systems in piezoelectric devices can help compensate for signal drift over time. These systems may periodically measure and correct for drift, ensuring that the device maintains its accuracy and reliability. By continuously adjusting for changes in the device's characteristics, long-term stability can be improved.

- Novel materials and fabrication techniques: Research into new piezoelectric materials and advanced fabrication techniques aims to reduce inherent signal drift. This includes developing materials with improved stability, exploring nanostructured piezoelectric elements, or utilizing novel deposition methods. By addressing the fundamental causes of drift at the material level, more stable and reliable piezoelectric devices can be created.

02 Signal processing and filtering

Advanced signal processing and filtering techniques are utilized to reduce signal drift in piezoelectric devices. These methods may include digital filtering, adaptive algorithms, or frequency domain analysis to separate the desired signal from drift components. By implementing sophisticated signal processing, the long-term stability and reliability of piezoelectric sensors can be enhanced.Expand Specific Solutions03 Structural design optimization

Optimizing the structural design of piezoelectric devices can help minimize signal drift. This may involve using specific materials, geometries, or mounting techniques that reduce the impact of environmental factors on the device's performance. By carefully considering the physical design, the inherent stability of piezoelectric sensors can be improved.Expand Specific Solutions04 Calibration and self-calibration methods

Regular calibration and self-calibration techniques are employed to address signal drift in piezoelectric devices. These methods may involve periodic recalibration using reference signals or implementing automatic self-calibration routines within the device. By maintaining accurate calibration, the long-term performance and reliability of piezoelectric sensors can be ensured.Expand Specific Solutions05 Feedback and compensation circuits

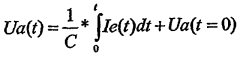

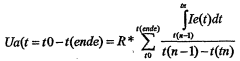

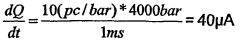

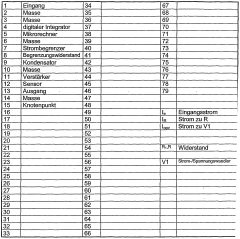

Specialized feedback and compensation circuits are designed to counteract signal drift in piezoelectric devices. These circuits may include charge amplifiers, integrators, or other electronic components that actively compensate for drift effects. By implementing appropriate feedback mechanisms, the stability and accuracy of piezoelectric sensor outputs can be maintained over extended periods.Expand Specific Solutions

Key Players in Piezoelectric Device Industry

The market for mitigating signal drift in piezoelectric devices is in a growth phase, driven by increasing demand for high-precision sensors across various industries. The global piezoelectric devices market is projected to reach significant size, with a compound annual growth rate exceeding 4% in the coming years. Technologically, the field is advancing rapidly, with companies like Murata Manufacturing, Kyocera, and TDK Electronics leading innovation. These firms are developing advanced materials and signal processing techniques to enhance stability and reduce drift. Other key players, including Honeywell International and Renesas Electronics, are focusing on integrated solutions that combine hardware and software approaches to mitigate signal drift, indicating a trend towards more comprehensive, system-level solutions in this competitive landscape.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced signal processing techniques to mitigate signal drift in piezoelectric devices. Their approach involves implementing temperature compensation algorithms and utilizing high-precision analog-to-digital converters (ADCs) to minimize thermal effects on sensor output[1]. Additionally, Murata employs proprietary crystal designs and packaging methods to enhance long-term stability. They have also introduced active feedback loops that continuously monitor and adjust for drift, ensuring consistent performance over time[3]. Murata's solutions often incorporate multi-sensor fusion, combining data from piezoelectric sensors with other sensor types to cross-validate measurements and correct for drift-induced errors[5].

Strengths: Comprehensive approach addressing multiple drift sources; industry-leading expertise in piezoelectric materials. Weaknesses: Solutions may be more complex and costly compared to simpler alternatives; potential dependency on proprietary technologies.

Meggitt SA

Technical Solution: Meggitt has developed a multi-faceted approach to mitigate signal drift in piezoelectric devices, particularly for aerospace and industrial applications. Their strategy includes the use of charge amplifiers with ultra-low leakage characteristics to minimize charge loss over time[2]. Meggitt also employs advanced digital signal processing (DSP) techniques, including adaptive filtering and real-time drift compensation algorithms. A key innovation is their implementation of self-calibrating sensors that periodically perform in-situ recalibration to maintain accuracy[4]. Additionally, Meggitt has developed specialized packaging and shielding techniques to protect piezoelectric elements from environmental factors that contribute to drift, such as temperature fluctuations and electromagnetic interference[6].

Strengths: Robust solutions suitable for harsh environments; expertise in high-reliability applications. Weaknesses: Solutions may be overengineered for simpler use cases; potentially higher cost due to focus on high-end markets.

Innovative Approaches to Signal Stability

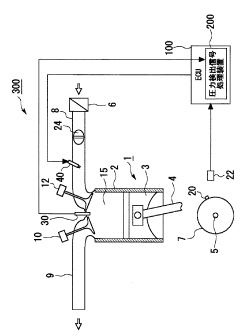

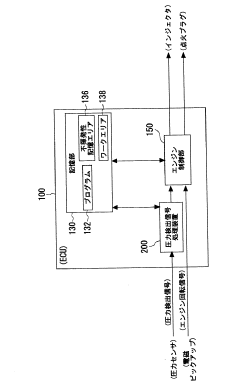

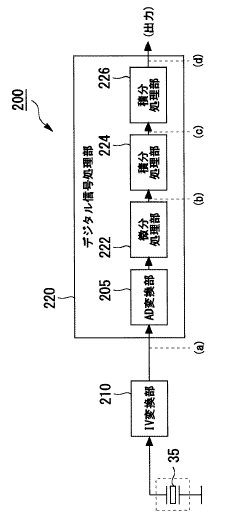

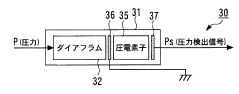

Pressure detection signal processing device, engine control system and program

PatentInactiveJP2020084804A

Innovation

- A pressure detection signal processing device that includes an IV converter to convert current signals into voltage signals, followed by digital signal processing units for differential and integration processing to remove drift caused by leakage currents in piezoelectric elements.

Method and device for measuring physical variables using piezoelectric sensors and a digital integrator

PatentWO2006024384A1

Innovation

- A method using a digital integrator with a microcomputer or programmable logic module to process voltage from the amplifier, replacing capacitors with resistors to reduce impedance and eliminate drift, allowing connection of lower-impedance sensors without reset, and enabling uniform output signals across various sensors with electronic sensitivity correction.

Environmental Factors Affecting Piezoelectric Drift

Piezoelectric devices are highly susceptible to environmental factors that can significantly impact their signal stability and performance. Temperature fluctuations are one of the primary contributors to signal drift in these devices. As the ambient temperature changes, it can cause thermal expansion or contraction of the piezoelectric material, altering its mechanical properties and electrical response. This thermal sensitivity can lead to variations in the device's output signal, even when the input remains constant.

Humidity is another critical environmental factor affecting piezoelectric drift. Moisture absorption by the piezoelectric material or its surrounding components can modify their electrical and mechanical characteristics. This can result in changes to the device's capacitance and overall performance, leading to signal drift over time. In extreme cases, prolonged exposure to high humidity may even cause degradation of the piezoelectric material itself.

Mechanical stress and vibration from the surrounding environment can also contribute to signal drift in piezoelectric devices. External forces applied to the device, whether through handling, mounting, or ambient vibrations, can induce unintended deformations in the piezoelectric material. These deformations may cause temporary or permanent changes in the device's response characteristics, leading to inconsistent signal output.

Atmospheric pressure variations, particularly in applications involving altitude changes or pressurized environments, can impact the performance of piezoelectric devices. Changes in pressure can affect the mechanical stress on the piezoelectric material, potentially altering its electrical response and contributing to signal drift.

Electromagnetic interference (EMI) from nearby electronic equipment or power sources can introduce noise and distortions in the piezoelectric device's signal. This interference can manifest as drift in the output signal, particularly in sensitive applications where small variations can be significant.

Chemical exposure is another environmental factor that can lead to signal drift in piezoelectric devices. Certain gases, liquids, or particulates in the atmosphere may react with the piezoelectric material or its electrodes, causing gradual changes in their properties. This chemical interaction can result in long-term drift and degradation of the device's performance.

Radiation exposure, while less common in most applications, can be a significant factor in certain environments such as space or nuclear facilities. Ionizing radiation can cause structural changes in the piezoelectric material at the atomic level, potentially altering its piezoelectric properties and leading to signal drift over time.

Humidity is another critical environmental factor affecting piezoelectric drift. Moisture absorption by the piezoelectric material or its surrounding components can modify their electrical and mechanical characteristics. This can result in changes to the device's capacitance and overall performance, leading to signal drift over time. In extreme cases, prolonged exposure to high humidity may even cause degradation of the piezoelectric material itself.

Mechanical stress and vibration from the surrounding environment can also contribute to signal drift in piezoelectric devices. External forces applied to the device, whether through handling, mounting, or ambient vibrations, can induce unintended deformations in the piezoelectric material. These deformations may cause temporary or permanent changes in the device's response characteristics, leading to inconsistent signal output.

Atmospheric pressure variations, particularly in applications involving altitude changes or pressurized environments, can impact the performance of piezoelectric devices. Changes in pressure can affect the mechanical stress on the piezoelectric material, potentially altering its electrical response and contributing to signal drift.

Electromagnetic interference (EMI) from nearby electronic equipment or power sources can introduce noise and distortions in the piezoelectric device's signal. This interference can manifest as drift in the output signal, particularly in sensitive applications where small variations can be significant.

Chemical exposure is another environmental factor that can lead to signal drift in piezoelectric devices. Certain gases, liquids, or particulates in the atmosphere may react with the piezoelectric material or its electrodes, causing gradual changes in their properties. This chemical interaction can result in long-term drift and degradation of the device's performance.

Radiation exposure, while less common in most applications, can be a significant factor in certain environments such as space or nuclear facilities. Ionizing radiation can cause structural changes in the piezoelectric material at the atomic level, potentially altering its piezoelectric properties and leading to signal drift over time.

Standardization of Drift Measurement Protocols

Standardization of drift measurement protocols is crucial for addressing signal drift in piezoelectric devices. The development of uniform procedures ensures consistency and comparability across different research and industrial applications. These protocols typically encompass several key elements, including environmental control, calibration methods, and data analysis techniques.

Environmental control is a fundamental aspect of standardized drift measurement. Protocols often specify precise temperature and humidity ranges, as these factors significantly influence piezoelectric performance. Vibration isolation and electromagnetic shielding requirements are also commonly included to minimize external interference. By maintaining consistent environmental conditions, researchers can isolate drift phenomena more effectively.

Calibration methods form another critical component of standardized protocols. These may involve the use of reference materials or devices with known characteristics to establish baseline measurements. Protocols often detail the frequency and duration of calibration procedures, as well as acceptable tolerance levels. Some standards may require periodic recalibration to account for long-term changes in device behavior.

Data acquisition and analysis techniques are carefully defined in standardized protocols. This includes specifications for sampling rates, signal filtering, and noise reduction methods. Statistical analysis procedures are often prescribed to ensure reliable interpretation of drift data. Many protocols incorporate guidelines for uncertainty estimation and error analysis to enhance the robustness of measurements.

Temporal considerations play a significant role in drift measurement standards. Protocols typically define the duration of measurement periods, ranging from short-term stability tests to extended long-term drift evaluations. They may also specify warm-up times and settling periods to account for initial instabilities in piezoelectric devices.

Reporting requirements are an integral part of standardized protocols. These often include guidelines for data presentation, such as specific graph formats or statistical metrics. Protocols may mandate the inclusion of certain metadata, such as device specifications, environmental conditions, and calibration history, to ensure comprehensive documentation of drift measurements.

Interlaboratory comparison is sometimes incorporated into standardized protocols to validate measurement consistency across different facilities. This process involves multiple laboratories performing identical measurements on similar devices, following the same protocol. The results are then compared to assess the reproducibility and reliability of the standardized methods.

As piezoelectric technology evolves, standardization efforts must adapt to new challenges and innovations. Regular review and updating of protocols ensure their continued relevance and effectiveness in mitigating signal drift across a wide range of applications and device types.

Environmental control is a fundamental aspect of standardized drift measurement. Protocols often specify precise temperature and humidity ranges, as these factors significantly influence piezoelectric performance. Vibration isolation and electromagnetic shielding requirements are also commonly included to minimize external interference. By maintaining consistent environmental conditions, researchers can isolate drift phenomena more effectively.

Calibration methods form another critical component of standardized protocols. These may involve the use of reference materials or devices with known characteristics to establish baseline measurements. Protocols often detail the frequency and duration of calibration procedures, as well as acceptable tolerance levels. Some standards may require periodic recalibration to account for long-term changes in device behavior.

Data acquisition and analysis techniques are carefully defined in standardized protocols. This includes specifications for sampling rates, signal filtering, and noise reduction methods. Statistical analysis procedures are often prescribed to ensure reliable interpretation of drift data. Many protocols incorporate guidelines for uncertainty estimation and error analysis to enhance the robustness of measurements.

Temporal considerations play a significant role in drift measurement standards. Protocols typically define the duration of measurement periods, ranging from short-term stability tests to extended long-term drift evaluations. They may also specify warm-up times and settling periods to account for initial instabilities in piezoelectric devices.

Reporting requirements are an integral part of standardized protocols. These often include guidelines for data presentation, such as specific graph formats or statistical metrics. Protocols may mandate the inclusion of certain metadata, such as device specifications, environmental conditions, and calibration history, to ensure comprehensive documentation of drift measurements.

Interlaboratory comparison is sometimes incorporated into standardized protocols to validate measurement consistency across different facilities. This process involves multiple laboratories performing identical measurements on similar devices, following the same protocol. The results are then compared to assess the reproducibility and reliability of the standardized methods.

As piezoelectric technology evolves, standardization efforts must adapt to new challenges and innovations. Regular review and updating of protocols ensure their continued relevance and effectiveness in mitigating signal drift across a wide range of applications and device types.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!