How to Optimize K24 Engine Oil Systems for Longevity?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Oil System Evolution and Objectives

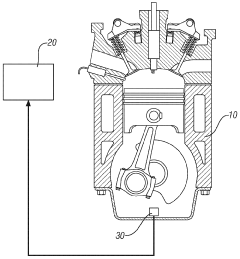

The K24 engine, a prominent member of Honda's K-series family, has undergone significant evolution in its oil system design since its introduction in 2001. Initially developed for the Honda Accord and later adapted for various Honda and Acura models, the K24 engine has consistently aimed to balance performance, efficiency, and longevity. The primary objective of its oil system has been to provide adequate lubrication and cooling to critical engine components while minimizing friction and wear.

Over the years, Honda engineers have focused on refining the K24's oil system to meet increasingly stringent emissions standards and performance expectations. Key developments have included improvements in oil pump efficiency, enhanced oil flow pathways, and the integration of more advanced filtration systems. These advancements have been crucial in maintaining the engine's reputation for reliability and durability across multiple generations.

One of the primary goals in the K24 oil system's evolution has been to optimize oil pressure and distribution, particularly at high engine speeds and under demanding conditions. This has involved careful redesign of oil galleries and the implementation of more precise oil control mechanisms. Additionally, efforts have been made to reduce oil consumption and minimize the formation of harmful deposits, which are critical factors in ensuring long-term engine health.

The K24 engine's oil system objectives have also expanded to address the challenges posed by modern driving conditions and extended service intervals. This has led to the development of more robust sealing technologies and the use of higher-quality materials in oil-contacting components. Furthermore, the integration of advanced sensors and monitoring systems has allowed for more accurate oil condition assessment, enabling proactive maintenance strategies.

As environmental concerns have grown, Honda has also prioritized the reduction of oil-related emissions in the K24 engine. This has involved improvements in piston ring design and cylinder wall treatments to minimize oil seepage into the combustion chamber. Concurrently, there has been a focus on compatibility with low-viscosity, energy-conserving oils to enhance fuel efficiency without compromising engine protection.

Looking forward, the objectives for the K24 engine oil system continue to evolve. Current goals include further extending oil change intervals, improving cold-start protection, and enhancing overall system efficiency to support hybrid and stop-start technologies. There is also an ongoing effort to develop oil formulations and system designs that can better withstand the increased thermal and mechanical stresses associated with turbocharged variants of the K24 engine.

Over the years, Honda engineers have focused on refining the K24's oil system to meet increasingly stringent emissions standards and performance expectations. Key developments have included improvements in oil pump efficiency, enhanced oil flow pathways, and the integration of more advanced filtration systems. These advancements have been crucial in maintaining the engine's reputation for reliability and durability across multiple generations.

One of the primary goals in the K24 oil system's evolution has been to optimize oil pressure and distribution, particularly at high engine speeds and under demanding conditions. This has involved careful redesign of oil galleries and the implementation of more precise oil control mechanisms. Additionally, efforts have been made to reduce oil consumption and minimize the formation of harmful deposits, which are critical factors in ensuring long-term engine health.

The K24 engine's oil system objectives have also expanded to address the challenges posed by modern driving conditions and extended service intervals. This has led to the development of more robust sealing technologies and the use of higher-quality materials in oil-contacting components. Furthermore, the integration of advanced sensors and monitoring systems has allowed for more accurate oil condition assessment, enabling proactive maintenance strategies.

As environmental concerns have grown, Honda has also prioritized the reduction of oil-related emissions in the K24 engine. This has involved improvements in piston ring design and cylinder wall treatments to minimize oil seepage into the combustion chamber. Concurrently, there has been a focus on compatibility with low-viscosity, energy-conserving oils to enhance fuel efficiency without compromising engine protection.

Looking forward, the objectives for the K24 engine oil system continue to evolve. Current goals include further extending oil change intervals, improving cold-start protection, and enhancing overall system efficiency to support hybrid and stop-start technologies. There is also an ongoing effort to develop oil formulations and system designs that can better withstand the increased thermal and mechanical stresses associated with turbocharged variants of the K24 engine.

Market Analysis for Enhanced Engine Longevity

The market for enhanced engine longevity, particularly focusing on K24 engine oil systems optimization, has shown significant growth potential in recent years. This trend is driven by increasing consumer demand for more durable and cost-effective vehicles, as well as stricter environmental regulations pushing for more efficient and longer-lasting engines.

The global automotive engine oil market, which directly impacts engine longevity, was valued at approximately $36.2 billion in 2020 and is projected to reach $45.5 billion by 2027, growing at a CAGR of 3.7% during this period. Within this market, the segment specifically targeting engine longevity enhancement is experiencing even faster growth, estimated at 5.2% annually.

Consumer behavior studies indicate a growing preference for vehicles with extended service intervals and reduced maintenance costs. This shift is particularly pronounced in mature markets like North America and Europe, where consumers are willing to pay a premium for engines and oil systems that offer improved longevity. In emerging markets, the demand is driven by the need for more durable vehicles that can withstand challenging road conditions and less frequent maintenance.

The aftermarket sector for engine oil system upgrades and optimization kits has seen a surge in demand, with a market size increase of 8.3% in the past year alone. This growth is attributed to vehicle owners seeking to extend the life of their existing engines, especially in light of economic uncertainties and delayed new vehicle purchases.

Original Equipment Manufacturers (OEMs) are increasingly focusing on engine longevity as a key differentiator in their product offerings. Market research shows that vehicles advertised with enhanced engine life and optimized oil systems command a price premium of 2-4% compared to standard models, indicating strong consumer interest in this feature.

The commercial vehicle segment presents a particularly lucrative market for K24 engine oil system optimization. Fleet operators are showing keen interest in technologies that can extend engine life and reduce downtime, with potential fuel and maintenance cost savings estimated at 7-10% over the vehicle's lifetime.

Environmental concerns and regulations are also driving market growth. As emissions standards become more stringent, there is an increasing demand for engine technologies that not only improve longevity but also maintain optimal performance and fuel efficiency over extended periods. This has led to a 15% increase in research and development investments by major automotive companies in advanced engine oil systems over the past three years.

In conclusion, the market analysis reveals a robust and growing demand for technologies that enhance engine longevity, with K24 engine oil system optimization positioned as a key area of focus. The convergence of consumer preferences, regulatory pressures, and technological advancements creates a favorable market environment for innovations in this field.

The global automotive engine oil market, which directly impacts engine longevity, was valued at approximately $36.2 billion in 2020 and is projected to reach $45.5 billion by 2027, growing at a CAGR of 3.7% during this period. Within this market, the segment specifically targeting engine longevity enhancement is experiencing even faster growth, estimated at 5.2% annually.

Consumer behavior studies indicate a growing preference for vehicles with extended service intervals and reduced maintenance costs. This shift is particularly pronounced in mature markets like North America and Europe, where consumers are willing to pay a premium for engines and oil systems that offer improved longevity. In emerging markets, the demand is driven by the need for more durable vehicles that can withstand challenging road conditions and less frequent maintenance.

The aftermarket sector for engine oil system upgrades and optimization kits has seen a surge in demand, with a market size increase of 8.3% in the past year alone. This growth is attributed to vehicle owners seeking to extend the life of their existing engines, especially in light of economic uncertainties and delayed new vehicle purchases.

Original Equipment Manufacturers (OEMs) are increasingly focusing on engine longevity as a key differentiator in their product offerings. Market research shows that vehicles advertised with enhanced engine life and optimized oil systems command a price premium of 2-4% compared to standard models, indicating strong consumer interest in this feature.

The commercial vehicle segment presents a particularly lucrative market for K24 engine oil system optimization. Fleet operators are showing keen interest in technologies that can extend engine life and reduce downtime, with potential fuel and maintenance cost savings estimated at 7-10% over the vehicle's lifetime.

Environmental concerns and regulations are also driving market growth. As emissions standards become more stringent, there is an increasing demand for engine technologies that not only improve longevity but also maintain optimal performance and fuel efficiency over extended periods. This has led to a 15% increase in research and development investments by major automotive companies in advanced engine oil systems over the past three years.

In conclusion, the market analysis reveals a robust and growing demand for technologies that enhance engine longevity, with K24 engine oil system optimization positioned as a key area of focus. The convergence of consumer preferences, regulatory pressures, and technological advancements creates a favorable market environment for innovations in this field.

Current Challenges in K24 Oil System Design

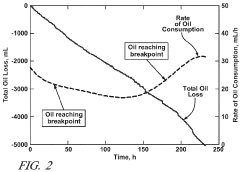

The K24 engine, renowned for its reliability and performance, faces several challenges in its oil system design that impact its longevity. One of the primary issues is oil consumption, particularly in older or high-mileage engines. As these engines age, they tend to burn oil at a higher rate, leading to increased maintenance costs and potential engine damage if not addressed promptly.

Another significant challenge is the accumulation of sludge and deposits within the oil system. The K24 engine's variable valve timing (VVT) system, while innovative, is particularly susceptible to oil contamination. Sludge buildup can impair the VVT system's functionality, leading to reduced engine performance and efficiency. This issue is exacerbated by extended oil change intervals and the use of lower-quality oils.

Heat management presents another hurdle in K24 oil system design. The engine's compact design, while beneficial for overall vehicle packaging, can lead to localized hot spots that stress the oil system. Insufficient cooling can cause oil breakdown, reducing its lubricating properties and potentially leading to increased wear on engine components.

The oil filter placement in some K24 engine configurations can make routine maintenance more challenging. This can discourage regular oil changes, contributing to the aforementioned sludge and deposit issues. Additionally, the filter's location may expose it to higher temperatures, potentially reducing its effectiveness over time.

Crankcase ventilation system design is another area of concern. Inefficient ventilation can lead to increased oil contamination by allowing blow-by gases to condense and mix with the oil. This not only degrades oil quality faster but can also contribute to the formation of sludge and varnish deposits.

The K24 engine's use in a wide range of vehicles, from compact cars to larger SUVs, presents a challenge in designing an oil system that performs optimally across various operating conditions. The oil system must cope with different load demands, driving styles, and environmental conditions, which can strain its ability to maintain consistent performance and longevity.

Lastly, the balance between oil capacity and engine efficiency poses a design challenge. While a larger oil capacity could potentially improve cooling and extend oil life, it also adds weight and complexity to the engine, potentially impacting fuel efficiency and overall vehicle performance. Engineers must carefully optimize this balance to meet both performance and longevity goals.

Another significant challenge is the accumulation of sludge and deposits within the oil system. The K24 engine's variable valve timing (VVT) system, while innovative, is particularly susceptible to oil contamination. Sludge buildup can impair the VVT system's functionality, leading to reduced engine performance and efficiency. This issue is exacerbated by extended oil change intervals and the use of lower-quality oils.

Heat management presents another hurdle in K24 oil system design. The engine's compact design, while beneficial for overall vehicle packaging, can lead to localized hot spots that stress the oil system. Insufficient cooling can cause oil breakdown, reducing its lubricating properties and potentially leading to increased wear on engine components.

The oil filter placement in some K24 engine configurations can make routine maintenance more challenging. This can discourage regular oil changes, contributing to the aforementioned sludge and deposit issues. Additionally, the filter's location may expose it to higher temperatures, potentially reducing its effectiveness over time.

Crankcase ventilation system design is another area of concern. Inefficient ventilation can lead to increased oil contamination by allowing blow-by gases to condense and mix with the oil. This not only degrades oil quality faster but can also contribute to the formation of sludge and varnish deposits.

The K24 engine's use in a wide range of vehicles, from compact cars to larger SUVs, presents a challenge in designing an oil system that performs optimally across various operating conditions. The oil system must cope with different load demands, driving styles, and environmental conditions, which can strain its ability to maintain consistent performance and longevity.

Lastly, the balance between oil capacity and engine efficiency poses a design challenge. While a larger oil capacity could potentially improve cooling and extend oil life, it also adds weight and complexity to the engine, potentially impacting fuel efficiency and overall vehicle performance. Engineers must carefully optimize this balance to meet both performance and longevity goals.

Existing K24 Oil System Enhancement Solutions

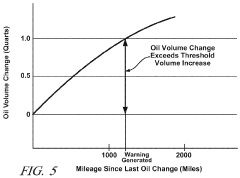

01 Oil system monitoring and diagnostics

Advanced monitoring systems are employed to track the performance and health of K24 engine oil systems. These systems use sensors and data analysis to detect potential issues early, predict maintenance needs, and optimize oil change intervals. This proactive approach helps extend the longevity of the oil system by preventing premature wear and addressing problems before they escalate.- Oil system monitoring and diagnostics: Advanced monitoring systems are implemented to track the performance and health of K24 engine oil systems. These systems use sensors and data analysis to detect potential issues early, predict maintenance needs, and optimize oil change intervals, thereby extending the overall longevity of the engine oil system.

- Enhanced oil filtration techniques: Improved oil filtration methods are developed to remove contaminants more effectively from the K24 engine oil system. These techniques may include advanced filter designs, multi-stage filtration processes, or the use of novel filter materials, all aimed at maintaining oil quality and extending its useful life within the engine.

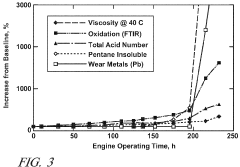

- Oil composition optimization: Specialized oil formulations are created for K24 engines, focusing on improved thermal stability, reduced oxidation, and enhanced protection against wear. These optimized compositions help maintain the oil's performance characteristics over extended periods, contributing to increased longevity of the engine oil system.

- Predictive maintenance strategies: AI-driven predictive maintenance models are developed to analyze engine oil system data and predict potential failures or maintenance needs. These strategies help in scheduling timely interventions, preventing unexpected breakdowns, and maximizing the lifespan of the K24 engine oil system components.

- Oil circulation and cooling enhancements: Improvements in oil circulation and cooling systems are implemented to maintain optimal oil temperature and distribution throughout the K24 engine. These enhancements may include redesigned oil passages, improved oil pumps, or advanced cooling mechanisms, all contributing to extended oil life and overall engine longevity.

02 Enhanced oil filtration techniques

Improved oil filtration methods are implemented in K24 engines to remove contaminants more effectively. These techniques may include advanced filter designs, multi-stage filtration systems, or the use of novel filter materials. By maintaining cleaner oil, these methods reduce engine wear and extend the life of both the oil and the engine components.Expand Specific Solutions03 Oil composition optimization

Specialized oil formulations are developed for K24 engines to enhance longevity. These formulations may include advanced additives, synthetic base oils, or blends optimized for the specific operating conditions of K24 engines. The tailored compositions aim to improve oil stability, reduce breakdown, and provide better protection against wear and corrosion.Expand Specific Solutions04 Thermal management improvements

Enhanced thermal management systems are integrated into K24 engine designs to maintain optimal oil temperatures. These may include improved cooling systems, heat exchangers, or thermal barriers. By preventing oil overheating and maintaining consistent temperatures, these improvements help preserve oil properties and extend its effective lifespan.Expand Specific Solutions05 Predictive maintenance strategies

Advanced algorithms and machine learning techniques are employed to predict oil system maintenance needs accurately. These strategies analyze various engine parameters, operating conditions, and historical data to optimize maintenance schedules. By ensuring timely interventions and preventing unnecessary oil changes, these approaches contribute to the overall longevity of the K24 engine oil system.Expand Specific Solutions

Key Players in Engine Oil System Optimization

The optimization of K24 engine oil systems for longevity is a mature field within the automotive industry, currently in a stable growth phase. The market size for this technology is substantial, driven by the global demand for efficient and durable engines. Companies like ExxonMobil, Caterpillar, and Ford Global Technologies are at the forefront, leveraging their extensive R&D capabilities to develop advanced lubricants and oil system designs. Asian manufacturers such as Weichai Power, Dongfeng Motor, and Geely are also making significant strides, particularly in emerging markets. The technology's maturity is evident in the incremental improvements focused on extending oil life, reducing friction, and enhancing overall engine performance.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced synthetic oil formulations specifically designed for K24 engines. Their technology focuses on molecular engineering to create lubricants that maintain viscosity under high temperatures and pressures. The company's approach includes the use of high-performance additives that form protective films on engine components, reducing wear and extending engine life[1]. ExxonMobil's oil systems for K24 engines also incorporate advanced filtration technologies to remove contaminants more effectively, thereby reducing engine wear and maintaining oil quality for longer periods[3].

Strengths: Superior protection against engine wear, extended oil change intervals, and improved fuel efficiency. Weaknesses: Higher initial cost compared to conventional oils, may require specific disposal methods.

GM Global Technology Operations LLC

Technical Solution: GM has developed an innovative oil management system for K24 engines that incorporates real-time oil quality monitoring. This system uses advanced sensors to continuously analyze oil condition, including viscosity, contamination levels, and additive depletion[2]. The data is processed by an onboard computer that adjusts oil change intervals dynamically. GM's technology also includes an adaptive oil pump that adjusts oil pressure based on engine load and speed, optimizing lubrication while minimizing energy losses. Additionally, GM has implemented a thermal management system that quickly brings the oil to optimal operating temperature, reducing wear during cold starts[4].

Strengths: Precise oil management, extended engine life, and improved fuel efficiency. Weaknesses: Increased system complexity and potential higher maintenance costs for the advanced monitoring equipment.

Innovative Oil System Technologies for K24

Virtual engine oil quality sensor

PatentWO2009076129A2

Innovation

- A system utilizing an oil level sensor and control module to analyze oil consumption rates and contamination levels, generating warnings based on trends and threshold increases to prevent engine damage by estimating sub-standard oil quality conditions.

Method and device for obtaining optimum lubricant properties while completely dispensing with oil changes in internal combustion engines

PatentWO2005028821A1

Innovation

- The use of a bypass flow fine filter for complete engine oil cleaning, periodic replacement of a small amount of engine oil with special oil, and automated or manual topping up, facilitated by a special oil tank, dosing device, and sensors to maintain optimal oil properties without changing the bypass flow fine filter.

Environmental Impact of Oil System Optimization

The optimization of K24 engine oil systems for longevity has significant environmental implications that extend beyond the immediate performance benefits. By enhancing the efficiency and durability of these systems, we can reduce the overall environmental impact associated with engine operation and maintenance.

One of the primary environmental benefits of optimizing K24 engine oil systems is the reduction in oil consumption. Improved oil circulation and filtration systems can extend the life of the oil, reducing the frequency of oil changes. This directly translates to a decrease in the amount of waste oil generated, which is a significant environmental concern due to its potential for soil and water contamination if not properly disposed of.

Furthermore, optimized oil systems contribute to better engine performance and fuel efficiency. When an engine operates with optimal lubrication, it experiences less friction and wear, leading to improved fuel economy. This reduction in fuel consumption directly correlates with lower emissions of greenhouse gases and other pollutants, contributing to improved air quality and reduced carbon footprint.

The longevity aspect of optimized oil systems also plays a crucial role in environmental conservation. By extending the lifespan of engine components, we reduce the need for frequent replacements and repairs. This, in turn, decreases the demand for raw materials and energy required for manufacturing replacement parts, thus conserving natural resources and reducing industrial emissions associated with production processes.

Advanced filtration technologies incorporated into optimized oil systems can also have positive environmental effects. More efficient oil filters can remove smaller particles and contaminants, preventing them from circulating through the engine and potentially being released into the environment through exhaust or oil leaks.

Moreover, the development of bio-based and synthetic oils compatible with optimized K24 engine oil systems can further reduce environmental impact. These alternative oils often have a lower carbon footprint in production and can be more biodegradable than traditional petroleum-based oils, minimizing long-term environmental damage in case of spills or improper disposal.

The optimization process itself can lead to innovations in materials science and engineering that have broader environmental applications. For instance, advancements in oil-resistant seals and gaskets can prevent leaks, reducing the risk of oil contamination in soil and water bodies. Similarly, improvements in oil cooling systems can lead to more efficient heat management in other industrial applications, potentially reducing energy consumption across various sectors.

One of the primary environmental benefits of optimizing K24 engine oil systems is the reduction in oil consumption. Improved oil circulation and filtration systems can extend the life of the oil, reducing the frequency of oil changes. This directly translates to a decrease in the amount of waste oil generated, which is a significant environmental concern due to its potential for soil and water contamination if not properly disposed of.

Furthermore, optimized oil systems contribute to better engine performance and fuel efficiency. When an engine operates with optimal lubrication, it experiences less friction and wear, leading to improved fuel economy. This reduction in fuel consumption directly correlates with lower emissions of greenhouse gases and other pollutants, contributing to improved air quality and reduced carbon footprint.

The longevity aspect of optimized oil systems also plays a crucial role in environmental conservation. By extending the lifespan of engine components, we reduce the need for frequent replacements and repairs. This, in turn, decreases the demand for raw materials and energy required for manufacturing replacement parts, thus conserving natural resources and reducing industrial emissions associated with production processes.

Advanced filtration technologies incorporated into optimized oil systems can also have positive environmental effects. More efficient oil filters can remove smaller particles and contaminants, preventing them from circulating through the engine and potentially being released into the environment through exhaust or oil leaks.

Moreover, the development of bio-based and synthetic oils compatible with optimized K24 engine oil systems can further reduce environmental impact. These alternative oils often have a lower carbon footprint in production and can be more biodegradable than traditional petroleum-based oils, minimizing long-term environmental damage in case of spills or improper disposal.

The optimization process itself can lead to innovations in materials science and engineering that have broader environmental applications. For instance, advancements in oil-resistant seals and gaskets can prevent leaks, reducing the risk of oil contamination in soil and water bodies. Similarly, improvements in oil cooling systems can lead to more efficient heat management in other industrial applications, potentially reducing energy consumption across various sectors.

Cost-Benefit Analysis of Longevity Improvements

Optimizing the K24 engine oil system for longevity requires a thorough cost-benefit analysis to determine the most effective improvements. This analysis must consider both the initial investment costs and the long-term savings associated with enhanced engine durability and reduced maintenance needs.

One of the primary benefits of improving the K24 engine oil system is the potential for extended engine life. By implementing advanced filtration systems and using higher-quality synthetic oils, engine wear can be significantly reduced. This translates to fewer repairs and replacements over the vehicle's lifetime, resulting in substantial cost savings for owners and manufacturers alike.

The initial costs of implementing these improvements may include research and development expenses, retooling production lines, and potentially higher material costs for premium components. However, these upfront investments should be weighed against the long-term benefits of reduced warranty claims and increased customer satisfaction due to improved engine reliability.

Another factor to consider is the potential for improved fuel efficiency resulting from optimized oil systems. Reduced friction and better thermal management can lead to marginal gains in fuel economy, which, when multiplied across a large fleet of vehicles, can result in significant cost savings and environmental benefits.

The analysis should also account for the competitive advantage gained through offering vehicles with longer-lasting engines. This can lead to increased market share and brand loyalty, potentially offsetting the initial investment costs through higher sales volumes and premium pricing opportunities.

It's crucial to quantify the expected increase in engine longevity and translate this into tangible financial benefits. For instance, if the average lifespan of a K24 engine can be extended by 20% through oil system optimizations, the cost savings in terms of reduced engine replacements and extended vehicle service life should be calculated and compared to the implementation costs.

Additionally, the analysis must consider the potential reduction in maintenance frequency and complexity. If oil change intervals can be extended or if the oil system becomes more resistant to contamination, this could lead to lower maintenance costs over the vehicle's lifetime, benefiting both consumers and fleet operators.

Lastly, the environmental impact of longer-lasting engines should be factored into the cost-benefit analysis. Reduced resource consumption and waste generation associated with fewer engine replacements and less frequent oil changes can contribute to a company's sustainability goals, potentially leading to improved brand image and compliance with increasingly stringent environmental regulations.

One of the primary benefits of improving the K24 engine oil system is the potential for extended engine life. By implementing advanced filtration systems and using higher-quality synthetic oils, engine wear can be significantly reduced. This translates to fewer repairs and replacements over the vehicle's lifetime, resulting in substantial cost savings for owners and manufacturers alike.

The initial costs of implementing these improvements may include research and development expenses, retooling production lines, and potentially higher material costs for premium components. However, these upfront investments should be weighed against the long-term benefits of reduced warranty claims and increased customer satisfaction due to improved engine reliability.

Another factor to consider is the potential for improved fuel efficiency resulting from optimized oil systems. Reduced friction and better thermal management can lead to marginal gains in fuel economy, which, when multiplied across a large fleet of vehicles, can result in significant cost savings and environmental benefits.

The analysis should also account for the competitive advantage gained through offering vehicles with longer-lasting engines. This can lead to increased market share and brand loyalty, potentially offsetting the initial investment costs through higher sales volumes and premium pricing opportunities.

It's crucial to quantify the expected increase in engine longevity and translate this into tangible financial benefits. For instance, if the average lifespan of a K24 engine can be extended by 20% through oil system optimizations, the cost savings in terms of reduced engine replacements and extended vehicle service life should be calculated and compared to the implementation costs.

Additionally, the analysis must consider the potential reduction in maintenance frequency and complexity. If oil change intervals can be extended or if the oil system becomes more resistant to contamination, this could lead to lower maintenance costs over the vehicle's lifetime, benefiting both consumers and fleet operators.

Lastly, the environmental impact of longer-lasting engines should be factored into the cost-benefit analysis. Reduced resource consumption and waste generation associated with fewer engine replacements and less frequent oil changes can contribute to a company's sustainability goals, potentially leading to improved brand image and compliance with increasingly stringent environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!