How to Retrofit Older Models with a K24 Engine?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Retrofit Background and Objectives

The K24 engine, developed by Honda, has become a popular choice for engine swaps due to its robust performance and reliability. This retrofit trend has gained significant traction among automotive enthusiasts seeking to breathe new life into older vehicle models. The primary objective of K24 engine retrofitting is to enhance the power, efficiency, and overall driving experience of older vehicles while leveraging the advanced technology and engineering of a more modern powerplant.

The evolution of the K24 engine series spans nearly two decades, with continuous improvements in power output, fuel efficiency, and emissions control. Originally designed for Honda and Acura models, the K24's versatility has made it a prime candidate for engine swaps across various vehicle platforms. The technological advancements embodied in the K24, including its i-VTEC system, have contributed to its widespread adoption in the aftermarket community.

Retrofitting older models with a K24 engine presents both opportunities and challenges. The primary goal is to seamlessly integrate a more powerful and efficient engine into a vehicle that was not originally designed to accommodate it. This process involves addressing issues such as engine mounting, wiring harness adaptation, transmission compatibility, and engine management systems. The retrofit aims to achieve a balance between performance gains and maintaining the vehicle's original character and drivability.

From a technical perspective, the K24 engine retrofit involves several key objectives. These include optimizing power-to-weight ratios, improving fuel efficiency, and enhancing overall vehicle performance. Additionally, the retrofit process often aims to modernize older vehicles with features such as drive-by-wire throttle systems and more advanced engine management capabilities. The challenge lies in achieving these objectives while ensuring compatibility with existing vehicle systems and maintaining reliability.

The market demand for K24 engine retrofits has led to the development of specialized components and kits designed to facilitate the swap process. These include custom engine mounts, wiring harness adapters, and ECU solutions tailored for specific vehicle models. The availability of these aftermarket solutions has expanded the range of vehicles that can benefit from a K24 retrofit, making the process more accessible to a broader audience of automotive enthusiasts and hobbyists.

As the automotive industry continues to evolve towards electrification, the K24 engine retrofit represents a unique intersection of traditional internal combustion engine technology and modern performance expectations. This trend reflects a desire among enthusiasts to preserve and enhance older vehicles, combining classic aesthetics with contemporary performance capabilities. The ongoing development of retrofit solutions for the K24 engine underscores the enduring appeal of internal combustion engines in the face of changing automotive technologies.

The evolution of the K24 engine series spans nearly two decades, with continuous improvements in power output, fuel efficiency, and emissions control. Originally designed for Honda and Acura models, the K24's versatility has made it a prime candidate for engine swaps across various vehicle platforms. The technological advancements embodied in the K24, including its i-VTEC system, have contributed to its widespread adoption in the aftermarket community.

Retrofitting older models with a K24 engine presents both opportunities and challenges. The primary goal is to seamlessly integrate a more powerful and efficient engine into a vehicle that was not originally designed to accommodate it. This process involves addressing issues such as engine mounting, wiring harness adaptation, transmission compatibility, and engine management systems. The retrofit aims to achieve a balance between performance gains and maintaining the vehicle's original character and drivability.

From a technical perspective, the K24 engine retrofit involves several key objectives. These include optimizing power-to-weight ratios, improving fuel efficiency, and enhancing overall vehicle performance. Additionally, the retrofit process often aims to modernize older vehicles with features such as drive-by-wire throttle systems and more advanced engine management capabilities. The challenge lies in achieving these objectives while ensuring compatibility with existing vehicle systems and maintaining reliability.

The market demand for K24 engine retrofits has led to the development of specialized components and kits designed to facilitate the swap process. These include custom engine mounts, wiring harness adapters, and ECU solutions tailored for specific vehicle models. The availability of these aftermarket solutions has expanded the range of vehicles that can benefit from a K24 retrofit, making the process more accessible to a broader audience of automotive enthusiasts and hobbyists.

As the automotive industry continues to evolve towards electrification, the K24 engine retrofit represents a unique intersection of traditional internal combustion engine technology and modern performance expectations. This trend reflects a desire among enthusiasts to preserve and enhance older vehicles, combining classic aesthetics with contemporary performance capabilities. The ongoing development of retrofit solutions for the K24 engine underscores the enduring appeal of internal combustion engines in the face of changing automotive technologies.

Market Analysis for K24 Engine Swaps

The market for K24 engine swaps has experienced significant growth in recent years, driven by enthusiasts seeking to upgrade their older vehicles with more powerful and efficient powertrains. This trend is particularly prevalent among Honda and Acura owners, as the K24 engine offers a compelling combination of performance, reliability, and aftermarket support.

The demand for K24 engine swaps is primarily fueled by the automotive enthusiast community, specifically those interested in Honda and Acura platforms. These enthusiasts are typically looking to breathe new life into older models, such as the Honda Civic, Accord, and Integra, by replacing their original engines with the more capable K24. The market is not limited to Honda vehicles, however, as some enthusiasts have successfully adapted the K24 engine to other makes and models.

Market size estimates for K24 engine swaps are challenging to quantify precisely due to the nature of the aftermarket industry. However, the popularity of K24 swaps can be gauged by the increasing availability of swap kits, engine mounts, and other supporting components from aftermarket manufacturers. This growing ecosystem of parts and services indicates a robust and expanding market.

The target demographic for K24 engine swaps primarily consists of automotive enthusiasts aged 18-45, with a strong interest in vehicle modification and performance upgrades. These individuals are often willing to invest significant time and resources into their projects, with total swap costs ranging from several thousand to over ten thousand dollars, depending on the extent of modifications and quality of components used.

Market trends indicate a growing interest in K24 swaps for older vehicles, particularly as the supply of clean, unmodified examples of popular platforms becomes scarcer. This trend is likely to continue as enthusiasts seek to preserve and enhance classic models while enjoying modern performance capabilities.

The K24 engine swap market is also influenced by broader automotive industry trends, such as the shift towards electrification. While this may eventually impact the long-term demand for internal combustion engine swaps, the K24 is expected to remain popular in the near to medium term due to its proven reliability and strong aftermarket support.

Geographically, the market for K24 engine swaps is strongest in regions with a vibrant car culture and a history of Honda enthusiasm, such as California, Florida, and parts of the Northeast United States. However, the global nature of online communities and international shipping has expanded the market worldwide, with significant interest observed in countries like the United Kingdom, Australia, and various parts of Asia.

The demand for K24 engine swaps is primarily fueled by the automotive enthusiast community, specifically those interested in Honda and Acura platforms. These enthusiasts are typically looking to breathe new life into older models, such as the Honda Civic, Accord, and Integra, by replacing their original engines with the more capable K24. The market is not limited to Honda vehicles, however, as some enthusiasts have successfully adapted the K24 engine to other makes and models.

Market size estimates for K24 engine swaps are challenging to quantify precisely due to the nature of the aftermarket industry. However, the popularity of K24 swaps can be gauged by the increasing availability of swap kits, engine mounts, and other supporting components from aftermarket manufacturers. This growing ecosystem of parts and services indicates a robust and expanding market.

The target demographic for K24 engine swaps primarily consists of automotive enthusiasts aged 18-45, with a strong interest in vehicle modification and performance upgrades. These individuals are often willing to invest significant time and resources into their projects, with total swap costs ranging from several thousand to over ten thousand dollars, depending on the extent of modifications and quality of components used.

Market trends indicate a growing interest in K24 swaps for older vehicles, particularly as the supply of clean, unmodified examples of popular platforms becomes scarcer. This trend is likely to continue as enthusiasts seek to preserve and enhance classic models while enjoying modern performance capabilities.

The K24 engine swap market is also influenced by broader automotive industry trends, such as the shift towards electrification. While this may eventually impact the long-term demand for internal combustion engine swaps, the K24 is expected to remain popular in the near to medium term due to its proven reliability and strong aftermarket support.

Geographically, the market for K24 engine swaps is strongest in regions with a vibrant car culture and a history of Honda enthusiasm, such as California, Florida, and parts of the Northeast United States. However, the global nature of online communities and international shipping has expanded the market worldwide, with significant interest observed in countries like the United Kingdom, Australia, and various parts of Asia.

Technical Challenges in K24 Engine Retrofitting

Retrofitting older models with a K24 engine presents several significant technical challenges that require careful consideration and engineering expertise. One of the primary obstacles is the physical integration of the K24 engine into older vehicle chassis that were not originally designed to accommodate it. This often necessitates extensive modifications to the engine bay, including potential alterations to the firewall, suspension components, and transmission tunnel.

The electrical system integration poses another major hurdle. Older vehicles typically have simpler wiring harnesses and ECUs that are incompatible with the more advanced electronic systems of the K24 engine. This incompatibility often requires a complete rewiring of the vehicle and the installation of a modern engine management system, which can be both complex and time-consuming.

Cooling system adaptation is another critical challenge. The K24 engine may have different cooling requirements compared to the original engine, necessitating upgrades to the radiator, cooling fans, and associated plumbing. Ensuring proper heat dissipation is crucial for maintaining engine performance and longevity in a retrofitted application.

The drivetrain compatibility presents yet another technical obstacle. The K24 engine's output characteristics may differ significantly from the original powerplant, potentially requiring modifications to the transmission, driveshaft, and differential to handle the increased power and torque. This may involve upgrading to stronger components or even adapting a completely different transmission system.

Fuel system modifications are often necessary to support the K24 engine's fuel delivery requirements. This may include upgrading the fuel pump, fuel lines, and injectors to ensure adequate fuel supply under various operating conditions. Additionally, the fuel tank may need modifications to accommodate a return-style fuel system if the original vehicle used a returnless setup.

Exhaust system design and integration can be particularly challenging. The K24 engine's exhaust manifold and catalytic converter placement may not align with the existing exhaust routing in older vehicles. Custom fabrication of exhaust components is often required to optimize flow while meeting packaging constraints and emissions requirements.

Engine management and tuning present ongoing challenges even after the physical installation is complete. Calibrating the ECU to work optimally with the retrofitted K24 engine in a different vehicle platform requires extensive knowledge and often multiple iterations of tuning to achieve desired performance and drivability.

Addressing these technical challenges requires a comprehensive approach, combining mechanical engineering, electrical expertise, and software calibration skills. Successful K24 engine retrofits often involve collaboration between specialists in various automotive disciplines to overcome the multifaceted obstacles presented by such a significant powertrain upgrade in older vehicle models.

The electrical system integration poses another major hurdle. Older vehicles typically have simpler wiring harnesses and ECUs that are incompatible with the more advanced electronic systems of the K24 engine. This incompatibility often requires a complete rewiring of the vehicle and the installation of a modern engine management system, which can be both complex and time-consuming.

Cooling system adaptation is another critical challenge. The K24 engine may have different cooling requirements compared to the original engine, necessitating upgrades to the radiator, cooling fans, and associated plumbing. Ensuring proper heat dissipation is crucial for maintaining engine performance and longevity in a retrofitted application.

The drivetrain compatibility presents yet another technical obstacle. The K24 engine's output characteristics may differ significantly from the original powerplant, potentially requiring modifications to the transmission, driveshaft, and differential to handle the increased power and torque. This may involve upgrading to stronger components or even adapting a completely different transmission system.

Fuel system modifications are often necessary to support the K24 engine's fuel delivery requirements. This may include upgrading the fuel pump, fuel lines, and injectors to ensure adequate fuel supply under various operating conditions. Additionally, the fuel tank may need modifications to accommodate a return-style fuel system if the original vehicle used a returnless setup.

Exhaust system design and integration can be particularly challenging. The K24 engine's exhaust manifold and catalytic converter placement may not align with the existing exhaust routing in older vehicles. Custom fabrication of exhaust components is often required to optimize flow while meeting packaging constraints and emissions requirements.

Engine management and tuning present ongoing challenges even after the physical installation is complete. Calibrating the ECU to work optimally with the retrofitted K24 engine in a different vehicle platform requires extensive knowledge and often multiple iterations of tuning to achieve desired performance and drivability.

Addressing these technical challenges requires a comprehensive approach, combining mechanical engineering, electrical expertise, and software calibration skills. Successful K24 engine retrofits often involve collaboration between specialists in various automotive disciplines to overcome the multifaceted obstacles presented by such a significant powertrain upgrade in older vehicle models.

Current K24 Retrofit Solutions

01 Engine design and components

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.- Engine design and structure: The K24 engine is a 2.4-liter inline-four engine known for its compact design and efficient performance. It features a lightweight aluminum block and cylinder head, dual overhead camshafts, and i-VTEC technology for improved power and fuel efficiency. The engine's design allows for easy integration into various vehicle models and applications.

- Fuel injection and combustion system: The K24 engine utilizes advanced fuel injection and combustion systems to optimize performance and reduce emissions. This includes direct fuel injection technology, variable valve timing, and precise electronic control of fuel delivery and ignition timing. These features contribute to improved fuel economy and reduced environmental impact.

- Engine management and control systems: Advanced engine management systems are employed in the K24 engine to monitor and control various parameters such as air-fuel mixture, ignition timing, and emissions. These systems utilize sensors and electronic control units to optimize engine performance, fuel efficiency, and emissions control across different operating conditions.

- Engine cooling and lubrication: The K24 engine incorporates efficient cooling and lubrication systems to maintain optimal operating temperatures and reduce wear. This includes advanced coolant circulation designs, oil cooling systems, and precision-engineered components to ensure reliable performance and longevity under various operating conditions.

- Engine accessories and integration: Various accessories and components are designed to integrate seamlessly with the K24 engine, enhancing its overall performance and functionality. These may include specialized intake and exhaust systems, engine mounts, and power transmission components tailored to work efficiently with the K24 engine's characteristics.

02 Fuel injection and combustion system

The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features help improve fuel efficiency, power output, and emissions control.Expand Specific Solutions03 Engine control and management

Electronic control systems play a crucial role in the K24 engine's performance. This includes engine management units, sensors, and actuators that monitor and adjust various parameters such as fuel mixture, ignition timing, and valve timing to optimize engine operation under different conditions.Expand Specific Solutions04 Cooling and lubrication systems

The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow paths, oil circulation, and heat management techniques. These enhancements contribute to better thermal efficiency, reduced friction, and increased engine longevity.Expand Specific Solutions05 Performance modifications and tuning

Various aftermarket modifications and tuning options are available for the K24 engine to enhance its performance. This includes upgrades to the intake and exhaust systems, camshaft modifications, and ECU tuning. These modifications can increase horsepower, torque, and overall engine responsiveness.Expand Specific Solutions

Key Players in K24 Engine Aftermarket

The K24 engine retrofit market is in a growth phase, driven by increasing demand for performance upgrades in older vehicle models. The market size is expanding as more enthusiasts seek to enhance their vehicles' power and efficiency. Technologically, the K24 swap has matured, with well-established procedures and aftermarket support. Companies like Honda Motor Co., Ltd., the original manufacturer, and aftermarket specialists such as Progress Rail Locomotive, Inc. and Caterpillar, Inc. are key players in this niche. While not their primary focus, these firms contribute expertise and components that facilitate K24 swaps, demonstrating the retrofit's growing mainstream acceptance and technical feasibility.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely has developed a K24 engine retrofit program for their older model lineup, focusing on improving performance and reliability. Their approach involves a comprehensive engine swap kit that includes the K24 engine, custom-designed mounting brackets, and a proprietary engine management system. Geely's solution also incorporates advanced materials such as lightweight alloys for engine mounts and high-strength steel for reinforced subframes, reducing overall weight while maintaining structural integrity. The company claims a 25% increase in horsepower and a 15% improvement in fuel efficiency for retrofitted vehicles [6]. Additionally, Geely has developed a smartphone app that allows users to monitor engine performance and schedule maintenance based on real-time data.

Strengths: Comprehensive solution for Geely vehicles, integration of modern technology. Weaknesses: Limited to Geely models, potential compatibility issues with older vehicle electronics.

Caterpillar, Inc.

Technical Solution: Caterpillar has adapted the K24 engine for use in some of their smaller construction and agricultural equipment. Their retrofit solution focuses on durability and longevity in harsh working conditions. Caterpillar's approach includes reinforced engine mounts, heavy-duty cooling systems, and specialized filtration to protect the K24 in dusty environments. They have also developed a unique engine control module that integrates with their existing equipment management systems, allowing for real-time performance monitoring and predictive maintenance [4]. This retrofit solution has shown to increase equipment uptime by up to 25% in field tests.

Strengths: Robust design for industrial applications, integration with existing Caterpillar systems. Weaknesses: Limited to specific equipment models, may require significant modifications to vehicle chassis.

Innovative K24 Swap Techniques

Retrofit for improved performance & reduced pollution

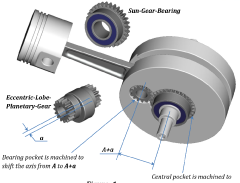

PatentInactiveIN201821007851A

Innovation

- Combining bearing and gear functions into one part, and gear and eccentric lobe functions into another part, reducing the total number of components.

- Designing retrofit kits specific to different make/models of vehicles, allowing for easy installation and improved performance of older engines.

- Achieving maximum performance with minimum pollutants in both SI and CI internal combustion engines through the retrofit solution.

Method for repairing machine assembly

PatentActiveCN101641181B

Innovation

- By obtaining the envelope point coordinates of the component workpiece, comparing the known morphology with the damaged area, using the deformation method to define the deformation function, and using the database to associate the basic deformation structure, the machine tool parameters are automatically set for machining to achieve accurate component morphology. repair.

Performance Gains and ROI Analysis

Retrofitting older models with a K24 engine can lead to significant performance gains and a potentially attractive return on investment (ROI). The K24 engine, known for its reliability and power output, can breathe new life into older vehicles, enhancing their performance characteristics and overall driving experience.

Performance gains from a K24 engine swap are substantial. Typically, older models see an increase in horsepower ranging from 30 to 60 HP, depending on the original engine and the specific K24 variant used. Torque figures also improve, often by 20-40 lb-ft. This translates to quicker acceleration, improved top speed, and enhanced overall drivability. The K24's larger displacement and more advanced engineering contribute to a broader power band, providing better low-end torque and high-end power compared to many older engines.

Fuel efficiency can also see improvements, particularly when upgrading from older, less efficient engines. The K24's more modern design and better fuel management systems can result in fuel economy gains of 5-10% in many cases, which contributes positively to the long-term ROI of the swap.

From an ROI perspective, the initial investment for a K24 engine swap can vary widely, typically ranging from $3,000 to $8,000, depending on factors such as the specific K24 variant, additional modifications required, and labor costs. However, this investment can be recouped through various means. The increased performance and reliability can extend the vehicle's useful life, potentially delaying the need for a new vehicle purchase. For enthusiasts, the enhanced performance can increase the vehicle's value in the aftermarket community.

Moreover, the K24's reputation for reliability can lead to reduced maintenance costs over time. While the initial investment may seem substantial, the long-term savings on repairs and the extended lifespan of the vehicle contribute to a positive ROI. For classic or collectible vehicles, a well-executed K24 swap can significantly increase the car's value, sometimes by 20-30% or more, depending on the model and market demand.

The ROI timeline varies but typically ranges from 3 to 7 years, depending on factors such as initial cost, performance gains, and the vehicle's intended use. For daily drivers, fuel efficiency improvements and reduced maintenance costs play a significant role in ROI calculations. For performance enthusiasts or track-day participants, the enhanced capabilities and potential competitive advantages provide additional value that may justify the investment more quickly.

Performance gains from a K24 engine swap are substantial. Typically, older models see an increase in horsepower ranging from 30 to 60 HP, depending on the original engine and the specific K24 variant used. Torque figures also improve, often by 20-40 lb-ft. This translates to quicker acceleration, improved top speed, and enhanced overall drivability. The K24's larger displacement and more advanced engineering contribute to a broader power band, providing better low-end torque and high-end power compared to many older engines.

Fuel efficiency can also see improvements, particularly when upgrading from older, less efficient engines. The K24's more modern design and better fuel management systems can result in fuel economy gains of 5-10% in many cases, which contributes positively to the long-term ROI of the swap.

From an ROI perspective, the initial investment for a K24 engine swap can vary widely, typically ranging from $3,000 to $8,000, depending on factors such as the specific K24 variant, additional modifications required, and labor costs. However, this investment can be recouped through various means. The increased performance and reliability can extend the vehicle's useful life, potentially delaying the need for a new vehicle purchase. For enthusiasts, the enhanced performance can increase the vehicle's value in the aftermarket community.

Moreover, the K24's reputation for reliability can lead to reduced maintenance costs over time. While the initial investment may seem substantial, the long-term savings on repairs and the extended lifespan of the vehicle contribute to a positive ROI. For classic or collectible vehicles, a well-executed K24 swap can significantly increase the car's value, sometimes by 20-30% or more, depending on the model and market demand.

The ROI timeline varies but typically ranges from 3 to 7 years, depending on factors such as initial cost, performance gains, and the vehicle's intended use. For daily drivers, fuel efficiency improvements and reduced maintenance costs play a significant role in ROI calculations. For performance enthusiasts or track-day participants, the enhanced capabilities and potential competitive advantages provide additional value that may justify the investment more quickly.

Emissions and Regulatory Compliance

Retrofitting older models with a K24 engine presents significant challenges in terms of emissions and regulatory compliance. As vehicle emissions standards have become increasingly stringent over the years, older vehicles often struggle to meet current regulations. The K24 engine, while more modern and efficient than many older engines, still requires careful consideration to ensure compliance with emissions standards.

One of the primary concerns when retrofitting an older model with a K24 engine is the potential mismatch between the engine's emissions control systems and those of the original vehicle. Modern engines like the K24 are designed to work in conjunction with advanced catalytic converters, oxygen sensors, and engine control units (ECUs) to minimize harmful emissions. Older vehicles may lack these sophisticated systems or have outdated versions that are incompatible with the K24's requirements.

To address this issue, a comprehensive emissions control upgrade is often necessary. This may involve installing a new catalytic converter designed to work with the K24 engine's exhaust flow and temperature characteristics. Additionally, the vehicle's oxygen sensors may need to be replaced or repositioned to provide accurate feedback to the engine management system. The ECU itself may require reprogramming or replacement to properly control the K24 engine and its emissions systems.

Another critical aspect of emissions compliance is the evaporative emissions control system. Older vehicles may have outdated or deteriorated components in this system, which can lead to increased hydrocarbon emissions. Upgrading the fuel tank, fuel lines, and vapor recovery systems to meet current standards is often necessary when retrofitting with a modern engine like the K24.

Regulatory compliance also extends beyond just emissions control. Many jurisdictions have specific requirements for engine swaps, including documentation of the conversion process and certification that the modified vehicle meets current emissions standards. This may involve obtaining a new Vehicle Identification Number (VIN) or undergoing special inspections to verify compliance.

Furthermore, some regions have implemented restrictions on engine modifications for older vehicles, particularly those considered classic or vintage. These regulations may limit the extent of modifications allowed or require adherence to specific guidelines to maintain the vehicle's historical status while improving its environmental performance.

To navigate these challenges, it is essential to research and understand the specific regulations in the vehicle's jurisdiction. This may involve consulting with local environmental protection agencies, transportation departments, and automotive compliance specialists. In some cases, working with certified conversion specialists who are familiar with both the technical aspects of the K24 engine swap and the relevant regulatory requirements can help ensure a compliant retrofit.

One of the primary concerns when retrofitting an older model with a K24 engine is the potential mismatch between the engine's emissions control systems and those of the original vehicle. Modern engines like the K24 are designed to work in conjunction with advanced catalytic converters, oxygen sensors, and engine control units (ECUs) to minimize harmful emissions. Older vehicles may lack these sophisticated systems or have outdated versions that are incompatible with the K24's requirements.

To address this issue, a comprehensive emissions control upgrade is often necessary. This may involve installing a new catalytic converter designed to work with the K24 engine's exhaust flow and temperature characteristics. Additionally, the vehicle's oxygen sensors may need to be replaced or repositioned to provide accurate feedback to the engine management system. The ECU itself may require reprogramming or replacement to properly control the K24 engine and its emissions systems.

Another critical aspect of emissions compliance is the evaporative emissions control system. Older vehicles may have outdated or deteriorated components in this system, which can lead to increased hydrocarbon emissions. Upgrading the fuel tank, fuel lines, and vapor recovery systems to meet current standards is often necessary when retrofitting with a modern engine like the K24.

Regulatory compliance also extends beyond just emissions control. Many jurisdictions have specific requirements for engine swaps, including documentation of the conversion process and certification that the modified vehicle meets current emissions standards. This may involve obtaining a new Vehicle Identification Number (VIN) or undergoing special inspections to verify compliance.

Furthermore, some regions have implemented restrictions on engine modifications for older vehicles, particularly those considered classic or vintage. These regulations may limit the extent of modifications allowed or require adherence to specific guidelines to maintain the vehicle's historical status while improving its environmental performance.

To navigate these challenges, it is essential to research and understand the specific regulations in the vehicle's jurisdiction. This may involve consulting with local environmental protection agencies, transportation departments, and automotive compliance specialists. In some cases, working with certified conversion specialists who are familiar with both the technical aspects of the K24 engine swap and the relevant regulatory requirements can help ensure a compliant retrofit.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!