How to Streamline Workflow with Automated Gel Electrophoresis?

JUL 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automated Gel Electrophoresis Background and Objectives

Gel electrophoresis has been a cornerstone technique in molecular biology for decades, enabling the separation and analysis of DNA, RNA, and proteins. As research demands have grown, the need for more efficient and streamlined processes has become increasingly apparent. Automated gel electrophoresis represents a significant advancement in this field, offering the potential to revolutionize laboratory workflows and enhance research productivity.

The evolution of gel electrophoresis technology can be traced back to the 1930s, with major developments occurring in the 1950s and 1960s. Traditional manual methods, while effective, are time-consuming and prone to human error. The introduction of automation in gel electrophoresis aims to address these limitations, marking a new era in molecular biology research.

The primary objective of automated gel electrophoresis is to streamline the workflow by reducing manual intervention, increasing throughput, and improving reproducibility. This technology integrates sample loading, electrophoresis, staining, imaging, and analysis into a single automated process. By doing so, it not only saves time but also minimizes the risk of contamination and human error.

One of the key goals in developing automated gel electrophoresis systems is to enhance standardization across experiments. This is crucial for ensuring consistent and comparable results, particularly in large-scale studies or clinical applications. Additionally, automation aims to improve data quality by reducing variability introduced by manual handling and subjective interpretation.

Another important objective is to increase the accessibility of gel electrophoresis techniques. By simplifying the process through automation, researchers with varying levels of expertise can perform complex analyses more easily. This democratization of technology has the potential to accelerate research across diverse fields, from genomics to proteomics.

The development of automated gel electrophoresis also aligns with broader trends in laboratory automation and the push towards high-throughput screening methods. As research projects grow in scale and complexity, the ability to process large numbers of samples quickly and accurately becomes increasingly valuable. Automated systems are designed to meet this demand, enabling researchers to handle higher sample volumes without compromising on quality.

Furthermore, the integration of automated gel electrophoresis with other laboratory technologies is a key objective. This includes connectivity with laboratory information management systems (LIMS), data analysis software, and other automated instruments. Such integration aims to create a seamless workflow from sample preparation to data interpretation, further enhancing efficiency and data management.

As we explore the current state and future potential of automated gel electrophoresis, it is clear that this technology represents a significant step forward in molecular biology research. By addressing the limitations of manual methods and leveraging the power of automation, it promises to accelerate scientific discovery and improve the quality and reliability of research outcomes.

The evolution of gel electrophoresis technology can be traced back to the 1930s, with major developments occurring in the 1950s and 1960s. Traditional manual methods, while effective, are time-consuming and prone to human error. The introduction of automation in gel electrophoresis aims to address these limitations, marking a new era in molecular biology research.

The primary objective of automated gel electrophoresis is to streamline the workflow by reducing manual intervention, increasing throughput, and improving reproducibility. This technology integrates sample loading, electrophoresis, staining, imaging, and analysis into a single automated process. By doing so, it not only saves time but also minimizes the risk of contamination and human error.

One of the key goals in developing automated gel electrophoresis systems is to enhance standardization across experiments. This is crucial for ensuring consistent and comparable results, particularly in large-scale studies or clinical applications. Additionally, automation aims to improve data quality by reducing variability introduced by manual handling and subjective interpretation.

Another important objective is to increase the accessibility of gel electrophoresis techniques. By simplifying the process through automation, researchers with varying levels of expertise can perform complex analyses more easily. This democratization of technology has the potential to accelerate research across diverse fields, from genomics to proteomics.

The development of automated gel electrophoresis also aligns with broader trends in laboratory automation and the push towards high-throughput screening methods. As research projects grow in scale and complexity, the ability to process large numbers of samples quickly and accurately becomes increasingly valuable. Automated systems are designed to meet this demand, enabling researchers to handle higher sample volumes without compromising on quality.

Furthermore, the integration of automated gel electrophoresis with other laboratory technologies is a key objective. This includes connectivity with laboratory information management systems (LIMS), data analysis software, and other automated instruments. Such integration aims to create a seamless workflow from sample preparation to data interpretation, further enhancing efficiency and data management.

As we explore the current state and future potential of automated gel electrophoresis, it is clear that this technology represents a significant step forward in molecular biology research. By addressing the limitations of manual methods and leveraging the power of automation, it promises to accelerate scientific discovery and improve the quality and reliability of research outcomes.

Market Demand Analysis for Streamlined Lab Workflows

The demand for streamlined laboratory workflows, particularly in the context of automated gel electrophoresis, has been steadily increasing across various sectors of the life sciences industry. This trend is driven by the growing need for higher throughput, improved accuracy, and reduced manual labor in research and diagnostic laboratories.

In academic research institutions, there is a significant push towards automation to handle the increasing volume of samples and to accelerate the pace of scientific discoveries. Automated gel electrophoresis systems are becoming essential tools in genomics, proteomics, and molecular biology research, where rapid and accurate analysis of DNA, RNA, and proteins is crucial.

The pharmaceutical and biotechnology industries are also major drivers of this market demand. These sectors require high-throughput screening methods for drug discovery and development processes. Automated gel electrophoresis systems offer the ability to process large numbers of samples quickly and consistently, which is vital for accelerating the drug development pipeline and reducing time-to-market for new therapeutics.

Clinical diagnostics laboratories represent another significant market segment with a growing demand for automated workflows. As personalized medicine and genetic testing become more prevalent, there is an increasing need for efficient and reliable methods to analyze patient samples. Automated gel electrophoresis systems can help these laboratories handle higher sample volumes while maintaining accuracy and reducing turnaround times for test results.

The food and beverage industry is also contributing to the market demand, particularly in quality control and safety testing. Automated gel electrophoresis can streamline the detection of foodborne pathogens and verify food authenticity, addressing the industry's need for rapid and reliable testing methods.

Environmental testing laboratories are another emerging market for automated gel electrophoresis systems. These labs require efficient methods for analyzing environmental samples, such as water quality testing and soil contamination assessments. Automated systems can help process more samples and provide faster results, which is crucial for timely environmental monitoring and decision-making.

The global market for automated gel electrophoresis systems is expected to grow significantly in the coming years. This growth is fueled by technological advancements in automation, increasing research and development activities in life sciences, and the rising demand for personalized medicine. Additionally, the ongoing COVID-19 pandemic has highlighted the importance of rapid and high-throughput testing methods, further driving the demand for automated laboratory workflows.

As laboratories across various sectors seek to improve efficiency, reduce costs, and enhance the quality of their results, the demand for automated gel electrophoresis systems is likely to continue its upward trajectory. This trend presents significant opportunities for manufacturers and developers of automated laboratory equipment to innovate and capture market share in this growing field.

In academic research institutions, there is a significant push towards automation to handle the increasing volume of samples and to accelerate the pace of scientific discoveries. Automated gel electrophoresis systems are becoming essential tools in genomics, proteomics, and molecular biology research, where rapid and accurate analysis of DNA, RNA, and proteins is crucial.

The pharmaceutical and biotechnology industries are also major drivers of this market demand. These sectors require high-throughput screening methods for drug discovery and development processes. Automated gel electrophoresis systems offer the ability to process large numbers of samples quickly and consistently, which is vital for accelerating the drug development pipeline and reducing time-to-market for new therapeutics.

Clinical diagnostics laboratories represent another significant market segment with a growing demand for automated workflows. As personalized medicine and genetic testing become more prevalent, there is an increasing need for efficient and reliable methods to analyze patient samples. Automated gel electrophoresis systems can help these laboratories handle higher sample volumes while maintaining accuracy and reducing turnaround times for test results.

The food and beverage industry is also contributing to the market demand, particularly in quality control and safety testing. Automated gel electrophoresis can streamline the detection of foodborne pathogens and verify food authenticity, addressing the industry's need for rapid and reliable testing methods.

Environmental testing laboratories are another emerging market for automated gel electrophoresis systems. These labs require efficient methods for analyzing environmental samples, such as water quality testing and soil contamination assessments. Automated systems can help process more samples and provide faster results, which is crucial for timely environmental monitoring and decision-making.

The global market for automated gel electrophoresis systems is expected to grow significantly in the coming years. This growth is fueled by technological advancements in automation, increasing research and development activities in life sciences, and the rising demand for personalized medicine. Additionally, the ongoing COVID-19 pandemic has highlighted the importance of rapid and high-throughput testing methods, further driving the demand for automated laboratory workflows.

As laboratories across various sectors seek to improve efficiency, reduce costs, and enhance the quality of their results, the demand for automated gel electrophoresis systems is likely to continue its upward trajectory. This trend presents significant opportunities for manufacturers and developers of automated laboratory equipment to innovate and capture market share in this growing field.

Current Challenges in Gel Electrophoresis Automation

Despite the significant advancements in gel electrophoresis automation, several challenges persist in streamlining the workflow effectively. One of the primary obstacles is the variability in sample preparation and loading. Automated systems often struggle to handle diverse sample types and volumes consistently, leading to potential errors in gel loading and subsequent analysis.

The optimization of run parameters remains a complex task, as different samples and experimental objectives require specific voltage, current, and run time settings. Current automated systems lack the flexibility to dynamically adjust these parameters based on real-time data, potentially compromising the quality and resolution of results.

Another significant challenge is the integration of automated gel electrophoresis systems with existing laboratory workflows and information management systems. Many laboratories face difficulties in seamlessly connecting these automated platforms with their Laboratory Information Management Systems (LIMS) or Electronic Lab Notebooks (ELNs), resulting in data silos and inefficient information transfer.

The interpretation and analysis of gel electrophoresis results also present ongoing challenges. While image capture has been largely automated, the accurate identification and quantification of bands still often require manual intervention. This bottleneck can significantly slow down the overall workflow, especially in high-throughput environments.

Maintenance and quality control of automated gel electrophoresis systems pose additional challenges. Regular calibration, buffer management, and gel quality assurance are critical for consistent results but can be time-consuming and prone to human error if not properly automated.

Cost considerations also play a role in the adoption of fully automated systems. The initial investment and ongoing operational expenses for advanced automated platforms can be prohibitive for smaller laboratories or academic institutions, limiting widespread adoption.

Lastly, the standardization of protocols across different automated systems remains a challenge. The lack of universal standards for automated gel electrophoresis makes it difficult to compare results between laboratories or replicate experiments using different platforms, potentially hindering collaborative research efforts and data reproducibility in the scientific community.

The optimization of run parameters remains a complex task, as different samples and experimental objectives require specific voltage, current, and run time settings. Current automated systems lack the flexibility to dynamically adjust these parameters based on real-time data, potentially compromising the quality and resolution of results.

Another significant challenge is the integration of automated gel electrophoresis systems with existing laboratory workflows and information management systems. Many laboratories face difficulties in seamlessly connecting these automated platforms with their Laboratory Information Management Systems (LIMS) or Electronic Lab Notebooks (ELNs), resulting in data silos and inefficient information transfer.

The interpretation and analysis of gel electrophoresis results also present ongoing challenges. While image capture has been largely automated, the accurate identification and quantification of bands still often require manual intervention. This bottleneck can significantly slow down the overall workflow, especially in high-throughput environments.

Maintenance and quality control of automated gel electrophoresis systems pose additional challenges. Regular calibration, buffer management, and gel quality assurance are critical for consistent results but can be time-consuming and prone to human error if not properly automated.

Cost considerations also play a role in the adoption of fully automated systems. The initial investment and ongoing operational expenses for advanced automated platforms can be prohibitive for smaller laboratories or academic institutions, limiting widespread adoption.

Lastly, the standardization of protocols across different automated systems remains a challenge. The lack of universal standards for automated gel electrophoresis makes it difficult to compare results between laboratories or replicate experiments using different platforms, potentially hindering collaborative research efforts and data reproducibility in the scientific community.

Existing Automated Gel Electrophoresis Solutions

01 Automated sample loading and separation

Automated systems for loading samples onto gels and performing electrophoretic separation. These systems may include robotic arms, automated pipetting, and programmable voltage control for consistent and efficient sample processing.- Automated sample loading and separation: Automated systems for loading samples onto gel electrophoresis devices and performing separation. These systems can handle multiple samples simultaneously, reducing manual labor and increasing throughput. They often include robotic arms or automated pipetting systems for precise sample handling.

- Integrated gel preparation and casting: Systems that automate the process of preparing and casting gels for electrophoresis. These systems can mix gel solutions, pour them into cassettes, and allow for polymerization, reducing variability and improving consistency in gel preparation.

- Automated buffer management and electrophoresis control: Systems that manage buffer levels, temperature, and electrical parameters during electrophoresis. These systems can automatically refill buffers, maintain optimal temperature, and adjust voltage or current to ensure consistent separation conditions throughout the run.

- Integrated imaging and analysis: Systems that incorporate automated imaging and analysis of electrophoresis gels. These systems can capture high-resolution images of gels, perform lane and band detection, and provide quantitative analysis of results, streamlining the post-electrophoresis workflow.

- Microfluidic electrophoresis devices: Miniaturized electrophoresis systems that use microfluidic channels for sample separation. These devices often integrate sample loading, separation, and detection into a single chip, allowing for rapid analysis with minimal sample volumes.

02 Integrated gel preparation and casting

Systems that automate the process of preparing and casting gels for electrophoresis. This may include mixing of gel components, pouring into cassettes, and polymerization, reducing manual labor and improving consistency.Expand Specific Solutions03 Automated buffer management and circulation

Systems for automated management of electrophoresis buffers, including circulation, temperature control, and pH monitoring. This ensures optimal conditions throughout the electrophoresis process and reduces manual intervention.Expand Specific Solutions04 Integrated imaging and analysis

Automated systems that incorporate imaging capabilities and analysis software. These systems can capture gel images, perform band detection, and analyze results without manual intervention, improving efficiency and reducing human error.Expand Specific Solutions05 Microfluidic electrophoresis devices

Miniaturized electrophoresis systems that integrate sample preparation, separation, and detection on a single chip or cartridge. These devices offer rapid analysis, reduced sample and reagent consumption, and potential for high-throughput applications.Expand Specific Solutions

Key Players in Lab Automation Industry

The automated gel electrophoresis market is in a growth phase, driven by increasing demand for efficient and high-throughput molecular biology techniques. The global market size is projected to expand significantly in the coming years, fueled by advancements in genomics and proteomics research. Leading players like Beckman Coulter, Life Technologies, and Sage Science are at the forefront of technological innovation, offering sophisticated automated systems. These companies, along with emerging players such as GeneMind Biosciences and Cytiva Sweden AB, are continuously improving the technology's accuracy, speed, and ease of use. The competitive landscape is characterized by a mix of established multinational corporations and specialized biotech firms, all striving to enhance workflow efficiency and data quality in research and clinical laboratories.

Beckman Coulter, Inc.

Technical Solution: Beckman Coulter has developed the Biomek Automated Workstations for gel electrophoresis automation. These systems integrate sample preparation, gel loading, and analysis into a single platform. The Biomek series utilizes liquid handling robotics to precisely pipette samples and reagents, reducing human error and increasing throughput. The system can prepare up to 96 samples simultaneously, significantly reducing hands-on time[1]. Additionally, Beckman Coulter's ProteomeLab PA 800 system automates capillary gel electrophoresis, offering high-resolution protein separation and quantification with minimal manual intervention[2].

Strengths: High throughput, reduced human error, and integrated workflow. Weaknesses: High initial cost and potential complexity for smaller laboratories.

Life Technologies Corp.

Technical Solution: Life Technologies (now part of Thermo Fisher Scientific) has introduced the E-Gel Power Snap Electrophoresis System, which streamlines gel electrophoresis workflow. This system uses pre-cast agarose gels with integrated electrodes, eliminating the need for gel preparation and buffer pouring. The E-Gel Power Snap device automatically detects the gel type and applies the optimal voltage and run time[3]. The system also incorporates real-time LED visualization, allowing researchers to monitor DNA migration without stopping the run. Furthermore, their E-Gel NGS system is specifically designed for next-generation sequencing library preparation, automating size selection and purification steps[4].

Strengths: User-friendly, time-saving, and adaptable to various applications. Weaknesses: Limited to proprietary gel formats, potentially higher consumable costs.

Innovative Technologies in Electrophoresis Automation

Device and method for collecting samples in polymer support materials

PatentInactiveEP1068520A1

Innovation

- A sample receiving device with multiple individually actuatable cutting tools, controlled by an image recording system, allows for automated and parallel sample transfer from separating gels to a target substrate, such as a microtiter plate, using capillary-shaped piercing tools and pneumatic actuation, enabling precise and efficient sample collection and storage.

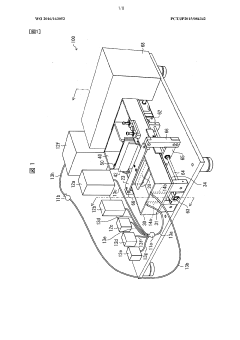

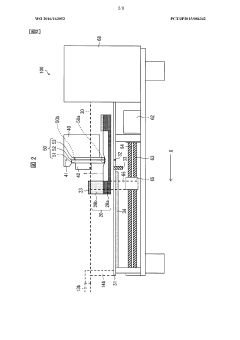

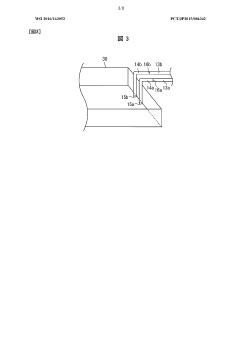

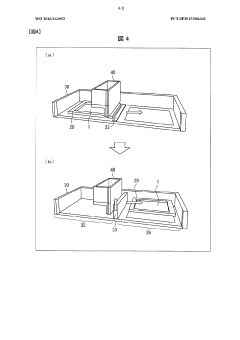

Sample separation and transfer device and sample analysis method

PatentWO2016163052A1

Innovation

- A sample separation and transfer device that automates the electrophoresis process by discharging separated samples into a buffer tank, transferring them to a transfer membrane, and performing subsequent processing using liquid pumps and controlled buffer solutions, enabling automated Western blotting.

Cost-Benefit Analysis of Automation Implementation

Implementing automated gel electrophoresis systems represents a significant investment for laboratories, necessitating a thorough cost-benefit analysis. The initial capital expenditure for automated systems can be substantial, often ranging from $30,000 to $100,000 or more, depending on the sophistication and capacity of the equipment. This upfront cost includes not only the automated gel electrophoresis apparatus but also associated software, imaging systems, and potentially robotic sample handling components.

However, the long-term benefits of automation can outweigh these initial costs. Labor savings are a primary advantage, as automated systems can significantly reduce the hands-on time required for gel preparation, sample loading, and result analysis. In a typical laboratory setting, manual gel electrophoresis can consume 2-3 hours of technician time per run. Automated systems can reduce this to less than 30 minutes of setup time, freeing up skilled personnel for other critical tasks.

Consumable costs should also be considered in the analysis. While automated systems may require specialized reagents or pre-cast gels, which can be more expensive than traditional materials, they often use smaller volumes and generate less waste. This can lead to cost savings over time, especially in high-throughput environments.

The increased throughput capability of automated systems is a crucial factor in the cost-benefit equation. Many automated platforms can process multiple gels simultaneously, potentially doubling or tripling the number of samples analyzed per day compared to manual methods. This increased capacity can be particularly valuable in clinical diagnostics or large-scale research projects where time-to-result is critical.

Quality improvements and error reduction are less tangible but equally important benefits. Automated systems offer greater consistency in gel preparation and running conditions, leading to more reproducible results. This can reduce the need for repeat experiments, saving both time and materials. Additionally, automated imaging and analysis software can provide more accurate and objective quantification of results, potentially improving the overall quality of research or diagnostic outputs.

Maintenance and operational costs must be factored into the long-term financial analysis. While automated systems may require specialized maintenance and occasional software updates, these costs are often offset by reduced labor requirements and improved efficiency. Furthermore, the standardization provided by automation can lead to better resource management and predictable operational costs over time.

In conclusion, while the initial investment in automated gel electrophoresis systems is significant, the long-term benefits in terms of labor savings, increased throughput, improved quality, and operational efficiency can provide a strong return on investment for many laboratories. The decision to implement automation should be based on a careful analysis of current workflow demands, projected sample volumes, and the specific needs of the research or diagnostic applications being performed.

However, the long-term benefits of automation can outweigh these initial costs. Labor savings are a primary advantage, as automated systems can significantly reduce the hands-on time required for gel preparation, sample loading, and result analysis. In a typical laboratory setting, manual gel electrophoresis can consume 2-3 hours of technician time per run. Automated systems can reduce this to less than 30 minutes of setup time, freeing up skilled personnel for other critical tasks.

Consumable costs should also be considered in the analysis. While automated systems may require specialized reagents or pre-cast gels, which can be more expensive than traditional materials, they often use smaller volumes and generate less waste. This can lead to cost savings over time, especially in high-throughput environments.

The increased throughput capability of automated systems is a crucial factor in the cost-benefit equation. Many automated platforms can process multiple gels simultaneously, potentially doubling or tripling the number of samples analyzed per day compared to manual methods. This increased capacity can be particularly valuable in clinical diagnostics or large-scale research projects where time-to-result is critical.

Quality improvements and error reduction are less tangible but equally important benefits. Automated systems offer greater consistency in gel preparation and running conditions, leading to more reproducible results. This can reduce the need for repeat experiments, saving both time and materials. Additionally, automated imaging and analysis software can provide more accurate and objective quantification of results, potentially improving the overall quality of research or diagnostic outputs.

Maintenance and operational costs must be factored into the long-term financial analysis. While automated systems may require specialized maintenance and occasional software updates, these costs are often offset by reduced labor requirements and improved efficiency. Furthermore, the standardization provided by automation can lead to better resource management and predictable operational costs over time.

In conclusion, while the initial investment in automated gel electrophoresis systems is significant, the long-term benefits in terms of labor savings, increased throughput, improved quality, and operational efficiency can provide a strong return on investment for many laboratories. The decision to implement automation should be based on a careful analysis of current workflow demands, projected sample volumes, and the specific needs of the research or diagnostic applications being performed.

Regulatory Compliance in Lab Automation

Regulatory compliance is a critical aspect of lab automation, particularly in the context of streamlining workflow with automated gel electrophoresis. As laboratories increasingly adopt automated systems, they must navigate a complex landscape of regulations and standards to ensure the safety, reliability, and integrity of their processes and results.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating laboratory automation, especially when it comes to medical devices and diagnostic tools. The FDA's Quality System Regulation (QSR) and Good Laboratory Practice (GLP) guidelines provide a framework for ensuring the quality and consistency of automated processes. Laboratories implementing automated gel electrophoresis systems must adhere to these regulations, which cover aspects such as equipment validation, data integrity, and process control.

The Clinical Laboratory Improvement Amendments (CLIA) also impact lab automation compliance, particularly for clinical laboratories. CLIA regulations set standards for laboratory testing to ensure accurate and reliable patient test results. Automated gel electrophoresis systems used in clinical settings must meet CLIA requirements for quality control, proficiency testing, and personnel qualifications.

Internationally, the International Organization for Standardization (ISO) has developed several standards relevant to lab automation. ISO 15189, which specifies requirements for quality and competence in medical laboratories, is particularly pertinent. This standard addresses the implementation and management of laboratory information systems, which often interface with automated gel electrophoresis equipment.

Compliance with data integrity regulations is another crucial aspect of lab automation. The FDA's guidance on data integrity emphasizes the ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate, plus Complete, Consistent, Enduring, and Available). Automated gel electrophoresis systems must incorporate features that ensure data integrity, such as audit trails, electronic signatures, and secure data storage.

Cybersecurity is an emerging concern in lab automation compliance. As automated systems become more interconnected, laboratories must implement robust cybersecurity measures to protect sensitive data and prevent unauthorized access. Regulatory bodies are increasingly focusing on this aspect, with the FDA issuing guidance on cybersecurity for medical devices.

To ensure compliance, laboratories implementing automated gel electrophoresis systems should establish comprehensive quality management systems. This includes developing standard operating procedures (SOPs), conducting regular internal audits, and maintaining thorough documentation of all processes and validations. Training programs for personnel operating automated systems are also essential to maintain compliance and ensure proper use of the equipment.

Vendors of automated gel electrophoresis systems play a crucial role in facilitating regulatory compliance. They should provide systems that are designed with compliance in mind, offering features such as user access controls, data encryption, and comprehensive audit trails. Additionally, vendors should supply documentation to support validation efforts and assist customers in meeting regulatory requirements.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating laboratory automation, especially when it comes to medical devices and diagnostic tools. The FDA's Quality System Regulation (QSR) and Good Laboratory Practice (GLP) guidelines provide a framework for ensuring the quality and consistency of automated processes. Laboratories implementing automated gel electrophoresis systems must adhere to these regulations, which cover aspects such as equipment validation, data integrity, and process control.

The Clinical Laboratory Improvement Amendments (CLIA) also impact lab automation compliance, particularly for clinical laboratories. CLIA regulations set standards for laboratory testing to ensure accurate and reliable patient test results. Automated gel electrophoresis systems used in clinical settings must meet CLIA requirements for quality control, proficiency testing, and personnel qualifications.

Internationally, the International Organization for Standardization (ISO) has developed several standards relevant to lab automation. ISO 15189, which specifies requirements for quality and competence in medical laboratories, is particularly pertinent. This standard addresses the implementation and management of laboratory information systems, which often interface with automated gel electrophoresis equipment.

Compliance with data integrity regulations is another crucial aspect of lab automation. The FDA's guidance on data integrity emphasizes the ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate, plus Complete, Consistent, Enduring, and Available). Automated gel electrophoresis systems must incorporate features that ensure data integrity, such as audit trails, electronic signatures, and secure data storage.

Cybersecurity is an emerging concern in lab automation compliance. As automated systems become more interconnected, laboratories must implement robust cybersecurity measures to protect sensitive data and prevent unauthorized access. Regulatory bodies are increasingly focusing on this aspect, with the FDA issuing guidance on cybersecurity for medical devices.

To ensure compliance, laboratories implementing automated gel electrophoresis systems should establish comprehensive quality management systems. This includes developing standard operating procedures (SOPs), conducting regular internal audits, and maintaining thorough documentation of all processes and validations. Training programs for personnel operating automated systems are also essential to maintain compliance and ensure proper use of the equipment.

Vendors of automated gel electrophoresis systems play a crucial role in facilitating regulatory compliance. They should provide systems that are designed with compliance in mind, offering features such as user access controls, data encryption, and comprehensive audit trails. Additionally, vendors should supply documentation to support validation efforts and assist customers in meeting regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!