How to Troubleshoot Common K24 Engine Problems?

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Overview

The K24 engine, developed by Honda, is a 2.4-liter inline-four cylinder engine that has been widely used in various Honda and Acura models since its introduction in 2001. Known for its reliability and performance, the K24 engine has undergone several iterations and improvements over the years, making it a popular choice among automotive enthusiasts and everyday drivers alike.

The K24 engine family is part of Honda's K-series engines, which replaced the B-series engines in many applications. It features an aluminum block and cylinder head, dual overhead camshafts (DOHC), and four valves per cylinder. The engine's design incorporates Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system, which enhances both low-end torque and high-end power output.

Throughout its production run, the K24 engine has been utilized in a variety of vehicles, including the Honda Accord, CR-V, Element, and Civic Si, as well as Acura models like the TSX and ILX. Its versatility and adaptability have contributed to its longevity in the automotive market, with different versions tailored to meet specific vehicle requirements and performance targets.

The K24 engine's displacement of 2.4 liters is achieved through a bore of 87 mm and a stroke of 99 mm. This configuration allows for a good balance between power output and fuel efficiency. Depending on the specific application and tuning, power output can range from around 160 to over 200 horsepower in stock form, with even higher figures achievable through aftermarket modifications.

One of the key strengths of the K24 engine is its robust construction, which provides a solid foundation for both reliability in daily driving and potential for performance upgrades. The engine block's design allows for increased cylinder pressure and higher RPMs, making it a favorite among tuners and racing enthusiasts.

Despite its overall reliability, the K24 engine, like any mechanical system, can experience issues over time. Common problems may include oil consumption in higher mileage engines, timing chain tensioner wear, and occasional issues with the variable valve timing system. Understanding these potential weak points is crucial for effective troubleshooting and maintenance of K24-equipped vehicles.

The K24 engine family is part of Honda's K-series engines, which replaced the B-series engines in many applications. It features an aluminum block and cylinder head, dual overhead camshafts (DOHC), and four valves per cylinder. The engine's design incorporates Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system, which enhances both low-end torque and high-end power output.

Throughout its production run, the K24 engine has been utilized in a variety of vehicles, including the Honda Accord, CR-V, Element, and Civic Si, as well as Acura models like the TSX and ILX. Its versatility and adaptability have contributed to its longevity in the automotive market, with different versions tailored to meet specific vehicle requirements and performance targets.

The K24 engine's displacement of 2.4 liters is achieved through a bore of 87 mm and a stroke of 99 mm. This configuration allows for a good balance between power output and fuel efficiency. Depending on the specific application and tuning, power output can range from around 160 to over 200 horsepower in stock form, with even higher figures achievable through aftermarket modifications.

One of the key strengths of the K24 engine is its robust construction, which provides a solid foundation for both reliability in daily driving and potential for performance upgrades. The engine block's design allows for increased cylinder pressure and higher RPMs, making it a favorite among tuners and racing enthusiasts.

Despite its overall reliability, the K24 engine, like any mechanical system, can experience issues over time. Common problems may include oil consumption in higher mileage engines, timing chain tensioner wear, and occasional issues with the variable valve timing system. Understanding these potential weak points is crucial for effective troubleshooting and maintenance of K24-equipped vehicles.

Market Demand Analysis

The market demand for K24 engine troubleshooting solutions has been steadily increasing due to the widespread use of this engine in various Honda and Acura models. As these vehicles age, owners and mechanics are increasingly seeking reliable information and tools to diagnose and resolve common K24 engine problems.

The automotive aftermarket sector has seen a significant uptick in demand for K24-specific diagnostic tools, repair manuals, and replacement parts. This trend is driven by the large number of K24-equipped vehicles still on the road, many of which are now reaching higher mileage and experiencing age-related issues.

Online automotive forums and social media platforms have witnessed a surge in discussions and queries related to K24 engine troubleshooting. This indicates a growing need for accessible, user-friendly troubleshooting guides and resources that cater to both DIY enthusiasts and professional mechanics.

The market for K24 engine repair services has also expanded, with specialized automotive shops reporting an increase in customers seeking expert assistance with these engines. This trend highlights the complexity of some K24 engine issues and the value placed on specialized knowledge in this area.

Environmental regulations and fuel efficiency standards have further influenced market demand. As older K24 engines struggle to meet newer emissions requirements, there's an increased need for troubleshooting solutions that can help maintain optimal engine performance and reduce emissions.

The rise of electric and hybrid vehicles has not significantly impacted the demand for K24 engine troubleshooting, as the large existing fleet of K24-equipped vehicles ensures a steady market for years to come. However, it has led to a growing interest in performance upgrades and modifications to extend the lifespan of these engines.

Manufacturers of aftermarket parts and diagnostic equipment have responded to this demand by developing more sophisticated tools and components specifically designed for K24 engines. This includes advanced OBD-II scanners with K24-specific codes, high-quality replacement parts, and performance enhancement products.

The global nature of Honda's vehicle distribution has created a worldwide market for K24 engine troubleshooting solutions. This has led to the development of multilingual resources and region-specific troubleshooting guides to cater to diverse markets.

As the automotive industry continues to evolve, the market for K24 engine troubleshooting is expected to remain robust in the medium term, driven by the engine's reliability, the large number of vehicles in circulation, and the growing trend of vehicle owners seeking to maintain their cars for longer periods.

The automotive aftermarket sector has seen a significant uptick in demand for K24-specific diagnostic tools, repair manuals, and replacement parts. This trend is driven by the large number of K24-equipped vehicles still on the road, many of which are now reaching higher mileage and experiencing age-related issues.

Online automotive forums and social media platforms have witnessed a surge in discussions and queries related to K24 engine troubleshooting. This indicates a growing need for accessible, user-friendly troubleshooting guides and resources that cater to both DIY enthusiasts and professional mechanics.

The market for K24 engine repair services has also expanded, with specialized automotive shops reporting an increase in customers seeking expert assistance with these engines. This trend highlights the complexity of some K24 engine issues and the value placed on specialized knowledge in this area.

Environmental regulations and fuel efficiency standards have further influenced market demand. As older K24 engines struggle to meet newer emissions requirements, there's an increased need for troubleshooting solutions that can help maintain optimal engine performance and reduce emissions.

The rise of electric and hybrid vehicles has not significantly impacted the demand for K24 engine troubleshooting, as the large existing fleet of K24-equipped vehicles ensures a steady market for years to come. However, it has led to a growing interest in performance upgrades and modifications to extend the lifespan of these engines.

Manufacturers of aftermarket parts and diagnostic equipment have responded to this demand by developing more sophisticated tools and components specifically designed for K24 engines. This includes advanced OBD-II scanners with K24-specific codes, high-quality replacement parts, and performance enhancement products.

The global nature of Honda's vehicle distribution has created a worldwide market for K24 engine troubleshooting solutions. This has led to the development of multilingual resources and region-specific troubleshooting guides to cater to diverse markets.

As the automotive industry continues to evolve, the market for K24 engine troubleshooting is expected to remain robust in the medium term, driven by the engine's reliability, the large number of vehicles in circulation, and the growing trend of vehicle owners seeking to maintain their cars for longer periods.

Common K24 Issues

The K24 engine, renowned for its reliability, still encounters several common issues that owners and mechanics should be aware of. One of the most prevalent problems is oil consumption. Some K24 engines, particularly in earlier models, tend to burn oil at a higher rate than expected. This can lead to decreased engine performance and potential long-term damage if not addressed promptly.

Another frequent issue is the failure of the variable valve timing (VTC) actuator. This component is crucial for optimizing engine performance and fuel efficiency. When it malfunctions, drivers may experience a rattling noise upon startup, reduced power output, and decreased fuel economy. The VTC actuator's failure is often attributed to wear and tear over time or contamination from degraded engine oil.

Timing chain tensioner problems are also common in K24 engines. A worn or faulty tensioner can cause the timing chain to become loose, resulting in a rattling noise from the engine and potential timing issues. In severe cases, this can lead to engine damage if the timing chain skips or breaks.

Many K24 owners report issues with the engine's idle air control valve (IACV). When this valve becomes clogged or fails, it can cause rough idling, stalling, or inconsistent engine performance. Regular cleaning and maintenance of the IACV can help prevent these issues.

Exhaust manifold cracks are another concern for K24 engines, especially in high-mileage vehicles. These cracks can cause exhaust leaks, leading to decreased engine performance, increased emissions, and a distinctive ticking noise from the engine bay.

Some K24 engines also experience problems with their fuel injectors. Clogged or failing injectors can cause misfires, reduced fuel efficiency, and overall poor engine performance. Regular fuel system maintenance and the use of quality fuel can help mitigate these issues.

Lastly, coolant leaks are not uncommon in K24 engines. These leaks can occur from various points, including the radiator, water pump, or coolant passages. If left unaddressed, coolant leaks can lead to overheating and potentially severe engine damage.

Understanding these common issues is crucial for effective troubleshooting and maintenance of K24 engines. Regular inspections, timely repairs, and adherence to recommended maintenance schedules can significantly extend the life and performance of these engines.

Another frequent issue is the failure of the variable valve timing (VTC) actuator. This component is crucial for optimizing engine performance and fuel efficiency. When it malfunctions, drivers may experience a rattling noise upon startup, reduced power output, and decreased fuel economy. The VTC actuator's failure is often attributed to wear and tear over time or contamination from degraded engine oil.

Timing chain tensioner problems are also common in K24 engines. A worn or faulty tensioner can cause the timing chain to become loose, resulting in a rattling noise from the engine and potential timing issues. In severe cases, this can lead to engine damage if the timing chain skips or breaks.

Many K24 owners report issues with the engine's idle air control valve (IACV). When this valve becomes clogged or fails, it can cause rough idling, stalling, or inconsistent engine performance. Regular cleaning and maintenance of the IACV can help prevent these issues.

Exhaust manifold cracks are another concern for K24 engines, especially in high-mileage vehicles. These cracks can cause exhaust leaks, leading to decreased engine performance, increased emissions, and a distinctive ticking noise from the engine bay.

Some K24 engines also experience problems with their fuel injectors. Clogged or failing injectors can cause misfires, reduced fuel efficiency, and overall poor engine performance. Regular fuel system maintenance and the use of quality fuel can help mitigate these issues.

Lastly, coolant leaks are not uncommon in K24 engines. These leaks can occur from various points, including the radiator, water pump, or coolant passages. If left unaddressed, coolant leaks can lead to overheating and potentially severe engine damage.

Understanding these common issues is crucial for effective troubleshooting and maintenance of K24 engines. Regular inspections, timely repairs, and adherence to recommended maintenance schedules can significantly extend the life and performance of these engines.

Troubleshooting Methods

01 Engine design and components

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, fuel efficiency, and overall reliability of the engine.- Engine design and components: The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, fuel efficiency, and overall reliability of the engine.

- Fuel injection and combustion system: The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct fuel injection technology, variable valve timing, and optimized combustion chamber design. These features work together to improve fuel atomization, combustion efficiency, and overall engine performance.

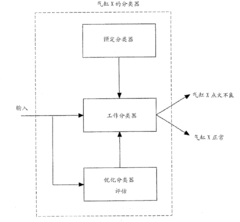

- Engine control and management systems: Advanced engine control and management systems are integrated into the K24 engine. These systems include electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. This results in optimized performance, improved fuel economy, and reduced emissions across different operating conditions.

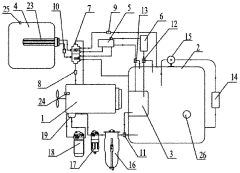

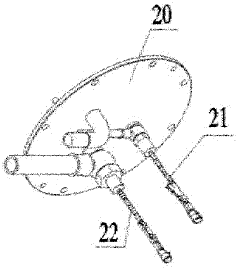

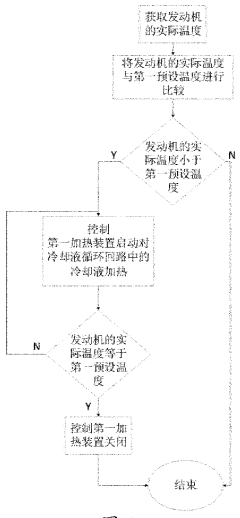

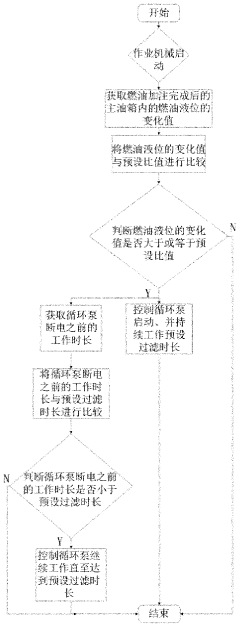

- Engine cooling and lubrication: The K24 engine features efficient cooling and lubrication systems. This includes advanced coolant circulation, oil pump designs, and thermal management strategies. These systems help maintain optimal operating temperatures, reduce friction, and enhance overall engine durability and longevity.

- Engine integration and compatibility: The K24 engine is designed for versatility and compatibility with various vehicle platforms. It can be integrated into different vehicle types, including sedans, SUVs, and performance cars. The engine's compact design and mounting options allow for flexible installation and integration with various transmission systems and vehicle architectures.

02 Fuel injection and combustion system

The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features work together to improve fuel atomization, combustion efficiency, and power output while reducing emissions.Expand Specific Solutions03 Engine control and management

Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. These systems optimize engine performance, fuel economy, and emissions control under different operating conditions.Expand Specific Solutions04 Cooling and lubrication systems

The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow paths, enhanced oil circulation, and advanced thermal management techniques. These systems help maintain optimal engine temperature, reduce friction, and extend engine life.Expand Specific Solutions05 Engine integration and compatibility

The K24 engine is designed for integration into various vehicle platforms and compatibility with different transmission systems. This includes considerations for engine mounting, power transfer, and integration with vehicle electronics. The engine's versatility allows for its use in a wide range of vehicle applications, from compact cars to SUVs.Expand Specific Solutions

Key Manufacturers

The K24 engine troubleshooting market is in a mature stage, with a well-established ecosystem of manufacturers, suppliers, and service providers. The global automotive engine market size is substantial, estimated to be over $200 billion annually. Technologically, K24 engine diagnostics and repair processes are well-developed, with companies like Honda Motor Co., Ltd., the original manufacturer, leading in expertise. Other major players like Toyota Motor Corp., Volkswagen AG, and General Motors contribute to the competitive landscape with their own engine technologies and diagnostic tools. Aftermarket parts and service providers such as Bosch and Cummins Filtration offer additional solutions, while specialized companies like UFI Filters focus on specific components. The market is characterized by ongoing incremental improvements in diagnostic technologies and repair techniques.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to troubleshooting K24 engine problems involves a comprehensive diagnostic system and targeted solutions. They utilize advanced OBD-II (On-Board Diagnostics) systems to quickly identify issues[1]. For common problems like oil consumption, Honda has developed improved piston rings and valve stem seals[2]. To address potential timing chain issues, they've implemented a more robust chain tensioner design[3]. Honda also focuses on preventive measures, recommending regular oil changes every 7,500 miles or 6 months, whichever comes first, to maintain engine health[4]. For vibration issues, they've refined engine mount designs and implemented active engine mounts in some models to reduce NVH (Noise, Vibration, Harshness)[5].

Strengths: Comprehensive diagnostic systems, targeted solutions for common issues, focus on preventive maintenance. Weaknesses: Some earlier K24 models may still experience oil consumption issues, potential for high repair costs for major problems.

Toyota Motor Corp.

Technical Solution: Toyota's strategy for troubleshooting K24 engine problems, while not directly manufacturing K24 engines, can be applied to similar inline-4 engines. They employ a multi-faceted approach including advanced diagnostic tools and preventive maintenance schedules. Toyota's technicians use specialized software to interpret engine data and pinpoint issues accurately[1]. For common problems like excessive oil consumption, Toyota has developed improved piston ring designs and implemented stricter quality control measures[2]. To address potential timing chain wear, they've introduced more durable chain materials and tensioner designs[3]. Toyota also emphasizes the importance of regular maintenance, recommending oil changes every 5,000 miles for conventional oil or 10,000 miles for synthetic oil[4]. For vibration issues, Toyota has implemented advanced engine mount designs and fine-tuned ECU (Engine Control Unit) parameters to optimize engine performance and reduce NVH levels[5].

Strengths: Advanced diagnostic tools, focus on durability and reliability, comprehensive maintenance schedules. Weaknesses: Solutions may not be directly applicable to K24 engines, potential for higher costs due to Toyota-specific parts and labor.

Advanced Diagnostics

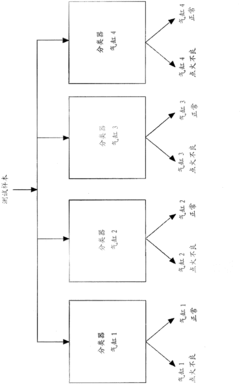

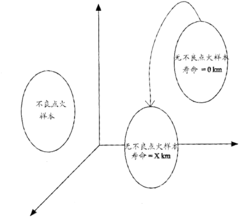

Method for the detection of a component malfunction along the life of an internal combustion engine

PatentInactiveCN102252853A

Innovation

- By defining a predetermined classifier at the beginning of engine life and acquiring signals related to component operation in real time, using the most recent signal recorded by the electronic control unit (ECU) to replace the classifier, taking into account component behavior changes and drift, and using adaptive logic to Adjust classifier parameters to improve detection accuracy.

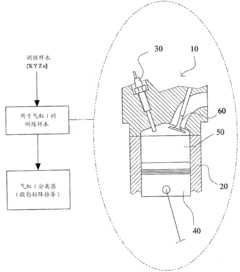

Quick startup system for engine, operation machine, and control method

PatentWO2024001186A1

Innovation

- A quick start system is designed, including a fuel tank, engine, coolant circulation system and heating device. Through the cooperation of temperature detection components and control devices, the heating of coolant and fuel is controlled, the viscosity of the fuel is reduced, and the engine preheating is improved. Efficiency ensures that the engine can start smoothly in low temperature environments.

Maintenance Best Practices

Regular maintenance is crucial for ensuring the longevity and optimal performance of the K24 engine. To effectively troubleshoot common problems, it is essential to adhere to a set of best practices. First and foremost, adhering to the manufacturer's recommended maintenance schedule is paramount. This includes regular oil changes, typically every 5,000 to 7,500 miles, using the specified grade of oil. The oil filter should be replaced simultaneously to ensure proper filtration.

Periodic inspection of the engine's cooling system is vital. This involves checking coolant levels, inspecting hoses for leaks or cracks, and ensuring the radiator is clean and free from debris. The thermostat should be tested for proper operation, as a faulty thermostat can lead to overheating issues. Additionally, the water pump should be inspected for signs of wear or leakage.

The ignition system requires attention to prevent misfires and poor performance. Spark plugs should be replaced according to the manufacturer's recommendations, typically every 30,000 to 100,000 miles, depending on the specific model. The ignition coils and wires should also be inspected for signs of wear or damage.

Maintaining the fuel system is crucial for optimal engine performance. This includes replacing the fuel filter at recommended intervals and using high-quality fuel to prevent deposits and maintain fuel injector efficiency. Periodically cleaning the throttle body and mass airflow sensor can help prevent rough idling and improve overall engine performance.

The timing chain, a critical component of the K24 engine, should be inspected for signs of wear or stretching. While the K24 uses a timing chain rather than a belt, it is not immune to wear over time. Unusual noises from the timing chain area should be investigated promptly to prevent potential engine damage.

Regular inspection of belts and hoses is essential. The serpentine belt should be checked for signs of wear, cracking, or glazing, and replaced as needed. Vacuum hoses should be inspected for cracks or leaks, as these can lead to various engine performance issues.

Lastly, maintaining proper records of all maintenance activities is crucial. This documentation helps track the engine's history, identify recurring issues, and ensure all components are serviced at appropriate intervals. By following these maintenance best practices, many common K24 engine problems can be prevented or detected early, ensuring reliable performance and longevity of the engine.

Periodic inspection of the engine's cooling system is vital. This involves checking coolant levels, inspecting hoses for leaks or cracks, and ensuring the radiator is clean and free from debris. The thermostat should be tested for proper operation, as a faulty thermostat can lead to overheating issues. Additionally, the water pump should be inspected for signs of wear or leakage.

The ignition system requires attention to prevent misfires and poor performance. Spark plugs should be replaced according to the manufacturer's recommendations, typically every 30,000 to 100,000 miles, depending on the specific model. The ignition coils and wires should also be inspected for signs of wear or damage.

Maintaining the fuel system is crucial for optimal engine performance. This includes replacing the fuel filter at recommended intervals and using high-quality fuel to prevent deposits and maintain fuel injector efficiency. Periodically cleaning the throttle body and mass airflow sensor can help prevent rough idling and improve overall engine performance.

The timing chain, a critical component of the K24 engine, should be inspected for signs of wear or stretching. While the K24 uses a timing chain rather than a belt, it is not immune to wear over time. Unusual noises from the timing chain area should be investigated promptly to prevent potential engine damage.

Regular inspection of belts and hoses is essential. The serpentine belt should be checked for signs of wear, cracking, or glazing, and replaced as needed. Vacuum hoses should be inspected for cracks or leaks, as these can lead to various engine performance issues.

Lastly, maintaining proper records of all maintenance activities is crucial. This documentation helps track the engine's history, identify recurring issues, and ensure all components are serviced at appropriate intervals. By following these maintenance best practices, many common K24 engine problems can be prevented or detected early, ensuring reliable performance and longevity of the engine.

Environmental Impact

The environmental impact of troubleshooting K24 engine problems extends beyond the immediate repair process. While addressing these issues is crucial for maintaining vehicle performance and longevity, it's equally important to consider the broader ecological implications.

Fuel efficiency plays a significant role in the environmental footprint of K24 engines. Common problems such as faulty oxygen sensors, clogged fuel injectors, or malfunctioning mass airflow sensors can lead to increased fuel consumption and higher emissions. By promptly diagnosing and resolving these issues, technicians can help reduce unnecessary fuel waste and minimize the vehicle's carbon footprint.

Oil leaks, another frequent concern with K24 engines, pose a direct threat to soil and water ecosystems. When left unaddressed, these leaks can contaminate groundwater and harm local flora and fauna. Proper troubleshooting and timely repairs prevent such environmental hazards, safeguarding natural resources and complying with environmental regulations.

The disposal of replaced parts and fluids during the troubleshooting process also warrants attention. Used oil, coolant, and other chemicals must be handled and recycled responsibly to prevent pollution. Similarly, worn-out components should be properly recycled or disposed of to minimize landfill waste and promote the conservation of raw materials.

Emissions control systems, integral to K24 engines, require regular maintenance and troubleshooting to ensure optimal performance. Malfunctions in components like the catalytic converter or exhaust gas recirculation (EGR) system can lead to increased emissions of harmful pollutants such as nitrogen oxides and carbon monoxide. By accurately diagnosing and rectifying these issues, technicians contribute to improved air quality and reduced environmental impact.

The manufacturing and distribution of replacement parts for K24 engines also carry environmental considerations. Opting for high-quality, durable components during troubleshooting can extend the engine's lifespan and reduce the frequency of replacements, thereby lowering the overall environmental impact associated with part production and transportation.

Lastly, the troubleshooting process itself can be optimized for environmental efficiency. Utilizing diagnostic tools and techniques that minimize unnecessary disassembly and parts replacement not only saves time and resources but also reduces waste generation. Additionally, employing eco-friendly cleaning products and methods during engine inspections further mitigates the environmental impact of maintenance procedures.

Fuel efficiency plays a significant role in the environmental footprint of K24 engines. Common problems such as faulty oxygen sensors, clogged fuel injectors, or malfunctioning mass airflow sensors can lead to increased fuel consumption and higher emissions. By promptly diagnosing and resolving these issues, technicians can help reduce unnecessary fuel waste and minimize the vehicle's carbon footprint.

Oil leaks, another frequent concern with K24 engines, pose a direct threat to soil and water ecosystems. When left unaddressed, these leaks can contaminate groundwater and harm local flora and fauna. Proper troubleshooting and timely repairs prevent such environmental hazards, safeguarding natural resources and complying with environmental regulations.

The disposal of replaced parts and fluids during the troubleshooting process also warrants attention. Used oil, coolant, and other chemicals must be handled and recycled responsibly to prevent pollution. Similarly, worn-out components should be properly recycled or disposed of to minimize landfill waste and promote the conservation of raw materials.

Emissions control systems, integral to K24 engines, require regular maintenance and troubleshooting to ensure optimal performance. Malfunctions in components like the catalytic converter or exhaust gas recirculation (EGR) system can lead to increased emissions of harmful pollutants such as nitrogen oxides and carbon monoxide. By accurately diagnosing and rectifying these issues, technicians contribute to improved air quality and reduced environmental impact.

The manufacturing and distribution of replacement parts for K24 engines also carry environmental considerations. Opting for high-quality, durable components during troubleshooting can extend the engine's lifespan and reduce the frequency of replacements, thereby lowering the overall environmental impact associated with part production and transportation.

Lastly, the troubleshooting process itself can be optimized for environmental efficiency. Utilizing diagnostic tools and techniques that minimize unnecessary disassembly and parts replacement not only saves time and resources but also reduces waste generation. Additionally, employing eco-friendly cleaning products and methods during engine inspections further mitigates the environmental impact of maintenance procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!