Impact of High Altitude on Scramjet Operational Dynamics

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet High Altitude Challenges and Objectives

Scramjet technology has been a focal point in aerospace engineering for decades, with its potential to revolutionize high-speed flight and space access. The development of scramjet engines has progressed significantly, driven by the need for hypersonic vehicles capable of operating at extreme altitudes. This research aims to explore the challenges and objectives associated with scramjet operation at high altitudes, where atmospheric conditions drastically differ from those at sea level.

The primary goal of this investigation is to comprehensively analyze the impact of high-altitude environments on scramjet performance and operational dynamics. By understanding these effects, we can identify critical areas for improvement and innovation in scramjet design and functionality. This research will contribute to the advancement of hypersonic flight capabilities, potentially enabling more efficient and reliable high-altitude and space operations.

One of the key challenges in high-altitude scramjet operation is the reduced air density. As altitude increases, the atmosphere becomes thinner, affecting the engine's ability to capture and compress sufficient air for combustion. This phenomenon necessitates innovative approaches to inlet design and air compression techniques to maintain optimal performance at varying altitudes. Additionally, the lower oxygen concentration at high altitudes poses challenges for fuel combustion efficiency and overall thrust generation.

Another significant objective is to address the thermal management issues associated with high-altitude scramjet operation. At extreme altitudes and hypersonic speeds, aerodynamic heating becomes a critical factor. The research aims to develop advanced materials and cooling systems capable of withstanding the intense heat generated during sustained high-speed flight in the upper atmosphere.

Furthermore, this study will explore the implications of reduced atmospheric pressure on scramjet combustion stability and flame-holding mechanisms. The altered chemical kinetics at high altitudes require a reevaluation of fuel injection strategies and combustor designs to ensure reliable and efficient combustion across a wide range of operational altitudes.

The research also aims to investigate the effects of atmospheric composition variations on scramjet performance. As the vehicle transitions through different layers of the atmosphere, changes in gas composition and temperature gradients can significantly impact engine efficiency and thrust output. Understanding these effects is crucial for developing adaptive control systems and optimizing engine performance throughout the flight envelope.

By addressing these challenges and objectives, this research seeks to push the boundaries of scramjet technology, paving the way for advanced hypersonic vehicles capable of efficient and reliable operation at unprecedented altitudes. The findings will contribute to the broader field of aerospace engineering and have potential applications in both civilian and military sectors.

The primary goal of this investigation is to comprehensively analyze the impact of high-altitude environments on scramjet performance and operational dynamics. By understanding these effects, we can identify critical areas for improvement and innovation in scramjet design and functionality. This research will contribute to the advancement of hypersonic flight capabilities, potentially enabling more efficient and reliable high-altitude and space operations.

One of the key challenges in high-altitude scramjet operation is the reduced air density. As altitude increases, the atmosphere becomes thinner, affecting the engine's ability to capture and compress sufficient air for combustion. This phenomenon necessitates innovative approaches to inlet design and air compression techniques to maintain optimal performance at varying altitudes. Additionally, the lower oxygen concentration at high altitudes poses challenges for fuel combustion efficiency and overall thrust generation.

Another significant objective is to address the thermal management issues associated with high-altitude scramjet operation. At extreme altitudes and hypersonic speeds, aerodynamic heating becomes a critical factor. The research aims to develop advanced materials and cooling systems capable of withstanding the intense heat generated during sustained high-speed flight in the upper atmosphere.

Furthermore, this study will explore the implications of reduced atmospheric pressure on scramjet combustion stability and flame-holding mechanisms. The altered chemical kinetics at high altitudes require a reevaluation of fuel injection strategies and combustor designs to ensure reliable and efficient combustion across a wide range of operational altitudes.

The research also aims to investigate the effects of atmospheric composition variations on scramjet performance. As the vehicle transitions through different layers of the atmosphere, changes in gas composition and temperature gradients can significantly impact engine efficiency and thrust output. Understanding these effects is crucial for developing adaptive control systems and optimizing engine performance throughout the flight envelope.

By addressing these challenges and objectives, this research seeks to push the boundaries of scramjet technology, paving the way for advanced hypersonic vehicles capable of efficient and reliable operation at unprecedented altitudes. The findings will contribute to the broader field of aerospace engineering and have potential applications in both civilian and military sectors.

Market Demand for High Altitude Scramjet Applications

The market demand for high altitude scramjet applications has been steadily growing, driven by both military and commercial interests. In the defense sector, there is a significant push for hypersonic weapons and reconnaissance platforms that can operate at extreme altitudes. These systems offer strategic advantages in terms of speed, maneuverability, and the ability to penetrate sophisticated air defense networks. The global hypersonic weapons market, which heavily relies on scramjet technology, is projected to expand rapidly in the coming years.

Commercial applications for high altitude scramjets are also emerging, particularly in the aerospace industry. There is increasing interest in developing hypersonic passenger aircraft that could drastically reduce intercontinental travel times. While still in the conceptual stage, such aircraft could potentially revolutionize long-distance air travel, creating a new market segment for ultra-fast, high-altitude transportation.

The satellite launch industry represents another significant market for high altitude scramjet technology. Scramjet-powered vehicles could offer more cost-effective and flexible access to space compared to traditional rocket systems. This aligns with the growing demand for small satellite launches and the expansion of satellite-based services across various sectors.

Environmental monitoring and climate research present additional opportunities for high altitude scramjet applications. Platforms equipped with this technology could provide unique capabilities for atmospheric data collection and Earth observation at altitudes that are challenging for conventional aircraft to reach consistently.

Despite the promising market outlook, it's important to note that the demand is currently limited by technological maturity and regulatory hurdles. The complex operational dynamics of scramjets at high altitudes pose significant engineering challenges that need to be overcome before widespread commercial adoption can occur.

The defense sector is likely to remain the primary driver of market demand in the near term, as military applications can justify the high development costs and accept higher levels of operational risk. However, as the technology matures and becomes more reliable, commercial applications are expected to grow, potentially leading to a diverse and expanding market for high altitude scramjet systems.

Commercial applications for high altitude scramjets are also emerging, particularly in the aerospace industry. There is increasing interest in developing hypersonic passenger aircraft that could drastically reduce intercontinental travel times. While still in the conceptual stage, such aircraft could potentially revolutionize long-distance air travel, creating a new market segment for ultra-fast, high-altitude transportation.

The satellite launch industry represents another significant market for high altitude scramjet technology. Scramjet-powered vehicles could offer more cost-effective and flexible access to space compared to traditional rocket systems. This aligns with the growing demand for small satellite launches and the expansion of satellite-based services across various sectors.

Environmental monitoring and climate research present additional opportunities for high altitude scramjet applications. Platforms equipped with this technology could provide unique capabilities for atmospheric data collection and Earth observation at altitudes that are challenging for conventional aircraft to reach consistently.

Despite the promising market outlook, it's important to note that the demand is currently limited by technological maturity and regulatory hurdles. The complex operational dynamics of scramjets at high altitudes pose significant engineering challenges that need to be overcome before widespread commercial adoption can occur.

The defense sector is likely to remain the primary driver of market demand in the near term, as military applications can justify the high development costs and accept higher levels of operational risk. However, as the technology matures and becomes more reliable, commercial applications are expected to grow, potentially leading to a diverse and expanding market for high altitude scramjet systems.

Current State and Limitations of Scramjet Technology at High Altitudes

Scramjet technology has made significant strides in recent years, particularly in the realm of hypersonic flight. However, its operation at high altitudes presents unique challenges that continue to limit its practical applications. Currently, scramjet engines are capable of operating at altitudes ranging from 20 to 50 kilometers, with most research focusing on the 30-40 kilometer range. At these altitudes, the air density is significantly lower than at sea level, which affects the engine's performance and efficiency.

One of the primary limitations of scramjet technology at high altitudes is the reduced air capture. As altitude increases, the air becomes thinner, making it more difficult for the engine to capture sufficient air for combustion. This reduced air capture directly impacts the engine's thrust production and overall performance. Engineers have been working on innovative inlet designs to maximize air capture at high altitudes, but this remains a significant challenge.

Another critical issue is the maintenance of stable combustion at high altitudes. The lower air density and pressure at these altitudes can lead to flame instability and potential flame-out. Researchers are exploring advanced fuel injection systems and combustor designs to ensure reliable ignition and sustained combustion under these challenging conditions. Additionally, the extreme temperatures experienced during hypersonic flight at high altitudes pose material challenges, requiring the development of advanced heat-resistant materials and cooling systems.

The control and stability of scramjet-powered vehicles at high altitudes also present significant technical hurdles. The reduced air density affects aerodynamic control surfaces, making precise maneuvering more challenging. This is particularly critical during the transition from subsonic to hypersonic speeds, where the vehicle must maintain stability while the scramjet engine is engaged.

Furthermore, the current state of scramjet technology is limited by the lack of extensive flight test data at high altitudes. While ground-based testing facilities can simulate some high-altitude conditions, they cannot fully replicate the complex interactions between the vehicle, the atmosphere, and the scramjet engine during actual flight. This gap in real-world data hinders the validation of computational models and the refinement of design parameters for high-altitude operation.

The integration of scramjet propulsion with other systems for sustained high-altitude flight remains a technological challenge. Current scramjet-powered vehicles typically rely on rocket boosters to reach the speeds and altitudes necessary for scramjet operation. Developing a fully integrated system capable of operating from takeoff to high-altitude cruise and back to landing is still a goal that eludes engineers and researchers in the field.

One of the primary limitations of scramjet technology at high altitudes is the reduced air capture. As altitude increases, the air becomes thinner, making it more difficult for the engine to capture sufficient air for combustion. This reduced air capture directly impacts the engine's thrust production and overall performance. Engineers have been working on innovative inlet designs to maximize air capture at high altitudes, but this remains a significant challenge.

Another critical issue is the maintenance of stable combustion at high altitudes. The lower air density and pressure at these altitudes can lead to flame instability and potential flame-out. Researchers are exploring advanced fuel injection systems and combustor designs to ensure reliable ignition and sustained combustion under these challenging conditions. Additionally, the extreme temperatures experienced during hypersonic flight at high altitudes pose material challenges, requiring the development of advanced heat-resistant materials and cooling systems.

The control and stability of scramjet-powered vehicles at high altitudes also present significant technical hurdles. The reduced air density affects aerodynamic control surfaces, making precise maneuvering more challenging. This is particularly critical during the transition from subsonic to hypersonic speeds, where the vehicle must maintain stability while the scramjet engine is engaged.

Furthermore, the current state of scramjet technology is limited by the lack of extensive flight test data at high altitudes. While ground-based testing facilities can simulate some high-altitude conditions, they cannot fully replicate the complex interactions between the vehicle, the atmosphere, and the scramjet engine during actual flight. This gap in real-world data hinders the validation of computational models and the refinement of design parameters for high-altitude operation.

The integration of scramjet propulsion with other systems for sustained high-altitude flight remains a technological challenge. Current scramjet-powered vehicles typically rely on rocket boosters to reach the speeds and altitudes necessary for scramjet operation. Developing a fully integrated system capable of operating from takeoff to high-altitude cruise and back to landing is still a goal that eludes engineers and researchers in the field.

Existing Solutions for High Altitude Scramjet Operation

01 Scramjet engine design and performance optimization

This category focuses on the design and optimization of scramjet engines to improve their operational dynamics. It includes innovations in engine geometry, fuel injection systems, and combustion chamber designs to enhance performance, efficiency, and thrust across various flight regimes. Advanced computational models and experimental techniques are used to analyze and refine scramjet engine components for better overall performance.- Inlet design and flow management: Scramjet operational dynamics heavily rely on efficient inlet design and flow management. This includes optimizing the shape and geometry of the inlet to capture and compress incoming air effectively at hypersonic speeds. Advanced techniques are employed to control shock waves, boundary layers, and ensure proper air compression for combustion.

- Combustion chamber optimization: The combustion chamber is a critical component in scramjet operations. Innovations focus on enhancing fuel injection, mixing, and combustion efficiency at supersonic speeds. This involves developing advanced materials to withstand extreme temperatures and pressures, as well as implementing novel combustion strategies to maintain stable and efficient burning.

- Propulsion system integration: Integrating the scramjet engine with the overall propulsion system is crucial for optimal performance. This includes designing efficient nozzles for thrust generation, managing thermal loads, and incorporating variable geometry components to adapt to changing flight conditions. Advanced control systems are developed to ensure seamless operation across a wide range of speeds and altitudes.

- Fuel management and cooling systems: Effective fuel management and cooling are essential for sustained scramjet operation. This involves developing advanced fuel injection systems, exploring novel cooling techniques such as regenerative cooling or endothermic fuels, and optimizing fuel flow rates to maintain engine performance and structural integrity under extreme conditions.

- Control and stability mechanisms: Maintaining control and stability in scramjet engines is challenging due to the complex flow dynamics at hypersonic speeds. Research focuses on developing advanced sensors, actuators, and control algorithms to manage engine parameters in real-time. This includes techniques for flame holding, shock positioning, and thrust vectoring to ensure stable and efficient operation across various flight regimes.

02 Thermal management and cooling systems

Effective thermal management is crucial for scramjet operational dynamics. This category covers innovative cooling systems and heat dissipation techniques to manage the extreme temperatures encountered during hypersonic flight. It includes advanced materials, regenerative cooling methods, and active thermal control systems to protect engine components and maintain optimal performance under high-temperature conditions.Expand Specific Solutions03 Fuel injection and mixing strategies

This category addresses the critical aspect of fuel injection and mixing in scramjet engines. It covers advanced fuel injection techniques, nozzle designs, and mixing strategies to achieve efficient combustion in supersonic airflow. Innovations in this area aim to improve fuel-air mixing, enhance combustion stability, and optimize fuel utilization across various flight conditions.Expand Specific Solutions04 Inlet and nozzle design for hypersonic flow

The design of inlets and nozzles plays a crucial role in scramjet operational dynamics. This category focuses on innovative inlet configurations and nozzle geometries optimized for hypersonic flow conditions. It includes variable geometry designs, shock wave management techniques, and advanced flow control methods to improve air capture, compression efficiency, and thrust generation across a wide range of flight speeds.Expand Specific Solutions05 Integration of scramjet propulsion with vehicle systems

This category addresses the challenges of integrating scramjet propulsion systems with overall vehicle design. It covers innovations in airframe-integrated scramjets, combined cycle propulsion systems, and adaptive control strategies for seamless operation across different flight regimes. The focus is on optimizing the interaction between the propulsion system and other vehicle components to enhance overall performance and efficiency in hypersonic flight.Expand Specific Solutions

Key Players in Scramjet and Hypersonic Technology

The competition landscape for high altitude scramjet operational dynamics is in a nascent stage, characterized by ongoing research and development efforts. The market size remains limited, primarily driven by government and military investments. Technologically, the field is still evolving, with key players like AVIC Shenyang Engine Research Institute, Harbin Institute of Technology, and Northwestern Polytechnical University leading research in China. In the US, entities such as the Naval Research Laboratory and Aerojet Rocketdyne are at the forefront. The technology's maturity is progressing, but significant challenges remain in achieving stable combustion and efficient propulsion at extreme altitudes.

AVIC Shenyang Engine Research Institute

Technical Solution: AVIC Shenyang Engine Research Institute has focused on developing scramjet technologies optimized for high-altitude operations in the stratosphere. Their approach involves a novel air intake design that efficiently captures and compresses the low-density air at high altitudes[8]. The institute has also developed advanced combustion chamber designs that maintain stable combustion in low-pressure environments[10]. Additionally, they have implemented innovative cooling techniques to manage the extreme temperatures encountered during high-altitude scramjet operation, utilizing a combination of regenerative cooling and advanced thermal barrier coatings[12].

Strengths: Strong expertise in high-altitude engine design, government support for research. Weaknesses: Potential limitations in international collaboration and technology transfer.

Government of the United States of America

Technical Solution: The U.S. government, through agencies like NASA and DARPA, has been at the forefront of scramjet research for high-altitude applications. Their approach involves a comprehensive program that addresses multiple aspects of high-altitude scramjet operations. This includes the development of advanced materials capable of withstanding extreme temperatures and low-density atmospheric conditions[13]. The research also focuses on innovative fuel injection systems that maintain efficient combustion at various altitudes[15]. Additionally, the U.S. government has invested in sophisticated computational fluid dynamics (CFD) models to simulate and optimize scramjet performance across a wide range of altitudes and flight conditions[17].

Strengths: Extensive research funding, access to advanced testing facilities, and collaboration with leading aerospace companies. Weaknesses: Potential bureaucratic hurdles in technology transfer to commercial applications.

Core Innovations in High Altitude Scramjet Dynamics

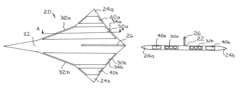

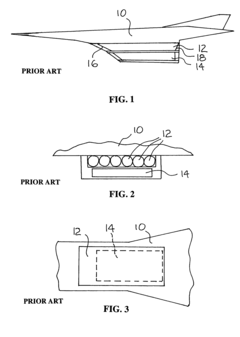

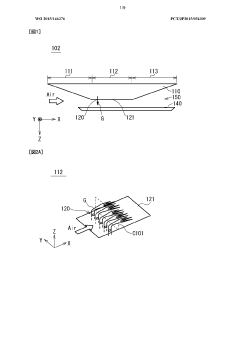

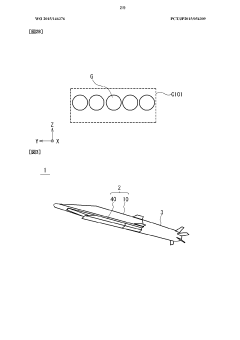

SCRAMjet arrangement for hypersonic aircraft

PatentActiveUS7828243B2

Innovation

- A lateral or side-by-side arrangement of turbojet and SCRAMjet engines, where the turbojet engines' inlet and outlet openings are covered to provide compression and expansion ramps for the SCRAMjet engines, reducing the need for a thick body and minimizing drag.

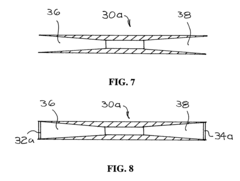

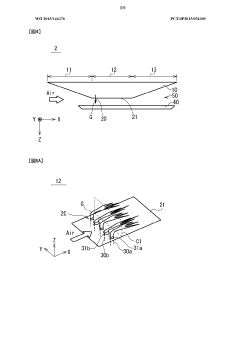

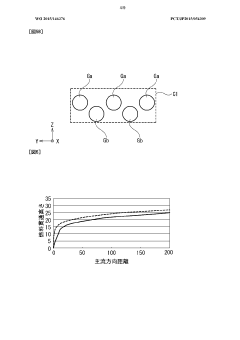

Jet engine, flying body, and method for operating jet engine

PatentWO2015146376A1

Innovation

- The jet engine incorporates a combustor with fuel injectors having multiple openings with different cross-sectional areas arranged perpendicular to the airflow path, allowing for controlled fuel injection and enhanced mixing by varying the penetration height of fuel, thereby reducing uneven distribution and promoting efficient combustion.

Environmental Impact of High Altitude Scramjet Operations

The environmental impact of high altitude scramjet operations is a critical consideration as this technology advances. At altitudes above 30 km, scramjet engines operate in a unique atmospheric environment characterized by extremely low air density and temperature. This operational regime presents both challenges and potential benefits from an environmental perspective.

One of the primary environmental concerns is the emission of nitrogen oxides (NOx) at high altitudes. Scramjet combustion occurs at extremely high temperatures, which can lead to increased NOx formation. These emissions at high altitudes can have a more significant impact on the ozone layer compared to emissions at lower altitudes. However, the overall quantity of emissions from scramjets is expected to be lower than traditional rocket propulsion systems due to their air-breathing nature.

The potential for stratospheric ozone depletion is a key area of focus. While the high-speed, high-altitude flight of scramjets may lead to some localized ozone depletion, the extent of this impact is still under investigation. Some studies suggest that the overall effect on global ozone levels may be minimal due to the limited number of flights and the rapid dispersion of emissions at these altitudes.

Water vapor emissions from scramjet engines at high altitudes present another environmental consideration. In the stratosphere, increased water vapor can lead to the formation of polar stratospheric clouds, which play a role in ozone depletion chemistry. However, the amount of water vapor produced by scramjets is relatively small compared to other sources, and its impact is likely to be localized.

The acoustic impact of scramjet operations at high altitudes is generally less severe than at lower altitudes due to the reduced air density. This results in less noise pollution reaching the ground. However, the potential for sonic booms during transonic flight phases remains a concern for populated areas beneath flight paths.

From a positive environmental perspective, scramjet technology could lead to more efficient high-altitude and high-speed transportation, potentially reducing overall emissions compared to current long-distance flight technologies. The ability to operate at very high altitudes also minimizes interference with conventional air traffic and reduces the impact on lower atmospheric layers.

As scramjet technology continues to develop, ongoing research is crucial to fully understand and mitigate its environmental impacts. This includes detailed atmospheric modeling, in-situ measurements of emissions at operational altitudes, and long-term monitoring of stratospheric composition changes. Balancing the potential benefits of scramjet technology with its environmental implications will be key to its sustainable integration into future aerospace applications.

One of the primary environmental concerns is the emission of nitrogen oxides (NOx) at high altitudes. Scramjet combustion occurs at extremely high temperatures, which can lead to increased NOx formation. These emissions at high altitudes can have a more significant impact on the ozone layer compared to emissions at lower altitudes. However, the overall quantity of emissions from scramjets is expected to be lower than traditional rocket propulsion systems due to their air-breathing nature.

The potential for stratospheric ozone depletion is a key area of focus. While the high-speed, high-altitude flight of scramjets may lead to some localized ozone depletion, the extent of this impact is still under investigation. Some studies suggest that the overall effect on global ozone levels may be minimal due to the limited number of flights and the rapid dispersion of emissions at these altitudes.

Water vapor emissions from scramjet engines at high altitudes present another environmental consideration. In the stratosphere, increased water vapor can lead to the formation of polar stratospheric clouds, which play a role in ozone depletion chemistry. However, the amount of water vapor produced by scramjets is relatively small compared to other sources, and its impact is likely to be localized.

The acoustic impact of scramjet operations at high altitudes is generally less severe than at lower altitudes due to the reduced air density. This results in less noise pollution reaching the ground. However, the potential for sonic booms during transonic flight phases remains a concern for populated areas beneath flight paths.

From a positive environmental perspective, scramjet technology could lead to more efficient high-altitude and high-speed transportation, potentially reducing overall emissions compared to current long-distance flight technologies. The ability to operate at very high altitudes also minimizes interference with conventional air traffic and reduces the impact on lower atmospheric layers.

As scramjet technology continues to develop, ongoing research is crucial to fully understand and mitigate its environmental impacts. This includes detailed atmospheric modeling, in-situ measurements of emissions at operational altitudes, and long-term monitoring of stratospheric composition changes. Balancing the potential benefits of scramjet technology with its environmental implications will be key to its sustainable integration into future aerospace applications.

Materials Science Advancements for Scramjet Technology

The advancement of materials science plays a crucial role in enhancing scramjet technology, particularly in addressing the challenges posed by high-altitude operations. As scramjets operate at extreme speeds and temperatures, the materials used in their construction must withstand severe thermal and mechanical stresses. Recent developments in materials science have focused on improving the performance and durability of scramjet components under these demanding conditions.

One of the key areas of materials science research for scramjets is the development of high-temperature resistant alloys. These alloys are designed to maintain their structural integrity and mechanical properties at the elevated temperatures experienced during hypersonic flight. Nickel-based superalloys and refractory metal alloys, such as those based on niobium and molybdenum, have shown promising results in withstanding temperatures exceeding 2000°C while retaining their strength and resistance to oxidation.

Ceramic matrix composites (CMCs) have emerged as another critical material for scramjet applications. These advanced materials offer excellent thermal resistance, low density, and high strength-to-weight ratios. Silicon carbide (SiC) and carbon fiber-reinforced silicon carbide (C/SiC) composites have demonstrated superior performance in scramjet combustor liners and nozzle components, effectively managing the extreme heat generated during combustion.

Thermal barrier coatings (TBCs) represent a significant advancement in protecting scramjet components from thermal damage. These multi-layer coating systems, typically composed of yttria-stabilized zirconia (YSZ) or other ceramic materials, provide insulation and reduce heat transfer to the underlying metal substrates. Recent research has focused on developing nanostructured TBCs with enhanced durability and thermal cycling resistance, crucial for the repeated heating and cooling cycles experienced by scramjets.

Advancements in additive manufacturing techniques have enabled the production of complex geometries and functionally graded materials tailored for scramjet applications. This technology allows for the creation of components with optimized thermal management properties, such as integrated cooling channels and variable material compositions across the part's cross-section.

The development of ultra-high temperature ceramics (UHTCs) has opened new possibilities for scramjet leading edges and nose cones. Materials such as zirconium diboride (ZrB2) and hafnium diboride (HfB2) exhibit exceptional resistance to oxidation and ablation at temperatures exceeding 2500°C, making them ideal candidates for the most thermally stressed regions of the scramjet.

As research in materials science continues to progress, the focus is shifting towards multi-functional materials that can simultaneously address multiple challenges in scramjet design. These include self-healing materials capable of repairing damage during flight, smart materials that can adapt to changing environmental conditions, and materials with integrated sensors for real-time monitoring of structural health and performance.

One of the key areas of materials science research for scramjets is the development of high-temperature resistant alloys. These alloys are designed to maintain their structural integrity and mechanical properties at the elevated temperatures experienced during hypersonic flight. Nickel-based superalloys and refractory metal alloys, such as those based on niobium and molybdenum, have shown promising results in withstanding temperatures exceeding 2000°C while retaining their strength and resistance to oxidation.

Ceramic matrix composites (CMCs) have emerged as another critical material for scramjet applications. These advanced materials offer excellent thermal resistance, low density, and high strength-to-weight ratios. Silicon carbide (SiC) and carbon fiber-reinforced silicon carbide (C/SiC) composites have demonstrated superior performance in scramjet combustor liners and nozzle components, effectively managing the extreme heat generated during combustion.

Thermal barrier coatings (TBCs) represent a significant advancement in protecting scramjet components from thermal damage. These multi-layer coating systems, typically composed of yttria-stabilized zirconia (YSZ) or other ceramic materials, provide insulation and reduce heat transfer to the underlying metal substrates. Recent research has focused on developing nanostructured TBCs with enhanced durability and thermal cycling resistance, crucial for the repeated heating and cooling cycles experienced by scramjets.

Advancements in additive manufacturing techniques have enabled the production of complex geometries and functionally graded materials tailored for scramjet applications. This technology allows for the creation of components with optimized thermal management properties, such as integrated cooling channels and variable material compositions across the part's cross-section.

The development of ultra-high temperature ceramics (UHTCs) has opened new possibilities for scramjet leading edges and nose cones. Materials such as zirconium diboride (ZrB2) and hafnium diboride (HfB2) exhibit exceptional resistance to oxidation and ablation at temperatures exceeding 2500°C, making them ideal candidates for the most thermally stressed regions of the scramjet.

As research in materials science continues to progress, the focus is shifting towards multi-functional materials that can simultaneously address multiple challenges in scramjet design. These include self-healing materials capable of repairing damage during flight, smart materials that can adapt to changing environmental conditions, and materials with integrated sensors for real-time monitoring of structural health and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!