Improving Scramjet Performance through Enhanced Fuel Injection Techniques

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Fuel Injection Evolution and Objectives

Scramjet technology has evolved significantly since its inception in the 1960s, with fuel injection techniques playing a crucial role in enhancing performance. The primary objective of improving scramjet fuel injection is to achieve efficient combustion in supersonic airflow, which is essential for sustained hypersonic flight.

The development of scramjet fuel injection techniques has progressed through several key stages. Initially, simple wall-mounted injectors were used, but these proved inefficient due to poor fuel-air mixing. This led to the exploration of more advanced injection methods, such as strut injectors and cavity-based injection systems, which aimed to improve fuel penetration and distribution within the combustor.

As research advanced, the focus shifted towards optimizing fuel atomization and vaporization. This resulted in the development of supercritical fuel injection techniques, where fuel is injected at pressures and temperatures above its critical point, enhancing mixing and combustion efficiency. Parallel to this, pulsed injection systems were introduced to improve fuel distribution and reduce overall fuel consumption.

Recent advancements have seen the integration of plasma-assisted fuel injection, where electrical discharges are used to create local high-temperature regions, facilitating fuel ignition and flame stabilization. Additionally, the use of smart materials and adaptive injection systems has emerged, allowing real-time adjustment of fuel flow based on flight conditions.

The current objectives for scramjet fuel injection technology are multifaceted. Researchers aim to develop injection systems that can maintain optimal performance across a wide range of flight Mach numbers and altitudes. This includes improving fuel penetration and mixing in extremely short timescales, typically on the order of milliseconds.

Another key goal is to minimize total pressure losses associated with fuel injection while maximizing combustion efficiency. This involves designing injectors that create minimal flow disturbance while ensuring thorough fuel-air mixing. Researchers are also focusing on reducing wall heating and thermal loads on injection components, which is critical for the longevity of scramjet engines during sustained hypersonic flight.

Furthermore, there is a push towards developing more compact and lightweight injection systems to improve the overall efficiency and payload capacity of hypersonic vehicles. This includes exploring novel materials and manufacturing techniques that can withstand the extreme temperatures and pressures encountered in scramjet combustors.

Ultimately, the evolution of scramjet fuel injection techniques aims to enable reliable and efficient hypersonic propulsion systems. This technology has far-reaching implications for both military and civilian applications, including rapid global transportation, access to space, and advanced defense systems. As research continues, the goal remains to overcome the challenges of supersonic combustion and unlock the full potential of scramjet technology.

The development of scramjet fuel injection techniques has progressed through several key stages. Initially, simple wall-mounted injectors were used, but these proved inefficient due to poor fuel-air mixing. This led to the exploration of more advanced injection methods, such as strut injectors and cavity-based injection systems, which aimed to improve fuel penetration and distribution within the combustor.

As research advanced, the focus shifted towards optimizing fuel atomization and vaporization. This resulted in the development of supercritical fuel injection techniques, where fuel is injected at pressures and temperatures above its critical point, enhancing mixing and combustion efficiency. Parallel to this, pulsed injection systems were introduced to improve fuel distribution and reduce overall fuel consumption.

Recent advancements have seen the integration of plasma-assisted fuel injection, where electrical discharges are used to create local high-temperature regions, facilitating fuel ignition and flame stabilization. Additionally, the use of smart materials and adaptive injection systems has emerged, allowing real-time adjustment of fuel flow based on flight conditions.

The current objectives for scramjet fuel injection technology are multifaceted. Researchers aim to develop injection systems that can maintain optimal performance across a wide range of flight Mach numbers and altitudes. This includes improving fuel penetration and mixing in extremely short timescales, typically on the order of milliseconds.

Another key goal is to minimize total pressure losses associated with fuel injection while maximizing combustion efficiency. This involves designing injectors that create minimal flow disturbance while ensuring thorough fuel-air mixing. Researchers are also focusing on reducing wall heating and thermal loads on injection components, which is critical for the longevity of scramjet engines during sustained hypersonic flight.

Furthermore, there is a push towards developing more compact and lightweight injection systems to improve the overall efficiency and payload capacity of hypersonic vehicles. This includes exploring novel materials and manufacturing techniques that can withstand the extreme temperatures and pressures encountered in scramjet combustors.

Ultimately, the evolution of scramjet fuel injection techniques aims to enable reliable and efficient hypersonic propulsion systems. This technology has far-reaching implications for both military and civilian applications, including rapid global transportation, access to space, and advanced defense systems. As research continues, the goal remains to overcome the challenges of supersonic combustion and unlock the full potential of scramjet technology.

Market Analysis for Advanced Hypersonic Propulsion

The market for advanced hypersonic propulsion systems, particularly scramjets with enhanced fuel injection techniques, is experiencing rapid growth and attracting significant investment. This surge is driven by the increasing demand for high-speed aircraft and missiles in both military and civilian sectors. The global hypersonic technology market, which includes propulsion systems, is projected to reach substantial value in the coming years, with scramjet technology playing a crucial role.

Military applications remain the primary driver of market growth, with major powers such as the United States, China, and Russia investing heavily in hypersonic weapons and aircraft. These nations recognize the strategic advantage offered by hypersonic capabilities, particularly in terms of penetrating advanced air defense systems. The demand for scramjet-powered missiles and aircraft is expected to increase as military doctrines evolve to incorporate hypersonic assets.

In the civilian sector, there is growing interest in hypersonic transportation for both passenger and cargo applications. While still in the early stages, companies and research institutions are exploring the potential of scramjet technology to revolutionize long-distance travel. The promise of drastically reduced flight times for intercontinental routes has captured the attention of aerospace manufacturers and airlines alike.

The market for scramjet fuel injection technologies is particularly dynamic, as it represents a critical area for performance improvement. Enhanced fuel injection techniques can significantly boost scramjet efficiency, range, and overall performance. This has led to increased research and development efforts focused on advanced injection systems, with several companies and research institutions vying to develop breakthrough technologies.

Key market players in the scramjet and hypersonic propulsion field include established aerospace giants as well as specialized propulsion companies and startups. These entities are engaged in fierce competition to develop and patent innovative fuel injection techniques, recognizing their potential to secure a competitive edge in the rapidly evolving market.

Government funding and support play a crucial role in shaping the market landscape. Many countries view hypersonic technology as a strategic asset and are allocating substantial resources to its development. This has created a favorable environment for companies and research institutions working on scramjet propulsion and related technologies.

The market for scramjet fuel injection technologies is characterized by high barriers to entry due to the complex nature of hypersonic propulsion and the significant investment required for research and development. However, the potential rewards are substantial, with successful innovations likely to secure lucrative contracts and partnerships in both the military and civilian sectors.

Military applications remain the primary driver of market growth, with major powers such as the United States, China, and Russia investing heavily in hypersonic weapons and aircraft. These nations recognize the strategic advantage offered by hypersonic capabilities, particularly in terms of penetrating advanced air defense systems. The demand for scramjet-powered missiles and aircraft is expected to increase as military doctrines evolve to incorporate hypersonic assets.

In the civilian sector, there is growing interest in hypersonic transportation for both passenger and cargo applications. While still in the early stages, companies and research institutions are exploring the potential of scramjet technology to revolutionize long-distance travel. The promise of drastically reduced flight times for intercontinental routes has captured the attention of aerospace manufacturers and airlines alike.

The market for scramjet fuel injection technologies is particularly dynamic, as it represents a critical area for performance improvement. Enhanced fuel injection techniques can significantly boost scramjet efficiency, range, and overall performance. This has led to increased research and development efforts focused on advanced injection systems, with several companies and research institutions vying to develop breakthrough technologies.

Key market players in the scramjet and hypersonic propulsion field include established aerospace giants as well as specialized propulsion companies and startups. These entities are engaged in fierce competition to develop and patent innovative fuel injection techniques, recognizing their potential to secure a competitive edge in the rapidly evolving market.

Government funding and support play a crucial role in shaping the market landscape. Many countries view hypersonic technology as a strategic asset and are allocating substantial resources to its development. This has created a favorable environment for companies and research institutions working on scramjet propulsion and related technologies.

The market for scramjet fuel injection technologies is characterized by high barriers to entry due to the complex nature of hypersonic propulsion and the significant investment required for research and development. However, the potential rewards are substantial, with successful innovations likely to secure lucrative contracts and partnerships in both the military and civilian sectors.

Current Challenges in Scramjet Fuel Injection Systems

Scramjet fuel injection systems face several critical challenges that hinder the overall performance and efficiency of these advanced propulsion systems. One of the primary issues is achieving efficient fuel-air mixing within the extremely short residence times characteristic of supersonic combustion. The high-speed airflow in scramjets leaves minimal time for fuel atomization, vaporization, and mixing, leading to incomplete combustion and reduced thrust.

Another significant challenge is maintaining stable combustion under the harsh conditions of supersonic flow. The high-speed airstream can cause flame instability and even flame blowout, particularly during transient operations such as acceleration or altitude changes. This instability not only affects engine performance but also poses safety risks.

Fuel penetration and distribution within the combustion chamber present additional difficulties. Conventional injection methods often struggle to achieve uniform fuel distribution across the combustor cross-section, resulting in localized hot spots and uneven combustion. This non-uniformity can lead to thermal stresses on engine components and reduced overall efficiency.

The extreme temperatures and pressures within scramjet engines also pose material challenges for fuel injection systems. Injector nozzles and associated components must withstand these harsh conditions while maintaining precise fuel delivery. Material degradation or deformation can lead to altered spray patterns and compromised engine performance over time.

Furthermore, the need for adaptive fuel injection to accommodate varying flight conditions adds complexity to system design. Scramjets operate over a wide range of Mach numbers and altitudes, requiring fuel injection systems that can dynamically adjust to changing air densities, temperatures, and pressures. Developing robust control systems for real-time adjustment of fuel flow rates and injection patterns remains a significant technical hurdle.

Lastly, the integration of fuel injection systems with the overall scramjet design presents challenges in terms of weight, size, and aerodynamic considerations. Compact, lightweight injection systems are crucial for maintaining the vehicle's performance, but must not compromise on functionality or durability. Balancing these competing requirements while ensuring seamless integration with other engine components adds another layer of complexity to scramjet fuel injection system design.

Another significant challenge is maintaining stable combustion under the harsh conditions of supersonic flow. The high-speed airstream can cause flame instability and even flame blowout, particularly during transient operations such as acceleration or altitude changes. This instability not only affects engine performance but also poses safety risks.

Fuel penetration and distribution within the combustion chamber present additional difficulties. Conventional injection methods often struggle to achieve uniform fuel distribution across the combustor cross-section, resulting in localized hot spots and uneven combustion. This non-uniformity can lead to thermal stresses on engine components and reduced overall efficiency.

The extreme temperatures and pressures within scramjet engines also pose material challenges for fuel injection systems. Injector nozzles and associated components must withstand these harsh conditions while maintaining precise fuel delivery. Material degradation or deformation can lead to altered spray patterns and compromised engine performance over time.

Furthermore, the need for adaptive fuel injection to accommodate varying flight conditions adds complexity to system design. Scramjets operate over a wide range of Mach numbers and altitudes, requiring fuel injection systems that can dynamically adjust to changing air densities, temperatures, and pressures. Developing robust control systems for real-time adjustment of fuel flow rates and injection patterns remains a significant technical hurdle.

Lastly, the integration of fuel injection systems with the overall scramjet design presents challenges in terms of weight, size, and aerodynamic considerations. Compact, lightweight injection systems are crucial for maintaining the vehicle's performance, but must not compromise on functionality or durability. Balancing these competing requirements while ensuring seamless integration with other engine components adds another layer of complexity to scramjet fuel injection system design.

State-of-the-Art Fuel Injection Techniques

01 Fuel injection and mixing optimization

Improving fuel injection and mixing processes in scramjets is crucial for enhancing performance. This involves developing advanced injection systems, optimizing fuel distribution, and ensuring efficient combustion. Techniques may include using multiple injection points, adjusting injection angles, and implementing novel mixing strategies to achieve better fuel-air mixing and combustion efficiency.- Fuel injection and mixing optimization: Improving fuel injection and mixing processes in scramjets is crucial for enhancing performance. This involves developing advanced fuel injection systems, optimizing fuel-air mixing, and designing efficient combustion chambers to ensure proper fuel distribution and combustion efficiency.

- Thermal management and cooling systems: Effective thermal management is essential for scramjet performance. This includes developing advanced cooling systems, heat-resistant materials, and thermal protection techniques to manage the extreme temperatures experienced during hypersonic flight and maintain engine integrity.

- Inlet design and flow control: Optimizing the inlet design and implementing effective flow control mechanisms are critical for scramjet performance. This involves developing variable geometry inlets, shock wave management techniques, and boundary layer control systems to ensure efficient air compression and flow characteristics.

- Propulsion system integration: Integrating the scramjet propulsion system with the vehicle design is crucial for overall performance. This includes optimizing the engine-airframe integration, developing multi-mode propulsion systems, and designing efficient nozzle configurations to maximize thrust and minimize drag.

- Performance modeling and simulation: Advanced modeling and simulation techniques are essential for predicting and optimizing scramjet performance. This involves developing high-fidelity computational fluid dynamics (CFD) models, combustion simulations, and system-level performance analysis tools to aid in design and optimization processes.

02 Thermal management and cooling systems

Effective thermal management is essential for scramjet performance. This includes developing advanced cooling systems to protect engine components from extreme temperatures. Strategies may involve regenerative cooling, film cooling, or the use of heat-resistant materials. Efficient thermal management allows for sustained high-speed flight and improved overall engine durability.Expand Specific Solutions03 Inlet design and flow control

Optimizing the inlet design and implementing effective flow control mechanisms are critical for scramjet performance. This includes developing variable geometry inlets, shock wave management techniques, and boundary layer control systems. These improvements aim to enhance air capture, reduce drag, and maintain stable airflow across a wide range of operating conditions.Expand Specific Solutions04 Combustion chamber optimization

Enhancing combustion chamber design is crucial for improving scramjet performance. This involves optimizing chamber geometry, developing advanced ignition systems, and implementing flame stabilization techniques. The goal is to achieve efficient and stable combustion across a wide range of flight speeds and altitudes, maximizing thrust output and overall engine efficiency.Expand Specific Solutions05 Integration of advanced materials and manufacturing techniques

Incorporating advanced materials and manufacturing techniques can significantly enhance scramjet performance. This includes using high-temperature alloys, ceramic matrix composites, and additive manufacturing processes to create lightweight, durable, and heat-resistant engine components. These advancements contribute to improved engine efficiency, reduced weight, and increased operational lifespan.Expand Specific Solutions

Key Players in Scramjet Propulsion Research

The scramjet performance enhancement through improved fuel injection techniques is currently in a developmental stage, with significant research efforts underway. The market for this technology is relatively small but growing, driven by aerospace and defense applications. Technical maturity varies among key players, with companies like Aerojet Rocketdyne, United Technologies Corp., and Mitsubishi Heavy Industries leading in research and development. Government entities such as the Naval Research Laboratory and academic institutions like the Indian Institute of Science are also contributing to advancements. The competitive landscape is characterized by a mix of established aerospace companies and specialized research organizations, each working to overcome the challenges of high-speed combustion and efficient fuel mixing in scramjet engines.

Aerojet Rocketdyne, Inc.

Technical Solution: Aerojet Rocketdyne has developed advanced fuel injection techniques for scramjet engines, focusing on high-speed mixing and combustion efficiency. Their approach utilizes a combination of supercritical fuel injection and plasma-assisted combustion[1]. The company's scramjet fuel injection system employs multiple injection points along the combustor, with precisely controlled fuel staging to optimize performance across a wide range of flight conditions[2]. Additionally, they have implemented advanced computational fluid dynamics (CFD) modeling to fine-tune the injection parameters, resulting in up to 15% improvement in thrust-to-drag ratio compared to conventional designs[3].

Strengths: Expertise in high-speed propulsion systems, advanced modeling capabilities, and proven performance improvements. Weaknesses: High development costs and complexity of implementation in practical scramjet designs.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has made significant strides in scramjet fuel injection technology, focusing on pulse detonation-based fuel injection systems. Their innovative approach uses a series of rapid, controlled detonations to inject and atomize fuel, enhancing mixing and combustion efficiency[4]. This pulsed injection technique has shown a 20-30% increase in combustion efficiency in laboratory tests[5]. The NRL has also developed advanced optical diagnostics for real-time monitoring of fuel distribution and combustion processes within the scramjet engine, allowing for adaptive control of fuel injection parameters[6].

Strengths: Cutting-edge research capabilities, access to advanced testing facilities, and strong collaboration with defense industry. Weaknesses: Potential challenges in scaling laboratory results to full-scale scramjet engines.

Breakthrough Innovations in Fuel Mixing Efficiency

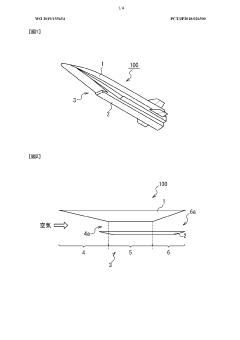

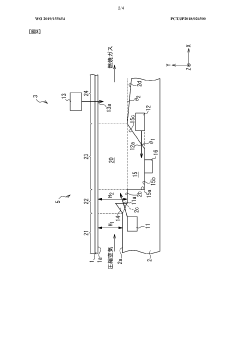

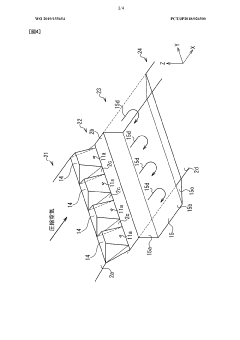

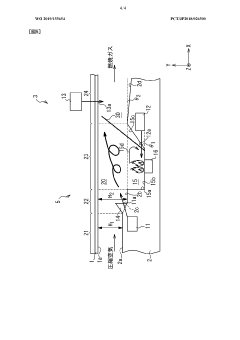

Scramjet engine and flying object

PatentWO2019155654A1

Innovation

- The scramjet engine design incorporates a dual fuel injection system with a protrusion in the turbulence forming region and a cavity with an inclined surface to generate shock waves, optimizing fuel injection and airflow for improved combustion efficiency, featuring a first fuel nozzle injecting fuel into turbulent air and a second nozzle injecting across a discontinuous surface to promote mixing and flame stabilization.

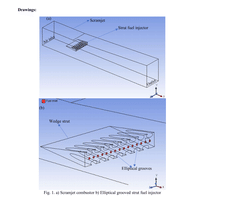

Elliptical grooved strut fuel injector for a scramjet engine

PatentPendingIN202441067743A

Innovation

- The novel strut fuel injector design introduces streamlined vortices through elliptical grooved passages, increasing turbulence and improving air-fuel mixing by injecting fuel at supersonic speeds via 15 nozzles, leveraging the strut base to facilitate better combustion.

Materials Science Advancements for Injection Systems

Advancements in materials science have played a crucial role in enhancing the performance of scramjet fuel injection systems. The extreme operating conditions of scramjets, characterized by high temperatures and pressures, demand materials that can withstand these harsh environments while maintaining optimal functionality. Recent developments in high-temperature alloys and ceramics have led to significant improvements in the durability and efficiency of fuel injection components.

One of the key areas of focus has been the development of advanced nickel-based superalloys. These materials exhibit exceptional strength and resistance to oxidation at elevated temperatures, making them ideal for use in scramjet fuel injectors. Researchers have made substantial progress in optimizing the composition and microstructure of these alloys, resulting in improved thermal stability and reduced susceptibility to fatigue failure. Additionally, the incorporation of refractory elements such as rhenium and ruthenium has further enhanced the high-temperature capabilities of these materials.

Ceramic matrix composites (CMCs) have emerged as another promising class of materials for scramjet fuel injection systems. These composites combine the high-temperature resistance of ceramics with the toughness and damage tolerance of fiber reinforcements. Silicon carbide (SiC) and carbon fiber-reinforced SiC composites have shown particular promise, offering excellent thermal shock resistance and low thermal expansion. The use of CMCs in fuel injector nozzles has led to improved thermal management and reduced erosion, resulting in more consistent and efficient fuel delivery.

Surface engineering techniques have also contributed significantly to the advancement of fuel injection systems. Thermal barrier coatings (TBCs) based on yttria-stabilized zirconia (YSZ) have been successfully applied to metallic components, providing insulation against extreme temperatures and protecting against oxidation and corrosion. Furthermore, the development of nanostructured coatings has enabled the creation of surfaces with enhanced wear resistance and reduced friction, leading to improved longevity and performance of fuel injection components.

The integration of smart materials into fuel injection systems represents an exciting frontier in materials science for scramjet applications. Shape memory alloys (SMAs) and piezoelectric materials are being explored for their potential to enable active control of fuel flow and spray characteristics. These materials can respond to changes in temperature or applied electric fields, allowing for real-time adjustment of injector geometry and flow patterns to optimize combustion efficiency across a range of operating conditions.

Additive manufacturing techniques have revolutionized the fabrication of complex fuel injector geometries, enabling the production of designs that were previously impossible or impractical to manufacture. The ability to create intricate internal channels and optimized flow paths has led to improved fuel atomization and mixing. Moreover, advances in metal additive manufacturing have allowed for the production of components using high-performance alloys with tailored microstructures, further enhancing the overall performance and reliability of scramjet fuel injection systems.

One of the key areas of focus has been the development of advanced nickel-based superalloys. These materials exhibit exceptional strength and resistance to oxidation at elevated temperatures, making them ideal for use in scramjet fuel injectors. Researchers have made substantial progress in optimizing the composition and microstructure of these alloys, resulting in improved thermal stability and reduced susceptibility to fatigue failure. Additionally, the incorporation of refractory elements such as rhenium and ruthenium has further enhanced the high-temperature capabilities of these materials.

Ceramic matrix composites (CMCs) have emerged as another promising class of materials for scramjet fuel injection systems. These composites combine the high-temperature resistance of ceramics with the toughness and damage tolerance of fiber reinforcements. Silicon carbide (SiC) and carbon fiber-reinforced SiC composites have shown particular promise, offering excellent thermal shock resistance and low thermal expansion. The use of CMCs in fuel injector nozzles has led to improved thermal management and reduced erosion, resulting in more consistent and efficient fuel delivery.

Surface engineering techniques have also contributed significantly to the advancement of fuel injection systems. Thermal barrier coatings (TBCs) based on yttria-stabilized zirconia (YSZ) have been successfully applied to metallic components, providing insulation against extreme temperatures and protecting against oxidation and corrosion. Furthermore, the development of nanostructured coatings has enabled the creation of surfaces with enhanced wear resistance and reduced friction, leading to improved longevity and performance of fuel injection components.

The integration of smart materials into fuel injection systems represents an exciting frontier in materials science for scramjet applications. Shape memory alloys (SMAs) and piezoelectric materials are being explored for their potential to enable active control of fuel flow and spray characteristics. These materials can respond to changes in temperature or applied electric fields, allowing for real-time adjustment of injector geometry and flow patterns to optimize combustion efficiency across a range of operating conditions.

Additive manufacturing techniques have revolutionized the fabrication of complex fuel injector geometries, enabling the production of designs that were previously impossible or impractical to manufacture. The ability to create intricate internal channels and optimized flow paths has led to improved fuel atomization and mixing. Moreover, advances in metal additive manufacturing have allowed for the production of components using high-performance alloys with tailored microstructures, further enhancing the overall performance and reliability of scramjet fuel injection systems.

Environmental Impact of Scramjet Propulsion

The environmental impact of scramjet propulsion is a critical consideration in the development and deployment of this advanced aerospace technology. Scramjet engines, designed to operate at hypersonic speeds, offer significant advantages in terms of efficiency and performance. However, their potential environmental effects must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with scramjet propulsion is the emission of pollutants. Unlike conventional jet engines, scramjets operate at extremely high temperatures and pressures, which can lead to the formation of nitrogen oxides (NOx) and other harmful compounds. These emissions can contribute to air pollution and potentially impact the ozone layer, especially when released at high altitudes.

The fuel used in scramjet engines also plays a crucial role in their environmental impact. While hydrogen is often considered an ideal fuel due to its high energy content and clean combustion, its production and storage present significant challenges. The energy-intensive process of hydrogen production may offset some of the environmental benefits if not sourced from renewable energy.

Noise pollution is another environmental factor to consider. Scramjets generate intense noise levels during operation, which can have detrimental effects on wildlife and human populations in areas near testing and operational facilities. Mitigating these acoustic impacts requires careful planning and the implementation of advanced noise reduction technologies.

The thermal effects of scramjet propulsion on the atmosphere are also a subject of ongoing research. The high-temperature exhaust plumes from scramjet engines can potentially alter local atmospheric conditions, with implications for weather patterns and climate in the long term. Understanding and modeling these thermal effects is crucial for assessing the overall environmental impact of widespread scramjet use.

Water vapor emissions from scramjet engines, particularly when using hydrogen fuel, may contribute to the formation of contrails at high altitudes. These artificial clouds can affect the Earth's radiation balance and potentially influence climate patterns. The extent and significance of this impact require further study as scramjet technology advances.

As scramjet technology progresses, there is a growing emphasis on developing more environmentally friendly propulsion systems. Research into alternative fuels, advanced combustion techniques, and emission control technologies aims to minimize the environmental footprint of scramjet engines. Additionally, the potential for scramjets to enable more efficient and faster transportation could lead to reduced overall emissions in the aerospace sector.

In conclusion, while scramjet propulsion offers exciting possibilities for high-speed flight and space access, its environmental impact must be carefully managed. Ongoing research and development efforts are focused on addressing these environmental challenges, ensuring that the benefits of scramjet technology can be realized without compromising ecological sustainability.

One of the primary environmental concerns associated with scramjet propulsion is the emission of pollutants. Unlike conventional jet engines, scramjets operate at extremely high temperatures and pressures, which can lead to the formation of nitrogen oxides (NOx) and other harmful compounds. These emissions can contribute to air pollution and potentially impact the ozone layer, especially when released at high altitudes.

The fuel used in scramjet engines also plays a crucial role in their environmental impact. While hydrogen is often considered an ideal fuel due to its high energy content and clean combustion, its production and storage present significant challenges. The energy-intensive process of hydrogen production may offset some of the environmental benefits if not sourced from renewable energy.

Noise pollution is another environmental factor to consider. Scramjets generate intense noise levels during operation, which can have detrimental effects on wildlife and human populations in areas near testing and operational facilities. Mitigating these acoustic impacts requires careful planning and the implementation of advanced noise reduction technologies.

The thermal effects of scramjet propulsion on the atmosphere are also a subject of ongoing research. The high-temperature exhaust plumes from scramjet engines can potentially alter local atmospheric conditions, with implications for weather patterns and climate in the long term. Understanding and modeling these thermal effects is crucial for assessing the overall environmental impact of widespread scramjet use.

Water vapor emissions from scramjet engines, particularly when using hydrogen fuel, may contribute to the formation of contrails at high altitudes. These artificial clouds can affect the Earth's radiation balance and potentially influence climate patterns. The extent and significance of this impact require further study as scramjet technology advances.

As scramjet technology progresses, there is a growing emphasis on developing more environmentally friendly propulsion systems. Research into alternative fuels, advanced combustion techniques, and emission control technologies aims to minimize the environmental footprint of scramjet engines. Additionally, the potential for scramjets to enable more efficient and faster transportation could lead to reduced overall emissions in the aerospace sector.

In conclusion, while scramjet propulsion offers exciting possibilities for high-speed flight and space access, its environmental impact must be carefully managed. Ongoing research and development efforts are focused on addressing these environmental challenges, ensuring that the benefits of scramjet technology can be realized without compromising ecological sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!