Adaptive Reusable Scramjet Systems for Sustainable Aerospace Endeavors

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Evolution

The evolution of scramjet technology represents a significant milestone in aerospace engineering, marking a paradigm shift in propulsion systems for hypersonic flight. Scramjets, or supersonic combustion ramjets, have undergone a remarkable transformation since their conceptualization in the 1950s. Initially proposed as a theoretical solution to the limitations of traditional jet engines at high Mach numbers, scramjets have progressed from abstract concepts to tangible, flight-tested systems.

The early stages of scramjet development were characterized by fundamental research into supersonic combustion and flow physics. Pioneering work by Antonio Ferri and others in the 1960s laid the groundwork for understanding the complex interactions between shockwaves, boundary layers, and combustion in hypersonic flows. This period saw the emergence of key design principles that would shape future scramjet configurations.

The 1970s and 1980s witnessed a surge in experimental programs, with ground-based testing facilities pushing the boundaries of scramjet technology. Notable achievements included the successful demonstration of sustained supersonic combustion and the development of advanced computational fluid dynamics (CFD) tools for scramjet design. These advancements paved the way for more ambitious flight test programs in the following decades.

The 1990s and early 2000s marked a turning point in scramjet evolution, with several high-profile flight tests demonstrating the feasibility of scramjet-powered flight. The NASA Hyper-X program, culminating in the successful flights of the X-43A vehicle in 2004, achieved Mach 9.6 using a hydrogen-fueled scramjet. This milestone was followed by other significant programs, such as the U.S. Air Force's X-51 WaveRider, which demonstrated sustained scramjet propulsion using hydrocarbon fuel.

Recent years have seen a shift towards more practical applications of scramjet technology, with a focus on reusability and integration into broader aerospace systems. The concept of adaptive, reusable scramjet systems has gained traction, driven by the need for more sustainable and cost-effective hypersonic capabilities. This evolution has been supported by advancements in materials science, enabling the development of thermal protection systems and structures capable of withstanding the extreme conditions of hypersonic flight.

The trajectory of scramjet evolution points towards increasingly sophisticated, multi-cycle propulsion systems that can operate efficiently across a wide range of flight regimes. Ongoing research is exploring variable geometry inlets, advanced fuel injection techniques, and active flow control mechanisms to enhance scramjet performance and adaptability. As the technology matures, the focus is shifting towards integrating scramjets into practical vehicle designs for applications ranging from high-speed military aircraft to reusable space launch systems.

The early stages of scramjet development were characterized by fundamental research into supersonic combustion and flow physics. Pioneering work by Antonio Ferri and others in the 1960s laid the groundwork for understanding the complex interactions between shockwaves, boundary layers, and combustion in hypersonic flows. This period saw the emergence of key design principles that would shape future scramjet configurations.

The 1970s and 1980s witnessed a surge in experimental programs, with ground-based testing facilities pushing the boundaries of scramjet technology. Notable achievements included the successful demonstration of sustained supersonic combustion and the development of advanced computational fluid dynamics (CFD) tools for scramjet design. These advancements paved the way for more ambitious flight test programs in the following decades.

The 1990s and early 2000s marked a turning point in scramjet evolution, with several high-profile flight tests demonstrating the feasibility of scramjet-powered flight. The NASA Hyper-X program, culminating in the successful flights of the X-43A vehicle in 2004, achieved Mach 9.6 using a hydrogen-fueled scramjet. This milestone was followed by other significant programs, such as the U.S. Air Force's X-51 WaveRider, which demonstrated sustained scramjet propulsion using hydrocarbon fuel.

Recent years have seen a shift towards more practical applications of scramjet technology, with a focus on reusability and integration into broader aerospace systems. The concept of adaptive, reusable scramjet systems has gained traction, driven by the need for more sustainable and cost-effective hypersonic capabilities. This evolution has been supported by advancements in materials science, enabling the development of thermal protection systems and structures capable of withstanding the extreme conditions of hypersonic flight.

The trajectory of scramjet evolution points towards increasingly sophisticated, multi-cycle propulsion systems that can operate efficiently across a wide range of flight regimes. Ongoing research is exploring variable geometry inlets, advanced fuel injection techniques, and active flow control mechanisms to enhance scramjet performance and adaptability. As the technology matures, the focus is shifting towards integrating scramjets into practical vehicle designs for applications ranging from high-speed military aircraft to reusable space launch systems.

Aerospace Market Trends

The aerospace market has been experiencing significant growth and transformation in recent years, driven by technological advancements, increasing demand for air travel, and the emergence of new space exploration initiatives. The global aerospace market size was valued at $298 billion in 2020 and is projected to reach $430 billion by 2025, growing at a CAGR of 7.7% during the forecast period.

Commercial aviation remains the largest segment of the aerospace market, accounting for approximately 60% of the total market share. The demand for new aircraft is primarily driven by the replacement of aging fleets and the expansion of air travel in emerging markets. Despite the temporary setback caused by the COVID-19 pandemic, long-term projections indicate a steady recovery and growth in air passenger traffic.

The space sector is experiencing a renaissance, with increased investment from both government agencies and private companies. The global space economy is expected to grow from $350 billion in 2020 to over $1 trillion by 2040. This growth is fueled by the commercialization of space activities, including satellite launches, space tourism, and plans for lunar and Mars exploration.

Defense aerospace is another crucial segment, with governments worldwide increasing their defense budgets in response to evolving geopolitical tensions. The global defense aerospace market is projected to grow at a CAGR of 3.5% from 2021 to 2026, reaching a value of $260 billion by the end of the forecast period.

Emerging trends in the aerospace market include the development of electric and hybrid-electric propulsion systems, the integration of artificial intelligence and autonomous technologies, and the increasing focus on sustainable aviation. The push for more environmentally friendly aircraft has led to significant investments in research and development of alternative fuels and more efficient propulsion systems.

The unmanned aerial vehicle (UAV) market is experiencing rapid growth, with applications expanding beyond military use to include commercial and civilian sectors. The global UAV market is expected to reach $58.4 billion by 2026, growing at a CAGR of 16.4% from 2021 to 2026.

In the context of scramjet technology, there is growing interest in hypersonic flight capabilities for both military and civilian applications. The global hypersonic technology market is projected to grow from $4.98 billion in 2020 to $12.18 billion by 2025, at a CAGR of 19.6%. This growth is driven by increasing investments in hypersonic weapons development and the potential for hypersonic passenger aircraft in the future.

Commercial aviation remains the largest segment of the aerospace market, accounting for approximately 60% of the total market share. The demand for new aircraft is primarily driven by the replacement of aging fleets and the expansion of air travel in emerging markets. Despite the temporary setback caused by the COVID-19 pandemic, long-term projections indicate a steady recovery and growth in air passenger traffic.

The space sector is experiencing a renaissance, with increased investment from both government agencies and private companies. The global space economy is expected to grow from $350 billion in 2020 to over $1 trillion by 2040. This growth is fueled by the commercialization of space activities, including satellite launches, space tourism, and plans for lunar and Mars exploration.

Defense aerospace is another crucial segment, with governments worldwide increasing their defense budgets in response to evolving geopolitical tensions. The global defense aerospace market is projected to grow at a CAGR of 3.5% from 2021 to 2026, reaching a value of $260 billion by the end of the forecast period.

Emerging trends in the aerospace market include the development of electric and hybrid-electric propulsion systems, the integration of artificial intelligence and autonomous technologies, and the increasing focus on sustainable aviation. The push for more environmentally friendly aircraft has led to significant investments in research and development of alternative fuels and more efficient propulsion systems.

The unmanned aerial vehicle (UAV) market is experiencing rapid growth, with applications expanding beyond military use to include commercial and civilian sectors. The global UAV market is expected to reach $58.4 billion by 2026, growing at a CAGR of 16.4% from 2021 to 2026.

In the context of scramjet technology, there is growing interest in hypersonic flight capabilities for both military and civilian applications. The global hypersonic technology market is projected to grow from $4.98 billion in 2020 to $12.18 billion by 2025, at a CAGR of 19.6%. This growth is driven by increasing investments in hypersonic weapons development and the potential for hypersonic passenger aircraft in the future.

Scramjet Tech Challenges

Scramjet technology, while promising for hypersonic flight, faces numerous technical challenges that hinder its widespread adoption and operational efficiency. One of the primary obstacles is the management of extreme temperatures generated during hypersonic flight. The intense heat produced by air friction and combustion can cause structural damage and compromise the integrity of the engine components, necessitating advanced materials and cooling systems.

Another significant challenge lies in achieving efficient combustion at hypersonic speeds. The extremely short residence time of air in the combustion chamber makes it difficult to achieve complete fuel-air mixing and combustion. This issue is further compounded by the need for precise fuel injection and ignition timing to maintain stable combustion across a wide range of flight conditions.

The control and stability of scramjet engines present additional hurdles. As the vehicle transitions from subsonic to hypersonic speeds, maintaining stable airflow and combustion becomes increasingly complex. Engineers must develop sophisticated control systems to manage thrust, fuel flow, and vehicle attitude throughout the flight envelope.

Fuel selection and storage pose unique challenges for scramjet systems. Conventional hydrocarbon fuels may not provide sufficient cooling capacity or energy density for sustained hypersonic flight. Alternative fuels, such as hydrogen, offer higher energy content but present storage and handling difficulties due to their cryogenic nature.

The integration of scramjet engines with airframe designs introduces aerodynamic challenges. The engine inlet must efficiently capture and compress incoming air while minimizing drag. Simultaneously, the vehicle's shape must be optimized to manage shock waves and thermal loads associated with hypersonic flight.

Reusability and sustainability aspects of scramjet systems present their own set of challenges. Developing materials and structures that can withstand repeated exposure to extreme temperatures and stresses while maintaining performance is crucial for cost-effective operations. Additionally, ensuring reliable engine restart capabilities and managing thermal cycling effects are essential for multi-mission scenarios.

Lastly, the development of accurate simulation and testing methodologies for scramjet systems remains an ongoing challenge. The extreme conditions encountered in hypersonic flight are difficult to replicate in ground-based facilities, necessitating advanced computational models and innovative testing approaches to validate designs and predict performance.

Another significant challenge lies in achieving efficient combustion at hypersonic speeds. The extremely short residence time of air in the combustion chamber makes it difficult to achieve complete fuel-air mixing and combustion. This issue is further compounded by the need for precise fuel injection and ignition timing to maintain stable combustion across a wide range of flight conditions.

The control and stability of scramjet engines present additional hurdles. As the vehicle transitions from subsonic to hypersonic speeds, maintaining stable airflow and combustion becomes increasingly complex. Engineers must develop sophisticated control systems to manage thrust, fuel flow, and vehicle attitude throughout the flight envelope.

Fuel selection and storage pose unique challenges for scramjet systems. Conventional hydrocarbon fuels may not provide sufficient cooling capacity or energy density for sustained hypersonic flight. Alternative fuels, such as hydrogen, offer higher energy content but present storage and handling difficulties due to their cryogenic nature.

The integration of scramjet engines with airframe designs introduces aerodynamic challenges. The engine inlet must efficiently capture and compress incoming air while minimizing drag. Simultaneously, the vehicle's shape must be optimized to manage shock waves and thermal loads associated with hypersonic flight.

Reusability and sustainability aspects of scramjet systems present their own set of challenges. Developing materials and structures that can withstand repeated exposure to extreme temperatures and stresses while maintaining performance is crucial for cost-effective operations. Additionally, ensuring reliable engine restart capabilities and managing thermal cycling effects are essential for multi-mission scenarios.

Lastly, the development of accurate simulation and testing methodologies for scramjet systems remains an ongoing challenge. The extreme conditions encountered in hypersonic flight are difficult to replicate in ground-based facilities, necessitating advanced computational models and innovative testing approaches to validate designs and predict performance.

Current Scramjet Design

01 Adaptive propulsion systems for scramjet engines

Adaptive propulsion systems for scramjet engines incorporate adjustable components to optimize performance across various flight conditions. These systems can modify inlet geometry, fuel injection, and combustion parameters to maintain efficiency and thrust at different speeds and altitudes. The adaptability allows for improved fuel efficiency and extended operational range.- Adaptive propulsion systems for scramjet engines: Scramjet engines can be designed with adaptive propulsion systems that adjust to varying flight conditions. These systems may include variable geometry inlets, adjustable fuel injection, and adaptive cooling mechanisms to optimize performance across a wide range of speeds and altitudes. This adaptability enhances the engine's efficiency and operational range.

- Reusable thermal management systems: Reusable thermal management systems are crucial for scramjet engines to withstand extreme temperatures during multiple missions. These systems may incorporate advanced materials, regenerative cooling techniques, and heat exchangers to protect critical components and maintain optimal operating temperatures. The reusability of these systems contributes to the overall cost-effectiveness of scramjet-powered vehicles.

- Modular design for enhanced reusability: Scramjet systems can be designed with a modular approach, allowing for easy replacement and maintenance of individual components. This modular design enhances reusability by facilitating quick turnaround times between missions and reducing overall maintenance costs. It also allows for easier upgrades and modifications to improve performance over time.

- Adaptive control systems for scramjet operation: Advanced control systems are essential for managing the complex operations of scramjet engines across various flight regimes. These adaptive control systems use real-time data and predictive algorithms to optimize engine performance, fuel efficiency, and stability. They can adjust parameters such as fuel flow, combustion timing, and nozzle geometry to maintain optimal thrust and efficiency throughout the flight envelope.

- Integration of scramjet systems with reusable launch vehicles: Scramjet engines can be integrated into reusable launch vehicles to enable efficient and cost-effective access to space. This integration involves designing adaptable interfaces between the scramjet system and the vehicle structure, as well as developing operational procedures for multiple launches and recoveries. The combination of scramjet propulsion with reusable vehicle designs has the potential to revolutionize space transportation.

02 Reusable thermal management systems for scramjets

Reusable thermal management systems are crucial for scramjet engines to withstand extreme temperatures during hypersonic flight. These systems employ advanced materials, cooling techniques, and heat-resistant coatings to protect critical components. The reusability aspect focuses on designing components that can endure multiple flight cycles without significant degradation.Expand Specific Solutions03 Modular design for scramjet engine components

Modular design approaches for scramjet engines enhance adaptability and reusability. By creating interchangeable components, maintenance and upgrades become more efficient. This design philosophy allows for easier replacement of worn parts and integration of new technologies without redesigning the entire engine system.Expand Specific Solutions04 Advanced control systems for scramjet operation

Advanced control systems are developed to manage the complex operations of scramjet engines. These systems utilize real-time data processing, adaptive algorithms, and predictive modeling to optimize engine performance. They enable rapid adjustments to changing flight conditions and ensure stable combustion across a wide range of speeds.Expand Specific Solutions05 Innovative fuel management for scramjet reusability

Innovative fuel management techniques are employed to enhance the reusability of scramjet engines. These include advanced fuel injection systems, multi-mode combustion capabilities, and intelligent fuel distribution. Such innovations allow for efficient operation across various flight regimes and extend the operational lifespan of the engine.Expand Specific Solutions

Scramjet Industry Players

The research on adaptive reusable scramjet systems for sustainable aerospace endeavors is in an early developmental stage, with significant potential for growth. The market size is expanding as governments and private companies invest in hypersonic technologies. While the technology is not yet fully mature, several key players are making advancements. Universities like Harbin Institute of Technology, Northwestern Polytechnical University, and Nanjing University of Aeronautics & Astronautics are conducting foundational research. Companies such as Boeing, Northrop Grumman, and ArianeGroup are developing practical applications. Government agencies like NASA and the US Department of Defense are also heavily involved, driving innovation and funding research initiatives.

The Boeing Co.

Technical Solution: Boeing's approach to adaptive reusable scramjet systems involves the development of the X-51A WaveRider in collaboration with the U.S. Air Force. Their design incorporates a hydrocarbon-fueled scramjet engine with a waverider-shaped vehicle to maximize lift and propulsion efficiency[4]. Boeing is also exploring novel thermal management systems, including regenerative cooling and heat pipes, to address the extreme temperatures encountered during hypersonic flight. Additionally, they are investigating adaptive control systems that can optimize engine performance across a wide range of flight conditions[5].

Strengths: Strong integration capabilities and experience with military aerospace projects. Weaknesses: Limited commercial applications for scramjet technology in the near term.

ArianeGroup SAS

Technical Solution: ArianeGroup's research on adaptive reusable scramjet systems is part of their broader efforts in developing next-generation space transportation systems. They are focusing on the integration of scramjet technology with reusable launch vehicles to reduce the cost of access to space. ArianeGroup is exploring the use of hydrogen fuel for scramjet propulsion, which offers higher specific impulse compared to hydrocarbon fuels[8]. Their research also includes the development of advanced thermal protection systems and lightweight structural materials to enhance vehicle reusability. Additionally, ArianeGroup is investigating adaptive nozzle designs that can optimize thrust across a wide range of altitudes and flight speeds[9].

Strengths: Extensive experience in space launch systems and cryogenic propulsion. Weaknesses: Limited experience with air-breathing hypersonic propulsion compared to some competitors.

Key Scramjet Patents

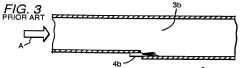

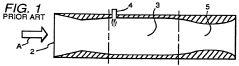

Step cylinder combustor design

PatentInactiveUS3864907A

Innovation

- A combustor chamber design with multiple stabilizing steps followed by constant area cylindrical sections allows for selective heat addition, avoiding divergent flow issues and enabling greater heat and energy input through progressively increasing diameter chambers.

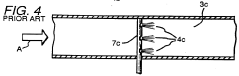

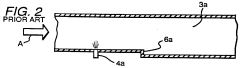

Apparatus for supersonic combustion in a restricted length

PatentInactiveUS5253474A

Innovation

- A supersonic combustor design featuring a backward-facing step with a forward-facing ramp and axial or normal fuel injection, where the ramp converges into the combustion cavity to ensure fuel penetration and mixing, and optionally spanwise channels to enhance shear mixing, allowing for rapid combustion within a distance of one foot or less.

Sustainable Aerospace

Sustainable aerospace has emerged as a critical focus in the aviation and space industry, driven by the urgent need to address environmental concerns and ensure long-term viability of space exploration and air travel. This paradigm shift encompasses a wide range of initiatives aimed at reducing the ecological footprint of aerospace activities while enhancing their economic and operational efficiency.

At the forefront of sustainable aerospace efforts is the development of advanced propulsion systems, particularly adaptive reusable scramjet technologies. These systems offer the potential for significant improvements in fuel efficiency, reduced emissions, and increased operational flexibility across a variety of aerospace applications. By enabling vehicles to operate efficiently at hypersonic speeds in the atmosphere, scramjets could revolutionize both commercial air travel and space access.

The pursuit of sustainable aerospace also extends to the materials and manufacturing processes used in aircraft and spacecraft construction. Advanced composites, bio-inspired materials, and additive manufacturing techniques are being explored to create lighter, stronger, and more environmentally friendly aerospace structures. These innovations not only reduce fuel consumption but also enhance the overall performance and longevity of aerospace vehicles.

Another key aspect of sustainable aerospace is the development of green propellants and alternative energy sources. Research into hydrogen fuel cells, electric propulsion systems, and sustainable aviation fuels derived from renewable sources is gaining momentum. These technologies promise to dramatically reduce greenhouse gas emissions and dependence on fossil fuels in the aerospace sector.

Space debris mitigation and management have also become crucial components of sustainable aerospace practices. As the number of satellites and space missions increases, so does the risk of collisions and the generation of orbital debris. Innovative solutions, such as active debris removal technologies and improved space traffic management systems, are being developed to ensure the long-term sustainability of space activities.

Furthermore, sustainable aerospace encompasses the concept of circular economy principles applied to the industry. This includes designing aircraft and spacecraft for easier disassembly and recycling, as well as developing more efficient maintenance and repair processes to extend the operational life of aerospace assets. By minimizing waste and maximizing resource utilization, the industry aims to reduce its environmental impact while improving economic sustainability.

At the forefront of sustainable aerospace efforts is the development of advanced propulsion systems, particularly adaptive reusable scramjet technologies. These systems offer the potential for significant improvements in fuel efficiency, reduced emissions, and increased operational flexibility across a variety of aerospace applications. By enabling vehicles to operate efficiently at hypersonic speeds in the atmosphere, scramjets could revolutionize both commercial air travel and space access.

The pursuit of sustainable aerospace also extends to the materials and manufacturing processes used in aircraft and spacecraft construction. Advanced composites, bio-inspired materials, and additive manufacturing techniques are being explored to create lighter, stronger, and more environmentally friendly aerospace structures. These innovations not only reduce fuel consumption but also enhance the overall performance and longevity of aerospace vehicles.

Another key aspect of sustainable aerospace is the development of green propellants and alternative energy sources. Research into hydrogen fuel cells, electric propulsion systems, and sustainable aviation fuels derived from renewable sources is gaining momentum. These technologies promise to dramatically reduce greenhouse gas emissions and dependence on fossil fuels in the aerospace sector.

Space debris mitigation and management have also become crucial components of sustainable aerospace practices. As the number of satellites and space missions increases, so does the risk of collisions and the generation of orbital debris. Innovative solutions, such as active debris removal technologies and improved space traffic management systems, are being developed to ensure the long-term sustainability of space activities.

Furthermore, sustainable aerospace encompasses the concept of circular economy principles applied to the industry. This includes designing aircraft and spacecraft for easier disassembly and recycling, as well as developing more efficient maintenance and repair processes to extend the operational life of aerospace assets. By minimizing waste and maximizing resource utilization, the industry aims to reduce its environmental impact while improving economic sustainability.

Materials Innovations

Materials innovations play a crucial role in the development of adaptive reusable scramjet systems for sustainable aerospace endeavors. The extreme operating conditions of scramjet engines demand materials that can withstand high temperatures, intense pressures, and severe oxidation. Recent advancements in material science have led to significant breakthroughs in this field.

One of the key areas of focus is the development of ultra-high temperature ceramics (UHTCs). These materials, including zirconium diboride (ZrB2) and hafnium diboride (HfB2), exhibit exceptional thermal stability and oxidation resistance at temperatures exceeding 2000°C. Researchers are exploring various composite formulations and manufacturing techniques to enhance the mechanical properties and thermal shock resistance of UHTCs, making them ideal candidates for scramjet combustion chamber linings and leading edges.

Another promising avenue is the advancement of ceramic matrix composites (CMCs). These materials combine the high-temperature capabilities of ceramics with the toughness and damage tolerance of composite structures. Silicon carbide (SiC) fiber-reinforced SiC matrix composites have shown remarkable performance in scramjet applications, offering improved durability and reduced weight compared to traditional metallic components.

Thermal barrier coatings (TBCs) have also seen significant progress in recent years. Novel multilayer coating systems, incorporating yttria-stabilized zirconia (YSZ) and rare-earth zirconates, provide enhanced thermal insulation and erosion resistance. These coatings are essential for protecting the underlying structural materials from the extreme heat generated during scramjet operation.

Advancements in additive manufacturing techniques have opened up new possibilities for creating complex geometries and functionally graded materials tailored for scramjet applications. This technology allows for the fabrication of intricate cooling channels and optimized structural designs that were previously impossible to manufacture using traditional methods.

Nanomaterials and nanocomposites are emerging as potential game-changers in scramjet material development. Carbon nanotubes and graphene-reinforced materials show promise in enhancing the strength, thermal conductivity, and oxidation resistance of existing aerospace alloys. These nanoscale additives can potentially lead to significant weight reductions while maintaining or improving overall performance.

The integration of smart materials and self-healing systems is another area of active research. Shape memory alloys and piezoelectric materials are being investigated for their potential to create adaptive structures that can respond to changing flight conditions. Additionally, self-healing polymers and ceramics are being developed to extend the operational life of scramjet components by autonomously repairing minor damage during flight.

One of the key areas of focus is the development of ultra-high temperature ceramics (UHTCs). These materials, including zirconium diboride (ZrB2) and hafnium diboride (HfB2), exhibit exceptional thermal stability and oxidation resistance at temperatures exceeding 2000°C. Researchers are exploring various composite formulations and manufacturing techniques to enhance the mechanical properties and thermal shock resistance of UHTCs, making them ideal candidates for scramjet combustion chamber linings and leading edges.

Another promising avenue is the advancement of ceramic matrix composites (CMCs). These materials combine the high-temperature capabilities of ceramics with the toughness and damage tolerance of composite structures. Silicon carbide (SiC) fiber-reinforced SiC matrix composites have shown remarkable performance in scramjet applications, offering improved durability and reduced weight compared to traditional metallic components.

Thermal barrier coatings (TBCs) have also seen significant progress in recent years. Novel multilayer coating systems, incorporating yttria-stabilized zirconia (YSZ) and rare-earth zirconates, provide enhanced thermal insulation and erosion resistance. These coatings are essential for protecting the underlying structural materials from the extreme heat generated during scramjet operation.

Advancements in additive manufacturing techniques have opened up new possibilities for creating complex geometries and functionally graded materials tailored for scramjet applications. This technology allows for the fabrication of intricate cooling channels and optimized structural designs that were previously impossible to manufacture using traditional methods.

Nanomaterials and nanocomposites are emerging as potential game-changers in scramjet material development. Carbon nanotubes and graphene-reinforced materials show promise in enhancing the strength, thermal conductivity, and oxidation resistance of existing aerospace alloys. These nanoscale additives can potentially lead to significant weight reductions while maintaining or improving overall performance.

The integration of smart materials and self-healing systems is another area of active research. Shape memory alloys and piezoelectric materials are being investigated for their potential to create adaptive structures that can respond to changing flight conditions. Additionally, self-healing polymers and ceramics are being developed to extend the operational life of scramjet components by autonomously repairing minor damage during flight.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!