Hybrid Technologies Leveraging Scramjets for Ultra-Long-Range Travel

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Evolution

The evolution of scramjet technology has been a journey of continuous innovation and engineering breakthroughs. Scramjets, or supersonic combustion ramjets, have their roots in the mid-20th century, with theoretical concepts emerging in the 1950s. However, practical development didn't gain significant momentum until the late 1980s and early 1990s.

The initial phase of scramjet development focused on understanding the fundamental principles of supersonic combustion and overcoming the challenges of maintaining stable combustion at hypersonic speeds. Early experiments were primarily conducted in ground-based facilities, simulating the extreme conditions these engines would face in flight.

A major milestone in scramjet evolution came with NASA's Hyper-X program in the early 2000s. The X-43A vehicle achieved the first successful scramjet-powered flight in 2004, reaching speeds of Mach 9.6. This breakthrough demonstrated the viability of scramjet propulsion and paved the way for further advancements.

Following the success of the X-43A, various nations and organizations intensified their scramjet research efforts. The U.S. Air Force's X-51 Waverider program, initiated in the mid-2000s, aimed to develop a more practical scramjet design. In 2013, the X-51A achieved sustained scramjet-powered flight for over three minutes, reaching Mach 5.1.

Parallel to these developments, other countries, including Russia, China, and India, have been actively pursuing scramjet technology. These efforts have led to diverse approaches in engine design, fuel systems, and materials science, contributing to the overall evolution of scramjet capabilities.

Recent years have seen a shift towards more practical applications of scramjet technology. Research has increasingly focused on integrating scramjets into viable aircraft designs, addressing challenges such as thermal management, fuel efficiency, and operational reliability. The concept of combined cycle engines, which incorporate scramjet technology alongside traditional jet engines, has gained traction as a potential solution for ultra-long-range travel.

As we look towards the future, the evolution of scramjet technology is likely to continue along several key trajectories. These include improving combustion efficiency at higher Mach numbers, developing more robust materials capable of withstanding extreme temperatures, and refining control systems for stable flight across a wide range of speeds. Additionally, there is growing interest in exploring alternative fuels and propulsion concepts that could further enhance the performance and practicality of scramjet-powered vehicles.

The initial phase of scramjet development focused on understanding the fundamental principles of supersonic combustion and overcoming the challenges of maintaining stable combustion at hypersonic speeds. Early experiments were primarily conducted in ground-based facilities, simulating the extreme conditions these engines would face in flight.

A major milestone in scramjet evolution came with NASA's Hyper-X program in the early 2000s. The X-43A vehicle achieved the first successful scramjet-powered flight in 2004, reaching speeds of Mach 9.6. This breakthrough demonstrated the viability of scramjet propulsion and paved the way for further advancements.

Following the success of the X-43A, various nations and organizations intensified their scramjet research efforts. The U.S. Air Force's X-51 Waverider program, initiated in the mid-2000s, aimed to develop a more practical scramjet design. In 2013, the X-51A achieved sustained scramjet-powered flight for over three minutes, reaching Mach 5.1.

Parallel to these developments, other countries, including Russia, China, and India, have been actively pursuing scramjet technology. These efforts have led to diverse approaches in engine design, fuel systems, and materials science, contributing to the overall evolution of scramjet capabilities.

Recent years have seen a shift towards more practical applications of scramjet technology. Research has increasingly focused on integrating scramjets into viable aircraft designs, addressing challenges such as thermal management, fuel efficiency, and operational reliability. The concept of combined cycle engines, which incorporate scramjet technology alongside traditional jet engines, has gained traction as a potential solution for ultra-long-range travel.

As we look towards the future, the evolution of scramjet technology is likely to continue along several key trajectories. These include improving combustion efficiency at higher Mach numbers, developing more robust materials capable of withstanding extreme temperatures, and refining control systems for stable flight across a wide range of speeds. Additionally, there is growing interest in exploring alternative fuels and propulsion concepts that could further enhance the performance and practicality of scramjet-powered vehicles.

Ultra-Long-Range Market

The ultra-long-range travel market is experiencing significant growth and transformation, driven by increasing global connectivity and the demand for faster, more efficient transportation options. This market segment primarily caters to intercontinental flights and missions that require covering vast distances without refueling stops. The potential applications span both civilian and military sectors, including commercial aviation, space exploration, and strategic defense operations.

In the commercial aviation sector, there is a growing demand for non-stop flights connecting distant city pairs. Airlines are constantly seeking ways to extend the range of their aircraft to offer more direct routes, reduce travel times, and improve fuel efficiency. This trend is particularly evident in the development of ultra-long-range aircraft like the Airbus A350 ULR and Boeing 777X, which can fly distances exceeding 15,000 kilometers.

The space exploration industry also presents significant opportunities for ultra-long-range technologies. As space agencies and private companies set their sights on missions to Mars and beyond, the need for propulsion systems capable of sustaining extended journeys becomes critical. The development of advanced propulsion technologies, including those leveraging scramjet engines, could revolutionize interplanetary travel and open up new possibilities for deep space exploration.

Military applications form another crucial segment of the ultra-long-range market. Strategic bombers, reconnaissance aircraft, and unmanned aerial vehicles (UAVs) require the ability to cover vast distances quickly and efficiently. The development of hypersonic vehicles utilizing scramjet technology could provide a significant advantage in terms of speed, range, and operational flexibility.

The market for ultra-long-range travel is closely tied to advancements in propulsion technologies, materials science, and aerodynamics. Scramjet engines, in particular, hold great promise for achieving hypersonic speeds and extending the range of aircraft and spacecraft. The integration of these engines into hybrid propulsion systems could potentially bridge the gap between conventional jet engines and rocket propulsion, offering a more versatile solution for ultra-long-range applications.

As environmental concerns gain prominence, the ultra-long-range market is also focusing on developing more sustainable solutions. This includes research into alternative fuels, such as hydrogen and biofuels, as well as the optimization of flight paths and operational procedures to reduce emissions and improve overall efficiency.

The economic impact of ultra-long-range travel technologies is substantial, with potential benefits extending beyond the aerospace industry. Improved global connectivity could facilitate international trade, tourism, and cultural exchange, while advancements in propulsion technologies could have spillover effects in other sectors, such as energy production and materials manufacturing.

In the commercial aviation sector, there is a growing demand for non-stop flights connecting distant city pairs. Airlines are constantly seeking ways to extend the range of their aircraft to offer more direct routes, reduce travel times, and improve fuel efficiency. This trend is particularly evident in the development of ultra-long-range aircraft like the Airbus A350 ULR and Boeing 777X, which can fly distances exceeding 15,000 kilometers.

The space exploration industry also presents significant opportunities for ultra-long-range technologies. As space agencies and private companies set their sights on missions to Mars and beyond, the need for propulsion systems capable of sustaining extended journeys becomes critical. The development of advanced propulsion technologies, including those leveraging scramjet engines, could revolutionize interplanetary travel and open up new possibilities for deep space exploration.

Military applications form another crucial segment of the ultra-long-range market. Strategic bombers, reconnaissance aircraft, and unmanned aerial vehicles (UAVs) require the ability to cover vast distances quickly and efficiently. The development of hypersonic vehicles utilizing scramjet technology could provide a significant advantage in terms of speed, range, and operational flexibility.

The market for ultra-long-range travel is closely tied to advancements in propulsion technologies, materials science, and aerodynamics. Scramjet engines, in particular, hold great promise for achieving hypersonic speeds and extending the range of aircraft and spacecraft. The integration of these engines into hybrid propulsion systems could potentially bridge the gap between conventional jet engines and rocket propulsion, offering a more versatile solution for ultra-long-range applications.

As environmental concerns gain prominence, the ultra-long-range market is also focusing on developing more sustainable solutions. This includes research into alternative fuels, such as hydrogen and biofuels, as well as the optimization of flight paths and operational procedures to reduce emissions and improve overall efficiency.

The economic impact of ultra-long-range travel technologies is substantial, with potential benefits extending beyond the aerospace industry. Improved global connectivity could facilitate international trade, tourism, and cultural exchange, while advancements in propulsion technologies could have spillover effects in other sectors, such as energy production and materials manufacturing.

Scramjet Challenges

Scramjet technology, while promising for ultra-long-range travel, faces several significant challenges that hinder its widespread adoption and practical implementation. One of the primary obstacles is the extreme heat generated during hypersonic flight. At speeds exceeding Mach 5, the air friction causes temperatures to soar, potentially reaching several thousand degrees Celsius. This intense heat can compromise the structural integrity of the vehicle and its components, necessitating advanced materials and cooling systems that are yet to be fully developed.

Another major challenge lies in the precise control of airflow and combustion within the scramjet engine. Unlike traditional jet engines, scramjets rely on the compression of incoming air at hypersonic speeds, which must be carefully managed to achieve efficient combustion. The slightest miscalculation in this process can lead to engine flameout or inefficient fuel consumption, severely impacting the vehicle's performance and range.

Fuel efficiency and management present additional hurdles. Scramjets require specialized fuels that can ignite and burn efficiently at hypersonic speeds. Developing and storing these fuels, as well as designing systems for their controlled injection and combustion, remain areas of ongoing research and development. The need for large fuel reserves to achieve ultra-long-range travel further complicates the design and weight considerations of scramjet-powered vehicles.

The integration of scramjet technology with conventional propulsion systems for takeoff and landing poses another significant challenge. Scramjets only function effectively at hypersonic speeds, necessitating alternative propulsion methods for low-speed operations. This hybrid approach adds complexity to the vehicle design and increases the overall weight, potentially limiting payload capacity and range.

Navigation and control systems for hypersonic flight represent yet another area of difficulty. The extreme speeds involved require ultra-fast reaction times and precise adjustments, pushing the limits of current avionics and control technologies. Additionally, the ionized plasma that forms around the vehicle at hypersonic speeds can interfere with communication and navigation systems, requiring innovative solutions to maintain reliable connectivity and positioning.

Environmental and regulatory concerns also present challenges to scramjet development. The potential impact of frequent hypersonic flights on the upper atmosphere and ozone layer is not yet fully understood, raising questions about the long-term sustainability of this technology. Moreover, the regulatory framework for hypersonic civilian travel is still in its infancy, necessitating the development of new safety standards and operational protocols.

Another major challenge lies in the precise control of airflow and combustion within the scramjet engine. Unlike traditional jet engines, scramjets rely on the compression of incoming air at hypersonic speeds, which must be carefully managed to achieve efficient combustion. The slightest miscalculation in this process can lead to engine flameout or inefficient fuel consumption, severely impacting the vehicle's performance and range.

Fuel efficiency and management present additional hurdles. Scramjets require specialized fuels that can ignite and burn efficiently at hypersonic speeds. Developing and storing these fuels, as well as designing systems for their controlled injection and combustion, remain areas of ongoing research and development. The need for large fuel reserves to achieve ultra-long-range travel further complicates the design and weight considerations of scramjet-powered vehicles.

The integration of scramjet technology with conventional propulsion systems for takeoff and landing poses another significant challenge. Scramjets only function effectively at hypersonic speeds, necessitating alternative propulsion methods for low-speed operations. This hybrid approach adds complexity to the vehicle design and increases the overall weight, potentially limiting payload capacity and range.

Navigation and control systems for hypersonic flight represent yet another area of difficulty. The extreme speeds involved require ultra-fast reaction times and precise adjustments, pushing the limits of current avionics and control technologies. Additionally, the ionized plasma that forms around the vehicle at hypersonic speeds can interfere with communication and navigation systems, requiring innovative solutions to maintain reliable connectivity and positioning.

Environmental and regulatory concerns also present challenges to scramjet development. The potential impact of frequent hypersonic flights on the upper atmosphere and ozone layer is not yet fully understood, raising questions about the long-term sustainability of this technology. Moreover, the regulatory framework for hypersonic civilian travel is still in its infancy, necessitating the development of new safety standards and operational protocols.

Hybrid Propulsion Systems

01 Scramjet propulsion system integration

Integration of scramjet engines with hybrid propulsion systems to extend the operational range of aerospace vehicles. This approach combines the high-speed capabilities of scramjets with other propulsion technologies for improved performance across various flight regimes.- Scramjet propulsion system integration: Hybrid technologies are being developed to integrate scramjet propulsion systems with conventional engines, enhancing the range and performance of aerospace vehicles. These systems combine the high-speed capabilities of scramjets with the versatility of traditional propulsion methods, allowing for efficient operation across a wide range of flight regimes.

- Advanced materials for scramjet components: Research is focused on developing advanced materials capable of withstanding the extreme temperatures and pressures encountered in scramjet engines. These materials improve the durability and efficiency of critical components, thereby extending the operational range of scramjet-powered vehicles.

- Fuel management and injection systems: Innovative fuel management and injection systems are being designed to optimize combustion efficiency in scramjet engines. These systems aim to improve fuel distribution and mixing, leading to enhanced performance and increased range for scramjet-powered vehicles.

- Thermal management and cooling technologies: Advanced thermal management and cooling technologies are being developed to address the intense heat generated during scramjet operation. These innovations help maintain optimal engine performance and protect critical components, thereby extending the operational range of scramjet-powered vehicles.

- Control systems and flight dynamics: Sophisticated control systems and flight dynamics models are being created to manage the complex behavior of scramjet-powered vehicles across various flight regimes. These systems enhance stability, maneuverability, and overall performance, contributing to increased range and operational capabilities.

02 Advanced fuel management for scramjet-based hybrids

Development of sophisticated fuel management systems tailored for hybrid scramjet technologies. These systems optimize fuel consumption and distribution, enhancing the overall efficiency and range of scramjet-powered vehicles.Expand Specific Solutions03 Thermal management in hybrid scramjet systems

Implementation of innovative thermal management solutions to address the extreme heat generated by scramjet engines in hybrid configurations. These technologies aim to improve system durability and maintain optimal performance over extended operational ranges.Expand Specific Solutions04 Control systems for hybrid scramjet vehicles

Development of advanced control systems specifically designed for hybrid vehicles incorporating scramjet technology. These systems manage the transition between different propulsion modes and optimize vehicle performance across various flight phases to maximize range.Expand Specific Solutions05 Materials and structures for extended scramjet range

Utilization of advanced materials and structural designs to enhance the durability and efficiency of hybrid scramjet vehicles. These innovations focus on reducing weight, improving heat resistance, and optimizing aerodynamics to extend operational range.Expand Specific Solutions

Aerospace Leaders

The research on hybrid technologies leveraging scramjets for ultra-long-range travel is in an early developmental stage, with significant potential for growth. The market size is currently limited but expected to expand as the technology matures. Major players in this field include established aerospace companies like Boeing, Lockheed Martin, and Northrop Grumman, as well as research institutions such as NASA and universities like MIT. These organizations are investing heavily in R&D to overcome technical challenges and improve scramjet efficiency. While the technology is not yet commercially viable, progress is being made in areas such as hypersonic propulsion and thermal management, indicating a gradual increase in technological readiness level.

National University of Defense Technology

Technical Solution: The National University of Defense Technology (NUDT) has been at the forefront of scramjet research for ultra-long-range travel. Their approach focuses on developing a combined cycle engine that integrates scramjet technology with traditional turbine engines. This hybrid system allows for efficient operation across a wide range of speeds, from takeoff to hypersonic flight[1]. NUDT's research includes advanced computational fluid dynamics simulations to optimize scramjet combustion efficiency and thermal management systems to handle the extreme temperatures encountered during hypersonic flight[3]. They have also made significant progress in materials science, developing heat-resistant alloys and ceramic composites capable of withstanding the harsh conditions of scramjet operation[5].

Strengths: Strong expertise in military aerospace applications, access to advanced research facilities, and integration of multidisciplinary technologies. Weaknesses: Potential limitations in international collaboration due to defense-related nature of the institution.

The Boeing Co.

Technical Solution: Boeing's approach to scramjet technology for ultra-long-range travel involves the development of the X-51 Waverider, an unmanned research scramjet aircraft. The company's strategy focuses on a hydrocarbon-fueled scramjet engine, which offers practical advantages for potential commercial applications[2]. Boeing's design incorporates an innovative thermal protection system to manage the extreme heat generated during hypersonic flight. The X-51 program has achieved sustained scramjet-powered hypersonic flight, reaching speeds of Mach 5.1 for over three minutes[4]. Boeing is also exploring the integration of scramjet technology with conventional jet engines for a more versatile aircraft capable of operating across a wide range of speeds[6].

Strengths: Extensive experience in aerospace engineering, proven track record in hypersonic flight testing, and strong industry partnerships. Weaknesses: High development costs and regulatory challenges for commercial implementation of scramjet technology.

Scramjet Innovations

Ramjet engine combustion chamber and ramjet engine equipped with same

PatentInactiveUS7000398B2

Innovation

- A ramjet design featuring an elongate body with a combustion chamber having an inner skin made of porous thermostructural composite, allowing fuel to flow through an intermediate space for cooling and participating in combustion, reducing friction drag and eliminating the need for machining ducts, while the outer skin is also made of thermostructural composite for enhanced thermal resistance and sealing.

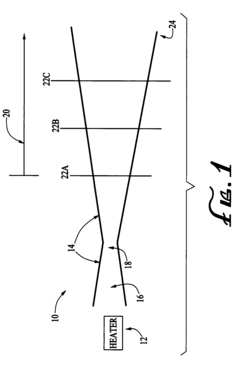

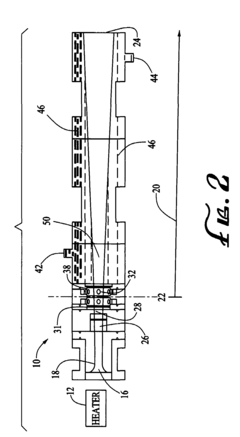

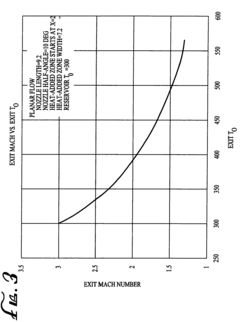

Method for using variable supersonic Mach number air heater utilizing supersonic combustion

PatentInactiveUS7296396B1

Innovation

- A supersonic combustion heater apparatus that varies exit plane Mach numbers through strategic fuel injection and flame stabilization in a fixed geometry nozzle, enhancing high enthalpy flow and flame stability without using expensive film cooled nozzles, allowing for mode transition testing in air-breathing propulsion systems.

Materials Research

Materials research plays a crucial role in the development of hybrid technologies leveraging scramjets for ultra-long-range travel. The extreme conditions encountered during hypersonic flight demand materials with exceptional properties to withstand high temperatures, thermal stresses, and oxidation.

Advanced ceramics and ceramic matrix composites (CMCs) are at the forefront of materials research for scramjet applications. These materials offer excellent high-temperature strength, thermal shock resistance, and oxidation resistance. Silicon carbide (SiC) and carbon fiber-reinforced silicon carbide (C/SiC) composites have shown promising results in scramjet combustor liners and leading edges.

Refractory metal alloys, such as niobium, molybdenum, and tungsten-based alloys, are being investigated for their potential use in scramjet components exposed to extreme temperatures. These materials exhibit high melting points and good strength retention at elevated temperatures. However, challenges remain in improving their oxidation resistance and manufacturability.

Ultra-high temperature ceramics (UHTCs), including zirconium diboride (ZrB2) and hafnium diboride (HfB2), are being explored for use in critical scramjet components. These materials offer exceptional thermal and chemical stability at temperatures exceeding 2000°C, making them suitable for leading edges and thermal protection systems.

Thermal barrier coatings (TBCs) are essential for protecting underlying structural materials from extreme heat. Research is focused on developing advanced TBCs with improved durability and thermal insulation properties. Yttria-stabilized zirconia (YSZ) remains a widely used TBC material, but new compositions and multilayer systems are being investigated to enhance performance.

Functionally graded materials (FGMs) are gaining attention for their ability to combine the properties of different materials in a single component. This approach allows for optimized thermal management and stress distribution in scramjet structures. Research is ongoing to develop FGMs that seamlessly transition from heat-resistant ceramics to tough structural alloys.

Additive manufacturing techniques are revolutionizing the fabrication of complex scramjet components. Research is focused on developing new materials and processes for 3D printing of high-temperature alloys, ceramics, and composites. This enables the creation of intricate cooling channels and optimized structures that were previously impossible to manufacture.

In conclusion, materials research for scramjet-based hybrid technologies is a multifaceted endeavor, encompassing a wide range of advanced materials and manufacturing processes. The development of these materials is crucial for realizing the full potential of scramjet propulsion in ultra-long-range travel applications.

Advanced ceramics and ceramic matrix composites (CMCs) are at the forefront of materials research for scramjet applications. These materials offer excellent high-temperature strength, thermal shock resistance, and oxidation resistance. Silicon carbide (SiC) and carbon fiber-reinforced silicon carbide (C/SiC) composites have shown promising results in scramjet combustor liners and leading edges.

Refractory metal alloys, such as niobium, molybdenum, and tungsten-based alloys, are being investigated for their potential use in scramjet components exposed to extreme temperatures. These materials exhibit high melting points and good strength retention at elevated temperatures. However, challenges remain in improving their oxidation resistance and manufacturability.

Ultra-high temperature ceramics (UHTCs), including zirconium diboride (ZrB2) and hafnium diboride (HfB2), are being explored for use in critical scramjet components. These materials offer exceptional thermal and chemical stability at temperatures exceeding 2000°C, making them suitable for leading edges and thermal protection systems.

Thermal barrier coatings (TBCs) are essential for protecting underlying structural materials from extreme heat. Research is focused on developing advanced TBCs with improved durability and thermal insulation properties. Yttria-stabilized zirconia (YSZ) remains a widely used TBC material, but new compositions and multilayer systems are being investigated to enhance performance.

Functionally graded materials (FGMs) are gaining attention for their ability to combine the properties of different materials in a single component. This approach allows for optimized thermal management and stress distribution in scramjet structures. Research is ongoing to develop FGMs that seamlessly transition from heat-resistant ceramics to tough structural alloys.

Additive manufacturing techniques are revolutionizing the fabrication of complex scramjet components. Research is focused on developing new materials and processes for 3D printing of high-temperature alloys, ceramics, and composites. This enables the creation of intricate cooling channels and optimized structures that were previously impossible to manufacture.

In conclusion, materials research for scramjet-based hybrid technologies is a multifaceted endeavor, encompassing a wide range of advanced materials and manufacturing processes. The development of these materials is crucial for realizing the full potential of scramjet propulsion in ultra-long-range travel applications.

Environmental Impact

The environmental impact of hybrid technologies leveraging scramjets for ultra-long-range travel is a critical consideration in the development and implementation of these advanced propulsion systems. As these technologies push the boundaries of high-speed travel, their potential effects on the environment must be carefully assessed and mitigated.

One of the primary environmental concerns associated with scramjet-powered vehicles is the emission of pollutants at high altitudes. Unlike conventional aircraft that operate in the lower troposphere, scramjet-powered vehicles typically fly in the stratosphere, where emissions can have more significant and longer-lasting effects on atmospheric chemistry. The high temperatures and pressures involved in scramjet combustion may lead to the formation of nitrogen oxides (NOx), which can contribute to ozone depletion and climate change.

Water vapor emissions from scramjet engines present another environmental challenge. At high altitudes, water vapor can form contrails and cirrus clouds, potentially altering the Earth's radiation balance and contributing to global warming. The extent of this impact depends on various factors, including flight frequency, altitude, and atmospheric conditions.

Noise pollution is also a significant concern, particularly during takeoff and landing phases. The extreme speeds and powerful propulsion systems of scramjet-powered vehicles can generate intense sonic booms, which may have detrimental effects on wildlife and human populations in affected areas. Mitigating these acoustic impacts will be crucial for the widespread adoption of this technology.

The production and use of specialized fuels for scramjet engines may have additional environmental implications. These fuels often require energy-intensive manufacturing processes and may involve the use of rare or environmentally sensitive materials. The lifecycle environmental impact of fuel production, transportation, and storage must be carefully evaluated and optimized.

On the positive side, the high efficiency of scramjet propulsion at hypersonic speeds could potentially reduce overall fuel consumption and emissions per passenger-mile traveled compared to conventional long-haul flights. This efficiency gain could lead to a net reduction in greenhouse gas emissions for ultra-long-range travel, provided that the technology is widely adopted and replaces less efficient modes of transportation.

The development of scramjet technology may also drive advancements in materials science and engineering that could have broader environmental benefits. For instance, research into heat-resistant materials and efficient combustion processes could lead to improvements in other industries, potentially reducing energy consumption and emissions across various sectors.

As research in this field progresses, it is essential to conduct comprehensive environmental impact assessments and life cycle analyses to fully understand and address the potential ecological consequences of widespread scramjet adoption. This proactive approach will be crucial in ensuring that the benefits of ultra-long-range travel are realized without compromising environmental sustainability.

One of the primary environmental concerns associated with scramjet-powered vehicles is the emission of pollutants at high altitudes. Unlike conventional aircraft that operate in the lower troposphere, scramjet-powered vehicles typically fly in the stratosphere, where emissions can have more significant and longer-lasting effects on atmospheric chemistry. The high temperatures and pressures involved in scramjet combustion may lead to the formation of nitrogen oxides (NOx), which can contribute to ozone depletion and climate change.

Water vapor emissions from scramjet engines present another environmental challenge. At high altitudes, water vapor can form contrails and cirrus clouds, potentially altering the Earth's radiation balance and contributing to global warming. The extent of this impact depends on various factors, including flight frequency, altitude, and atmospheric conditions.

Noise pollution is also a significant concern, particularly during takeoff and landing phases. The extreme speeds and powerful propulsion systems of scramjet-powered vehicles can generate intense sonic booms, which may have detrimental effects on wildlife and human populations in affected areas. Mitigating these acoustic impacts will be crucial for the widespread adoption of this technology.

The production and use of specialized fuels for scramjet engines may have additional environmental implications. These fuels often require energy-intensive manufacturing processes and may involve the use of rare or environmentally sensitive materials. The lifecycle environmental impact of fuel production, transportation, and storage must be carefully evaluated and optimized.

On the positive side, the high efficiency of scramjet propulsion at hypersonic speeds could potentially reduce overall fuel consumption and emissions per passenger-mile traveled compared to conventional long-haul flights. This efficiency gain could lead to a net reduction in greenhouse gas emissions for ultra-long-range travel, provided that the technology is widely adopted and replaces less efficient modes of transportation.

The development of scramjet technology may also drive advancements in materials science and engineering that could have broader environmental benefits. For instance, research into heat-resistant materials and efficient combustion processes could lead to improvements in other industries, potentially reducing energy consumption and emissions across various sectors.

As research in this field progresses, it is essential to conduct comprehensive environmental impact assessments and life cycle analyses to fully understand and address the potential ecological consequences of widespread scramjet adoption. This proactive approach will be crucial in ensuring that the benefits of ultra-long-range travel are realized without compromising environmental sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!