Dual-Use Scramjet Engines for Advanced Military Applications

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Tech Evolution

The evolution of scramjet technology has been marked by significant milestones and breakthroughs over the past several decades. Initially conceived in the 1950s, scramjet engines represented a revolutionary concept in propulsion systems, promising hypersonic flight capabilities for both civilian and military applications.

In the 1960s and 1970s, theoretical groundwork was laid for scramjet propulsion, with researchers focusing on understanding the complexities of supersonic combustion and airflow dynamics. This period saw the development of fundamental principles that would guide future experimental work.

The 1980s witnessed a surge in practical experimentation, with countries like the United States and Soviet Union investing heavily in scramjet research. Notable programs such as the National Aerospace Plane (NASP) in the US aimed to develop a single-stage-to-orbit vehicle using scramjet technology, although it was ultimately cancelled due to technical challenges and budget constraints.

The 1990s and early 2000s marked a period of significant progress in ground testing facilities and computational modeling. Advanced wind tunnels capable of simulating hypersonic conditions were constructed, allowing for more accurate testing of scramjet designs. Concurrently, improvements in computational fluid dynamics (CFD) enabled more sophisticated simulations of scramjet performance.

A major milestone was achieved in 2004 with NASA's X-43A demonstrator, which achieved sustained scramjet-powered flight at Mach 9.6, proving the viability of the technology. This success spurred further research and development efforts worldwide.

In the following years, focus shifted towards practical applications and integration of scramjet technology into weapon systems and potential civilian aircraft. The US Air Force's X-51 Waverider program, which conducted successful test flights between 2010 and 2013, demonstrated the potential for long-duration hypersonic flight using scramjet propulsion.

Recent developments have seen an increased emphasis on dual-use applications, with military interests driving much of the research. Countries like China, Russia, and India have also made significant strides in scramjet technology, conducting successful flight tests and expanding the global knowledge base.

The current frontier of scramjet evolution involves addressing key challenges such as thermal management, fuel efficiency, and operational reliability. Researchers are exploring advanced materials capable of withstanding extreme temperatures, innovative cooling systems, and more efficient combustion processes to enhance scramjet performance and durability.

In the 1960s and 1970s, theoretical groundwork was laid for scramjet propulsion, with researchers focusing on understanding the complexities of supersonic combustion and airflow dynamics. This period saw the development of fundamental principles that would guide future experimental work.

The 1980s witnessed a surge in practical experimentation, with countries like the United States and Soviet Union investing heavily in scramjet research. Notable programs such as the National Aerospace Plane (NASP) in the US aimed to develop a single-stage-to-orbit vehicle using scramjet technology, although it was ultimately cancelled due to technical challenges and budget constraints.

The 1990s and early 2000s marked a period of significant progress in ground testing facilities and computational modeling. Advanced wind tunnels capable of simulating hypersonic conditions were constructed, allowing for more accurate testing of scramjet designs. Concurrently, improvements in computational fluid dynamics (CFD) enabled more sophisticated simulations of scramjet performance.

A major milestone was achieved in 2004 with NASA's X-43A demonstrator, which achieved sustained scramjet-powered flight at Mach 9.6, proving the viability of the technology. This success spurred further research and development efforts worldwide.

In the following years, focus shifted towards practical applications and integration of scramjet technology into weapon systems and potential civilian aircraft. The US Air Force's X-51 Waverider program, which conducted successful test flights between 2010 and 2013, demonstrated the potential for long-duration hypersonic flight using scramjet propulsion.

Recent developments have seen an increased emphasis on dual-use applications, with military interests driving much of the research. Countries like China, Russia, and India have also made significant strides in scramjet technology, conducting successful flight tests and expanding the global knowledge base.

The current frontier of scramjet evolution involves addressing key challenges such as thermal management, fuel efficiency, and operational reliability. Researchers are exploring advanced materials capable of withstanding extreme temperatures, innovative cooling systems, and more efficient combustion processes to enhance scramjet performance and durability.

Military Demand Analysis

The military demand for dual-use scramjet engines in advanced applications has been steadily increasing due to their potential to revolutionize both tactical and strategic capabilities. These engines offer significant advantages in terms of speed, range, and operational flexibility, making them highly desirable for various military platforms.

In the realm of tactical operations, scramjet-powered missiles and aircraft could provide rapid response capabilities, allowing for quick strikes against time-sensitive targets. The hypersonic speeds achievable with scramjet propulsion systems would significantly reduce the time between target identification and engagement, enhancing the effectiveness of precision strike missions. This capability is particularly crucial in scenarios where adversaries employ mobile or relocatable targets.

Strategic applications of scramjet engines include long-range reconnaissance and surveillance platforms. The ability to cover vast distances at high speeds would enable military forces to gather critical intelligence and maintain situational awareness over extended areas of interest. This enhanced intelligence, surveillance, and reconnaissance (ISR) capability could provide a significant strategic advantage in both peacetime and conflict scenarios.

The development of scramjet-powered aircraft also holds promise for rapid global force projection. Such platforms could potentially transport troops and equipment across intercontinental distances in a fraction of the time required by conventional aircraft, allowing for swift response to emerging threats or humanitarian crises. This capability aligns with the growing emphasis on expeditionary operations and the need for rapid deployment of forces in an increasingly complex and unpredictable global security environment.

Furthermore, the dual-use nature of scramjet technology presents opportunities for cost-sharing and accelerated development through collaboration between military and civilian sectors. This synergy could lead to more efficient resource allocation and faster technological advancements, benefiting both defense and commercial applications.

However, the military demand for scramjet engines is not without challenges. The high costs associated with research, development, and production of these advanced propulsion systems necessitate careful consideration of budget allocations and long-term strategic planning. Additionally, the integration of scramjet technology into existing military doctrines and operational concepts requires thorough analysis and potential adjustments to tactics, techniques, and procedures.

As geopolitical tensions and technological competition intensify, the demand for scramjet engines in military applications is expected to grow. Nations seeking to maintain or gain strategic advantages are likely to invest heavily in this technology, driving further research and development efforts. The potential game-changing nature of scramjet-powered platforms in future conflicts underscores their importance in military planning and capability development.

In the realm of tactical operations, scramjet-powered missiles and aircraft could provide rapid response capabilities, allowing for quick strikes against time-sensitive targets. The hypersonic speeds achievable with scramjet propulsion systems would significantly reduce the time between target identification and engagement, enhancing the effectiveness of precision strike missions. This capability is particularly crucial in scenarios where adversaries employ mobile or relocatable targets.

Strategic applications of scramjet engines include long-range reconnaissance and surveillance platforms. The ability to cover vast distances at high speeds would enable military forces to gather critical intelligence and maintain situational awareness over extended areas of interest. This enhanced intelligence, surveillance, and reconnaissance (ISR) capability could provide a significant strategic advantage in both peacetime and conflict scenarios.

The development of scramjet-powered aircraft also holds promise for rapid global force projection. Such platforms could potentially transport troops and equipment across intercontinental distances in a fraction of the time required by conventional aircraft, allowing for swift response to emerging threats or humanitarian crises. This capability aligns with the growing emphasis on expeditionary operations and the need for rapid deployment of forces in an increasingly complex and unpredictable global security environment.

Furthermore, the dual-use nature of scramjet technology presents opportunities for cost-sharing and accelerated development through collaboration between military and civilian sectors. This synergy could lead to more efficient resource allocation and faster technological advancements, benefiting both defense and commercial applications.

However, the military demand for scramjet engines is not without challenges. The high costs associated with research, development, and production of these advanced propulsion systems necessitate careful consideration of budget allocations and long-term strategic planning. Additionally, the integration of scramjet technology into existing military doctrines and operational concepts requires thorough analysis and potential adjustments to tactics, techniques, and procedures.

As geopolitical tensions and technological competition intensify, the demand for scramjet engines in military applications is expected to grow. Nations seeking to maintain or gain strategic advantages are likely to invest heavily in this technology, driving further research and development efforts. The potential game-changing nature of scramjet-powered platforms in future conflicts underscores their importance in military planning and capability development.

Current Challenges

The development of dual-use scramjet engines for advanced military applications faces several significant challenges that require innovative solutions and continued research efforts. One of the primary obstacles is the extreme thermal management requirements inherent in hypersonic flight. The intense heat generated during high-speed atmospheric travel can cause material degradation and structural failure, necessitating advanced cooling systems and heat-resistant materials.

Another critical challenge lies in the precise control of airflow and combustion processes within the scramjet engine. Achieving stable supersonic combustion across a wide range of flight conditions remains a complex task, requiring sophisticated fuel injection systems and combustor designs. The need for rapid and efficient mixing of fuel and air in a supersonic flow regime presents unique engineering hurdles that must be overcome to ensure reliable engine performance.

Fuel selection and storage pose additional challenges for dual-use scramjet engines. The development of high-energy-density fuels that can withstand the extreme temperatures and pressures encountered during hypersonic flight is crucial. Moreover, the integration of fuel systems that can operate effectively in both military and civilian applications adds another layer of complexity to the design process.

The scalability of scramjet technology presents a significant challenge when considering dual-use applications. Adapting military-grade scramjet engines for civilian use requires careful consideration of factors such as noise reduction, emissions control, and operational safety. Balancing these requirements with the high-performance demands of military applications necessitates innovative design approaches and materials science advancements.

Control and stability issues during the transition from subsonic to hypersonic speeds remain a persistent challenge. Developing robust control systems that can manage the complex aerodynamics and propulsion characteristics across a wide range of Mach numbers is essential for the practical implementation of dual-use scramjet engines. This includes addressing issues such as inlet unstart, combustion instabilities, and thrust vectoring in varying atmospheric conditions.

Furthermore, the integration of scramjet engines with existing aerospace systems poses significant challenges. Designing airframes that can withstand the extreme forces and temperatures associated with hypersonic flight while accommodating the unique requirements of scramjet propulsion systems requires a multidisciplinary approach. This integration must also consider the potential for dual-use applications, balancing military performance with civilian safety and operational requirements.

Lastly, the development of reliable testing and validation methodologies for dual-use scramjet engines presents ongoing challenges. The extreme conditions under which these engines operate make ground-based testing difficult and expensive. Developing accurate simulation tools and scaling laws to predict full-scale performance from subscale tests remains a critical area of research in advancing scramjet technology for both military and civilian applications.

Another critical challenge lies in the precise control of airflow and combustion processes within the scramjet engine. Achieving stable supersonic combustion across a wide range of flight conditions remains a complex task, requiring sophisticated fuel injection systems and combustor designs. The need for rapid and efficient mixing of fuel and air in a supersonic flow regime presents unique engineering hurdles that must be overcome to ensure reliable engine performance.

Fuel selection and storage pose additional challenges for dual-use scramjet engines. The development of high-energy-density fuels that can withstand the extreme temperatures and pressures encountered during hypersonic flight is crucial. Moreover, the integration of fuel systems that can operate effectively in both military and civilian applications adds another layer of complexity to the design process.

The scalability of scramjet technology presents a significant challenge when considering dual-use applications. Adapting military-grade scramjet engines for civilian use requires careful consideration of factors such as noise reduction, emissions control, and operational safety. Balancing these requirements with the high-performance demands of military applications necessitates innovative design approaches and materials science advancements.

Control and stability issues during the transition from subsonic to hypersonic speeds remain a persistent challenge. Developing robust control systems that can manage the complex aerodynamics and propulsion characteristics across a wide range of Mach numbers is essential for the practical implementation of dual-use scramjet engines. This includes addressing issues such as inlet unstart, combustion instabilities, and thrust vectoring in varying atmospheric conditions.

Furthermore, the integration of scramjet engines with existing aerospace systems poses significant challenges. Designing airframes that can withstand the extreme forces and temperatures associated with hypersonic flight while accommodating the unique requirements of scramjet propulsion systems requires a multidisciplinary approach. This integration must also consider the potential for dual-use applications, balancing military performance with civilian safety and operational requirements.

Lastly, the development of reliable testing and validation methodologies for dual-use scramjet engines presents ongoing challenges. The extreme conditions under which these engines operate make ground-based testing difficult and expensive. Developing accurate simulation tools and scaling laws to predict full-scale performance from subscale tests remains a critical area of research in advancing scramjet technology for both military and civilian applications.

Existing Scramjet Designs

01 Dual-use scramjet engine design

Scramjet engines designed for both atmospheric and space propulsion, capable of operating in various flight regimes. These engines incorporate features that allow them to function efficiently in both air-breathing and rocket modes, enabling versatile applications in aerospace and defense sectors.- Dual-use scramjet engine design: Scramjet engines designed for both atmospheric and space propulsion, capable of operating in various flight regimes. These engines incorporate features that allow them to function efficiently in both air-breathing and rocket modes, enabling versatile applications in aerospace and defense sectors.

- Fuel injection and combustion optimization: Advanced fuel injection systems and combustion chamber designs for scramjet engines, focusing on improving fuel-air mixing, combustion efficiency, and thrust generation. These innovations aim to enhance engine performance across a wide range of operating conditions and flight speeds.

- Thermal management and cooling systems: Innovative cooling techniques and thermal management solutions for scramjet engines, addressing the extreme heat generated during high-speed flight. These systems aim to protect engine components and maintain optimal performance in both atmospheric and space environments.

- Integration with hypersonic vehicle design: Methods for integrating dual-use scramjet engines into hypersonic vehicle airframes, optimizing aerodynamics, and managing overall system performance. This includes considerations for inlet design, nozzle configuration, and vehicle control surfaces to maximize efficiency and maneuverability.

- Control systems and flight management: Advanced control systems and algorithms for managing dual-use scramjet engines during various flight phases, including mode transitions between air-breathing and rocket propulsion. These systems aim to optimize engine performance, fuel efficiency, and vehicle stability across a wide range of operating conditions.

02 Fuel injection and combustion optimization

Advanced fuel injection systems and combustion chamber designs to improve the performance of dual-use scramjet engines. These innovations focus on enhancing fuel-air mixing, combustion efficiency, and thrust generation across different operating conditions.Expand Specific Solutions03 Thermal management and cooling systems

Innovative cooling techniques and thermal management solutions for dual-use scramjet engines to withstand extreme temperatures during high-speed flight. These systems ensure engine durability and performance in both atmospheric and space environments.Expand Specific Solutions04 Integration with airframe and propulsion systems

Methods for integrating dual-use scramjet engines with aircraft or spacecraft structures and other propulsion systems. This includes designs for combined cycle engines, airframe-integrated scramjets, and multi-mode propulsion systems for enhanced vehicle performance.Expand Specific Solutions05 Control systems and flight management

Advanced control systems and algorithms for managing dual-use scramjet engines during various flight phases. These innovations focus on optimizing engine performance, ensuring stable operation, and facilitating smooth transitions between different propulsion modes.Expand Specific Solutions

Key Industry Players

The research on dual-use scramjet engines for advanced military applications is in a competitive and rapidly evolving phase. The market is experiencing significant growth due to increasing defense budgets and the demand for hypersonic technologies. While the technology is still maturing, several key players are making substantial progress. Companies like Northrop Grumman, Aerojet Rocketdyne, and Raytheon are at the forefront of scramjet development in the United States. Internationally, organizations such as the Japan Aerospace Exploration Agency and various Chinese institutions, including the National University of Defense Technology and Northwestern Polytechnical University, are actively pursuing scramjet research. The involvement of these diverse entities indicates a global race to achieve operational scramjet capabilities, with potential dual-use applications driving both military and commercial interests.

United Technologies Corp.

Technical Solution: United Technologies Corp. (UTC) has made significant advancements in dual-use scramjet engine technology through its Pratt & Whitney division. Their approach focuses on developing a versatile scramjet engine capable of operating across a wide range of Mach numbers, from high supersonic to hypersonic speeds[13]. UTC's design incorporates a variable geometry inlet and nozzle system, allowing for optimal performance at different flight regimes. The company has invested heavily in advanced materials research, developing heat-resistant alloys and ceramic matrix composites to withstand the extreme temperatures encountered during hypersonic flight[14]. UTC's scramjet engine features an innovative fuel injection and distribution system that enhances mixing and combustion efficiency, resulting in improved thrust and reduced fuel consumption[15]. The company has conducted successful ground tests of key components and is working towards full-scale engine demonstrations.

Strengths: Wide operating range, advanced materials technology, and extensive aerospace engineering expertise. Weaknesses: Relatively new entrant in the scramjet field compared to some competitors, and potential challenges in integrating the technology with existing military platforms.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has developed advanced dual-mode ramjet/scramjet propulsion systems for hypersonic applications. Their technology integrates a turbine-based combined cycle (TBCC) engine with a dual-mode ramjet/scramjet, allowing for efficient operation from takeoff to hypersonic speeds[1]. The company has successfully tested a full-scale, flight-weight scramjet engine capable of producing over 15,000 pounds of thrust[2]. Their design incorporates advanced thermal management systems and uses novel materials to withstand extreme temperatures, enabling sustained hypersonic flight[3]. Northrop Grumman's scramjet engines feature variable geometry inlets and nozzles, optimizing performance across a wide range of Mach numbers.

Strengths: Extensive experience in hypersonic propulsion, proven test results, and integration capabilities with other systems. Weaknesses: High development costs and complexity in transitioning from subsonic to hypersonic regimes.

Core Innovations

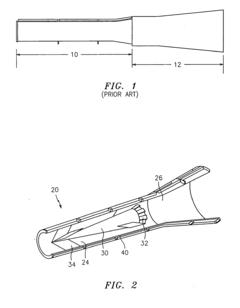

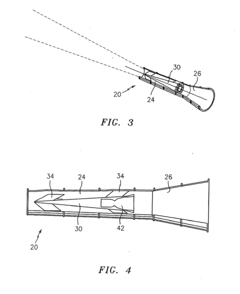

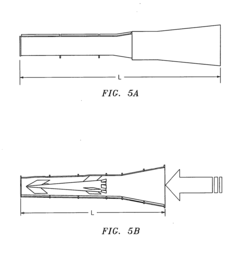

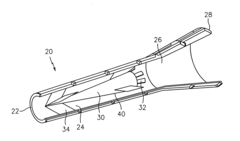

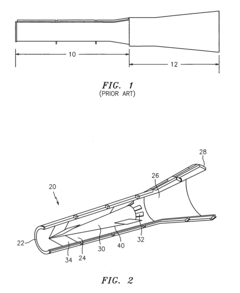

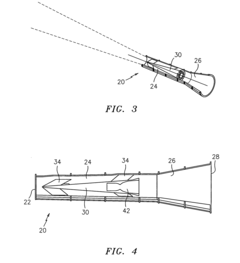

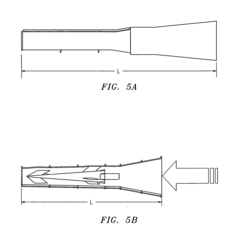

Scramjet/ramjet engine with annular isolator

PatentInactiveEP1916407A2

Innovation

- The dual mode scramjet engine incorporates a centerbody within the isolator that transitions from a circular to an annular cross section, featuring ramp injectors and a flameholder base area, which enhances fuel-air mixing, reduces combustor length, and allows for scalable engine design.

Annular isolator dual mode scramjet engine

PatentInactiveUS20080098741A1

Innovation

- The introduction of a centerbody within the isolator that transitions from a circular to an annular cross section, reducing combustor length and surface area, combined with ramp injectors and a variable geometry configuration, enhances fuel mixing, scalability, and flameholding capabilities.

Materials Advancements

The development of dual-use scramjet engines for advanced military applications heavily relies on materials advancements. High-temperature materials capable of withstanding extreme conditions are crucial for the success of these engines. Recent progress in materials science has led to significant improvements in the performance and durability of scramjet components.

Ceramic matrix composites (CMCs) have emerged as a promising material for scramjet engine components. These materials offer excellent thermal resistance, low density, and high strength-to-weight ratios. Silicon carbide (SiC) and carbon fiber-reinforced silicon carbide (C/SiC) composites have shown particular promise for use in combustion chambers and nozzles. These materials can withstand temperatures exceeding 1600°C while maintaining their structural integrity.

Advanced metallic alloys have also played a crucial role in scramjet engine development. Nickel-based superalloys, such as Inconel and Hastelloy, have been extensively used for their exceptional high-temperature strength and oxidation resistance. Recent advancements in powder metallurgy and additive manufacturing techniques have enabled the production of complex geometries with improved material properties, enhancing the overall engine performance.

Thermal barrier coatings (TBCs) have become an essential technology for protecting engine components from extreme temperatures. Yttria-stabilized zirconia (YSZ) coatings have been widely adopted, providing excellent thermal insulation and erosion resistance. Ongoing research focuses on developing advanced TBCs with improved durability and lower thermal conductivity, such as gadolinium zirconate and lanthanum zirconate-based systems.

Carbon-carbon (C/C) composites have found applications in scramjet engine components due to their exceptional thermal and mechanical properties. These materials exhibit low thermal expansion, high thermal conductivity, and excellent strength-to-weight ratios. Recent advancements in C/C composite manufacturing techniques have led to improved oxidation resistance and extended service life.

Refractory metal alloys, such as molybdenum and tungsten-based materials, are being explored for use in critical engine components. These alloys offer superior high-temperature strength and creep resistance compared to traditional superalloys. However, challenges related to oxidation resistance and manufacturability need to be addressed for widespread adoption in scramjet engines.

The development of novel cooling techniques and materials has also contributed to the advancement of scramjet engine technology. Transpiration cooling systems utilizing porous materials have shown promise in managing extreme heat loads. Additionally, the integration of phase change materials (PCMs) into engine components has been explored as a potential method for thermal management during transient operating conditions.

Ceramic matrix composites (CMCs) have emerged as a promising material for scramjet engine components. These materials offer excellent thermal resistance, low density, and high strength-to-weight ratios. Silicon carbide (SiC) and carbon fiber-reinforced silicon carbide (C/SiC) composites have shown particular promise for use in combustion chambers and nozzles. These materials can withstand temperatures exceeding 1600°C while maintaining their structural integrity.

Advanced metallic alloys have also played a crucial role in scramjet engine development. Nickel-based superalloys, such as Inconel and Hastelloy, have been extensively used for their exceptional high-temperature strength and oxidation resistance. Recent advancements in powder metallurgy and additive manufacturing techniques have enabled the production of complex geometries with improved material properties, enhancing the overall engine performance.

Thermal barrier coatings (TBCs) have become an essential technology for protecting engine components from extreme temperatures. Yttria-stabilized zirconia (YSZ) coatings have been widely adopted, providing excellent thermal insulation and erosion resistance. Ongoing research focuses on developing advanced TBCs with improved durability and lower thermal conductivity, such as gadolinium zirconate and lanthanum zirconate-based systems.

Carbon-carbon (C/C) composites have found applications in scramjet engine components due to their exceptional thermal and mechanical properties. These materials exhibit low thermal expansion, high thermal conductivity, and excellent strength-to-weight ratios. Recent advancements in C/C composite manufacturing techniques have led to improved oxidation resistance and extended service life.

Refractory metal alloys, such as molybdenum and tungsten-based materials, are being explored for use in critical engine components. These alloys offer superior high-temperature strength and creep resistance compared to traditional superalloys. However, challenges related to oxidation resistance and manufacturability need to be addressed for widespread adoption in scramjet engines.

The development of novel cooling techniques and materials has also contributed to the advancement of scramjet engine technology. Transpiration cooling systems utilizing porous materials have shown promise in managing extreme heat loads. Additionally, the integration of phase change materials (PCMs) into engine components has been explored as a potential method for thermal management during transient operating conditions.

Propulsion Integration

Propulsion integration is a critical aspect of scramjet engine development for advanced military applications. The successful integration of the propulsion system with the airframe is essential for achieving optimal performance and efficiency. In the context of dual-use scramjet engines, this integration becomes even more complex due to the need for versatility in both military and civilian applications.

One of the primary challenges in propulsion integration for scramjet engines is managing the high temperatures and pressures generated during supersonic combustion. The engine must be seamlessly integrated with the airframe to ensure proper heat dissipation and structural integrity. This requires advanced materials and cooling systems that can withstand extreme conditions while maintaining aerodynamic efficiency.

The inlet design plays a crucial role in propulsion integration, as it must efficiently capture and compress the incoming airflow. For dual-use applications, the inlet must be adaptable to various flight conditions and Mach numbers. Variable geometry inlets are often employed to optimize performance across a wide range of operating conditions, allowing for efficient operation in both military and civilian scenarios.

Fuel injection and mixing are also key considerations in propulsion integration. The fuel must be efficiently distributed and mixed with the supersonic airflow to achieve optimal combustion. Advanced injection techniques, such as strut-based injectors or cavity-based flame holders, are often utilized to enhance mixing and combustion efficiency while minimizing pressure losses.

The integration of the combustor with the airframe requires careful consideration of thermal management and structural design. The combustor must be able to withstand high temperatures and pressures while maintaining its shape and integrity. Advanced cooling techniques, such as regenerative cooling or film cooling, are often employed to protect the engine components and surrounding structures.

Nozzle integration is another critical aspect of propulsion integration for scramjet engines. The nozzle must be designed to efficiently expand the high-temperature exhaust gases while minimizing drag and maximizing thrust. For dual-use applications, variable geometry nozzles may be employed to optimize performance across different flight regimes and mission profiles.

The integration of control systems and sensors is essential for monitoring and managing the propulsion system's performance. Advanced sensors and control algorithms are required to optimize engine operation in real-time, adjusting parameters such as fuel flow, inlet geometry, and nozzle configuration to maintain optimal performance and efficiency.

In conclusion, propulsion integration for dual-use scramjet engines in advanced military applications requires a holistic approach that considers the complex interactions between the engine, airframe, and flight conditions. Successful integration demands innovative solutions in materials science, thermal management, aerodynamics, and control systems to achieve the desired performance and versatility for both military and civilian applications.

One of the primary challenges in propulsion integration for scramjet engines is managing the high temperatures and pressures generated during supersonic combustion. The engine must be seamlessly integrated with the airframe to ensure proper heat dissipation and structural integrity. This requires advanced materials and cooling systems that can withstand extreme conditions while maintaining aerodynamic efficiency.

The inlet design plays a crucial role in propulsion integration, as it must efficiently capture and compress the incoming airflow. For dual-use applications, the inlet must be adaptable to various flight conditions and Mach numbers. Variable geometry inlets are often employed to optimize performance across a wide range of operating conditions, allowing for efficient operation in both military and civilian scenarios.

Fuel injection and mixing are also key considerations in propulsion integration. The fuel must be efficiently distributed and mixed with the supersonic airflow to achieve optimal combustion. Advanced injection techniques, such as strut-based injectors or cavity-based flame holders, are often utilized to enhance mixing and combustion efficiency while minimizing pressure losses.

The integration of the combustor with the airframe requires careful consideration of thermal management and structural design. The combustor must be able to withstand high temperatures and pressures while maintaining its shape and integrity. Advanced cooling techniques, such as regenerative cooling or film cooling, are often employed to protect the engine components and surrounding structures.

Nozzle integration is another critical aspect of propulsion integration for scramjet engines. The nozzle must be designed to efficiently expand the high-temperature exhaust gases while minimizing drag and maximizing thrust. For dual-use applications, variable geometry nozzles may be employed to optimize performance across different flight regimes and mission profiles.

The integration of control systems and sensors is essential for monitoring and managing the propulsion system's performance. Advanced sensors and control algorithms are required to optimize engine operation in real-time, adjusting parameters such as fuel flow, inlet geometry, and nozzle configuration to maintain optimal performance and efficiency.

In conclusion, propulsion integration for dual-use scramjet engines in advanced military applications requires a holistic approach that considers the complex interactions between the engine, airframe, and flight conditions. Successful integration demands innovative solutions in materials science, thermal management, aerodynamics, and control systems to achieve the desired performance and versatility for both military and civilian applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!