Scramjet Engine Control Algorithms for Hypersonic Speed Variations

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Engine Evolution

The evolution of scramjet engines represents a significant milestone in the field of hypersonic propulsion. Initially conceptualized in the 1950s, scramjet technology has undergone substantial development over the past seven decades. The primary goal has been to achieve efficient propulsion at hypersonic speeds, typically above Mach 5, where traditional jet engines become ineffective.

In the early stages, theoretical work laid the foundation for scramjet design principles. The 1960s and 1970s saw the first experimental tests, primarily focusing on component-level studies. These efforts were crucial in understanding the complex flow physics and combustion processes at hypersonic speeds.

The 1980s marked a turning point with the initiation of major research programs, such as the U.S. National Aerospace Plane (NASP) project. Although the NASP was ultimately cancelled, it significantly advanced scramjet technology and sparked international interest in hypersonic research.

The 1990s and early 2000s witnessed several successful flight tests, demonstrating the viability of scramjet propulsion. Notable achievements include NASA's Hyper-X program, which culminated in the successful flights of the X-43A vehicle in 2004, achieving speeds up to Mach 9.6.

Recent years have seen a renewed focus on scramjet technology, driven by both military and commercial interests. Advanced computational tools and improved material technologies have enabled more sophisticated designs and better performance predictions. The development of robust control algorithms for managing engine performance across a wide range of hypersonic speeds has become a critical area of research.

Current challenges in scramjet evolution include improving combustion efficiency, managing thermal loads, and developing adaptive control systems capable of handling the extreme variations in flight conditions. The integration of scramjet engines with airframe designs for sustained hypersonic flight remains an active area of investigation.

Looking forward, the evolution of scramjet engines is likely to focus on enhancing operational flexibility, improving fuel efficiency, and extending the operational speed range. Advanced materials and manufacturing techniques, such as 3D printing of complex engine components, are expected to play a crucial role in future developments. Additionally, the integration of artificial intelligence and machine learning algorithms for real-time engine optimization and control is an emerging trend that promises to revolutionize scramjet performance and reliability in hypersonic flight regimes.

In the early stages, theoretical work laid the foundation for scramjet design principles. The 1960s and 1970s saw the first experimental tests, primarily focusing on component-level studies. These efforts were crucial in understanding the complex flow physics and combustion processes at hypersonic speeds.

The 1980s marked a turning point with the initiation of major research programs, such as the U.S. National Aerospace Plane (NASP) project. Although the NASP was ultimately cancelled, it significantly advanced scramjet technology and sparked international interest in hypersonic research.

The 1990s and early 2000s witnessed several successful flight tests, demonstrating the viability of scramjet propulsion. Notable achievements include NASA's Hyper-X program, which culminated in the successful flights of the X-43A vehicle in 2004, achieving speeds up to Mach 9.6.

Recent years have seen a renewed focus on scramjet technology, driven by both military and commercial interests. Advanced computational tools and improved material technologies have enabled more sophisticated designs and better performance predictions. The development of robust control algorithms for managing engine performance across a wide range of hypersonic speeds has become a critical area of research.

Current challenges in scramjet evolution include improving combustion efficiency, managing thermal loads, and developing adaptive control systems capable of handling the extreme variations in flight conditions. The integration of scramjet engines with airframe designs for sustained hypersonic flight remains an active area of investigation.

Looking forward, the evolution of scramjet engines is likely to focus on enhancing operational flexibility, improving fuel efficiency, and extending the operational speed range. Advanced materials and manufacturing techniques, such as 3D printing of complex engine components, are expected to play a crucial role in future developments. Additionally, the integration of artificial intelligence and machine learning algorithms for real-time engine optimization and control is an emerging trend that promises to revolutionize scramjet performance and reliability in hypersonic flight regimes.

Hypersonic Market Analysis

The hypersonic market is experiencing rapid growth and transformation, driven by advancements in scramjet engine technology and control algorithms for hypersonic speed variations. This market segment encompasses both military and commercial applications, with a primary focus on aerospace and defense sectors.

In the military domain, hypersonic technologies are revolutionizing strategic capabilities. Major powers are investing heavily in hypersonic weapons systems, including missiles and aircraft, to gain tactical advantages. These systems offer unprecedented speed and maneuverability, potentially reshaping global defense strategies. The demand for hypersonic capabilities has led to increased research and development funding from governments worldwide.

Commercial applications of hypersonic technology are also emerging, albeit at a slower pace. The prospect of ultra-fast global transportation is driving interest in hypersonic passenger aircraft. While still in early stages, companies are exploring the feasibility of intercontinental flights that could dramatically reduce travel times. This potential market has attracted attention from aerospace giants and innovative startups alike.

The market for scramjet engine control algorithms is a critical subset of the broader hypersonic market. As these engines operate at extreme speeds and conditions, sophisticated control systems are essential for maintaining stability and efficiency. This niche market is characterized by high technological barriers and intensive research requirements.

Key market drivers include the need for faster and more efficient propulsion systems, the strategic importance of hypersonic capabilities in defense, and the potential for revolutionary changes in global transportation. However, significant challenges remain, including material limitations, thermal management issues, and the complexity of controlling combustion at hypersonic speeds.

Market growth is further fueled by increasing collaborations between government agencies, research institutions, and private companies. These partnerships are crucial for overcoming the substantial technical and financial hurdles associated with hypersonic technology development.

The global nature of the hypersonic market is evident, with major players emerging from countries with advanced aerospace industries. Competition is fierce, as nations and companies race to achieve technological breakthroughs and secure intellectual property rights.

As the market evolves, regulatory frameworks and international agreements regarding the development and deployment of hypersonic technologies are likely to play a significant role in shaping market dynamics. Safety concerns and potential dual-use applications of hypersonic technologies add complexity to market growth projections.

In the military domain, hypersonic technologies are revolutionizing strategic capabilities. Major powers are investing heavily in hypersonic weapons systems, including missiles and aircraft, to gain tactical advantages. These systems offer unprecedented speed and maneuverability, potentially reshaping global defense strategies. The demand for hypersonic capabilities has led to increased research and development funding from governments worldwide.

Commercial applications of hypersonic technology are also emerging, albeit at a slower pace. The prospect of ultra-fast global transportation is driving interest in hypersonic passenger aircraft. While still in early stages, companies are exploring the feasibility of intercontinental flights that could dramatically reduce travel times. This potential market has attracted attention from aerospace giants and innovative startups alike.

The market for scramjet engine control algorithms is a critical subset of the broader hypersonic market. As these engines operate at extreme speeds and conditions, sophisticated control systems are essential for maintaining stability and efficiency. This niche market is characterized by high technological barriers and intensive research requirements.

Key market drivers include the need for faster and more efficient propulsion systems, the strategic importance of hypersonic capabilities in defense, and the potential for revolutionary changes in global transportation. However, significant challenges remain, including material limitations, thermal management issues, and the complexity of controlling combustion at hypersonic speeds.

Market growth is further fueled by increasing collaborations between government agencies, research institutions, and private companies. These partnerships are crucial for overcoming the substantial technical and financial hurdles associated with hypersonic technology development.

The global nature of the hypersonic market is evident, with major players emerging from countries with advanced aerospace industries. Competition is fierce, as nations and companies race to achieve technological breakthroughs and secure intellectual property rights.

As the market evolves, regulatory frameworks and international agreements regarding the development and deployment of hypersonic technologies are likely to play a significant role in shaping market dynamics. Safety concerns and potential dual-use applications of hypersonic technologies add complexity to market growth projections.

Control Challenges

Controlling a scramjet engine across hypersonic speed variations presents numerous challenges due to the complex and rapidly changing flow conditions. One of the primary difficulties is managing the airflow through the engine, which must be precisely controlled to maintain optimal combustion efficiency. As the vehicle accelerates from Mach 5 to Mach 10 and beyond, the incoming air temperature and pressure change dramatically, requiring real-time adjustments to fuel injection rates and combustor geometry.

The extreme temperatures encountered during hypersonic flight pose significant challenges for sensor systems and control actuators. Traditional sensors may become unreliable or fail completely under such conditions, necessitating the development of robust, high-temperature sensing technologies. Similarly, actuators used for fuel injection, variable geometry, and other control functions must operate reliably in this harsh environment.

Another major challenge is the short time scales involved in hypersonic flight. The flow through a scramjet engine can transit the entire combustor in less than a millisecond, leaving minimal time for mixing, ignition, and combustion. Control algorithms must be capable of making decisions and implementing changes on these extremely short time scales, pushing the limits of current computational capabilities.

The coupling between vehicle dynamics and engine performance adds another layer of complexity to the control problem. Changes in vehicle attitude or trajectory can significantly affect engine inlet conditions, potentially leading to unstart or flame-out if not properly managed. Control algorithms must therefore integrate both propulsion and flight control systems to ensure stable and efficient operation.

Uncertainty and variability in atmospheric conditions at high altitudes further complicate the control challenge. Fluctuations in air density, temperature, and composition can impact engine performance and require adaptive control strategies to maintain optimal operation across a wide range of flight conditions.

Lastly, the development and testing of control algorithms for scramjet engines are hindered by the limited availability of ground-based test facilities capable of accurately simulating hypersonic flight conditions. This necessitates heavy reliance on computational fluid dynamics (CFD) simulations and extrapolation from subscale tests, introducing additional uncertainties that must be accounted for in the control system design.

The extreme temperatures encountered during hypersonic flight pose significant challenges for sensor systems and control actuators. Traditional sensors may become unreliable or fail completely under such conditions, necessitating the development of robust, high-temperature sensing technologies. Similarly, actuators used for fuel injection, variable geometry, and other control functions must operate reliably in this harsh environment.

Another major challenge is the short time scales involved in hypersonic flight. The flow through a scramjet engine can transit the entire combustor in less than a millisecond, leaving minimal time for mixing, ignition, and combustion. Control algorithms must be capable of making decisions and implementing changes on these extremely short time scales, pushing the limits of current computational capabilities.

The coupling between vehicle dynamics and engine performance adds another layer of complexity to the control problem. Changes in vehicle attitude or trajectory can significantly affect engine inlet conditions, potentially leading to unstart or flame-out if not properly managed. Control algorithms must therefore integrate both propulsion and flight control systems to ensure stable and efficient operation.

Uncertainty and variability in atmospheric conditions at high altitudes further complicate the control challenge. Fluctuations in air density, temperature, and composition can impact engine performance and require adaptive control strategies to maintain optimal operation across a wide range of flight conditions.

Lastly, the development and testing of control algorithms for scramjet engines are hindered by the limited availability of ground-based test facilities capable of accurately simulating hypersonic flight conditions. This necessitates heavy reliance on computational fluid dynamics (CFD) simulations and extrapolation from subscale tests, introducing additional uncertainties that must be accounted for in the control system design.

Current Control Solutions

01 Adaptive control algorithms for scramjet engines

Advanced control algorithms that adapt to changing flight conditions and engine parameters are crucial for optimizing scramjet engine performance. These algorithms use real-time data to adjust fuel injection, combustion timing, and airflow management, ensuring efficient operation across a wide range of speeds and altitudes.- Adaptive control algorithms for scramjet engines: Advanced control algorithms are developed to adapt to the rapidly changing conditions in scramjet engines. These algorithms use real-time data to adjust fuel injection, combustion parameters, and airflow to optimize engine performance and maintain stable operation across a wide range of speeds and altitudes.

- Fuel injection and mixing optimization: Control algorithms focus on optimizing fuel injection and mixing processes to enhance combustion efficiency and engine performance. These algorithms regulate fuel flow rates, injection timing, and spray patterns based on flight conditions and engine parameters to achieve optimal fuel-air mixing and combustion.

- Thermal management and cooling systems: Algorithms are developed to manage the extreme temperatures in scramjet engines. These control systems regulate coolant flow, heat distribution, and thermal protection to maintain structural integrity and prevent engine damage while operating at hypersonic speeds.

- Inlet and nozzle geometry control: Control algorithms are designed to dynamically adjust the geometry of engine inlets and nozzles. These systems optimize airflow compression, shock wave positioning, and exhaust expansion to maximize thrust and efficiency across various flight regimes.

- Integration with flight control systems: Advanced algorithms are developed to integrate scramjet engine control with overall flight control systems. These algorithms coordinate engine performance with vehicle dynamics, trajectory optimization, and mission requirements to achieve efficient and stable hypersonic flight.

02 Fuel injection and mixing optimization

Precise control of fuel injection and mixing is essential for maintaining stable combustion in scramjet engines at high speeds. Advanced algorithms manage fuel flow rates, injection timing, and spray patterns to achieve optimal fuel-air mixing and combustion efficiency, thereby improving engine performance and speed control.Expand Specific Solutions03 Thermal management and cooling systems

Effective thermal management is critical for scramjet engines operating at hypersonic speeds. Control algorithms regulate cooling systems, manage heat distribution, and adjust engine geometry to prevent overheating and maintain structural integrity, allowing for sustained high-speed operation.Expand Specific Solutions04 Inlet flow control and shock wave management

Algorithms for controlling inlet airflow and managing shock waves are crucial for scramjet engine performance at various speeds. These systems adjust inlet geometry, manage boundary layer control, and optimize compression to ensure efficient air capture and combustion across a wide range of Mach numbers.Expand Specific Solutions05 Integration of sensor data for real-time performance optimization

Advanced sensor systems and data integration algorithms are employed to monitor and optimize scramjet engine performance in real-time. These systems collect and analyze data on pressure, temperature, airflow, and combustion parameters to make rapid adjustments, ensuring optimal engine operation and speed control.Expand Specific Solutions

Key Industry Players

The development of scramjet engine control algorithms for hypersonic speed variations is in an early stage, with significant potential for growth. The market size is expanding as hypersonic technology gains strategic importance in aerospace and defense sectors. Technologically, it remains challenging due to the complex aerodynamics and extreme conditions at hypersonic speeds. Key players like Northwestern Polytechnical University, National University of Defense Technology, and Beihang University are leading academic research efforts. Companies such as Northrop Grumman Systems Corp. and United Technologies Corp. are investing in advanced propulsion technologies, while government entities like the Naval Research Laboratory are also contributing to the field's advancement.

Northwestern Polytechnical University

Technical Solution: Northwestern Polytechnical University has developed advanced control algorithms for scramjet engines to address hypersonic speed variations. Their approach utilizes a combination of adaptive control and model predictive control techniques. The university's research team has implemented a robust feedback linearization method that can handle the nonlinear dynamics of scramjet engines across a wide range of Mach numbers[1]. They have also integrated a real-time optimization algorithm that continuously adjusts the fuel injection rate and combustor geometry to maintain optimal performance as flight conditions change[3]. Additionally, the university has developed a novel sensor fusion technique that combines data from multiple onboard sensors to provide accurate estimates of flow conditions and engine performance parameters, enabling more precise control actions[5].

Strengths: Cutting-edge adaptive control techniques, real-time optimization capabilities, and advanced sensor fusion. Weaknesses: Limited real-world testing opportunities and potential challenges in scaling up to full-size engines.

National University of Defense Technology

Technical Solution: The National University of Defense Technology has made significant strides in scramjet engine control for hypersonic applications. Their approach focuses on robust control strategies that can handle uncertainties and disturbances in the hypersonic flight environment. The university has developed a novel sliding mode control algorithm that provides rapid response to sudden changes in flight conditions while maintaining stability[2]. They have also implemented an intelligent control system that uses machine learning techniques to adapt to varying atmospheric conditions and engine performance characteristics[4]. Furthermore, the university has created a high-fidelity simulation environment that allows for extensive testing and validation of control algorithms before implementation in physical prototypes[6].

Strengths: Robust control strategies, adaptive learning capabilities, and advanced simulation tools. Weaknesses: Potential computational complexity and challenges in real-time implementation on resource-constrained flight hardware.

Innovative Control Techniques

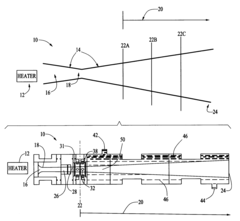

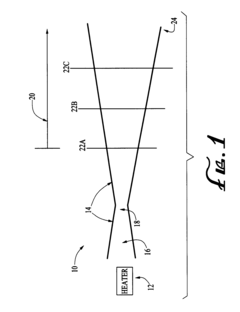

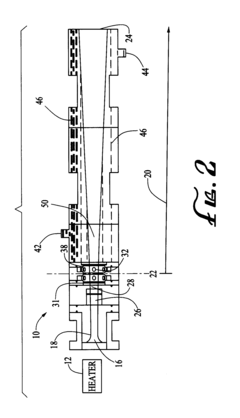

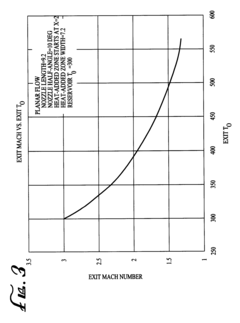

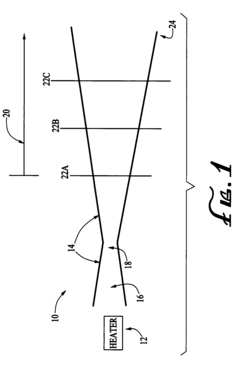

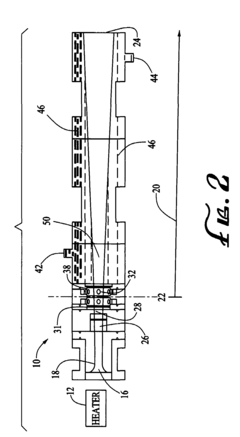

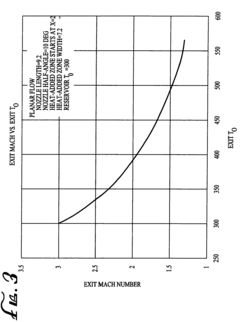

Variable supersonic mach number air heater utilizing supersonic combustion

PatentInactiveUS8087229B2

Innovation

- A supersonic combustion heater with strategically positioned fuel injection means and flame stabilization techniques that vary Mach numbers at the exit plane by heat addition in the diverging area, enhancing enthalpy flow, flame stability, and mixing without the need for expensive film-cooled nozzles, using a fixed geometric nozzle with converging and diverging areas and incorporating oxygen injection for stability.

Method for using variable supersonic Mach number air heater utilizing supersonic combustion

PatentInactiveUS7296396B1

Innovation

- A supersonic combustion heater apparatus that varies exit plane Mach numbers through strategic fuel injection and flame stabilization in a fixed geometry nozzle, enhancing high enthalpy flow and flame stability without using expensive film cooled nozzles, allowing for mode transition testing in air-breathing propulsion systems.

Materials and Thermal Management

The materials and thermal management aspects of scramjet engine control algorithms for hypersonic speed variations present significant challenges due to the extreme operating conditions. At hypersonic speeds, the intense aerodynamic heating and high-temperature combustion processes subject the engine components to severe thermal loads. Advanced materials and thermal management strategies are crucial for maintaining structural integrity and ensuring optimal engine performance across a wide range of speeds.

Ceramic matrix composites (CMCs) have emerged as promising materials for scramjet engine components due to their excellent high-temperature strength, thermal shock resistance, and low density. These materials, such as silicon carbide (SiC) and carbon-carbon (C/C) composites, can withstand temperatures exceeding 2000°C while maintaining their mechanical properties. The development of CMCs with tailored thermal expansion coefficients and improved oxidation resistance is ongoing to enhance their durability in the oxidizing environment of scramjet combustion chambers.

Active cooling systems play a vital role in thermal management for scramjet engines. Regenerative cooling, where the fuel is circulated through cooling channels before injection, is widely employed to protect engine walls from excessive heating. Advanced cooling techniques, such as transpiration cooling and film cooling, are being investigated to provide more effective thermal protection for critical components. These methods involve injecting a coolant through porous walls or small holes to create a protective layer between the hot gases and the engine surfaces.

The integration of thermal protection systems (TPS) with engine control algorithms is essential for managing heat loads during speed variations. Adaptive TPS concepts, which can adjust their thermal properties based on flight conditions, are being explored to optimize thermal management across the hypersonic speed range. These systems may incorporate phase change materials or variable geometry structures to enhance heat dissipation at different Mach numbers.

Computational fluid dynamics (CFD) and finite element analysis (FEA) tools are increasingly used to model the complex thermal behavior of scramjet engines. These simulations help in predicting temperature distributions, thermal stresses, and heat fluxes under various operating conditions. The integration of these thermal models with control algorithms allows for real-time adjustment of engine parameters to maintain optimal thermal conditions throughout the flight envelope.

Sensor technologies for accurate temperature and heat flux measurements in hypersonic environments are critical for effective thermal management. Advanced sensing techniques, such as fiber optic sensors and thin-film thermocouples, are being developed to provide high-resolution temperature data with minimal intrusion. These sensors enable real-time monitoring of engine thermal conditions, allowing control algorithms to respond rapidly to temperature variations and prevent thermal damage.

Ceramic matrix composites (CMCs) have emerged as promising materials for scramjet engine components due to their excellent high-temperature strength, thermal shock resistance, and low density. These materials, such as silicon carbide (SiC) and carbon-carbon (C/C) composites, can withstand temperatures exceeding 2000°C while maintaining their mechanical properties. The development of CMCs with tailored thermal expansion coefficients and improved oxidation resistance is ongoing to enhance their durability in the oxidizing environment of scramjet combustion chambers.

Active cooling systems play a vital role in thermal management for scramjet engines. Regenerative cooling, where the fuel is circulated through cooling channels before injection, is widely employed to protect engine walls from excessive heating. Advanced cooling techniques, such as transpiration cooling and film cooling, are being investigated to provide more effective thermal protection for critical components. These methods involve injecting a coolant through porous walls or small holes to create a protective layer between the hot gases and the engine surfaces.

The integration of thermal protection systems (TPS) with engine control algorithms is essential for managing heat loads during speed variations. Adaptive TPS concepts, which can adjust their thermal properties based on flight conditions, are being explored to optimize thermal management across the hypersonic speed range. These systems may incorporate phase change materials or variable geometry structures to enhance heat dissipation at different Mach numbers.

Computational fluid dynamics (CFD) and finite element analysis (FEA) tools are increasingly used to model the complex thermal behavior of scramjet engines. These simulations help in predicting temperature distributions, thermal stresses, and heat fluxes under various operating conditions. The integration of these thermal models with control algorithms allows for real-time adjustment of engine parameters to maintain optimal thermal conditions throughout the flight envelope.

Sensor technologies for accurate temperature and heat flux measurements in hypersonic environments are critical for effective thermal management. Advanced sensing techniques, such as fiber optic sensors and thin-film thermocouples, are being developed to provide high-resolution temperature data with minimal intrusion. These sensors enable real-time monitoring of engine thermal conditions, allowing control algorithms to respond rapidly to temperature variations and prevent thermal damage.

Simulation and Testing Methods

Simulation and testing methods play a crucial role in the development and validation of scramjet engine control algorithms for hypersonic speed variations. These methods provide a cost-effective and safe approach to evaluate the performance and robustness of control systems before actual flight tests.

Computational Fluid Dynamics (CFD) simulations are extensively used to model the complex flow dynamics within scramjet engines at various hypersonic speeds. These simulations help in understanding the behavior of shock waves, combustion processes, and thermal management under different flight conditions. Advanced CFD tools incorporate real gas effects, chemical kinetics, and turbulence models to accurately represent the hypersonic environment.

Hardware-in-the-Loop (HIL) simulations are employed to test the control algorithms in a more realistic setting. This approach integrates actual hardware components, such as sensors and actuators, with simulated engine models. HIL simulations allow engineers to evaluate the response time, accuracy, and stability of control systems under various operational scenarios and failure modes.

Wind tunnel testing remains an essential method for validating scramjet engine control algorithms. Hypersonic wind tunnels capable of simulating Mach numbers up to 15 are used to study the aerodynamic and thermodynamic characteristics of scramjet engines. These facilities often incorporate advanced diagnostic techniques, such as laser-based flow visualization and high-speed imaging, to capture detailed flow structures and combustion phenomena.

Plasma wind tunnels are increasingly being utilized to simulate the extreme temperatures and pressures encountered during hypersonic flight. These facilities can generate high-enthalpy flows that closely mimic the conditions experienced by scramjet engines, allowing researchers to study material behavior, heat transfer, and control system performance under realistic conditions.

Subscale flight testing using small-scale scramjet engines mounted on rocket-powered vehicles provides valuable data on control algorithm performance in actual flight conditions. These tests help validate simulation results and refine control strategies before full-scale flight demonstrations.

Advanced optimization techniques, such as genetic algorithms and machine learning, are employed to fine-tune control parameters based on simulation and test data. These methods enable the development of adaptive control algorithms capable of handling a wide range of flight conditions and uncertainties.

Virtual reality (VR) and augmented reality (AR) technologies are emerging as powerful tools for visualizing and analyzing complex simulation data. These immersive environments allow engineers to interact with 3D representations of scramjet engines and flow fields, facilitating a deeper understanding of control system behavior and potential design improvements.

Computational Fluid Dynamics (CFD) simulations are extensively used to model the complex flow dynamics within scramjet engines at various hypersonic speeds. These simulations help in understanding the behavior of shock waves, combustion processes, and thermal management under different flight conditions. Advanced CFD tools incorporate real gas effects, chemical kinetics, and turbulence models to accurately represent the hypersonic environment.

Hardware-in-the-Loop (HIL) simulations are employed to test the control algorithms in a more realistic setting. This approach integrates actual hardware components, such as sensors and actuators, with simulated engine models. HIL simulations allow engineers to evaluate the response time, accuracy, and stability of control systems under various operational scenarios and failure modes.

Wind tunnel testing remains an essential method for validating scramjet engine control algorithms. Hypersonic wind tunnels capable of simulating Mach numbers up to 15 are used to study the aerodynamic and thermodynamic characteristics of scramjet engines. These facilities often incorporate advanced diagnostic techniques, such as laser-based flow visualization and high-speed imaging, to capture detailed flow structures and combustion phenomena.

Plasma wind tunnels are increasingly being utilized to simulate the extreme temperatures and pressures encountered during hypersonic flight. These facilities can generate high-enthalpy flows that closely mimic the conditions experienced by scramjet engines, allowing researchers to study material behavior, heat transfer, and control system performance under realistic conditions.

Subscale flight testing using small-scale scramjet engines mounted on rocket-powered vehicles provides valuable data on control algorithm performance in actual flight conditions. These tests help validate simulation results and refine control strategies before full-scale flight demonstrations.

Advanced optimization techniques, such as genetic algorithms and machine learning, are employed to fine-tune control parameters based on simulation and test data. These methods enable the development of adaptive control algorithms capable of handling a wide range of flight conditions and uncertainties.

Virtual reality (VR) and augmented reality (AR) technologies are emerging as powerful tools for visualizing and analyzing complex simulation data. These immersive environments allow engineers to interact with 3D representations of scramjet engines and flow fields, facilitating a deeper understanding of control system behavior and potential design improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!