Logistical Applications of Scramjet-Powered Air Freighters

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Technology Evolution and Objectives

Scramjet technology has undergone significant evolution since its inception in the 1950s. Initially conceived as a theoretical concept, scramjets have progressed from experimental designs to functional prototypes, with the potential to revolutionize air transportation, particularly in the realm of high-speed logistics.

The primary objective of scramjet technology in the context of air freighters is to achieve hypersonic speeds, enabling rapid global cargo delivery. This goal aligns with the increasing demand for faster and more efficient logistics solutions in our interconnected world. By leveraging the principles of supersonic combustion, scramjets aim to overcome the limitations of traditional jet engines, potentially reducing intercontinental travel times from hours to mere minutes.

The evolution of scramjet technology has been marked by several key milestones. Early research focused on understanding the complex fluid dynamics and combustion processes at hypersonic speeds. This led to the development of ground-based test facilities and computational models to simulate extreme flight conditions. The X-43A program, conducted by NASA in the early 2000s, demonstrated the viability of scramjet propulsion in atmospheric flight, achieving speeds of Mach 9.6.

Subsequent advancements have centered on improving fuel efficiency, thermal management, and materials science to withstand the extreme temperatures generated during hypersonic flight. The integration of advanced composite materials and novel cooling systems has been crucial in addressing these challenges. Recent efforts have also focused on scaling up scramjet technology for practical applications, including the development of larger engines capable of powering air freighters.

The current technological objectives for scramjet-powered air freighters include enhancing operational reliability, extending flight duration, and optimizing payload capacity. Researchers are exploring innovative fuel formulations and injection systems to improve combustion efficiency at various altitudes and speeds. Additionally, efforts are underway to develop adaptive control systems that can manage the complex aerodynamics of hypersonic flight, ensuring stability and maneuverability across a wide range of operating conditions.

Looking ahead, the future of scramjet technology in logistics applications holds immense potential. Objectives include achieving sustained hypersonic flight for extended periods, developing reusable scramjet engines to reduce operational costs, and integrating scramjet propulsion with conventional jet engines for versatile aircraft designs. These advancements could pave the way for a new era of ultra-rapid global cargo transportation, fundamentally transforming supply chain dynamics and international trade.

The primary objective of scramjet technology in the context of air freighters is to achieve hypersonic speeds, enabling rapid global cargo delivery. This goal aligns with the increasing demand for faster and more efficient logistics solutions in our interconnected world. By leveraging the principles of supersonic combustion, scramjets aim to overcome the limitations of traditional jet engines, potentially reducing intercontinental travel times from hours to mere minutes.

The evolution of scramjet technology has been marked by several key milestones. Early research focused on understanding the complex fluid dynamics and combustion processes at hypersonic speeds. This led to the development of ground-based test facilities and computational models to simulate extreme flight conditions. The X-43A program, conducted by NASA in the early 2000s, demonstrated the viability of scramjet propulsion in atmospheric flight, achieving speeds of Mach 9.6.

Subsequent advancements have centered on improving fuel efficiency, thermal management, and materials science to withstand the extreme temperatures generated during hypersonic flight. The integration of advanced composite materials and novel cooling systems has been crucial in addressing these challenges. Recent efforts have also focused on scaling up scramjet technology for practical applications, including the development of larger engines capable of powering air freighters.

The current technological objectives for scramjet-powered air freighters include enhancing operational reliability, extending flight duration, and optimizing payload capacity. Researchers are exploring innovative fuel formulations and injection systems to improve combustion efficiency at various altitudes and speeds. Additionally, efforts are underway to develop adaptive control systems that can manage the complex aerodynamics of hypersonic flight, ensuring stability and maneuverability across a wide range of operating conditions.

Looking ahead, the future of scramjet technology in logistics applications holds immense potential. Objectives include achieving sustained hypersonic flight for extended periods, developing reusable scramjet engines to reduce operational costs, and integrating scramjet propulsion with conventional jet engines for versatile aircraft designs. These advancements could pave the way for a new era of ultra-rapid global cargo transportation, fundamentally transforming supply chain dynamics and international trade.

Air Freight Market Analysis

The global air freight market has experienced significant growth in recent years, driven by increasing international trade, e-commerce expansion, and the need for rapid transportation of high-value goods. In 2020, the air cargo market was valued at approximately $270 billion, with projections indicating continued growth at a compound annual growth rate (CAGR) of 5.6% through 2027. This growth trajectory presents a substantial opportunity for innovative technologies like scramjet-powered air freighters to revolutionize the industry.

The demand for air freight services is primarily fueled by industries requiring time-sensitive deliveries, such as pharmaceuticals, electronics, and perishable goods. These sectors prioritize speed and reliability over cost, making them ideal candidates for advanced air freight solutions. The COVID-19 pandemic has further accelerated the shift towards air cargo, as supply chain disruptions and the urgent need for medical supplies highlighted the importance of rapid, efficient transportation networks.

Geographically, the Asia-Pacific region dominates the air freight market, accounting for over 35% of global air cargo traffic. This is largely due to the region's manufacturing hubs, particularly in China, and the growing middle-class consumer base in countries like India and Indonesia. North America and Europe follow closely, with significant air freight volumes driven by their advanced economies and high-value exports.

The integration of scramjet-powered air freighters into this market landscape could potentially disrupt traditional air cargo operations. These hypersonic vehicles promise dramatically reduced transit times, which could open new possibilities for ultra-fast global logistics. For instance, a scramjet-powered freighter could theoretically transport goods between continents in a matter of hours rather than days, revolutionizing supply chain dynamics for time-critical industries.

However, the market adoption of such advanced technology would face several challenges. Infrastructure requirements, regulatory hurdles, and the need for significant capital investments are primary concerns. Additionally, the air freight industry's current focus on sustainability and reducing carbon emissions may influence the reception of scramjet technology, depending on its environmental impact and fuel efficiency.

Despite these challenges, the potential benefits of scramjet-powered air freighters align well with the evolving needs of the air cargo market. As global trade continues to grow and supply chains become increasingly complex, the demand for faster, more efficient transportation solutions is likely to rise. This creates a favorable environment for the development and eventual integration of revolutionary technologies like scramjet-powered air freighters, potentially reshaping the future of global logistics and trade.

The demand for air freight services is primarily fueled by industries requiring time-sensitive deliveries, such as pharmaceuticals, electronics, and perishable goods. These sectors prioritize speed and reliability over cost, making them ideal candidates for advanced air freight solutions. The COVID-19 pandemic has further accelerated the shift towards air cargo, as supply chain disruptions and the urgent need for medical supplies highlighted the importance of rapid, efficient transportation networks.

Geographically, the Asia-Pacific region dominates the air freight market, accounting for over 35% of global air cargo traffic. This is largely due to the region's manufacturing hubs, particularly in China, and the growing middle-class consumer base in countries like India and Indonesia. North America and Europe follow closely, with significant air freight volumes driven by their advanced economies and high-value exports.

The integration of scramjet-powered air freighters into this market landscape could potentially disrupt traditional air cargo operations. These hypersonic vehicles promise dramatically reduced transit times, which could open new possibilities for ultra-fast global logistics. For instance, a scramjet-powered freighter could theoretically transport goods between continents in a matter of hours rather than days, revolutionizing supply chain dynamics for time-critical industries.

However, the market adoption of such advanced technology would face several challenges. Infrastructure requirements, regulatory hurdles, and the need for significant capital investments are primary concerns. Additionally, the air freight industry's current focus on sustainability and reducing carbon emissions may influence the reception of scramjet technology, depending on its environmental impact and fuel efficiency.

Despite these challenges, the potential benefits of scramjet-powered air freighters align well with the evolving needs of the air cargo market. As global trade continues to grow and supply chains become increasingly complex, the demand for faster, more efficient transportation solutions is likely to rise. This creates a favorable environment for the development and eventual integration of revolutionary technologies like scramjet-powered air freighters, potentially reshaping the future of global logistics and trade.

Scramjet Challenges in Logistics

The integration of scramjet technology into air freight logistics presents significant challenges that must be addressed for successful implementation. One of the primary obstacles is the high operational costs associated with scramjet-powered aircraft. The advanced materials and complex engineering required for scramjet engines contribute to elevated manufacturing and maintenance expenses, potentially offsetting the benefits of increased speed and efficiency in cargo transport.

Another critical challenge lies in the fuel consumption and efficiency of scramjet engines. While these engines offer exceptional performance at hypersonic speeds, they require substantial amounts of fuel to achieve and maintain such velocities. This high fuel demand not only impacts operational costs but also raises environmental concerns, necessitating the development of more sustainable fuel solutions for long-term viability in the logistics sector.

The limited payload capacity of scramjet-powered aircraft poses a significant hurdle for their adoption in air freight. The need for streamlined designs to achieve hypersonic speeds often results in reduced cargo space compared to conventional freight aircraft. This limitation may restrict the types and quantities of goods that can be transported, potentially limiting the technology's applicability to specific high-value, time-sensitive cargo segments.

Infrastructure requirements present another substantial challenge. Scramjet-powered air freighters would require specialized facilities for takeoff, landing, and maintenance. Existing airports and cargo handling systems may need significant upgrades to accommodate these advanced aircraft, involving considerable investment in new infrastructure and training for ground personnel.

Regulatory hurdles and safety concerns also pose significant challenges to the implementation of scramjet technology in logistics. The operation of hypersonic aircraft in commercial airspace requires the development of new air traffic control systems and safety protocols. Regulatory bodies will need to establish comprehensive frameworks to ensure the safe integration of these high-speed vehicles into existing air traffic patterns.

Technical reliability and operational consistency are crucial factors that need to be addressed. Scramjet engines must demonstrate consistent performance across various atmospheric conditions and flight durations to be viable for commercial logistics operations. Ensuring the reliability of these complex propulsion systems under the demanding conditions of regular freight schedules presents a significant engineering challenge.

Another critical challenge lies in the fuel consumption and efficiency of scramjet engines. While these engines offer exceptional performance at hypersonic speeds, they require substantial amounts of fuel to achieve and maintain such velocities. This high fuel demand not only impacts operational costs but also raises environmental concerns, necessitating the development of more sustainable fuel solutions for long-term viability in the logistics sector.

The limited payload capacity of scramjet-powered aircraft poses a significant hurdle for their adoption in air freight. The need for streamlined designs to achieve hypersonic speeds often results in reduced cargo space compared to conventional freight aircraft. This limitation may restrict the types and quantities of goods that can be transported, potentially limiting the technology's applicability to specific high-value, time-sensitive cargo segments.

Infrastructure requirements present another substantial challenge. Scramjet-powered air freighters would require specialized facilities for takeoff, landing, and maintenance. Existing airports and cargo handling systems may need significant upgrades to accommodate these advanced aircraft, involving considerable investment in new infrastructure and training for ground personnel.

Regulatory hurdles and safety concerns also pose significant challenges to the implementation of scramjet technology in logistics. The operation of hypersonic aircraft in commercial airspace requires the development of new air traffic control systems and safety protocols. Regulatory bodies will need to establish comprehensive frameworks to ensure the safe integration of these high-speed vehicles into existing air traffic patterns.

Technical reliability and operational consistency are crucial factors that need to be addressed. Scramjet engines must demonstrate consistent performance across various atmospheric conditions and flight durations to be viable for commercial logistics operations. Ensuring the reliability of these complex propulsion systems under the demanding conditions of regular freight schedules presents a significant engineering challenge.

Current Scramjet Freight Solutions

01 Scramjet engine design for air freighters

Innovative scramjet engine designs specifically tailored for air freighters, focusing on improved efficiency, thrust, and fuel consumption at high speeds. These designs incorporate advanced combustion techniques and materials to withstand extreme temperatures and pressures encountered during hypersonic flight.- Scramjet engine design for air freighters: Specialized scramjet engine designs for air freighters focus on optimizing performance at high speeds and altitudes. These engines incorporate advanced combustion techniques, fuel injection systems, and thermal management to achieve efficient propulsion for large cargo-carrying aircraft. The designs aim to balance thrust output with fuel efficiency to make scramjet-powered air freighters economically viable for long-distance, high-speed cargo transport.

- Airframe integration for scramjet-powered freighters: Integrating scramjet engines into air freighter airframes requires careful consideration of aerodynamics, structural integrity, and payload capacity. Designs focus on optimizing the airframe shape to reduce drag at hypersonic speeds while maintaining stability and control. Special attention is given to thermal protection systems and materials to withstand the extreme temperatures generated during high-speed flight.

- Fuel systems for scramjet-powered air freighters: Advanced fuel systems are crucial for scramjet-powered air freighters to operate efficiently at high speeds. These systems include cryogenic fuel storage, high-pressure fuel pumps, and precise fuel injection mechanisms. The fuel systems are designed to provide optimal fuel-air mixing in the supersonic airflow, ensuring efficient combustion and thrust generation throughout the flight envelope.

- Control systems for scramjet-powered air freighters: Sophisticated control systems are essential for managing the complex operations of scramjet-powered air freighters. These systems include advanced flight control algorithms, real-time engine performance monitoring, and adaptive control mechanisms. They are designed to maintain stability and optimize performance across a wide range of flight conditions, from takeoff to hypersonic cruise and landing.

- Payload management for scramjet-powered air freighters: Efficient payload management systems are crucial for maximizing the cargo-carrying capacity of scramjet-powered air freighters. These systems include advanced loading and unloading mechanisms, weight distribution optimization, and cargo securing methods suitable for high-speed flight. The designs focus on minimizing turnaround time at airports while ensuring payload integrity during hypersonic transport.

02 Airframe integration and aerodynamics

Specialized airframe designs optimized for scramjet-powered air freighters, addressing the unique challenges of hypersonic flight. This includes advanced aerodynamic configurations, thermal management systems, and integration of the propulsion system with the airframe to minimize drag and maximize payload capacity.Expand Specific Solutions03 Fuel systems and management

Advanced fuel systems designed for scramjet-powered air freighters, including innovative storage, delivery, and cooling mechanisms. These systems focus on managing cryogenic fuels, ensuring efficient combustion at hypersonic speeds, and optimizing fuel consumption for long-range cargo transport.Expand Specific Solutions04 Cargo handling and payload systems

Specialized cargo handling and payload systems adapted for scramjet-powered air freighters, addressing the challenges of loading, securing, and unloading cargo at high-speed airports. These systems are designed to withstand the extreme conditions of hypersonic flight while maximizing cargo capacity and efficiency.Expand Specific Solutions05 Control systems and flight management

Advanced control systems and flight management technologies tailored for scramjet-powered air freighters, including sophisticated avionics, navigation systems, and autonomous flight capabilities. These systems are designed to handle the unique challenges of hypersonic flight, ensuring safe and efficient operation of air cargo transport at extreme speeds.Expand Specific Solutions

Key Players in Scramjet Freight

The competitive landscape for logistical applications of scramjet-powered air freighters is in an early developmental stage, with a small but growing market size and relatively low technological maturity. Key players include aerospace giants like Boeing and Northrop Grumman, alongside specialized propulsion companies such as Aerojet Rocketdyne. Research institutions like Nanjing University of Aeronautics & Astronautics and Beihang University are contributing to advancing the technology. While still experimental, interest is growing due to potential for ultra-high-speed cargo delivery, though significant technical and regulatory hurdles remain before commercial viability.

The Boeing Co.

Technical Solution: Boeing has been actively researching scramjet technology for potential application in air freighters. Their approach focuses on integrating scramjet propulsion systems into large-scale aircraft designs. The company is developing a hybrid propulsion system that combines traditional jet engines for takeoff and landing with scramjet engines for high-speed cruise[1]. This system aims to achieve hypersonic speeds (Mach 5+) for intercontinental cargo transport. Boeing's design incorporates advanced thermal management systems to handle the extreme temperatures generated during hypersonic flight[2]. They are also exploring novel airframe designs that can withstand the aerodynamic stresses of hypersonic travel while maintaining cargo capacity[3].

Strengths: Extensive experience in aircraft design and manufacturing; significant R&D resources. Weaknesses: High development costs; regulatory challenges for hypersonic civilian aircraft.

United Technologies Corp.

Technical Solution: United Technologies Corp. (UTC) is exploring scramjet technology for air freighter applications through its aerospace divisions. Their approach combines advanced propulsion research with innovative aircraft design concepts. UTC is developing a variable-geometry inlet system for scramjet engines, allowing for optimal performance across a wide range of speeds and altitudes[13]. The company is also investigating hybrid propulsion systems that integrate traditional turbofan engines with scramjets for versatile operation from takeoff to hypersonic cruise[14]. UTC's research includes advanced thermal management solutions to address the intense heat generated during hypersonic flight, incorporating novel heat exchanger designs and high-temperature materials[15].

Strengths: Broad expertise across multiple aerospace technologies; strong systems integration capabilities. Weaknesses: Potential organizational challenges due to recent mergers and acquisitions; competition from other aerospace priorities.

Breakthrough Scramjet Patents

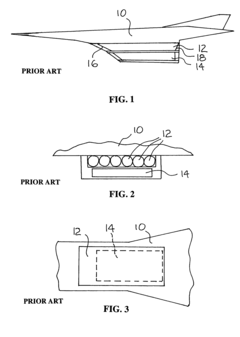

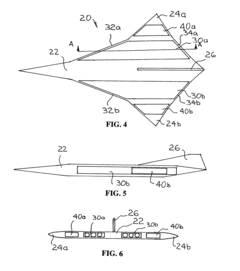

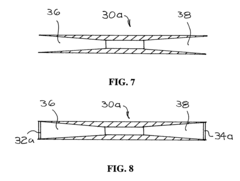

SCRAMjet arrangement for hypersonic aircraft

PatentActiveUS7828243B2

Innovation

- A lateral or side-by-side arrangement of turbojet and SCRAMjet engines, where the turbojet engines' inlet and outlet openings are covered to provide compression and expansion ramps for the SCRAMjet engines, reducing the need for a thick body and minimizing drag.

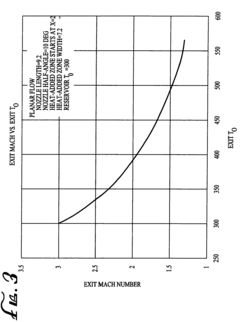

Method for using variable supersonic Mach number air heater utilizing supersonic combustion

PatentInactiveUS7296396B1

Innovation

- A supersonic combustion heater apparatus that varies exit plane Mach numbers through strategic fuel injection and flame stabilization in a fixed geometry nozzle, enhancing high enthalpy flow and flame stability without using expensive film cooled nozzles, allowing for mode transition testing in air-breathing propulsion systems.

Environmental Impact Assessment

The environmental impact of scramjet-powered air freighters is a critical consideration in their potential logistical applications. These advanced aircraft, capable of reaching hypersonic speeds, present both challenges and opportunities in terms of their ecological footprint.

One of the primary environmental concerns is the emissions produced by scramjet engines. Unlike conventional jet engines, scramjets utilize supersonic airflow for combustion, potentially resulting in different exhaust compositions. The high temperatures and pressures involved in scramjet operation may lead to increased nitrogen oxide (NOx) production, a significant contributor to air pollution and ozone depletion. However, the efficiency of scramjets at high speeds could potentially offset some of these emissions by reducing flight times and fuel consumption for long-distance cargo transport.

Noise pollution is another crucial factor to assess. Scramjet-powered aircraft operating at hypersonic speeds generate substantial sonic booms, which could have significant impacts on both human populations and wildlife along flight paths. This may necessitate careful route planning and potential restrictions on overland flights, particularly in densely populated areas or sensitive ecosystems.

The manufacturing and maintenance of scramjet-powered air freighters also warrant environmental scrutiny. The advanced materials and complex systems required for these aircraft may involve energy-intensive production processes and the use of rare or potentially hazardous materials. Life cycle assessments would be necessary to fully understand the environmental implications of scramjet freighter fleets from production to decommissioning.

On the positive side, the high-speed capabilities of scramjet-powered freighters could lead to reduced overall air traffic, as fewer flights would be needed to transport the same volume of cargo over long distances. This could potentially decrease the cumulative environmental impact of global air freight operations, including reduced contrail formation and lower overall fuel consumption.

The potential for scramjets to utilize alternative fuels, such as hydrogen, presents an opportunity for reducing carbon emissions. However, the production and storage of such fuels come with their own environmental considerations, including energy requirements and potential safety hazards.

Lastly, the impact on the upper atmosphere must be carefully studied. Scramjet operations at high altitudes could affect atmospheric chemistry and potentially contribute to climate change in ways that are not yet fully understood. Comprehensive atmospheric modeling and long-term studies would be essential to predict and mitigate any adverse effects on global climate systems.

In conclusion, while scramjet-powered air freighters offer promising advancements in logistics, their environmental impact must be thoroughly assessed and balanced against their potential benefits. Ongoing research and development should focus on minimizing emissions, noise pollution, and atmospheric effects to ensure that this technology contributes positively to sustainable global transportation systems.

One of the primary environmental concerns is the emissions produced by scramjet engines. Unlike conventional jet engines, scramjets utilize supersonic airflow for combustion, potentially resulting in different exhaust compositions. The high temperatures and pressures involved in scramjet operation may lead to increased nitrogen oxide (NOx) production, a significant contributor to air pollution and ozone depletion. However, the efficiency of scramjets at high speeds could potentially offset some of these emissions by reducing flight times and fuel consumption for long-distance cargo transport.

Noise pollution is another crucial factor to assess. Scramjet-powered aircraft operating at hypersonic speeds generate substantial sonic booms, which could have significant impacts on both human populations and wildlife along flight paths. This may necessitate careful route planning and potential restrictions on overland flights, particularly in densely populated areas or sensitive ecosystems.

The manufacturing and maintenance of scramjet-powered air freighters also warrant environmental scrutiny. The advanced materials and complex systems required for these aircraft may involve energy-intensive production processes and the use of rare or potentially hazardous materials. Life cycle assessments would be necessary to fully understand the environmental implications of scramjet freighter fleets from production to decommissioning.

On the positive side, the high-speed capabilities of scramjet-powered freighters could lead to reduced overall air traffic, as fewer flights would be needed to transport the same volume of cargo over long distances. This could potentially decrease the cumulative environmental impact of global air freight operations, including reduced contrail formation and lower overall fuel consumption.

The potential for scramjets to utilize alternative fuels, such as hydrogen, presents an opportunity for reducing carbon emissions. However, the production and storage of such fuels come with their own environmental considerations, including energy requirements and potential safety hazards.

Lastly, the impact on the upper atmosphere must be carefully studied. Scramjet operations at high altitudes could affect atmospheric chemistry and potentially contribute to climate change in ways that are not yet fully understood. Comprehensive atmospheric modeling and long-term studies would be essential to predict and mitigate any adverse effects on global climate systems.

In conclusion, while scramjet-powered air freighters offer promising advancements in logistics, their environmental impact must be thoroughly assessed and balanced against their potential benefits. Ongoing research and development should focus on minimizing emissions, noise pollution, and atmospheric effects to ensure that this technology contributes positively to sustainable global transportation systems.

Regulatory Framework for Hypersonic Freight

The regulatory framework for hypersonic freight is a complex and evolving landscape that requires careful consideration as scramjet-powered air freighters become a reality. Currently, there is no comprehensive international regulatory structure specifically designed for hypersonic freight operations. Existing aviation regulations, primarily developed for subsonic and supersonic flight, are inadequate to address the unique challenges posed by hypersonic transportation.

The International Civil Aviation Organization (ICAO) is expected to play a crucial role in developing global standards and recommended practices for hypersonic freight operations. However, this process is likely to be lengthy and require extensive collaboration between member states, industry stakeholders, and technical experts.

Key areas that need to be addressed in the regulatory framework include safety standards, airspace management, environmental impact, and noise regulations. Safety standards will need to account for the extreme speeds and temperatures experienced by hypersonic aircraft, as well as the potential risks associated with scramjet propulsion systems. Airspace management regulations must be updated to accommodate the unique flight profiles and rapid transit times of hypersonic freighters.

Environmental considerations are particularly critical, given the potential impact of hypersonic flight on the upper atmosphere and ozone layer. Regulations will need to establish limits on emissions and require ongoing monitoring of environmental effects. Noise regulations will also need to be revisited, as the sonic boom produced by hypersonic aircraft presents unique challenges for populated areas.

Certification processes for hypersonic freight aircraft and their components will need to be developed, requiring close cooperation between regulatory bodies and manufacturers. This may involve the creation of new testing protocols and performance standards specific to hypersonic flight.

International agreements on overflight rights and air traffic management will need to be negotiated to facilitate the global operation of hypersonic freight services. This may require updates to existing bilateral and multilateral air service agreements to account for the rapid transit times and unique operational characteristics of hypersonic aircraft.

As the technology matures, it is likely that a phased approach to regulation will be adopted. Initial regulations may focus on experimental and limited commercial operations, with more comprehensive frameworks being developed as the industry grows and operational experience is gained.

The International Civil Aviation Organization (ICAO) is expected to play a crucial role in developing global standards and recommended practices for hypersonic freight operations. However, this process is likely to be lengthy and require extensive collaboration between member states, industry stakeholders, and technical experts.

Key areas that need to be addressed in the regulatory framework include safety standards, airspace management, environmental impact, and noise regulations. Safety standards will need to account for the extreme speeds and temperatures experienced by hypersonic aircraft, as well as the potential risks associated with scramjet propulsion systems. Airspace management regulations must be updated to accommodate the unique flight profiles and rapid transit times of hypersonic freighters.

Environmental considerations are particularly critical, given the potential impact of hypersonic flight on the upper atmosphere and ozone layer. Regulations will need to establish limits on emissions and require ongoing monitoring of environmental effects. Noise regulations will also need to be revisited, as the sonic boom produced by hypersonic aircraft presents unique challenges for populated areas.

Certification processes for hypersonic freight aircraft and their components will need to be developed, requiring close cooperation between regulatory bodies and manufacturers. This may involve the creation of new testing protocols and performance standards specific to hypersonic flight.

International agreements on overflight rights and air traffic management will need to be negotiated to facilitate the global operation of hypersonic freight services. This may require updates to existing bilateral and multilateral air service agreements to account for the rapid transit times and unique operational characteristics of hypersonic aircraft.

As the technology matures, it is likely that a phased approach to regulation will be adopted. Initial regulations may focus on experimental and limited commercial operations, with more comprehensive frameworks being developed as the industry grows and operational experience is gained.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!