Exploring Micro-combustor Technologies in Miniature Scramjets

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro-combustor Evolution and Objectives

Micro-combustor technology in miniature scramjets has evolved significantly over the past few decades, driven by the increasing demand for compact propulsion systems in aerospace applications. The development of these miniaturized combustion devices has been closely tied to advancements in materials science, fluid dynamics, and combustion chemistry.

The journey of micro-combustor evolution began in the late 1990s with initial conceptual designs and feasibility studies. Early research focused on understanding the fundamental challenges of maintaining stable combustion in extremely small volumes. As the field progressed, researchers tackled issues such as heat management, fuel-air mixing, and flame stability in micro-scale environments.

By the mid-2000s, significant breakthroughs were achieved in fabrication techniques, allowing for the creation of more intricate and efficient micro-combustor designs. The integration of advanced materials, such as ceramics and high-temperature alloys, enabled improved thermal management and durability. Concurrently, computational fluid dynamics (CFD) simulations became more sophisticated, facilitating the optimization of combustor geometries and flow patterns.

The objectives of micro-combustor technology in miniature scramjets have been multifaceted. Primarily, researchers aim to achieve efficient and stable combustion in extremely confined spaces while maintaining high thrust-to-weight ratios. This goal necessitates overcoming challenges such as incomplete fuel-air mixing, thermal quenching, and boundary layer effects that are exacerbated at micro scales.

Another critical objective is to enhance the operational flexibility of micro-combustors, allowing them to function effectively across a wide range of flight conditions and fuel types. This includes developing adaptive control systems and innovative fuel injection methods to optimize performance in varying atmospheric conditions.

Improving the durability and lifespan of micro-combustors remains a key focus. The extreme temperatures and pressures experienced in scramjet engines pose significant material challenges, driving research into advanced cooling techniques and heat-resistant materials.

As the technology continues to mature, the overarching goal is to transition micro-combustor technology from laboratory experiments to practical, flight-worthy systems. This involves scaling up successful designs, integrating them with other scramjet components, and conducting extensive testing under realistic flight conditions.

Looking forward, the field of micro-combustor technology aims to push the boundaries of miniaturization while maintaining or improving combustion efficiency. Emerging objectives include the development of smart materials that can adapt to changing conditions, the integration of nanotechnology for enhanced surface properties, and the exploration of novel combustion concepts such as detonation-based propulsion at micro scales.

The journey of micro-combustor evolution began in the late 1990s with initial conceptual designs and feasibility studies. Early research focused on understanding the fundamental challenges of maintaining stable combustion in extremely small volumes. As the field progressed, researchers tackled issues such as heat management, fuel-air mixing, and flame stability in micro-scale environments.

By the mid-2000s, significant breakthroughs were achieved in fabrication techniques, allowing for the creation of more intricate and efficient micro-combustor designs. The integration of advanced materials, such as ceramics and high-temperature alloys, enabled improved thermal management and durability. Concurrently, computational fluid dynamics (CFD) simulations became more sophisticated, facilitating the optimization of combustor geometries and flow patterns.

The objectives of micro-combustor technology in miniature scramjets have been multifaceted. Primarily, researchers aim to achieve efficient and stable combustion in extremely confined spaces while maintaining high thrust-to-weight ratios. This goal necessitates overcoming challenges such as incomplete fuel-air mixing, thermal quenching, and boundary layer effects that are exacerbated at micro scales.

Another critical objective is to enhance the operational flexibility of micro-combustors, allowing them to function effectively across a wide range of flight conditions and fuel types. This includes developing adaptive control systems and innovative fuel injection methods to optimize performance in varying atmospheric conditions.

Improving the durability and lifespan of micro-combustors remains a key focus. The extreme temperatures and pressures experienced in scramjet engines pose significant material challenges, driving research into advanced cooling techniques and heat-resistant materials.

As the technology continues to mature, the overarching goal is to transition micro-combustor technology from laboratory experiments to practical, flight-worthy systems. This involves scaling up successful designs, integrating them with other scramjet components, and conducting extensive testing under realistic flight conditions.

Looking forward, the field of micro-combustor technology aims to push the boundaries of miniaturization while maintaining or improving combustion efficiency. Emerging objectives include the development of smart materials that can adapt to changing conditions, the integration of nanotechnology for enhanced surface properties, and the exploration of novel combustion concepts such as detonation-based propulsion at micro scales.

Market Analysis for Miniature Scramjet Applications

The market for miniature scramjet applications is experiencing significant growth, driven by increasing demand in aerospace and defense sectors. Miniature scramjets offer potential advantages in high-speed propulsion for small-scale vehicles, including missiles, drones, and experimental aircraft. The global market for these technologies is projected to expand rapidly over the next decade, with a compound annual growth rate exceeding industry averages.

Key factors contributing to market growth include advancements in materials science, improved manufacturing techniques, and rising investment in hypersonic technologies. The defense sector remains the primary driver, with several nations actively pursuing hypersonic weapon systems that could benefit from miniaturized scramjet propulsion. Additionally, there is growing interest from commercial space companies exploring reusable launch vehicles and high-speed point-to-point transportation concepts.

The market landscape is characterized by a mix of established aerospace companies and innovative startups. Major defense contractors are investing heavily in scramjet research and development, while newer entrants are focusing on niche applications and novel design approaches. Collaborations between industry and academic institutions are also accelerating progress in this field.

Geographically, North America currently dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, has made significant investments in hypersonic technologies, including miniature scramjet development. However, countries like China and Russia are rapidly advancing their capabilities, potentially reshaping the competitive landscape in the coming years.

Despite the promising outlook, several challenges could impact market growth. These include technical hurdles in achieving stable combustion at microscale, high development costs, and regulatory uncertainties surrounding hypersonic technologies. Additionally, concerns about the proliferation of advanced weapon systems may lead to export restrictions and limit market access for some players.

Looking ahead, the market for miniature scramjet applications is expected to diversify beyond military use. Potential civilian applications include high-speed atmospheric research platforms, rapid response vehicles for disaster management, and even future high-speed commercial transportation. However, these applications are likely to materialize in the longer term, as technology matures and costs decrease.

Overall, the market analysis indicates a robust growth trajectory for miniature scramjet technologies, driven by strategic defense priorities and the promise of revolutionary capabilities in aerospace applications. As research progresses and demonstration projects yield successful results, investor confidence is likely to strengthen, further fueling market expansion and technological innovation in this cutting-edge field.

Key factors contributing to market growth include advancements in materials science, improved manufacturing techniques, and rising investment in hypersonic technologies. The defense sector remains the primary driver, with several nations actively pursuing hypersonic weapon systems that could benefit from miniaturized scramjet propulsion. Additionally, there is growing interest from commercial space companies exploring reusable launch vehicles and high-speed point-to-point transportation concepts.

The market landscape is characterized by a mix of established aerospace companies and innovative startups. Major defense contractors are investing heavily in scramjet research and development, while newer entrants are focusing on niche applications and novel design approaches. Collaborations between industry and academic institutions are also accelerating progress in this field.

Geographically, North America currently dominates the market, followed by Europe and Asia-Pacific. The United States, in particular, has made significant investments in hypersonic technologies, including miniature scramjet development. However, countries like China and Russia are rapidly advancing their capabilities, potentially reshaping the competitive landscape in the coming years.

Despite the promising outlook, several challenges could impact market growth. These include technical hurdles in achieving stable combustion at microscale, high development costs, and regulatory uncertainties surrounding hypersonic technologies. Additionally, concerns about the proliferation of advanced weapon systems may lead to export restrictions and limit market access for some players.

Looking ahead, the market for miniature scramjet applications is expected to diversify beyond military use. Potential civilian applications include high-speed atmospheric research platforms, rapid response vehicles for disaster management, and even future high-speed commercial transportation. However, these applications are likely to materialize in the longer term, as technology matures and costs decrease.

Overall, the market analysis indicates a robust growth trajectory for miniature scramjet technologies, driven by strategic defense priorities and the promise of revolutionary capabilities in aerospace applications. As research progresses and demonstration projects yield successful results, investor confidence is likely to strengthen, further fueling market expansion and technological innovation in this cutting-edge field.

Micro-combustor Challenges and Limitations

Micro-combustors in miniature scramjets face significant challenges and limitations due to their small scale and extreme operating conditions. One of the primary obstacles is achieving stable and efficient combustion within the confined space. The reduced residence time of the fuel-air mixture in the combustor limits the time available for mixing and reaction, potentially leading to incomplete combustion and reduced efficiency.

The high-speed flow characteristic of scramjet engines further complicates the combustion process in micro-combustors. The supersonic airflow leaves minimal time for fuel injection, mixing, and ignition, making it challenging to maintain a stable flame. Additionally, the high-speed flow can cause flame blowout, where the flame is extinguished due to excessive flow velocity.

Thermal management presents another significant challenge in micro-combustor design. The high heat flux generated during combustion, combined with the limited surface area for heat dissipation, can lead to material degradation and structural failure. Ensuring adequate cooling while maintaining combustor performance is a delicate balance that engineers must strike.

Material selection for micro-combustors is crucial yet challenging. The materials must withstand extreme temperatures, thermal cycling, and oxidative environments while remaining lightweight. Advanced ceramics and high-temperature alloys are often employed, but their long-term durability and cost-effectiveness remain concerns.

Fuel injection and mixing in micro-combustors pose additional challenges. Achieving uniform fuel distribution and efficient mixing with the incoming air stream is difficult due to the limited space and short timescales involved. Innovative injector designs and mixing enhancement techniques are necessary to overcome these limitations.

Ignition and flame-holding in micro-combustors are also problematic. Traditional ignition methods may be inadequate or impractical at this scale, necessitating the development of novel ignition techniques. Maintaining a stable flame in the high-speed, turbulent flow environment requires careful design of flame-holding mechanisms.

Scaling effects introduce further complications in micro-combustor performance. As the combustor size decreases, surface area-to-volume ratios increase, leading to enhanced heat transfer and potential quenching of chemical reactions. This scaling effect can significantly impact combustion efficiency and stability.

Lastly, the integration of micro-combustors with other scramjet components presents its own set of challenges. Ensuring seamless interaction between the inlet, combustor, and nozzle while maintaining overall engine performance is a complex task that requires careful system-level design and optimization.

The high-speed flow characteristic of scramjet engines further complicates the combustion process in micro-combustors. The supersonic airflow leaves minimal time for fuel injection, mixing, and ignition, making it challenging to maintain a stable flame. Additionally, the high-speed flow can cause flame blowout, where the flame is extinguished due to excessive flow velocity.

Thermal management presents another significant challenge in micro-combustor design. The high heat flux generated during combustion, combined with the limited surface area for heat dissipation, can lead to material degradation and structural failure. Ensuring adequate cooling while maintaining combustor performance is a delicate balance that engineers must strike.

Material selection for micro-combustors is crucial yet challenging. The materials must withstand extreme temperatures, thermal cycling, and oxidative environments while remaining lightweight. Advanced ceramics and high-temperature alloys are often employed, but their long-term durability and cost-effectiveness remain concerns.

Fuel injection and mixing in micro-combustors pose additional challenges. Achieving uniform fuel distribution and efficient mixing with the incoming air stream is difficult due to the limited space and short timescales involved. Innovative injector designs and mixing enhancement techniques are necessary to overcome these limitations.

Ignition and flame-holding in micro-combustors are also problematic. Traditional ignition methods may be inadequate or impractical at this scale, necessitating the development of novel ignition techniques. Maintaining a stable flame in the high-speed, turbulent flow environment requires careful design of flame-holding mechanisms.

Scaling effects introduce further complications in micro-combustor performance. As the combustor size decreases, surface area-to-volume ratios increase, leading to enhanced heat transfer and potential quenching of chemical reactions. This scaling effect can significantly impact combustion efficiency and stability.

Lastly, the integration of micro-combustors with other scramjet components presents its own set of challenges. Ensuring seamless interaction between the inlet, combustor, and nozzle while maintaining overall engine performance is a complex task that requires careful system-level design and optimization.

Current Micro-combustor Design Solutions

01 Design optimization for improved combustion efficiency

Micro-combustors can be optimized through various design improvements to enhance combustion efficiency. This includes optimizing the combustion chamber geometry, fuel-air mixing mechanisms, and heat transfer characteristics. Advanced designs may incorporate features like swirl generators, catalytic surfaces, or micro-scale heat exchangers to promote better mixing and more complete combustion.- Design optimization for micro-combustors: Optimizing the design of micro-combustors is crucial for improving combustion efficiency. This includes considerations such as chamber geometry, fuel-air mixing mechanisms, and heat transfer characteristics. Advanced design techniques and computational fluid dynamics simulations can be employed to enhance the overall performance of micro-combustors.

- Catalytic combustion in micro-combustors: Incorporating catalytic materials in micro-combustors can significantly improve combustion efficiency. Catalysts promote complete combustion at lower temperatures, reduce emissions, and enhance fuel utilization. The selection and integration of appropriate catalytic materials are essential for optimizing the performance of micro-scale combustion systems.

- Fuel injection and mixing techniques: Efficient fuel injection and mixing are critical for achieving high combustion efficiency in micro-combustors. Advanced techniques such as micro-atomization, swirl-based mixing, and porous media injection can improve fuel-air mixing and combustion stability. Optimizing these processes leads to more complete combustion and reduced emissions.

- Heat recirculation and thermal management: Effective heat recirculation and thermal management strategies are essential for maintaining high combustion efficiency in micro-combustors. This includes the use of heat exchangers, insulation techniques, and innovative materials to minimize heat losses and maintain optimal combustion temperatures. Proper thermal management also contributes to the overall system efficiency and durability.

- Integration of micro-combustors with energy conversion systems: Integrating micro-combustors with various energy conversion systems, such as thermoelectric generators or micro-turbines, can enhance overall system efficiency. This integration requires careful consideration of interface design, power output optimization, and system-level efficiency improvements. The synergistic combination of micro-combustion and energy conversion technologies offers potential for compact and efficient power generation solutions.

02 Fuel injection and atomization techniques

Efficient fuel delivery and atomization are crucial for micro-combustor performance. Advanced fuel injection systems and atomization techniques can be employed to create finer droplets and improve fuel-air mixing. This may include the use of micro-nozzles, ultrasonic atomizers, or electrospray techniques to achieve better fuel dispersion and more uniform combustion.Expand Specific Solutions03 Catalytic combustion for enhanced efficiency

Incorporating catalytic materials or surfaces in micro-combustors can significantly improve combustion efficiency. Catalysts can lower the activation energy required for combustion reactions, allowing for more complete fuel oxidation at lower temperatures. This approach can lead to reduced emissions and improved overall system performance.Expand Specific Solutions04 Heat recirculation and thermal management

Effective thermal management and heat recirculation strategies can enhance micro-combustor efficiency. This may involve the use of heat exchangers, regenerative heating systems, or innovative insulation techniques to minimize heat losses and maintain optimal combustion temperatures. Proper thermal management can lead to improved flame stability and more complete fuel utilization.Expand Specific Solutions05 Integration of micro-combustors with power generation systems

Micro-combustors can be integrated with various power generation systems to improve overall energy conversion efficiency. This includes coupling micro-combustors with thermoelectric generators, micro-turbines, or other micro-scale power conversion devices. Such integration can lead to compact and efficient power generation solutions for portable or distributed energy applications.Expand Specific Solutions

Key Players in Micro-combustor Development

The exploration of micro-combustor technologies in miniature scramjets is in its early developmental stage, with a growing market potential driven by increasing interest in hypersonic propulsion systems. The competitive landscape is characterized by a mix of academic institutions and specialized aerospace companies. Key players include National University of Defense Technology, Beihang University, and Nanjing University of Aeronautics & Astronautics, which are at the forefront of research in this field. The technology is still in the experimental phase, with ongoing efforts to improve combustion efficiency and stability at microscale levels. Companies like Jiangxi Hongdu Aviation Industry and Sichuan Aerospace Zhongtian Power Equipment are likely to play crucial roles in translating research into practical applications as the technology matures.

National University of Defense Technology

Technical Solution: The National University of Defense Technology (NUDT) has been at the forefront of micro-combustor technologies for miniature scramjets. Their research focuses on developing advanced combustion systems that can operate efficiently in supersonic airflows. NUDT has pioneered the use of cavity-based flame holders to enhance fuel-air mixing and stabilize combustion in micro-scale environments[1]. They have also implemented innovative fuel injection strategies, including transverse and angled injection, to optimize fuel distribution and combustion efficiency in miniature scramjet engines[2]. Additionally, NUDT has made significant progress in thermal management techniques, utilizing advanced materials and cooling systems to mitigate the extreme temperatures encountered in micro-combustors[3].

Strengths: Extensive experience in supersonic combustion, advanced flame stabilization techniques, and thermal management. Weaknesses: Potential limitations in scaling up technologies for larger applications, and possible restrictions on international collaboration due to defense-related research.

Beihang University

Technical Solution: Beihang University has made substantial contributions to micro-combustor technologies for miniature scramjets. Their research team has developed innovative plasma-assisted combustion techniques to enhance flame stability and combustion efficiency in micro-scale environments[1]. They have also explored the use of nano-energetic materials as additives to conventional hydrocarbon fuels, significantly improving ignition characteristics and combustion rates in miniature scramjet engines[2]. Beihang's researchers have implemented advanced diagnostic techniques, such as high-speed imaging and laser-induced fluorescence, to gain deeper insights into the complex flow and combustion phenomena within micro-combustors[3]. Furthermore, they have made progress in computational fluid dynamics (CFD) simulations, enabling more accurate predictions of combustor performance and optimization of design parameters[4].

Strengths: Cutting-edge plasma-assisted combustion techniques, expertise in nano-energetic materials, and advanced diagnostic capabilities. Weaknesses: Potential challenges in transitioning laboratory-scale technologies to practical applications, and possible limitations in long-duration testing of micro-combustors.

Innovative Micro-combustor Technologies

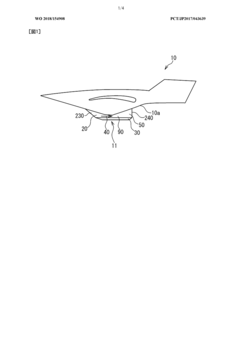

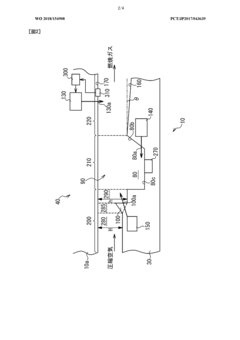

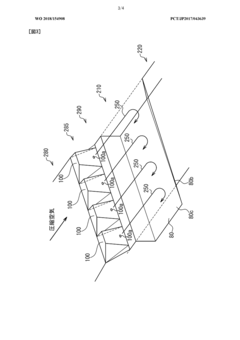

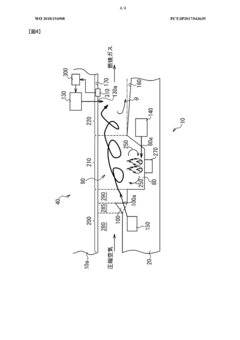

Scramjet engine

PatentWO2018154908A1

Innovation

- The scramjet engine design incorporates a flow path with convex portions on the first surface to create turbulence, a cavity for flame holding, and multiple fuel injection sections to efficiently mix and combust air and fuel, ensuring complete combustion by controlling the fuel injection amount and direction.

Apparatus for supersonic combustion in a restricted length

PatentInactiveUS5253474A

Innovation

- A supersonic combustor design featuring a backward-facing step with a forward-facing ramp and axial or normal fuel injection, where the ramp converges into the combustion cavity to ensure fuel penetration and mixing, and optionally spanwise channels to enhance shear mixing, allowing for rapid combustion within a distance of one foot or less.

Materials Science Advancements for Micro-combustors

The development of micro-combustor technologies for miniature scramjets has been significantly influenced by advancements in materials science. These advancements have played a crucial role in overcoming the challenges associated with high-temperature environments and extreme operating conditions.

One of the key areas of focus has been the development of high-temperature resistant materials. Ceramic matrix composites (CMCs) have emerged as promising candidates for micro-combustor applications due to their excellent thermal and mechanical properties. These materials, such as silicon carbide (SiC) and carbon-carbon (C/C) composites, can withstand temperatures exceeding 2000°C while maintaining structural integrity.

Thermal barrier coatings (TBCs) have also seen significant improvements. Advanced TBCs, typically composed of yttria-stabilized zirconia (YSZ), provide enhanced thermal insulation and protection against oxidation. Recent research has focused on developing nanostructured TBCs with improved durability and lower thermal conductivity.

Novel manufacturing techniques have enabled the production of complex geometries and intricate cooling channels within micro-combustors. Additive manufacturing, particularly selective laser melting (SLM) and electron beam melting (EBM), has allowed for the fabrication of lightweight, high-strength components with optimized internal structures.

The integration of smart materials and sensors into micro-combustor designs has been another area of advancement. Shape memory alloys (SMAs) and piezoelectric materials have been explored for active flow control and combustion optimization. These materials can respond to changes in temperature and pressure, allowing for real-time adjustments to combustor performance.

Nanomaterials have also shown promise in enhancing combustion efficiency and stability. Catalytic nanoparticles, such as platinum and palladium, have been incorporated into combustor walls to promote fuel oxidation and reduce emissions. Carbon nanotubes and graphene-based materials have been investigated for their potential to improve heat transfer and structural properties.

Advancements in surface engineering have led to the development of coatings with improved catalytic activity and durability. Plasma-sprayed catalytic coatings and atomic layer deposition (ALD) techniques have enabled the creation of highly active and stable surfaces for enhanced combustion performance.

The pursuit of materials with lower thermal expansion coefficients has been crucial for maintaining dimensional stability in micro-combustors. Materials such as low expansion superalloys and ceramic-metal composites (cermets) have been developed to minimize thermal stresses and improve overall system reliability.

One of the key areas of focus has been the development of high-temperature resistant materials. Ceramic matrix composites (CMCs) have emerged as promising candidates for micro-combustor applications due to their excellent thermal and mechanical properties. These materials, such as silicon carbide (SiC) and carbon-carbon (C/C) composites, can withstand temperatures exceeding 2000°C while maintaining structural integrity.

Thermal barrier coatings (TBCs) have also seen significant improvements. Advanced TBCs, typically composed of yttria-stabilized zirconia (YSZ), provide enhanced thermal insulation and protection against oxidation. Recent research has focused on developing nanostructured TBCs with improved durability and lower thermal conductivity.

Novel manufacturing techniques have enabled the production of complex geometries and intricate cooling channels within micro-combustors. Additive manufacturing, particularly selective laser melting (SLM) and electron beam melting (EBM), has allowed for the fabrication of lightweight, high-strength components with optimized internal structures.

The integration of smart materials and sensors into micro-combustor designs has been another area of advancement. Shape memory alloys (SMAs) and piezoelectric materials have been explored for active flow control and combustion optimization. These materials can respond to changes in temperature and pressure, allowing for real-time adjustments to combustor performance.

Nanomaterials have also shown promise in enhancing combustion efficiency and stability. Catalytic nanoparticles, such as platinum and palladium, have been incorporated into combustor walls to promote fuel oxidation and reduce emissions. Carbon nanotubes and graphene-based materials have been investigated for their potential to improve heat transfer and structural properties.

Advancements in surface engineering have led to the development of coatings with improved catalytic activity and durability. Plasma-sprayed catalytic coatings and atomic layer deposition (ALD) techniques have enabled the creation of highly active and stable surfaces for enhanced combustion performance.

The pursuit of materials with lower thermal expansion coefficients has been crucial for maintaining dimensional stability in micro-combustors. Materials such as low expansion superalloys and ceramic-metal composites (cermets) have been developed to minimize thermal stresses and improve overall system reliability.

Environmental Impact of Micro-combustor Technologies

The environmental impact of micro-combustor technologies in miniature scramjets is a critical consideration as these advanced propulsion systems continue to evolve. While these technologies offer significant advantages in terms of efficiency and performance, their potential environmental effects must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with micro-combustor technologies is the emission of pollutants. Due to the high temperatures and pressures involved in scramjet combustion, there is a potential for increased production of nitrogen oxides (NOx), which are known contributors to air pollution and acid rain. However, the compact nature of micro-combustors may actually lead to more efficient combustion processes, potentially reducing overall emissions compared to larger-scale propulsion systems.

The use of advanced materials in micro-combustor design also raises environmental considerations. Many of these materials are rare or difficult to extract, and their production may have significant environmental impacts. Additionally, the disposal or recycling of these specialized components at the end of their lifecycle presents challenges that must be addressed to minimize environmental harm.

Noise pollution is another environmental factor to consider. While miniature scramjets are generally quieter than their larger counterparts, the high-speed nature of their operation still produces significant acoustic emissions. This could have implications for wildlife and human populations in areas where these technologies are deployed or tested.

From a broader perspective, the development of micro-combustor technologies could lead to more efficient and capable aerospace vehicles. This, in turn, could result in reduced fuel consumption and emissions on a per-mission basis. However, it may also enable more frequent and widespread use of high-speed aircraft, potentially offsetting these gains.

The impact on the upper atmosphere is an area of particular concern. As miniature scramjets are designed to operate at very high altitudes, their emissions could have direct effects on the sensitive balance of gases in the stratosphere and mesosphere. This includes potential interactions with the ozone layer, which plays a crucial role in protecting Earth from harmful ultraviolet radiation.

Water vapor emissions from these advanced propulsion systems, while often overlooked, can also have significant environmental implications. At high altitudes, water vapor can contribute to the formation of clouds, potentially affecting global climate patterns. The extent of this impact would depend on the scale of deployment and operational frequency of vehicles utilizing micro-combustor technologies.

In conclusion, while micro-combustor technologies in miniature scramjets offer promising advancements in aerospace propulsion, their environmental impact must be thoroughly assessed and managed. Ongoing research and development efforts should prioritize minimizing emissions, optimizing material use, and understanding long-term atmospheric effects to ensure that these technologies can be implemented sustainably.

One of the primary environmental concerns associated with micro-combustor technologies is the emission of pollutants. Due to the high temperatures and pressures involved in scramjet combustion, there is a potential for increased production of nitrogen oxides (NOx), which are known contributors to air pollution and acid rain. However, the compact nature of micro-combustors may actually lead to more efficient combustion processes, potentially reducing overall emissions compared to larger-scale propulsion systems.

The use of advanced materials in micro-combustor design also raises environmental considerations. Many of these materials are rare or difficult to extract, and their production may have significant environmental impacts. Additionally, the disposal or recycling of these specialized components at the end of their lifecycle presents challenges that must be addressed to minimize environmental harm.

Noise pollution is another environmental factor to consider. While miniature scramjets are generally quieter than their larger counterparts, the high-speed nature of their operation still produces significant acoustic emissions. This could have implications for wildlife and human populations in areas where these technologies are deployed or tested.

From a broader perspective, the development of micro-combustor technologies could lead to more efficient and capable aerospace vehicles. This, in turn, could result in reduced fuel consumption and emissions on a per-mission basis. However, it may also enable more frequent and widespread use of high-speed aircraft, potentially offsetting these gains.

The impact on the upper atmosphere is an area of particular concern. As miniature scramjets are designed to operate at very high altitudes, their emissions could have direct effects on the sensitive balance of gases in the stratosphere and mesosphere. This includes potential interactions with the ozone layer, which plays a crucial role in protecting Earth from harmful ultraviolet radiation.

Water vapor emissions from these advanced propulsion systems, while often overlooked, can also have significant environmental implications. At high altitudes, water vapor can contribute to the formation of clouds, potentially affecting global climate patterns. The extent of this impact would depend on the scale of deployment and operational frequency of vehicles utilizing micro-combustor technologies.

In conclusion, while micro-combustor technologies in miniature scramjets offer promising advancements in aerospace propulsion, their environmental impact must be thoroughly assessed and managed. Ongoing research and development efforts should prioritize minimizing emissions, optimizing material use, and understanding long-term atmospheric effects to ensure that these technologies can be implemented sustainably.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!