Thermal Stress Analysis of Scramjets During Sustained Operations

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Thermal Stress Background and Objectives

Scramjet technology has been a focal point in aerospace engineering for decades, with its potential to revolutionize high-speed flight and space access. The concept of supersonic combustion ramjets, or scramjets, dates back to the 1950s, but significant progress has been made in recent years. These engines offer the promise of hypersonic flight, operating at speeds above Mach 5, by utilizing the high-speed airflow to compress incoming air without the need for moving parts.

The evolution of scramjet technology has been marked by several key milestones, including the successful flight of NASA's X-43A in 2004, which achieved a speed of Mach 9.6, and more recently, the development of the X-51 Waverider. These achievements have demonstrated the viability of scramjet propulsion and have set the stage for further advancements in the field.

However, one of the most critical challenges facing scramjet technology is the management of thermal stress during sustained operations. As scramjets operate at extreme velocities, they generate intense heat due to air friction and combustion processes. This heat can cause significant thermal stress on the engine components, potentially leading to structural failure or performance degradation.

The primary objective of thermal stress analysis in scramjets is to ensure the structural integrity and operational efficiency of the engine during prolonged flight. This involves understanding the complex interplay between aerodynamic heating, material properties, and structural design. Researchers aim to develop materials and cooling systems that can withstand the extreme temperatures and stresses encountered during hypersonic flight.

Another key goal is to optimize the engine design to minimize thermal stress while maintaining performance. This includes investigating advanced cooling techniques, such as regenerative cooling and transpiration cooling, as well as exploring novel materials with high temperature resistance and low thermal expansion coefficients.

Furthermore, the development of accurate simulation models for thermal stress analysis is crucial. These models must account for the complex fluid dynamics, heat transfer, and structural mechanics involved in scramjet operation. By improving the fidelity of these simulations, engineers can better predict and mitigate thermal stress issues before physical testing, thereby reducing development costs and accelerating the design process.

Ultimately, the successful management of thermal stress in scramjets is essential for realizing their full potential in applications such as high-speed military aircraft, rapid global transportation, and affordable space access. As research in this field progresses, it is expected to drive innovations in materials science, computational modeling, and aerospace engineering, paving the way for a new era of hypersonic flight capabilities.

The evolution of scramjet technology has been marked by several key milestones, including the successful flight of NASA's X-43A in 2004, which achieved a speed of Mach 9.6, and more recently, the development of the X-51 Waverider. These achievements have demonstrated the viability of scramjet propulsion and have set the stage for further advancements in the field.

However, one of the most critical challenges facing scramjet technology is the management of thermal stress during sustained operations. As scramjets operate at extreme velocities, they generate intense heat due to air friction and combustion processes. This heat can cause significant thermal stress on the engine components, potentially leading to structural failure or performance degradation.

The primary objective of thermal stress analysis in scramjets is to ensure the structural integrity and operational efficiency of the engine during prolonged flight. This involves understanding the complex interplay between aerodynamic heating, material properties, and structural design. Researchers aim to develop materials and cooling systems that can withstand the extreme temperatures and stresses encountered during hypersonic flight.

Another key goal is to optimize the engine design to minimize thermal stress while maintaining performance. This includes investigating advanced cooling techniques, such as regenerative cooling and transpiration cooling, as well as exploring novel materials with high temperature resistance and low thermal expansion coefficients.

Furthermore, the development of accurate simulation models for thermal stress analysis is crucial. These models must account for the complex fluid dynamics, heat transfer, and structural mechanics involved in scramjet operation. By improving the fidelity of these simulations, engineers can better predict and mitigate thermal stress issues before physical testing, thereby reducing development costs and accelerating the design process.

Ultimately, the successful management of thermal stress in scramjets is essential for realizing their full potential in applications such as high-speed military aircraft, rapid global transportation, and affordable space access. As research in this field progresses, it is expected to drive innovations in materials science, computational modeling, and aerospace engineering, paving the way for a new era of hypersonic flight capabilities.

Market Demand for Hypersonic Technologies

The market demand for hypersonic technologies has been experiencing significant growth in recent years, driven by both military and commercial applications. In the defense sector, the development of hypersonic weapons and vehicles has become a top priority for major global powers, including the United States, Russia, and China. These nations are investing heavily in research and development to gain strategic advantages in this cutting-edge field.

The commercial aerospace industry is also showing increased interest in hypersonic technologies, particularly for long-distance travel and space exploration. Companies like SpaceX, Boeing, and Lockheed Martin are actively pursuing hypersonic aircraft designs that could revolutionize intercontinental travel, potentially reducing flight times between major cities to just a few hours.

The global hypersonic technology market is projected to grow substantially over the next decade. This growth is fueled by increasing defense budgets, advancements in materials science, and breakthroughs in propulsion systems. The scramjet engine, a key component in hypersonic vehicles, is at the forefront of this technological revolution.

Thermal stress analysis of scramjets during sustained operations is a critical area of research within the hypersonic technology field. As hypersonic vehicles operate at extreme speeds and temperatures, managing thermal stresses becomes paramount for ensuring the structural integrity and performance of these advanced propulsion systems. This has led to a surge in demand for sophisticated thermal management solutions and high-temperature materials capable of withstanding the harsh conditions encountered during hypersonic flight.

The market for thermal stress analysis tools and techniques specific to scramjet engines is expanding rapidly. Engineering firms, aerospace manufacturers, and research institutions are seeking advanced simulation software, testing facilities, and specialized sensors to accurately model and measure thermal stresses in hypersonic environments. This demand is driving innovation in computational fluid dynamics (CFD) software, thermal imaging technologies, and advanced materials testing equipment.

Furthermore, the need for skilled professionals specializing in hypersonic thermal analysis is growing. Universities and research centers are developing specialized programs to train the next generation of engineers and scientists in this field, responding to the increasing demand from both government agencies and private sector companies involved in hypersonic technology development.

As the market for hypersonic technologies continues to evolve, the importance of thermal stress analysis in scramjet design and operation is likely to become even more pronounced. This trend is expected to drive further investments in research, development, and testing facilities dedicated to addressing the unique challenges posed by sustained hypersonic flight.

The commercial aerospace industry is also showing increased interest in hypersonic technologies, particularly for long-distance travel and space exploration. Companies like SpaceX, Boeing, and Lockheed Martin are actively pursuing hypersonic aircraft designs that could revolutionize intercontinental travel, potentially reducing flight times between major cities to just a few hours.

The global hypersonic technology market is projected to grow substantially over the next decade. This growth is fueled by increasing defense budgets, advancements in materials science, and breakthroughs in propulsion systems. The scramjet engine, a key component in hypersonic vehicles, is at the forefront of this technological revolution.

Thermal stress analysis of scramjets during sustained operations is a critical area of research within the hypersonic technology field. As hypersonic vehicles operate at extreme speeds and temperatures, managing thermal stresses becomes paramount for ensuring the structural integrity and performance of these advanced propulsion systems. This has led to a surge in demand for sophisticated thermal management solutions and high-temperature materials capable of withstanding the harsh conditions encountered during hypersonic flight.

The market for thermal stress analysis tools and techniques specific to scramjet engines is expanding rapidly. Engineering firms, aerospace manufacturers, and research institutions are seeking advanced simulation software, testing facilities, and specialized sensors to accurately model and measure thermal stresses in hypersonic environments. This demand is driving innovation in computational fluid dynamics (CFD) software, thermal imaging technologies, and advanced materials testing equipment.

Furthermore, the need for skilled professionals specializing in hypersonic thermal analysis is growing. Universities and research centers are developing specialized programs to train the next generation of engineers and scientists in this field, responding to the increasing demand from both government agencies and private sector companies involved in hypersonic technology development.

As the market for hypersonic technologies continues to evolve, the importance of thermal stress analysis in scramjet design and operation is likely to become even more pronounced. This trend is expected to drive further investments in research, development, and testing facilities dedicated to addressing the unique challenges posed by sustained hypersonic flight.

Current Challenges in Scramjet Thermal Management

Scramjet thermal management presents significant challenges due to the extreme operating conditions these engines encounter during sustained hypersonic flight. The primary issue stems from the intense aerodynamic heating experienced at high Mach numbers, which can cause structural damage and compromise engine performance. Current thermal protection systems struggle to dissipate heat effectively while maintaining the structural integrity of the engine.

One of the main challenges is the development of advanced materials capable of withstanding prolonged exposure to temperatures exceeding 2000°C. Traditional aerospace alloys and composites often fail under such extreme conditions, necessitating the exploration of novel materials like ultra-high temperature ceramics (UHTCs) and ceramic matrix composites (CMCs). However, these materials present their own set of challenges, including manufacturing difficulties, brittleness, and thermal expansion mismatches.

Another critical issue is the design of efficient cooling systems that can manage the heat load without significantly impacting engine performance. Active cooling methods, such as regenerative cooling using the fuel as a heat sink, are promising but require complex fuel management systems and introduce additional weight. Passive cooling techniques, like thermal barrier coatings, are limited in their effectiveness during extended operations.

The accurate prediction and mitigation of thermal stresses pose a significant challenge in scramjet design. The non-uniform heating of engine components leads to thermal gradients that induce mechanical stresses, potentially causing warping, cracking, or failure of critical structures. Developing reliable computational models to predict these thermal stresses under various operating conditions remains an ongoing challenge.

Furthermore, the integration of thermal management systems with other engine subsystems presents a complex engineering problem. Balancing the requirements for thermal protection with those for propulsion efficiency, structural integrity, and overall vehicle performance requires a holistic approach to engine design. This integration challenge is compounded by the limited space and weight constraints inherent in hypersonic vehicle design.

The development of durable seals and joints capable of maintaining their integrity under extreme thermal cycling is another area of concern. These components are critical for preventing hot gas ingestion and maintaining engine efficiency but are particularly vulnerable to thermal stress and wear.

Lastly, the lack of comprehensive flight test data for sustained scramjet operations hinders the validation of thermal management strategies. Ground-based testing facilities struggle to fully replicate the combined thermal, mechanical, and aerodynamic loads experienced during actual hypersonic flight, making it difficult to verify the long-term effectiveness of thermal protection systems.

One of the main challenges is the development of advanced materials capable of withstanding prolonged exposure to temperatures exceeding 2000°C. Traditional aerospace alloys and composites often fail under such extreme conditions, necessitating the exploration of novel materials like ultra-high temperature ceramics (UHTCs) and ceramic matrix composites (CMCs). However, these materials present their own set of challenges, including manufacturing difficulties, brittleness, and thermal expansion mismatches.

Another critical issue is the design of efficient cooling systems that can manage the heat load without significantly impacting engine performance. Active cooling methods, such as regenerative cooling using the fuel as a heat sink, are promising but require complex fuel management systems and introduce additional weight. Passive cooling techniques, like thermal barrier coatings, are limited in their effectiveness during extended operations.

The accurate prediction and mitigation of thermal stresses pose a significant challenge in scramjet design. The non-uniform heating of engine components leads to thermal gradients that induce mechanical stresses, potentially causing warping, cracking, or failure of critical structures. Developing reliable computational models to predict these thermal stresses under various operating conditions remains an ongoing challenge.

Furthermore, the integration of thermal management systems with other engine subsystems presents a complex engineering problem. Balancing the requirements for thermal protection with those for propulsion efficiency, structural integrity, and overall vehicle performance requires a holistic approach to engine design. This integration challenge is compounded by the limited space and weight constraints inherent in hypersonic vehicle design.

The development of durable seals and joints capable of maintaining their integrity under extreme thermal cycling is another area of concern. These components are critical for preventing hot gas ingestion and maintaining engine efficiency but are particularly vulnerable to thermal stress and wear.

Lastly, the lack of comprehensive flight test data for sustained scramjet operations hinders the validation of thermal management strategies. Ground-based testing facilities struggle to fully replicate the combined thermal, mechanical, and aerodynamic loads experienced during actual hypersonic flight, making it difficult to verify the long-term effectiveness of thermal protection systems.

Existing Thermal Stress Mitigation Strategies

01 Thermal management systems for scramjets

Advanced thermal management systems are crucial for scramjets to handle the extreme heat generated during hypersonic flight. These systems may include active cooling methods, heat-resistant materials, and innovative heat dissipation techniques to protect critical components and maintain structural integrity under high thermal stress.- Thermal management systems for scramjets: Advanced thermal management systems are crucial for scramjets to handle extreme temperatures during hypersonic flight. These systems may include active cooling methods, heat-resistant materials, and innovative heat dissipation techniques to protect critical components and maintain structural integrity under high thermal stress.

- Materials selection for thermal stress resistance: Selecting appropriate materials that can withstand high temperatures and thermal stress is essential for scramjet design. This includes the use of advanced alloys, ceramics, and composite materials that offer superior heat resistance and maintain their mechanical properties under extreme conditions.

- Thermal stress analysis and simulation: Utilizing advanced computational methods and simulation tools to analyze and predict thermal stress distribution in scramjet components. This helps in identifying critical areas prone to thermal fatigue and optimizing the design to mitigate potential failures due to thermal stress.

- Cooling techniques for scramjet engines: Implementing innovative cooling techniques to manage thermal stress in scramjet engines. This may include regenerative cooling systems, film cooling, transpiration cooling, or the use of coolant flows to protect engine components from excessive heat and maintain optimal performance.

- Structural design for thermal stress mitigation: Developing specialized structural designs that can accommodate thermal expansion and contraction while maintaining the integrity of the scramjet. This includes the use of flexible joints, thermal expansion gaps, and strategic placement of components to minimize thermal stress concentrations.

02 Heat-resistant materials and coatings

Development of specialized heat-resistant materials and coatings is essential for scramjet components exposed to extreme temperatures. These materials may include advanced ceramics, metal alloys, or composite materials designed to withstand high thermal stress and maintain their properties in hypersonic environments.Expand Specific Solutions03 Structural design optimization for thermal stress mitigation

Innovative structural designs are employed to mitigate thermal stress in scramjets. This may involve the use of thermal expansion joints, stress-relieving geometries, or adaptive structures that can accommodate thermal deformation without compromising performance or safety.Expand Specific Solutions04 Thermal sensors and monitoring systems

Advanced thermal sensors and monitoring systems are integrated into scramjets to provide real-time data on temperature distribution and thermal stress. This information is crucial for active thermal management and early detection of potential issues related to thermal stress.Expand Specific Solutions05 Computational modeling and simulation for thermal stress analysis

Sophisticated computational modeling and simulation techniques are used to analyze and predict thermal stress in scramjet engines. These tools help in optimizing designs, materials selection, and thermal management strategies before physical testing, reducing development time and costs.Expand Specific Solutions

Key Players in Scramjet Development

The thermal stress analysis of scramjets during sustained operations represents a critical challenge in the field of hypersonic propulsion. This technology is currently in an advanced development stage, with significant market potential in aerospace and defense sectors. The global market for scramjet technology is expanding, driven by increasing investments in hypersonic research. Technologically, the field is maturing rapidly, with key players like National University of Defense Technology, Harbin Institute of Technology, and Northwestern Polytechnical University leading research efforts in China. In the United States, institutions such as Mississippi State University are contributing to advancements, while companies like GE Infrastructure Technology and Mitsubishi Heavy Industries are developing industrial applications. The competitive landscape is characterized by a mix of academic institutions and aerospace corporations, indicating a collaborative approach to solving complex thermal management issues in scramjet operations.

National University of Defense Technology

Technical Solution: The National University of Defense Technology (NUDT) has developed advanced computational fluid dynamics (CFD) models for thermal stress analysis of scramjets during sustained operations. Their approach integrates high-fidelity numerical simulations with experimental data to accurately predict temperature distributions and thermal stresses in critical components. NUDT's method employs adaptive mesh refinement techniques to capture complex flow structures and heat transfer phenomena, resulting in improved computational efficiency[1]. The university has also pioneered the use of machine learning algorithms to optimize scramjet designs for enhanced thermal management, reducing the need for extensive wind tunnel testing[3].

Strengths: Advanced CFD capabilities, integration of experimental and numerical methods, and innovative use of machine learning. Weaknesses: Potential limitations in real-world validation due to the classified nature of some scramjet technologies.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology (HIT) has developed a comprehensive thermal stress analysis framework for scramjets, focusing on the interaction between aerodynamic heating and structural deformation. Their approach utilizes a coupled fluid-structure interaction (FSI) model that accounts for the complex interplay between high-speed flow, heat transfer, and material behavior. HIT's methodology incorporates advanced material models for high-temperature alloys and composites commonly used in scramjet construction[2]. The institute has also developed novel cooling strategies, including transpiration cooling and regenerative cooling systems, to mitigate thermal stresses during sustained operations[4]. Their research has led to the development of a thermal protection system that can withstand temperatures exceeding 2000°C for extended periods[5].

Strengths: Comprehensive FSI modeling, advanced material characterization, and innovative cooling strategies. Weaknesses: Potential challenges in scaling laboratory results to full-scale scramjet engines.

Innovative Materials for Scramjet Heat Resistance

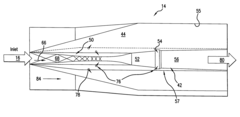

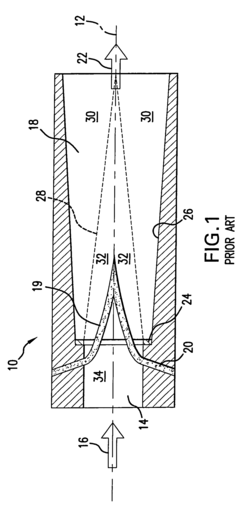

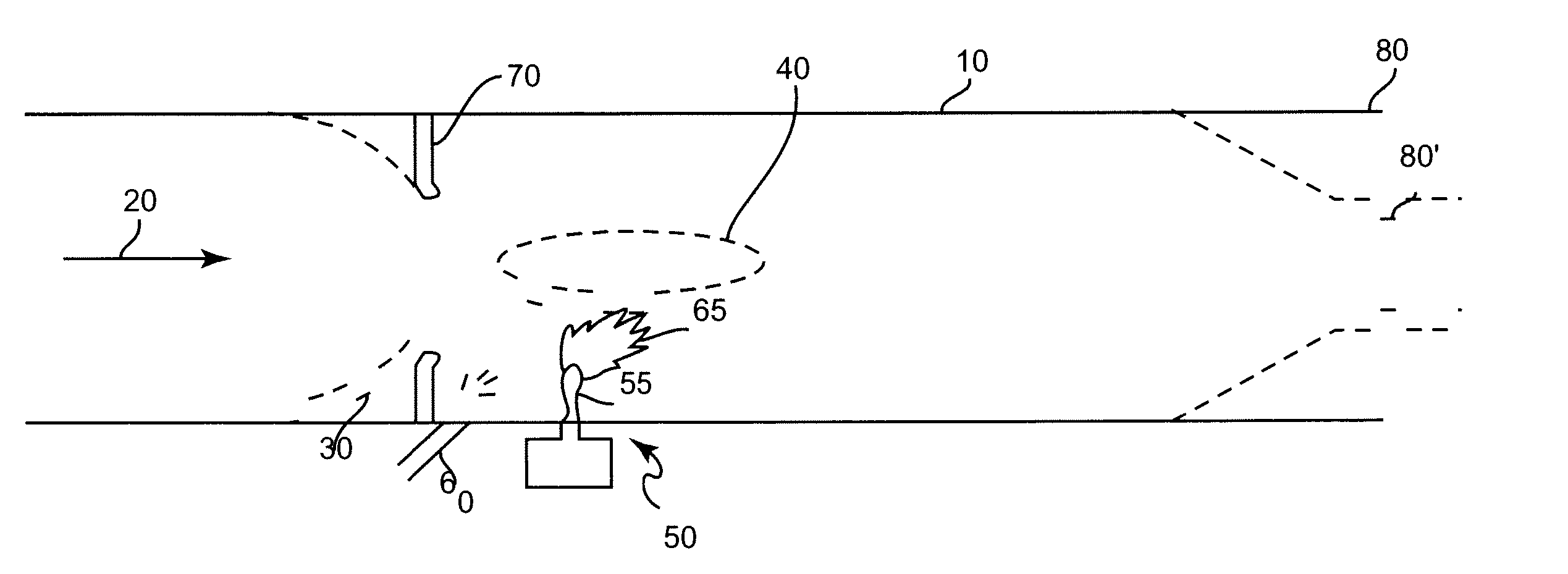

Core burning for scramjet engines

PatentInactiveUS7797943B2

Innovation

- The implementation of a strut pilot system with in-stream fuel injection and a lean outer annulus in the scramjet combustor, where the flame front is delayed to reduce heat load on the walls, and the bulk of combustion is confined to the combustor center, referred to as 'core-burning', minimizing hot spots and reducing combustor length.

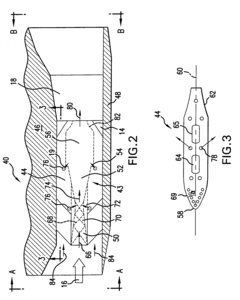

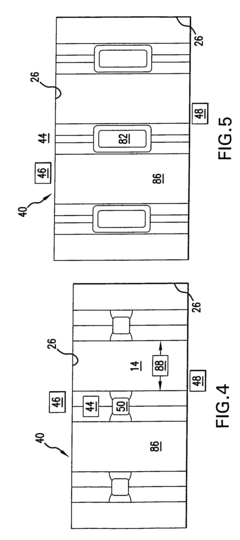

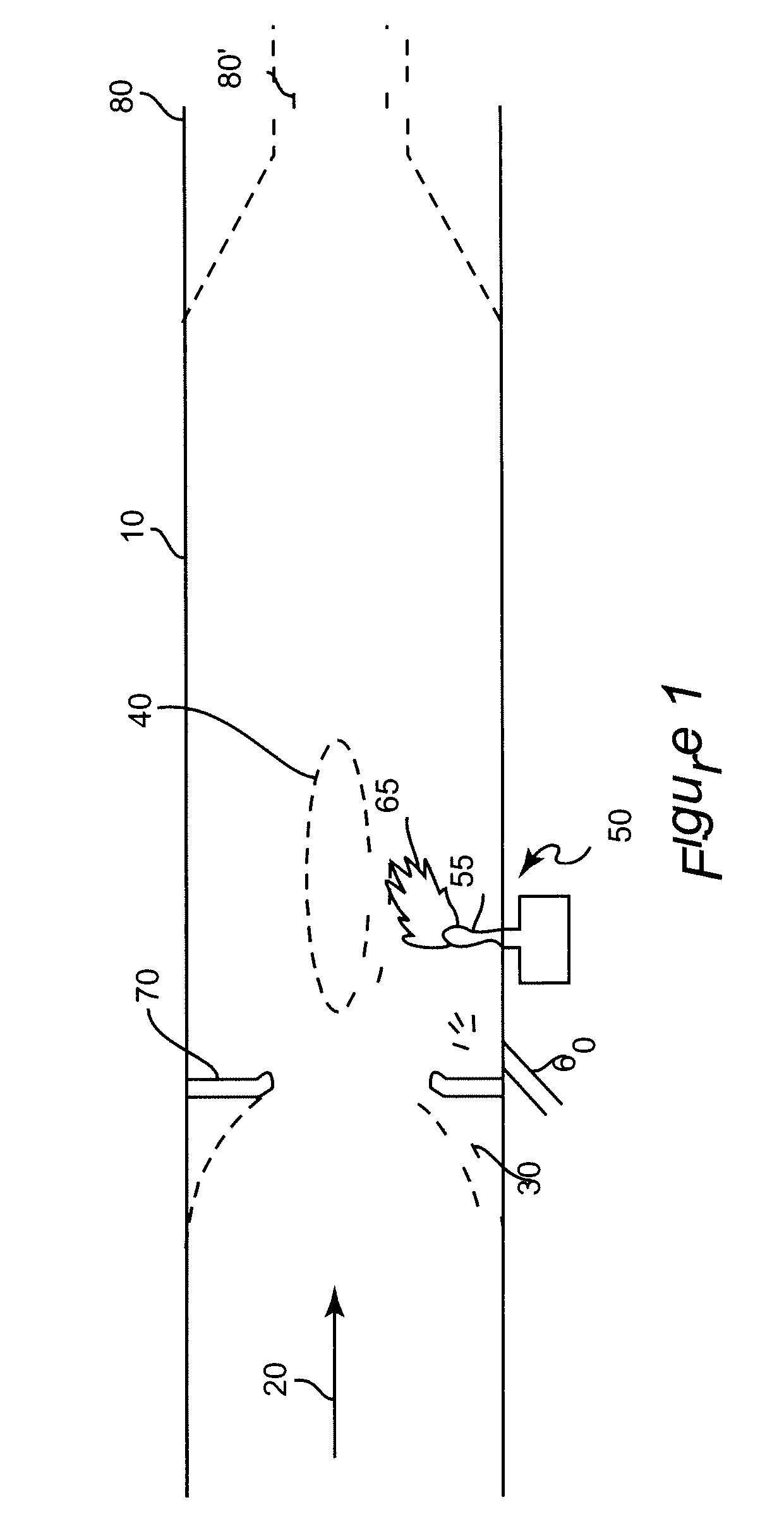

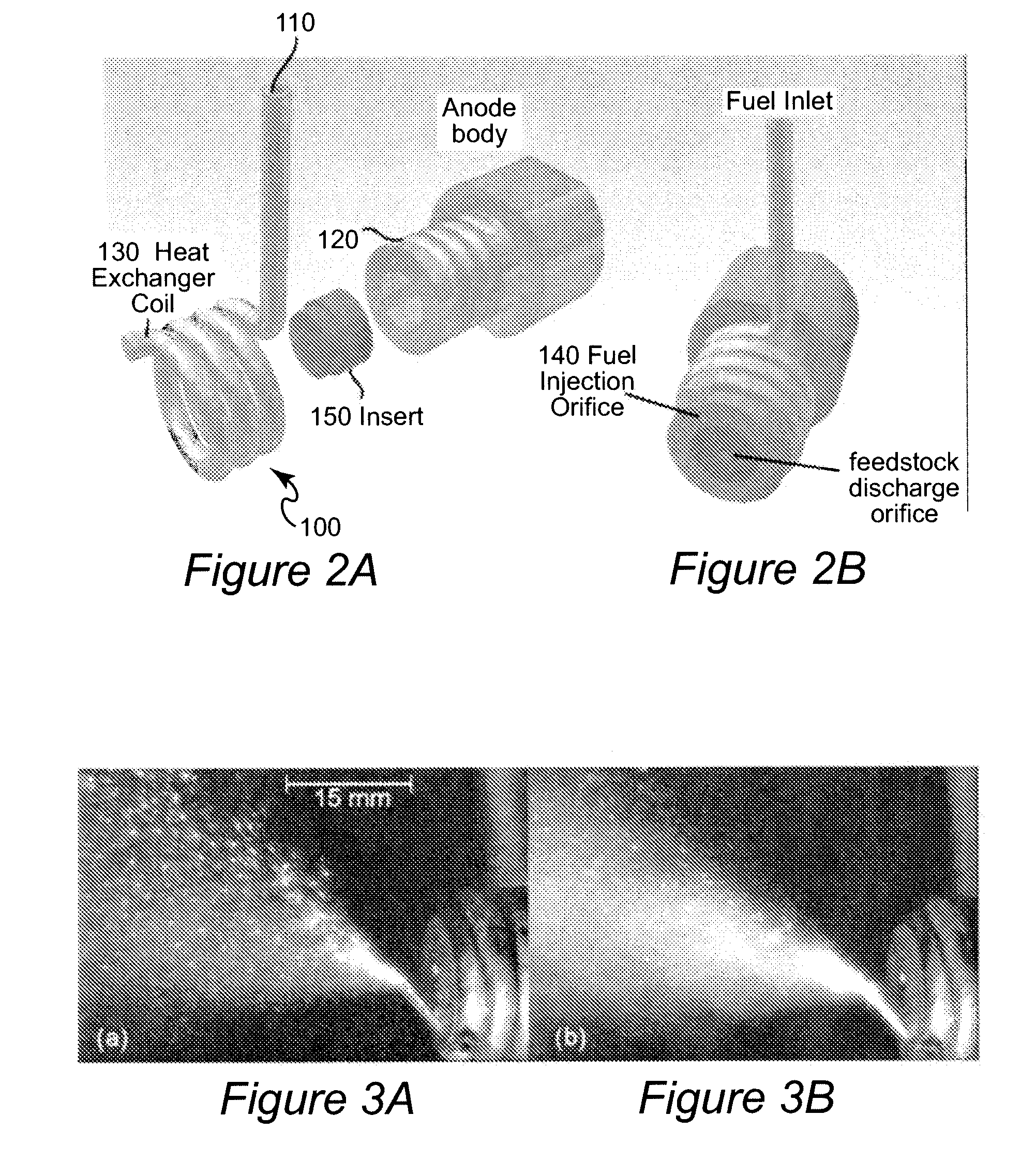

Improved Plasma Torch for Ignition, Flameholding and Enhancement of Combustion in High Speed Flows

PatentInactiveUS20070044449A1

Innovation

- A plasma torch with a fuel injector and heat exchanger is integrated or retrofitted to improve fuel mixing and atomization, providing controllable ignition and flameholding, with features like unsteady energization and the use of nitrogen as a feedstock gas to enhance combustion efficiency.

Environmental Impact of Scramjet Operations

The environmental impact of scramjet operations is a critical consideration in the development and deployment of this advanced propulsion technology. Scramjet engines, designed for hypersonic flight, have the potential to significantly affect the atmosphere and surrounding ecosystems due to their unique operational characteristics.

One of the primary environmental concerns associated with scramjet operations is the emission of pollutants. During sustained operations, scramjets produce high levels of nitrogen oxides (NOx) due to the extreme temperatures and pressures within the combustion chamber. These NOx emissions can contribute to the formation of smog and acid rain, potentially impacting air quality and ecosystems in the vicinity of launch sites and along flight paths.

Additionally, the high-speed nature of scramjet-powered vehicles leads to the generation of sonic booms. These intense pressure waves can cause disturbances to wildlife and human populations, particularly in areas beneath flight corridors. The frequency and intensity of these sonic booms may necessitate careful route planning and operational restrictions to minimize their impact on sensitive ecosystems and populated areas.

Water vapor emissions from scramjet engines, while not typically considered a pollutant, can have significant effects on the upper atmosphere. The injection of water vapor at high altitudes can lead to the formation of artificial clouds, potentially altering local weather patterns and contributing to changes in the Earth's radiation balance.

The thermal footprint of scramjet operations is another environmental consideration. The extreme heat generated during sustained flight can potentially affect local atmospheric conditions and contribute to localized warming effects. This thermal impact may be particularly pronounced in areas where frequent scramjet operations occur, such as near testing facilities or launch sites.

Fuel production and storage for scramjet engines also present environmental challenges. The specialized fuels required for scramjet propulsion often involve energy-intensive manufacturing processes and may pose risks of contamination if not properly handled and stored. Ensuring environmentally responsible fuel production and management practices is crucial to mitigating these potential impacts.

As scramjet technology advances and its applications expand, it is essential to conduct comprehensive environmental impact assessments. These studies should consider not only the immediate effects of scramjet operations but also the long-term cumulative impacts on global atmospheric composition, climate patterns, and biodiversity. Developing strategies to monitor and mitigate these environmental effects will be crucial for the sustainable integration of scramjet technology into future aerospace applications.

One of the primary environmental concerns associated with scramjet operations is the emission of pollutants. During sustained operations, scramjets produce high levels of nitrogen oxides (NOx) due to the extreme temperatures and pressures within the combustion chamber. These NOx emissions can contribute to the formation of smog and acid rain, potentially impacting air quality and ecosystems in the vicinity of launch sites and along flight paths.

Additionally, the high-speed nature of scramjet-powered vehicles leads to the generation of sonic booms. These intense pressure waves can cause disturbances to wildlife and human populations, particularly in areas beneath flight corridors. The frequency and intensity of these sonic booms may necessitate careful route planning and operational restrictions to minimize their impact on sensitive ecosystems and populated areas.

Water vapor emissions from scramjet engines, while not typically considered a pollutant, can have significant effects on the upper atmosphere. The injection of water vapor at high altitudes can lead to the formation of artificial clouds, potentially altering local weather patterns and contributing to changes in the Earth's radiation balance.

The thermal footprint of scramjet operations is another environmental consideration. The extreme heat generated during sustained flight can potentially affect local atmospheric conditions and contribute to localized warming effects. This thermal impact may be particularly pronounced in areas where frequent scramjet operations occur, such as near testing facilities or launch sites.

Fuel production and storage for scramjet engines also present environmental challenges. The specialized fuels required for scramjet propulsion often involve energy-intensive manufacturing processes and may pose risks of contamination if not properly handled and stored. Ensuring environmentally responsible fuel production and management practices is crucial to mitigating these potential impacts.

As scramjet technology advances and its applications expand, it is essential to conduct comprehensive environmental impact assessments. These studies should consider not only the immediate effects of scramjet operations but also the long-term cumulative impacts on global atmospheric composition, climate patterns, and biodiversity. Developing strategies to monitor and mitigate these environmental effects will be crucial for the sustainable integration of scramjet technology into future aerospace applications.

Scramjet Integration with Launch Systems

The integration of scramjets with launch systems represents a critical advancement in hypersonic propulsion technology, offering significant potential for high-speed atmospheric flight and space access. This integration process involves complex engineering challenges, particularly in managing thermal stresses during sustained operations.

Scramjet engines, designed to operate at hypersonic speeds, require careful integration with launch vehicles to ensure optimal performance and structural integrity. The primary challenge lies in managing the extreme temperatures generated during sustained flight, which can cause thermal expansion, material degradation, and structural deformation. These thermal stresses must be carefully analyzed and mitigated to prevent catastrophic failure of the integrated system.

One key aspect of scramjet integration is the design of thermal protection systems (TPS) that can withstand the intense heat generated during hypersonic flight. Advanced materials such as ceramic matrix composites and carbon-carbon composites are often employed in TPS designs due to their high temperature resistance and low thermal conductivity. These materials help insulate critical components and maintain structural integrity under extreme thermal conditions.

Another crucial consideration is the interface between the scramjet engine and the launch vehicle. This interface must be designed to accommodate thermal expansion and contraction while maintaining proper alignment and sealing. Flexible joints, thermal expansion gaps, and advanced sealing technologies are often employed to address these challenges.

The integration process also involves careful consideration of aerodynamic heating effects on the entire vehicle structure. Computational fluid dynamics (CFD) simulations and wind tunnel testing are essential tools for predicting and analyzing thermal loads during various flight regimes. These analyses inform the design of cooling systems, heat sinks, and thermal management strategies to maintain acceptable temperature levels throughout the integrated system.

Furthermore, the integration of scramjets with launch systems necessitates a holistic approach to vehicle design. The placement and orientation of the scramjet engine within the launch vehicle must be optimized to balance aerodynamic performance, thermal management, and overall system efficiency. This often involves trade-offs between engine performance, structural weight, and thermal protection requirements.

In conclusion, the successful integration of scramjets with launch systems requires a multidisciplinary approach that addresses thermal stress analysis, materials science, aerodynamics, and systems engineering. As research in this field progresses, advancements in thermal management technologies and materials will play a crucial role in enabling sustained hypersonic flight and expanding the capabilities of space launch systems.

Scramjet engines, designed to operate at hypersonic speeds, require careful integration with launch vehicles to ensure optimal performance and structural integrity. The primary challenge lies in managing the extreme temperatures generated during sustained flight, which can cause thermal expansion, material degradation, and structural deformation. These thermal stresses must be carefully analyzed and mitigated to prevent catastrophic failure of the integrated system.

One key aspect of scramjet integration is the design of thermal protection systems (TPS) that can withstand the intense heat generated during hypersonic flight. Advanced materials such as ceramic matrix composites and carbon-carbon composites are often employed in TPS designs due to their high temperature resistance and low thermal conductivity. These materials help insulate critical components and maintain structural integrity under extreme thermal conditions.

Another crucial consideration is the interface between the scramjet engine and the launch vehicle. This interface must be designed to accommodate thermal expansion and contraction while maintaining proper alignment and sealing. Flexible joints, thermal expansion gaps, and advanced sealing technologies are often employed to address these challenges.

The integration process also involves careful consideration of aerodynamic heating effects on the entire vehicle structure. Computational fluid dynamics (CFD) simulations and wind tunnel testing are essential tools for predicting and analyzing thermal loads during various flight regimes. These analyses inform the design of cooling systems, heat sinks, and thermal management strategies to maintain acceptable temperature levels throughout the integrated system.

Furthermore, the integration of scramjets with launch systems necessitates a holistic approach to vehicle design. The placement and orientation of the scramjet engine within the launch vehicle must be optimized to balance aerodynamic performance, thermal management, and overall system efficiency. This often involves trade-offs between engine performance, structural weight, and thermal protection requirements.

In conclusion, the successful integration of scramjets with launch systems requires a multidisciplinary approach that addresses thermal stress analysis, materials science, aerodynamics, and systems engineering. As research in this field progresses, advancements in thermal management technologies and materials will play a crucial role in enabling sustained hypersonic flight and expanding the capabilities of space launch systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!