Reliability Assurances in Military Scramjet Operations

AUG 13, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Tech Evolution

The evolution of scramjet technology has been marked by significant milestones and breakthroughs over the past several decades. Initially conceived in the 1950s, scramjet engines represented a revolutionary approach to hypersonic propulsion, promising to overcome the limitations of traditional jet engines at extreme speeds.

In the 1960s and 1970s, theoretical groundwork was laid for scramjet propulsion, with researchers focusing on understanding the complex aerodynamics and combustion processes involved. This period saw the development of fundamental concepts and mathematical models that would form the basis for future advancements.

The 1980s and 1990s witnessed a surge in experimental testing, with countries like the United States, Russia, and Australia conducting ground-based and flight tests. Notable programs such as the U.S. National Aerospace Plane (NASP) and Russia's AJAX project pushed the boundaries of scramjet technology, although they faced significant technical challenges.

The turn of the millennium marked a new era for scramjet development. In 2002, the University of Queensland's HyShot program achieved the first successful flight test of a scramjet engine, demonstrating sustained hypersonic combustion. This breakthrough paved the way for more ambitious projects and renewed interest in scramjet technology for military applications.

The following decade saw rapid advancements in materials science, computational fluid dynamics, and propulsion system integration. These developments enabled more sophisticated scramjet designs capable of operating under the extreme conditions of hypersonic flight. Programs like NASA's X-43A and the U.S. Air Force's X-51A Waverider demonstrated increasingly longer flight durations and higher speeds.

Recent years have focused on enhancing the reliability and operational capabilities of scramjet engines for military use. Efforts have been directed towards improving fuel efficiency, expanding the operational envelope, and addressing the challenges of thermal management and structural integrity at hypersonic speeds.

Looking forward, the evolution of scramjet technology is expected to continue with a focus on miniaturization, increased durability, and integration with advanced guidance and control systems. These developments aim to transform scramjets from experimental platforms to practical, deployable systems for military operations, potentially revolutionizing strategic capabilities in areas such as rapid global strike and reconnaissance.

In the 1960s and 1970s, theoretical groundwork was laid for scramjet propulsion, with researchers focusing on understanding the complex aerodynamics and combustion processes involved. This period saw the development of fundamental concepts and mathematical models that would form the basis for future advancements.

The 1980s and 1990s witnessed a surge in experimental testing, with countries like the United States, Russia, and Australia conducting ground-based and flight tests. Notable programs such as the U.S. National Aerospace Plane (NASP) and Russia's AJAX project pushed the boundaries of scramjet technology, although they faced significant technical challenges.

The turn of the millennium marked a new era for scramjet development. In 2002, the University of Queensland's HyShot program achieved the first successful flight test of a scramjet engine, demonstrating sustained hypersonic combustion. This breakthrough paved the way for more ambitious projects and renewed interest in scramjet technology for military applications.

The following decade saw rapid advancements in materials science, computational fluid dynamics, and propulsion system integration. These developments enabled more sophisticated scramjet designs capable of operating under the extreme conditions of hypersonic flight. Programs like NASA's X-43A and the U.S. Air Force's X-51A Waverider demonstrated increasingly longer flight durations and higher speeds.

Recent years have focused on enhancing the reliability and operational capabilities of scramjet engines for military use. Efforts have been directed towards improving fuel efficiency, expanding the operational envelope, and addressing the challenges of thermal management and structural integrity at hypersonic speeds.

Looking forward, the evolution of scramjet technology is expected to continue with a focus on miniaturization, increased durability, and integration with advanced guidance and control systems. These developments aim to transform scramjets from experimental platforms to practical, deployable systems for military operations, potentially revolutionizing strategic capabilities in areas such as rapid global strike and reconnaissance.

Military Demand Analysis

The military demand for reliable scramjet operations has been steadily increasing in recent years, driven by the need for hypersonic capabilities in modern warfare scenarios. Scramjet technology offers significant advantages in terms of speed, range, and operational flexibility, making it a critical asset for military applications. The ability to achieve sustained hypersonic flight has become a strategic priority for many advanced militaries worldwide.

The primary demand for scramjet technology in military operations stems from its potential to revolutionize long-range strike capabilities. Hypersonic weapons powered by scramjets can significantly reduce the time-to-target, enhancing the element of surprise and minimizing the enemy's reaction time. This capability is particularly valuable in time-sensitive strike missions and for penetrating sophisticated air defense systems.

Another key driver of military demand is the potential for scramjet-powered reconnaissance platforms. These high-speed vehicles can rapidly gather intelligence over vast areas, providing commanders with near-real-time situational awareness. The ability to quickly enter and exit contested airspace makes scramjet-powered reconnaissance assets highly valuable in modern conflict scenarios.

The development of scramjet-powered interceptors is also gaining traction in military circles. These platforms could potentially intercept incoming hypersonic threats, addressing a critical gap in current air defense capabilities. As more nations develop hypersonic weapons, the demand for effective countermeasures is expected to grow significantly.

Space access is another area where military demand for scramjet technology is emerging. Scramjet-powered vehicles could potentially offer more responsive and cost-effective means of deploying small satellites or other payloads into low Earth orbit, enhancing military space capabilities.

However, the military demand for scramjet technology is tempered by the significant technical challenges associated with its development and operation. Reliability concerns, particularly in the harsh operating conditions of hypersonic flight, remain a major hurdle. Military planners are keenly aware of the need for robust reliability assurances before fully integrating scramjet-powered systems into operational doctrines.

The global nature of the scramjet technology race is also shaping military demand. As nations like China and Russia make progress in hypersonic capabilities, there is increased pressure on other military powers to accelerate their own scramjet programs. This competitive dynamic is driving investment and research efforts across the globe.

The primary demand for scramjet technology in military operations stems from its potential to revolutionize long-range strike capabilities. Hypersonic weapons powered by scramjets can significantly reduce the time-to-target, enhancing the element of surprise and minimizing the enemy's reaction time. This capability is particularly valuable in time-sensitive strike missions and for penetrating sophisticated air defense systems.

Another key driver of military demand is the potential for scramjet-powered reconnaissance platforms. These high-speed vehicles can rapidly gather intelligence over vast areas, providing commanders with near-real-time situational awareness. The ability to quickly enter and exit contested airspace makes scramjet-powered reconnaissance assets highly valuable in modern conflict scenarios.

The development of scramjet-powered interceptors is also gaining traction in military circles. These platforms could potentially intercept incoming hypersonic threats, addressing a critical gap in current air defense capabilities. As more nations develop hypersonic weapons, the demand for effective countermeasures is expected to grow significantly.

Space access is another area where military demand for scramjet technology is emerging. Scramjet-powered vehicles could potentially offer more responsive and cost-effective means of deploying small satellites or other payloads into low Earth orbit, enhancing military space capabilities.

However, the military demand for scramjet technology is tempered by the significant technical challenges associated with its development and operation. Reliability concerns, particularly in the harsh operating conditions of hypersonic flight, remain a major hurdle. Military planners are keenly aware of the need for robust reliability assurances before fully integrating scramjet-powered systems into operational doctrines.

The global nature of the scramjet technology race is also shaping military demand. As nations like China and Russia make progress in hypersonic capabilities, there is increased pressure on other military powers to accelerate their own scramjet programs. This competitive dynamic is driving investment and research efforts across the globe.

Scramjet Challenges

Scramjet technology, while promising for high-speed military applications, faces numerous challenges that hinder its widespread adoption and operational reliability. One of the primary obstacles is the extreme thermal management requirements. The hypersonic speeds at which scramjets operate generate intense heat, necessitating advanced materials and cooling systems to prevent structural failure and ensure consistent performance.

Another significant challenge lies in the precise control of airflow and combustion processes within the engine. The supersonic airflow through the combustion chamber leaves minimal time for fuel mixing and burning, requiring sophisticated fuel injection systems and combustion chamber designs. Achieving stable combustion across a wide range of flight conditions remains a formidable task.

The development of robust and efficient propulsion systems for scramjets presents another hurdle. Traditional turbine engines are unsuitable for hypersonic speeds, necessitating the creation of new propulsion technologies capable of operating effectively at Mach 5 and beyond. This includes addressing issues such as fuel efficiency, thrust generation, and engine durability under extreme conditions.

Fuel selection and management pose additional challenges. Scramjets require specialized fuels that can ignite and burn efficiently in supersonic airflows. Developing and storing these fuels, as well as designing systems for their effective distribution and combustion, are critical areas of ongoing research and development.

The integration of scramjet engines with airframe designs presents complex aerodynamic challenges. Engineers must optimize the vehicle's shape to manage shock waves, reduce drag, and maintain stability at hypersonic speeds. This requires advanced computational fluid dynamics modeling and extensive wind tunnel testing.

Reliability and durability concerns are paramount in military applications. Scramjet engines must operate consistently and withstand the harsh conditions of hypersonic flight for extended periods. This necessitates the development of robust materials, advanced manufacturing techniques, and comprehensive testing protocols to ensure operational readiness and longevity.

Navigation and control systems for scramjet-powered vehicles face unique challenges due to the extreme speeds involved. Developing sensors, guidance systems, and control algorithms capable of operating effectively in hypersonic environments is crucial for mission success and vehicle survivability.

Another significant challenge lies in the precise control of airflow and combustion processes within the engine. The supersonic airflow through the combustion chamber leaves minimal time for fuel mixing and burning, requiring sophisticated fuel injection systems and combustion chamber designs. Achieving stable combustion across a wide range of flight conditions remains a formidable task.

The development of robust and efficient propulsion systems for scramjets presents another hurdle. Traditional turbine engines are unsuitable for hypersonic speeds, necessitating the creation of new propulsion technologies capable of operating effectively at Mach 5 and beyond. This includes addressing issues such as fuel efficiency, thrust generation, and engine durability under extreme conditions.

Fuel selection and management pose additional challenges. Scramjets require specialized fuels that can ignite and burn efficiently in supersonic airflows. Developing and storing these fuels, as well as designing systems for their effective distribution and combustion, are critical areas of ongoing research and development.

The integration of scramjet engines with airframe designs presents complex aerodynamic challenges. Engineers must optimize the vehicle's shape to manage shock waves, reduce drag, and maintain stability at hypersonic speeds. This requires advanced computational fluid dynamics modeling and extensive wind tunnel testing.

Reliability and durability concerns are paramount in military applications. Scramjet engines must operate consistently and withstand the harsh conditions of hypersonic flight for extended periods. This necessitates the development of robust materials, advanced manufacturing techniques, and comprehensive testing protocols to ensure operational readiness and longevity.

Navigation and control systems for scramjet-powered vehicles face unique challenges due to the extreme speeds involved. Developing sensors, guidance systems, and control algorithms capable of operating effectively in hypersonic environments is crucial for mission success and vehicle survivability.

Current Reliability Solutions

01 Fuel injection and mixing optimization

Improving fuel injection and mixing systems in scramjets is crucial for enhancing reliability. This involves developing advanced fuel injection techniques, optimizing fuel-air mixing, and designing efficient combustion chambers. These improvements help ensure stable combustion and consistent performance across a wide range of operating conditions.- Fuel injection and mixing optimization: Improving fuel injection and mixing systems in scramjets is crucial for enhancing reliability. This involves developing advanced fuel injectors, optimizing fuel distribution, and ensuring efficient combustion. Proper fuel-air mixing is essential for stable operation and performance across various flight conditions.

- Thermal management and cooling systems: Effective thermal management is critical for scramjet reliability. This includes developing advanced cooling systems to protect engine components from extreme temperatures, implementing heat-resistant materials, and designing efficient heat exchangers. Proper thermal control ensures longevity and consistent performance of the engine.

- Inlet design and flow control: Optimizing the inlet design and implementing effective flow control mechanisms are essential for scramjet reliability. This involves developing variable geometry inlets, shock wave management systems, and boundary layer control techniques to ensure stable airflow and compression across a wide range of operating conditions.

- Combustion stability and flame holding: Ensuring combustion stability and effective flame holding is crucial for reliable scramjet operation. This includes developing advanced combustor designs, implementing flame stabilization techniques, and optimizing the combustion process to maintain stable burning across various flight regimes and fuel-air ratios.

- Materials and manufacturing techniques: Developing and utilizing advanced materials and manufacturing techniques is essential for improving scramjet reliability. This involves researching high-temperature alloys, ceramic matrix composites, and other innovative materials that can withstand the extreme conditions in scramjet engines. Additionally, advanced manufacturing methods such as additive manufacturing can enhance component durability and performance.

02 Thermal management and cooling systems

Effective thermal management is essential for scramjet reliability. This includes developing advanced cooling systems, heat-resistant materials, and thermal protection techniques. These innovations help manage the extreme temperatures experienced during hypersonic flight, protecting critical components and ensuring consistent performance.Expand Specific Solutions03 Inlet design and flow control

Optimizing the inlet design and implementing effective flow control mechanisms are crucial for scramjet reliability. This involves developing variable geometry inlets, shock wave management techniques, and boundary layer control systems. These advancements help maintain stable airflow and compression across various flight conditions.Expand Specific Solutions04 Materials and manufacturing techniques

Developing advanced materials and manufacturing techniques is vital for improving scramjet reliability. This includes researching high-temperature alloys, composite materials, and additive manufacturing processes. These innovations enhance the durability and performance of critical components, leading to more reliable scramjet engines.Expand Specific Solutions05 Control systems and instrumentation

Implementing sophisticated control systems and instrumentation is essential for ensuring scramjet reliability. This involves developing advanced sensors, real-time monitoring systems, and adaptive control algorithms. These technologies enable precise engine management, fault detection, and performance optimization across various flight regimes.Expand Specific Solutions

Key Industry Players

The competition landscape for "Reliability Assurances in Military Scramjet Operations" is characterized by a complex interplay of academic institutions and defense industry players. The market is in an early growth stage, with significant potential for expansion as military interest in hypersonic technologies increases. While the market size is difficult to quantify precisely, it is expected to grow substantially in the coming years. Technologically, the field is still maturing, with key players like National University of Defense Technology, Northwestern Polytechnical University, and Safran Aircraft Engines leading research efforts. Companies such as AVIC Group and Nexter Munitions are also contributing to advancements, indicating a blend of academic and industrial expertise driving innovation in this critical defense technology sector.

National University of Defense Technology

Technical Solution: The National University of Defense Technology (NUDT) has developed advanced reliability assurance techniques for military scramjet operations. Their approach integrates multi-physics modeling with real-time monitoring systems to predict and mitigate potential failures. NUDT's system employs machine learning algorithms to analyze sensor data from critical components, enabling proactive maintenance and reducing downtime[1]. They have also implemented a novel thermal management system that uses advanced materials to withstand extreme temperatures, improving overall engine durability[3]. Additionally, NUDT has developed a fault-tolerant control system that can adapt to sudden changes in operating conditions, ensuring consistent performance even under challenging scenarios[5].

Strengths: Comprehensive approach combining predictive analytics and adaptive control systems. Weaknesses: May require significant computational resources for real-time analysis.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics (NUAA) has focused on enhancing the reliability of scramjet fuel injection systems. Their innovative approach utilizes a pulsed detonation injection mechanism, which improves fuel-air mixing and combustion stability[2]. NUAA has also developed a smart diagnostic system that employs acoustic sensors to detect combustion instabilities in real-time, allowing for immediate adjustments to maintain optimal performance[4]. Furthermore, they have implemented a novel cooling strategy using regenerative cooling channels with shape memory alloys, which adapt to varying thermal loads and significantly extend the operational life of critical components[6].

Strengths: Innovative fuel injection and cooling technologies that directly address key reliability issues. Weaknesses: May require complex manufacturing processes, potentially increasing production costs.

Core Scramjet Innovations

Improved plasma torch for ignition, flameholding and enhancement of combustion in high speed flows

PatentWO2006125210A2

Innovation

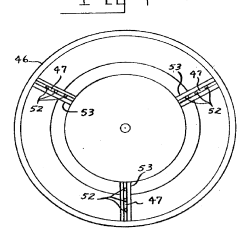

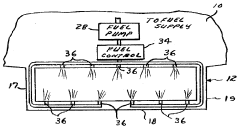

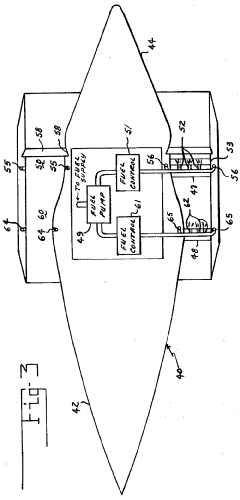

- A plasma torch with a fuel injector and heat exchanger is integrated to provide improved fuel mixing and atomization, allowing for controllable ignition and flameholding, featuring a plasma torch with an anode capable of producing a plasma plume, a heat exchanger for preheating fuel, and a nozzle for injecting preheated fuel into the plasma plume, along with unsteady energization to enhance atomization and mixing.

Dual mode supersonic combustion ramjet engine

PatentInactiveUS3667233A

Innovation

- A dual-mode combustion system with a combustor featuring a fixed geometry and parallel combustion section with uniform cross-section, utilizing fuel injection to stabilize flames and create choked flow, transitioning from subsonic to supersonic mode by manipulating shock waves through diverging sections and fuel distribution.

Material Advancements

Material advancements play a crucial role in enhancing the reliability of military scramjet operations. The extreme conditions encountered during hypersonic flight demand materials that can withstand high temperatures, intense pressures, and severe oxidation. Recent developments in high-temperature alloys and ceramic matrix composites (CMCs) have significantly improved the durability and performance of scramjet components.

Advanced nickel-based superalloys, such as those incorporating rhenium and ruthenium, have demonstrated exceptional strength and creep resistance at elevated temperatures. These alloys are particularly suitable for critical components like combustor liners and nozzle structures. The addition of refractory elements and precise control of microstructure through advanced processing techniques have pushed the temperature capabilities of these materials beyond 1100°C.

Ceramic matrix composites, especially those based on silicon carbide (SiC) fibers in a SiC matrix, have emerged as game-changers for scramjet applications. These materials offer an excellent combination of high-temperature strength, low density, and oxidation resistance. Recent innovations in fiber coatings and matrix densification processes have led to CMCs capable of operating at temperatures exceeding 1400°C for extended periods.

Thermal barrier coatings (TBCs) have also seen significant advancements. Multi-layer TBC systems incorporating rare earth elements have demonstrated improved phase stability and reduced thermal conductivity. These coatings can provide an additional temperature reduction of up to 200°C for underlying metal components, extending their operational life and reliability.

Ultra-high temperature ceramics (UHTCs), such as zirconium diboride and hafnium carbide, are being developed for use in leading edges and nose cones. These materials can withstand temperatures above 2000°C and offer excellent resistance to oxidation and erosion. Recent breakthroughs in processing techniques have improved the fracture toughness of UHTCs, addressing their historical brittleness issues.

Additive manufacturing technologies have opened new possibilities for creating complex geometries and functionally graded materials. This allows for optimized cooling channels and tailored material properties across components, enhancing overall system reliability. The ability to produce intricate internal structures has led to more efficient heat management in critical scramjet sections.

These material advancements collectively contribute to increased reliability in military scramjet operations by extending component lifetimes, improving thermal management, and enhancing overall system performance under extreme conditions. Ongoing research in nanomaterials and self-healing composites promises further improvements in the near future, potentially revolutionizing the durability and maintainability of scramjet engines.

Advanced nickel-based superalloys, such as those incorporating rhenium and ruthenium, have demonstrated exceptional strength and creep resistance at elevated temperatures. These alloys are particularly suitable for critical components like combustor liners and nozzle structures. The addition of refractory elements and precise control of microstructure through advanced processing techniques have pushed the temperature capabilities of these materials beyond 1100°C.

Ceramic matrix composites, especially those based on silicon carbide (SiC) fibers in a SiC matrix, have emerged as game-changers for scramjet applications. These materials offer an excellent combination of high-temperature strength, low density, and oxidation resistance. Recent innovations in fiber coatings and matrix densification processes have led to CMCs capable of operating at temperatures exceeding 1400°C for extended periods.

Thermal barrier coatings (TBCs) have also seen significant advancements. Multi-layer TBC systems incorporating rare earth elements have demonstrated improved phase stability and reduced thermal conductivity. These coatings can provide an additional temperature reduction of up to 200°C for underlying metal components, extending their operational life and reliability.

Ultra-high temperature ceramics (UHTCs), such as zirconium diboride and hafnium carbide, are being developed for use in leading edges and nose cones. These materials can withstand temperatures above 2000°C and offer excellent resistance to oxidation and erosion. Recent breakthroughs in processing techniques have improved the fracture toughness of UHTCs, addressing their historical brittleness issues.

Additive manufacturing technologies have opened new possibilities for creating complex geometries and functionally graded materials. This allows for optimized cooling channels and tailored material properties across components, enhancing overall system reliability. The ability to produce intricate internal structures has led to more efficient heat management in critical scramjet sections.

These material advancements collectively contribute to increased reliability in military scramjet operations by extending component lifetimes, improving thermal management, and enhancing overall system performance under extreme conditions. Ongoing research in nanomaterials and self-healing composites promises further improvements in the near future, potentially revolutionizing the durability and maintainability of scramjet engines.

Operational Safety Protocols

Operational safety protocols are paramount in ensuring the reliability and effectiveness of military scramjet operations. These protocols encompass a comprehensive set of guidelines, procedures, and safeguards designed to mitigate risks and maintain the highest standards of safety throughout all phases of scramjet operation.

At the core of these protocols is a rigorous pre-flight checklist system. This system involves a meticulous inspection of all critical components, including the engine, fuel systems, and control surfaces. Each item on the checklist is verified by multiple qualified personnel to minimize the risk of human error. Additionally, advanced diagnostic tools are employed to detect any potential anomalies that may not be visible during visual inspections.

Real-time monitoring systems play a crucial role in maintaining operational safety during flight. These systems continuously track key performance parameters such as engine temperature, fuel flow rates, and structural integrity. Any deviations from predetermined safe operating ranges trigger immediate alerts to both onboard systems and ground control, allowing for rapid response and corrective actions.

Emergency procedures form an integral part of the safety protocols. These procedures are extensively rehearsed and regularly updated based on the latest operational data and simulations. They cover a wide range of potential scenarios, from engine malfunctions to unexpected atmospheric conditions, ensuring that pilots and ground crews are prepared to handle any contingency.

Environmental factors are carefully considered in the safety protocols. This includes detailed analysis of weather patterns, atmospheric conditions, and potential debris in the flight path. Advanced weather prediction models are utilized to ensure optimal flight conditions, while sophisticated sensors are employed to detect and avoid potential hazards in real-time.

Crew training and certification are critical components of the safety protocols. Personnel involved in scramjet operations undergo rigorous training programs that combine theoretical knowledge with practical simulations. Regular recertification and ongoing education ensure that all team members remain up-to-date with the latest safety procedures and technological advancements.

Data analysis and continuous improvement form the backbone of these safety protocols. Every flight is meticulously documented and analyzed, with particular attention paid to any anomalies or near-miss incidents. This data is used to refine and enhance safety procedures, leading to an ever-evolving and improving safety framework.

At the core of these protocols is a rigorous pre-flight checklist system. This system involves a meticulous inspection of all critical components, including the engine, fuel systems, and control surfaces. Each item on the checklist is verified by multiple qualified personnel to minimize the risk of human error. Additionally, advanced diagnostic tools are employed to detect any potential anomalies that may not be visible during visual inspections.

Real-time monitoring systems play a crucial role in maintaining operational safety during flight. These systems continuously track key performance parameters such as engine temperature, fuel flow rates, and structural integrity. Any deviations from predetermined safe operating ranges trigger immediate alerts to both onboard systems and ground control, allowing for rapid response and corrective actions.

Emergency procedures form an integral part of the safety protocols. These procedures are extensively rehearsed and regularly updated based on the latest operational data and simulations. They cover a wide range of potential scenarios, from engine malfunctions to unexpected atmospheric conditions, ensuring that pilots and ground crews are prepared to handle any contingency.

Environmental factors are carefully considered in the safety protocols. This includes detailed analysis of weather patterns, atmospheric conditions, and potential debris in the flight path. Advanced weather prediction models are utilized to ensure optimal flight conditions, while sophisticated sensors are employed to detect and avoid potential hazards in real-time.

Crew training and certification are critical components of the safety protocols. Personnel involved in scramjet operations undergo rigorous training programs that combine theoretical knowledge with practical simulations. Regular recertification and ongoing education ensure that all team members remain up-to-date with the latest safety procedures and technological advancements.

Data analysis and continuous improvement form the backbone of these safety protocols. Every flight is meticulously documented and analyzed, with particular attention paid to any anomalies or near-miss incidents. This data is used to refine and enhance safety procedures, leading to an ever-evolving and improving safety framework.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!