Assessing Lifecycles of Hypersonic Vehicles Through Scramjet Data

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hypersonic Tech Evolution

The evolution of hypersonic technology has been marked by significant milestones and breakthroughs over the past decades. Initially driven by military applications, hypersonic research has expanded to encompass civilian and commercial interests, particularly in the realm of space exploration and rapid global transportation.

In the 1960s and 1970s, the focus was primarily on developing hypersonic wind tunnels and understanding the fundamental aerodynamics of hypersonic flight. This period saw the emergence of key concepts such as shock waves, boundary layer interactions, and thermal management challenges unique to hypersonic velocities.

The 1980s and 1990s witnessed a shift towards more practical applications, with the development of experimental hypersonic vehicles like the NASA X-15 and the National Aerospace Plane (NASP) project. These initiatives provided valuable data on materials, propulsion systems, and flight control at hypersonic speeds.

The turn of the millennium brought renewed interest in hypersonic technology, driven by advancements in computational fluid dynamics and materials science. This period saw the successful flight tests of the NASA X-43 and X-51 scramjet-powered vehicles, demonstrating the viability of air-breathing hypersonic propulsion.

Recent years have seen a global race to develop operational hypersonic weapons and vehicles. Countries like the United States, Russia, and China have made significant investments in hypersonic research, leading to the development of boost-glide vehicles and hypersonic cruise missiles.

The evolution of scramjet technology has been particularly crucial in assessing the lifecycles of hypersonic vehicles. Scramjets, or supersonic combustion ramjets, have progressed from theoretical concepts to practical demonstrations, enabling sustained hypersonic flight within the atmosphere.

Data from scramjet tests has been instrumental in advancing our understanding of hypersonic vehicle lifecycles. These tests have provided insights into fuel efficiency, thermal management, and structural integrity under extreme conditions. The information gathered has led to improvements in materials, cooling systems, and overall vehicle design, extending the operational lifespan of hypersonic platforms.

Looking forward, the evolution of hypersonic technology is expected to continue at a rapid pace. Areas of focus include improving the reliability and efficiency of scramjet engines, developing more durable heat-resistant materials, and enhancing guidance and control systems for precise maneuvering at hypersonic speeds.

In the 1960s and 1970s, the focus was primarily on developing hypersonic wind tunnels and understanding the fundamental aerodynamics of hypersonic flight. This period saw the emergence of key concepts such as shock waves, boundary layer interactions, and thermal management challenges unique to hypersonic velocities.

The 1980s and 1990s witnessed a shift towards more practical applications, with the development of experimental hypersonic vehicles like the NASA X-15 and the National Aerospace Plane (NASP) project. These initiatives provided valuable data on materials, propulsion systems, and flight control at hypersonic speeds.

The turn of the millennium brought renewed interest in hypersonic technology, driven by advancements in computational fluid dynamics and materials science. This period saw the successful flight tests of the NASA X-43 and X-51 scramjet-powered vehicles, demonstrating the viability of air-breathing hypersonic propulsion.

Recent years have seen a global race to develop operational hypersonic weapons and vehicles. Countries like the United States, Russia, and China have made significant investments in hypersonic research, leading to the development of boost-glide vehicles and hypersonic cruise missiles.

The evolution of scramjet technology has been particularly crucial in assessing the lifecycles of hypersonic vehicles. Scramjets, or supersonic combustion ramjets, have progressed from theoretical concepts to practical demonstrations, enabling sustained hypersonic flight within the atmosphere.

Data from scramjet tests has been instrumental in advancing our understanding of hypersonic vehicle lifecycles. These tests have provided insights into fuel efficiency, thermal management, and structural integrity under extreme conditions. The information gathered has led to improvements in materials, cooling systems, and overall vehicle design, extending the operational lifespan of hypersonic platforms.

Looking forward, the evolution of hypersonic technology is expected to continue at a rapid pace. Areas of focus include improving the reliability and efficiency of scramjet engines, developing more durable heat-resistant materials, and enhancing guidance and control systems for precise maneuvering at hypersonic speeds.

Scramjet Data Market Demand

The market demand for scramjet data in the context of assessing lifecycles of hypersonic vehicles is experiencing significant growth, driven by the increasing interest in hypersonic technology across military, aerospace, and commercial sectors. This demand is primarily fueled by the need for accurate and comprehensive data to support the development, testing, and optimization of hypersonic vehicles.

In the military domain, there is a pressing need for scramjet data to enhance the capabilities of hypersonic missiles and aircraft. Defense agencies and contractors require detailed information on scramjet performance, durability, and efficiency to design more advanced and reliable hypersonic weapon systems. This demand is particularly strong in countries like the United States, Russia, and China, where hypersonic technology is seen as a strategic asset.

The aerospace industry is another key driver of scramjet data demand. Companies involved in the development of hypersonic aircraft for both military and civilian applications require extensive data on scramjet propulsion systems. This includes information on fuel efficiency, thrust generation, thermal management, and overall engine performance across various flight conditions. The data is crucial for optimizing vehicle designs and improving the overall viability of hypersonic flight.

Commercial space companies are also contributing to the growing demand for scramjet data. As these organizations explore the potential of hypersonic technology for rapid point-to-point transportation and more efficient access to space, they require comprehensive data on scramjet performance and reliability. This information is essential for assessing the feasibility and economic viability of hypersonic commercial flights.

The research and development sector represents another significant market for scramjet data. Universities, research institutions, and government laboratories are actively seeking detailed information on scramjet technology to advance the field of hypersonic propulsion. This demand is driven by the need to overcome current technological limitations and push the boundaries of hypersonic flight.

Furthermore, there is an emerging market for scramjet data in the field of materials science. As hypersonic vehicles operate under extreme conditions, there is a growing need for data on material performance and durability in high-temperature, high-speed environments. This information is crucial for developing advanced materials capable of withstanding the harsh conditions associated with hypersonic flight.

The market demand for scramjet data is also influenced by the increasing focus on lifecycle assessment of hypersonic vehicles. Stakeholders across various sectors require comprehensive data to evaluate the long-term performance, maintenance requirements, and operational costs of these advanced vehicles. This demand is driven by the need to make informed decisions regarding investment in hypersonic technology and to optimize the lifecycle management of hypersonic assets.

In the military domain, there is a pressing need for scramjet data to enhance the capabilities of hypersonic missiles and aircraft. Defense agencies and contractors require detailed information on scramjet performance, durability, and efficiency to design more advanced and reliable hypersonic weapon systems. This demand is particularly strong in countries like the United States, Russia, and China, where hypersonic technology is seen as a strategic asset.

The aerospace industry is another key driver of scramjet data demand. Companies involved in the development of hypersonic aircraft for both military and civilian applications require extensive data on scramjet propulsion systems. This includes information on fuel efficiency, thrust generation, thermal management, and overall engine performance across various flight conditions. The data is crucial for optimizing vehicle designs and improving the overall viability of hypersonic flight.

Commercial space companies are also contributing to the growing demand for scramjet data. As these organizations explore the potential of hypersonic technology for rapid point-to-point transportation and more efficient access to space, they require comprehensive data on scramjet performance and reliability. This information is essential for assessing the feasibility and economic viability of hypersonic commercial flights.

The research and development sector represents another significant market for scramjet data. Universities, research institutions, and government laboratories are actively seeking detailed information on scramjet technology to advance the field of hypersonic propulsion. This demand is driven by the need to overcome current technological limitations and push the boundaries of hypersonic flight.

Furthermore, there is an emerging market for scramjet data in the field of materials science. As hypersonic vehicles operate under extreme conditions, there is a growing need for data on material performance and durability in high-temperature, high-speed environments. This information is crucial for developing advanced materials capable of withstanding the harsh conditions associated with hypersonic flight.

The market demand for scramjet data is also influenced by the increasing focus on lifecycle assessment of hypersonic vehicles. Stakeholders across various sectors require comprehensive data to evaluate the long-term performance, maintenance requirements, and operational costs of these advanced vehicles. This demand is driven by the need to make informed decisions regarding investment in hypersonic technology and to optimize the lifecycle management of hypersonic assets.

Hypersonic Challenges

Hypersonic vehicles face numerous challenges that push the boundaries of aerospace engineering and materials science. The extreme conditions encountered during hypersonic flight create a complex set of problems that must be addressed to ensure the viability and safety of these advanced vehicles.

One of the primary challenges is thermal management. At hypersonic speeds, air friction generates intense heat that can reach temperatures exceeding 2,000°C. This extreme heat can cause structural failure, compromise onboard systems, and degrade the performance of propulsion systems. Developing materials and cooling systems capable of withstanding these temperatures while maintaining structural integrity is a critical area of research.

Aerodynamic stability presents another significant challenge. The flow characteristics at hypersonic speeds are fundamentally different from those at lower speeds, leading to complex shock wave interactions and boundary layer phenomena. These effects can cause unpredictable changes in lift, drag, and control surface effectiveness, making it difficult to maintain stable flight and precise control.

Propulsion systems for hypersonic vehicles, particularly scramjet engines, face unique challenges. Achieving efficient combustion at supersonic speeds requires precise control of airflow and fuel injection. The short residence time of air in the combustion chamber demands rapid mixing and ignition, while the high temperatures and pressures place extreme demands on engine materials and design.

Guidance, navigation, and control systems must operate with exceptional accuracy and speed to manage the rapid changes in flight conditions. Traditional sensors and control systems may be inadequate for the extreme environments encountered during hypersonic flight, necessitating the development of new technologies and algorithms.

The structural design of hypersonic vehicles must balance conflicting requirements of strength, heat resistance, and weight. Advanced materials such as carbon-carbon composites and ceramic matrix composites show promise, but integrating these materials into practical vehicle designs remains challenging.

Communication and sensor systems face disruption due to the plasma sheath that forms around the vehicle at hypersonic speeds. This ionized layer can block radio signals, potentially isolating the vehicle from ground control and navigation systems. Developing reliable communication methods through this plasma sheath is crucial for operational effectiveness.

Finally, the testing and validation of hypersonic technologies present significant challenges. Ground-based facilities struggle to replicate the full range of conditions experienced during hypersonic flight, while flight testing is extremely expensive and risky. Advanced simulation and modeling techniques are essential but require extensive validation to ensure accuracy.

One of the primary challenges is thermal management. At hypersonic speeds, air friction generates intense heat that can reach temperatures exceeding 2,000°C. This extreme heat can cause structural failure, compromise onboard systems, and degrade the performance of propulsion systems. Developing materials and cooling systems capable of withstanding these temperatures while maintaining structural integrity is a critical area of research.

Aerodynamic stability presents another significant challenge. The flow characteristics at hypersonic speeds are fundamentally different from those at lower speeds, leading to complex shock wave interactions and boundary layer phenomena. These effects can cause unpredictable changes in lift, drag, and control surface effectiveness, making it difficult to maintain stable flight and precise control.

Propulsion systems for hypersonic vehicles, particularly scramjet engines, face unique challenges. Achieving efficient combustion at supersonic speeds requires precise control of airflow and fuel injection. The short residence time of air in the combustion chamber demands rapid mixing and ignition, while the high temperatures and pressures place extreme demands on engine materials and design.

Guidance, navigation, and control systems must operate with exceptional accuracy and speed to manage the rapid changes in flight conditions. Traditional sensors and control systems may be inadequate for the extreme environments encountered during hypersonic flight, necessitating the development of new technologies and algorithms.

The structural design of hypersonic vehicles must balance conflicting requirements of strength, heat resistance, and weight. Advanced materials such as carbon-carbon composites and ceramic matrix composites show promise, but integrating these materials into practical vehicle designs remains challenging.

Communication and sensor systems face disruption due to the plasma sheath that forms around the vehicle at hypersonic speeds. This ionized layer can block radio signals, potentially isolating the vehicle from ground control and navigation systems. Developing reliable communication methods through this plasma sheath is crucial for operational effectiveness.

Finally, the testing and validation of hypersonic technologies present significant challenges. Ground-based facilities struggle to replicate the full range of conditions experienced during hypersonic flight, while flight testing is extremely expensive and risky. Advanced simulation and modeling techniques are essential but require extensive validation to ensure accuracy.

Scramjet Data Analysis

01 Design and propulsion systems for hypersonic vehicles

This category focuses on the design and propulsion systems specific to hypersonic vehicles. It includes innovations in aerodynamic configurations, materials, and engine technologies that enable sustained flight at hypersonic speeds. These advancements aim to improve vehicle performance, efficiency, and durability throughout their operational lifecycle.- Design and propulsion systems for hypersonic vehicles: This category focuses on the design and propulsion systems specific to hypersonic vehicles. It includes innovations in aerodynamic configurations, materials, and engine technologies that enable sustained flight at hypersonic speeds. These advancements aim to improve vehicle performance, efficiency, and durability throughout their operational lifecycle.

- Thermal management and protection systems: Thermal management is crucial for hypersonic vehicles due to extreme temperatures encountered during flight. This category covers various thermal protection systems, heat-resistant materials, and cooling mechanisms designed to maintain structural integrity and protect onboard systems throughout the vehicle's lifecycle. These technologies are essential for ensuring the longevity and reliability of hypersonic vehicles.

- Guidance, navigation, and control systems: This category encompasses advanced guidance, navigation, and control systems specifically developed for hypersonic vehicles. These technologies enable precise maneuvering, trajectory optimization, and autonomous operation in extreme flight conditions. Such systems are critical for maintaining vehicle stability and achieving mission objectives throughout the operational lifecycle of hypersonic vehicles.

- Lifecycle maintenance and diagnostics: This category focuses on technologies and methodologies for maintaining and diagnosing hypersonic vehicles throughout their operational lifecycle. It includes advanced sensors, predictive maintenance systems, and non-destructive testing techniques designed to monitor vehicle health, detect potential issues, and extend the service life of these complex systems.

- Mission planning and operational lifecycle management: This category covers systems and methods for planning hypersonic vehicle missions and managing their operational lifecycle. It includes software tools for mission simulation, performance optimization, and lifecycle cost analysis. These technologies help in maximizing the efficiency and effectiveness of hypersonic vehicles throughout their service life, from initial deployment to retirement.

02 Thermal management and protection systems

Thermal management is crucial for hypersonic vehicles due to extreme temperatures encountered during flight. This category covers various thermal protection systems, heat-resistant materials, and cooling mechanisms designed to maintain structural integrity and protect onboard systems throughout the vehicle's lifecycle. These technologies are essential for extending the operational lifespan of hypersonic vehicles.Expand Specific Solutions03 Guidance, navigation, and control systems

This category encompasses advanced guidance, navigation, and control systems tailored for hypersonic vehicles. It includes technologies for precise trajectory planning, real-time flight path adjustments, and autonomous operation capabilities. These systems are critical for maintaining stability and accuracy throughout various phases of hypersonic flight, from launch to re-entry.Expand Specific Solutions04 Lifecycle maintenance and diagnostics

This category focuses on technologies and methodologies for maintaining and diagnosing hypersonic vehicles throughout their operational lifecycle. It includes advanced sensors, predictive maintenance systems, and non-destructive testing techniques designed to monitor vehicle health, detect potential issues, and extend the service life of these complex systems.Expand Specific Solutions05 Launch and recovery systems for hypersonic vehicles

This category covers specialized launch and recovery systems designed for hypersonic vehicles. It includes innovative launch platforms, assisted take-off technologies, and recovery methods that address the unique challenges of hypersonic flight. These systems are crucial for the safe and efficient deployment and retrieval of hypersonic vehicles throughout their operational lifecycle.Expand Specific Solutions

Hypersonic Industry Players

The competitive landscape for assessing lifecycles of hypersonic vehicles through scramjet data is in an early development stage, characterized by limited market size and emerging technologies. The field is primarily driven by aerospace and defense sectors, with key players including Lockheed Martin, Northrop Grumman, and General Electric. Academic institutions like Beihang University and Northwestern Polytechnical University are contributing significantly to research and development. The technology's maturity is still evolving, with companies like United Technologies Corp. and Hitachi Ltd. investing in advanced propulsion systems. As the market grows, collaboration between industry leaders and research institutions will be crucial for overcoming technical challenges and advancing hypersonic vehicle capabilities.

National University of Defense Technology

Technical Solution: The National University of Defense Technology (NUDT) has developed advanced computational fluid dynamics (CFD) models for hypersonic vehicle analysis. Their approach integrates high-fidelity simulations with machine learning algorithms to predict scramjet performance and lifecycle characteristics. The university has implemented a multi-scale modeling framework that combines molecular dynamics simulations with continuum mechanics to accurately capture the complex flow physics in scramjet engines[1]. NUDT researchers have also developed novel experimental techniques for high-enthalpy flow diagnostics, enabling real-time data collection during scramjet operation[3]. This data is then used to validate and refine their predictive models, improving the accuracy of lifecycle assessments for hypersonic vehicles.

Strengths: Advanced CFD capabilities, integration of machine learning, and novel experimental techniques. Weaknesses: Limited real-world testing opportunities and potential restrictions on international collaboration due to defense-related research.

Beihang University

Technical Solution: Beihang University has developed a sophisticated approach to assessing hypersonic vehicle lifecycles through scramjet data analysis. Their research focuses on the integration of multi-physics modeling with experimental data to accurately predict scramjet performance and durability. The university has established a state-of-the-art hypersonic wind tunnel facility that allows for high-fidelity testing of scramjet components under realistic flight conditions[7]. Beihang researchers have also developed advanced numerical methods for simulating the complex interactions between fluid dynamics, combustion, and material degradation in scramjet engines. Their approach incorporates machine learning algorithms to process large volumes of experimental and simulation data, enabling more accurate predictions of component lifespans and overall vehicle performance[8]. The university has collaborated with industry partners to validate their models against real-world flight data, further enhancing the reliability of their lifecycle assessments.

Strengths: Advanced experimental facilities, strong numerical modeling capabilities, and industry collaborations. Weaknesses: Potential limitations in accessing certain technologies or data due to international restrictions.

Key Scramjet Innovations

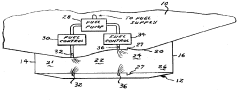

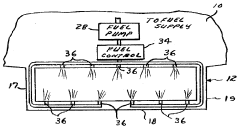

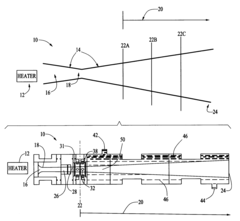

Dual mode supersonic combustion ramjet engine

PatentInactiveUS3667233A

Innovation

- A dual-mode combustion system with a combustor featuring a fixed geometry and parallel combustion section with uniform cross-section, utilizing fuel injection to stabilize flames and create choked flow, transitioning from subsonic to supersonic mode by manipulating shock waves through diverging sections and fuel distribution.

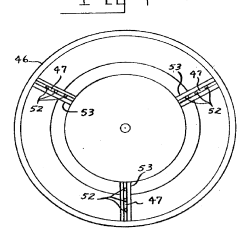

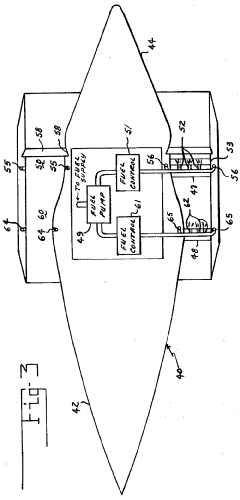

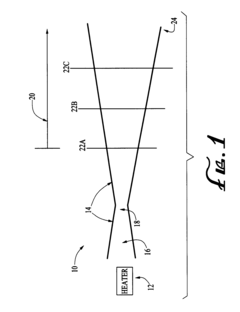

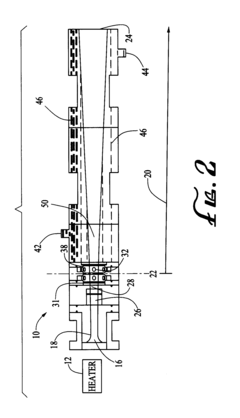

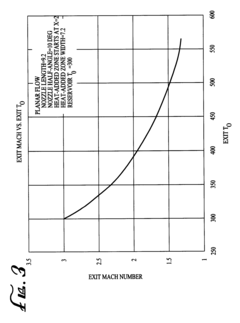

Variable supersonic mach number air heater utilizing supersonic combustion

PatentInactiveUS8087229B2

Innovation

- A supersonic combustion heater with strategically positioned fuel injection means and flame stabilization techniques that vary Mach numbers at the exit plane by heat addition in the diverging area, enhancing enthalpy flow, flame stability, and mixing without the need for expensive film-cooled nozzles, using a fixed geometric nozzle with converging and diverging areas and incorporating oxygen injection for stability.

Materials for Hypersonics

The development of hypersonic vehicles presents unique challenges in materials science due to the extreme conditions encountered during flight. Materials for hypersonic applications must withstand temperatures exceeding 2000°C, resist oxidation in high-speed air flows, and maintain structural integrity under severe thermal and mechanical stresses. Traditional aerospace materials such as titanium alloys and nickel-based superalloys are inadequate for these demanding environments.

Advanced ceramic matrix composites (CMCs) have emerged as promising candidates for hypersonic vehicle structures. These materials, such as carbon/carbon (C/C) and silicon carbide/silicon carbide (SiC/SiC) composites, offer excellent high-temperature strength and thermal shock resistance. However, they require protective coatings to prevent oxidation at extreme temperatures. Ultra-high temperature ceramics (UHTCs), including zirconium diboride (ZrB2) and hafnium diboride (HfB2), are being investigated for their exceptional oxidation resistance and mechanical properties at temperatures above 2000°C.

Refractory metal alloys, particularly those based on niobium, molybdenum, and tungsten, are also under consideration for hypersonic applications. These materials exhibit high melting points and good strength retention at elevated temperatures. However, their susceptibility to oxidation necessitates the development of advanced coatings or environmental barrier systems.

Thermal protection systems (TPS) play a crucial role in hypersonic vehicle design. Ablative materials, such as phenolic impregnated carbon ablators (PICA), are used for single-use applications like reentry vehicles. For reusable hypersonic vehicles, ceramic tiles and metallic heat shields are being developed to withstand multiple flight cycles.

Nanostructured materials and functionally graded composites are emerging as potential solutions for hypersonic applications. These materials offer tailored properties that can be optimized for specific regions of the vehicle, balancing thermal management, structural integrity, and weight considerations. Additionally, additive manufacturing techniques are being explored to fabricate complex geometries and integrated thermal management systems for hypersonic vehicles.

The development of materials for hypersonic applications requires a multidisciplinary approach, combining materials science, aerodynamics, and thermal management. Ongoing research focuses on improving material performance, developing novel processing techniques, and enhancing durability in extreme environments. As hypersonic vehicle technology advances, materials innovation will continue to play a critical role in enabling longer flight durations, increased maneuverability, and improved overall performance.

Advanced ceramic matrix composites (CMCs) have emerged as promising candidates for hypersonic vehicle structures. These materials, such as carbon/carbon (C/C) and silicon carbide/silicon carbide (SiC/SiC) composites, offer excellent high-temperature strength and thermal shock resistance. However, they require protective coatings to prevent oxidation at extreme temperatures. Ultra-high temperature ceramics (UHTCs), including zirconium diboride (ZrB2) and hafnium diboride (HfB2), are being investigated for their exceptional oxidation resistance and mechanical properties at temperatures above 2000°C.

Refractory metal alloys, particularly those based on niobium, molybdenum, and tungsten, are also under consideration for hypersonic applications. These materials exhibit high melting points and good strength retention at elevated temperatures. However, their susceptibility to oxidation necessitates the development of advanced coatings or environmental barrier systems.

Thermal protection systems (TPS) play a crucial role in hypersonic vehicle design. Ablative materials, such as phenolic impregnated carbon ablators (PICA), are used for single-use applications like reentry vehicles. For reusable hypersonic vehicles, ceramic tiles and metallic heat shields are being developed to withstand multiple flight cycles.

Nanostructured materials and functionally graded composites are emerging as potential solutions for hypersonic applications. These materials offer tailored properties that can be optimized for specific regions of the vehicle, balancing thermal management, structural integrity, and weight considerations. Additionally, additive manufacturing techniques are being explored to fabricate complex geometries and integrated thermal management systems for hypersonic vehicles.

The development of materials for hypersonic applications requires a multidisciplinary approach, combining materials science, aerodynamics, and thermal management. Ongoing research focuses on improving material performance, developing novel processing techniques, and enhancing durability in extreme environments. As hypersonic vehicle technology advances, materials innovation will continue to play a critical role in enabling longer flight durations, increased maneuverability, and improved overall performance.

Hypersonic Test Facilities

Hypersonic test facilities play a crucial role in assessing the lifecycles of hypersonic vehicles through scramjet data. These specialized facilities are designed to simulate the extreme conditions encountered during hypersonic flight, allowing researchers and engineers to gather vital information on vehicle performance, durability, and efficiency.

Ground-based hypersonic test facilities can be broadly categorized into wind tunnels, shock tunnels, and arc-heated facilities. Wind tunnels, such as the NASA Langley Research Center's 8-Foot High Temperature Tunnel, provide continuous flow conditions for extended periods, enabling detailed studies of aerodynamic heating and propulsion system performance. Shock tunnels, like the T4 facility at the University of Queensland, generate short-duration hypersonic flows, ideal for investigating the initial stages of scramjet ignition and combustion.

Arc-heated facilities, such as the LENS-XX facility at CUBRC, use high-temperature plasma to simulate the extreme heat experienced during atmospheric re-entry. These facilities are particularly valuable for testing thermal protection systems and materials used in hypersonic vehicle construction.

Flight test facilities, while less common due to their complexity and cost, offer the most realistic environment for assessing hypersonic vehicle lifecycles. The NASA X-43A and X-51A programs utilized specially modified B-52 aircraft as airborne launch platforms for their experimental hypersonic vehicles, providing invaluable data on real-world performance and operational challenges.

Computational facilities also play a significant role in hypersonic testing. High-performance computing clusters, such as those at the Air Force Research Laboratory, enable sophisticated computational fluid dynamics (CFD) simulations that complement physical testing and help predict vehicle behavior under various flight conditions.

The integration of data from these diverse testing facilities is crucial for a comprehensive understanding of hypersonic vehicle lifecycles. Advanced data acquisition systems and telemetry networks are employed to capture and transmit vast amounts of information during tests, while sophisticated data analysis tools help researchers interpret the results and refine vehicle designs.

As hypersonic technology continues to advance, test facilities are evolving to meet new challenges. Efforts are underway to develop facilities capable of simulating longer duration hypersonic flights, more accurately replicating the complex chemistry of hypersonic flows, and better integrating physical testing with computational simulations. These advancements will be essential for the continued development and assessment of next-generation hypersonic vehicles and their scramjet propulsion systems.

Ground-based hypersonic test facilities can be broadly categorized into wind tunnels, shock tunnels, and arc-heated facilities. Wind tunnels, such as the NASA Langley Research Center's 8-Foot High Temperature Tunnel, provide continuous flow conditions for extended periods, enabling detailed studies of aerodynamic heating and propulsion system performance. Shock tunnels, like the T4 facility at the University of Queensland, generate short-duration hypersonic flows, ideal for investigating the initial stages of scramjet ignition and combustion.

Arc-heated facilities, such as the LENS-XX facility at CUBRC, use high-temperature plasma to simulate the extreme heat experienced during atmospheric re-entry. These facilities are particularly valuable for testing thermal protection systems and materials used in hypersonic vehicle construction.

Flight test facilities, while less common due to their complexity and cost, offer the most realistic environment for assessing hypersonic vehicle lifecycles. The NASA X-43A and X-51A programs utilized specially modified B-52 aircraft as airborne launch platforms for their experimental hypersonic vehicles, providing invaluable data on real-world performance and operational challenges.

Computational facilities also play a significant role in hypersonic testing. High-performance computing clusters, such as those at the Air Force Research Laboratory, enable sophisticated computational fluid dynamics (CFD) simulations that complement physical testing and help predict vehicle behavior under various flight conditions.

The integration of data from these diverse testing facilities is crucial for a comprehensive understanding of hypersonic vehicle lifecycles. Advanced data acquisition systems and telemetry networks are employed to capture and transmit vast amounts of information during tests, while sophisticated data analysis tools help researchers interpret the results and refine vehicle designs.

As hypersonic technology continues to advance, test facilities are evolving to meet new challenges. Efforts are underway to develop facilities capable of simulating longer duration hypersonic flights, more accurately replicating the complex chemistry of hypersonic flows, and better integrating physical testing with computational simulations. These advancements will be essential for the continued development and assessment of next-generation hypersonic vehicles and their scramjet propulsion systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!