Hypersonic Lift Optimizations for Scramjet-enabled Aircraft

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hypersonic Lift Tech Evolution and Objectives

Hypersonic lift technology has evolved significantly since the inception of supersonic flight in the mid-20th century. The development of scramjet-enabled aircraft has pushed the boundaries of aerodynamics and propulsion, necessitating innovative approaches to lift generation at hypersonic speeds. The primary objective in this field is to optimize lift production while minimizing drag and managing extreme thermal loads encountered at Mach 5 and above.

The evolution of hypersonic lift technology can be traced through several key milestones. Early research focused on understanding the complex flow physics at hypersonic velocities, including shock wave interactions and boundary layer behavior. This foundational work led to the development of specialized airfoil shapes and wing configurations designed to operate efficiently in the hypersonic regime.

As scramjet technology advanced, the integration of propulsion and aerodynamics became a critical focus. Waverider configurations emerged as a promising concept, utilizing the shock wave generated by the vehicle to create a high-pressure region beneath the aircraft, enhancing lift production. Concurrent advancements in materials science enabled the creation of heat-resistant structures capable of withstanding the extreme temperatures associated with hypersonic flight.

Recent technological objectives in hypersonic lift optimization revolve around several key areas. Active flow control techniques are being explored to manipulate the boundary layer and shock wave interactions, potentially offering real-time adjustments to lift characteristics. Computational fluid dynamics (CFD) and advanced simulation tools have become instrumental in predicting and optimizing lift performance across a wide range of flight conditions.

Another significant objective is the development of adaptive structures that can modify their shape in flight to optimize lift-to-drag ratios at various speeds and altitudes. This includes research into morphing wings and variable geometry inlets that can adjust to changing flow conditions. Additionally, there is a growing focus on multi-disciplinary optimization approaches that consider aerodynamics, propulsion, and thermal management simultaneously to achieve holistic performance improvements.

The ultimate goal of current hypersonic lift technology research is to enable sustained, efficient flight at hypersonic speeds for both military and potential commercial applications. This involves not only maximizing lift but also addressing related challenges such as thermal protection, fuel efficiency, and overall vehicle stability and control. As the field progresses, the integration of advanced materials, smart structures, and cutting-edge computational methods will be crucial in realizing the full potential of scramjet-enabled hypersonic aircraft.

The evolution of hypersonic lift technology can be traced through several key milestones. Early research focused on understanding the complex flow physics at hypersonic velocities, including shock wave interactions and boundary layer behavior. This foundational work led to the development of specialized airfoil shapes and wing configurations designed to operate efficiently in the hypersonic regime.

As scramjet technology advanced, the integration of propulsion and aerodynamics became a critical focus. Waverider configurations emerged as a promising concept, utilizing the shock wave generated by the vehicle to create a high-pressure region beneath the aircraft, enhancing lift production. Concurrent advancements in materials science enabled the creation of heat-resistant structures capable of withstanding the extreme temperatures associated with hypersonic flight.

Recent technological objectives in hypersonic lift optimization revolve around several key areas. Active flow control techniques are being explored to manipulate the boundary layer and shock wave interactions, potentially offering real-time adjustments to lift characteristics. Computational fluid dynamics (CFD) and advanced simulation tools have become instrumental in predicting and optimizing lift performance across a wide range of flight conditions.

Another significant objective is the development of adaptive structures that can modify their shape in flight to optimize lift-to-drag ratios at various speeds and altitudes. This includes research into morphing wings and variable geometry inlets that can adjust to changing flow conditions. Additionally, there is a growing focus on multi-disciplinary optimization approaches that consider aerodynamics, propulsion, and thermal management simultaneously to achieve holistic performance improvements.

The ultimate goal of current hypersonic lift technology research is to enable sustained, efficient flight at hypersonic speeds for both military and potential commercial applications. This involves not only maximizing lift but also addressing related challenges such as thermal protection, fuel efficiency, and overall vehicle stability and control. As the field progresses, the integration of advanced materials, smart structures, and cutting-edge computational methods will be crucial in realizing the full potential of scramjet-enabled hypersonic aircraft.

Scramjet Aircraft Market Analysis

The market for scramjet-enabled aircraft is experiencing significant growth driven by increasing demand for hypersonic travel and advanced military capabilities. This emerging sector is poised for substantial expansion over the next decade, with both commercial and defense applications fueling development.

In the commercial sector, the promise of ultra-fast global travel is attracting investment from major aerospace companies and startups alike. The potential for reducing intercontinental flight times to under two hours is creating a new paradigm in air transportation. Market projections suggest that by 2030, the commercial hypersonic aircraft market could reach several billion dollars annually, with steady growth expected as technology matures and regulatory frameworks evolve.

The defense sector represents the primary driver of current scramjet aircraft development. Military strategists view hypersonic capabilities as a critical component of future warfare, leading to substantial government funding for research and development. The global defense hypersonic market is expected to grow at a compound annual growth rate exceeding 10% through 2025, reflecting the strategic importance placed on these technologies by major military powers.

Key market players in the scramjet aircraft sector include established aerospace giants such as Lockheed Martin, Boeing, and Northrop Grumman, as well as specialized hypersonic technology companies like Hermeus and Reaction Engines. These companies are investing heavily in overcoming technical challenges related to hypersonic lift optimization, thermal management, and propulsion efficiency.

Geographically, North America currently dominates the scramjet aircraft market, with the United States leading in both military and commercial development. However, significant investments and progress are also being made in China, Russia, and Europe, indicating a global race for hypersonic supremacy.

Market challenges include high development costs, technical complexities, and regulatory hurdles. The need for advanced materials capable of withstanding extreme temperatures and pressures at hypersonic speeds presents both a barrier and an opportunity for innovation in the aerospace materials industry.

Environmental concerns and sustainability issues are emerging as important factors shaping the market's future. The potential environmental impact of widespread hypersonic travel is driving research into more efficient propulsion systems and alternative fuels, which could open new market segments within the industry.

As the technology matures, ancillary markets are expected to develop, including specialized maintenance services, advanced simulation and training systems, and hypersonic-specific infrastructure. These secondary markets could significantly expand the overall economic footprint of the scramjet aircraft industry.

In the commercial sector, the promise of ultra-fast global travel is attracting investment from major aerospace companies and startups alike. The potential for reducing intercontinental flight times to under two hours is creating a new paradigm in air transportation. Market projections suggest that by 2030, the commercial hypersonic aircraft market could reach several billion dollars annually, with steady growth expected as technology matures and regulatory frameworks evolve.

The defense sector represents the primary driver of current scramjet aircraft development. Military strategists view hypersonic capabilities as a critical component of future warfare, leading to substantial government funding for research and development. The global defense hypersonic market is expected to grow at a compound annual growth rate exceeding 10% through 2025, reflecting the strategic importance placed on these technologies by major military powers.

Key market players in the scramjet aircraft sector include established aerospace giants such as Lockheed Martin, Boeing, and Northrop Grumman, as well as specialized hypersonic technology companies like Hermeus and Reaction Engines. These companies are investing heavily in overcoming technical challenges related to hypersonic lift optimization, thermal management, and propulsion efficiency.

Geographically, North America currently dominates the scramjet aircraft market, with the United States leading in both military and commercial development. However, significant investments and progress are also being made in China, Russia, and Europe, indicating a global race for hypersonic supremacy.

Market challenges include high development costs, technical complexities, and regulatory hurdles. The need for advanced materials capable of withstanding extreme temperatures and pressures at hypersonic speeds presents both a barrier and an opportunity for innovation in the aerospace materials industry.

Environmental concerns and sustainability issues are emerging as important factors shaping the market's future. The potential environmental impact of widespread hypersonic travel is driving research into more efficient propulsion systems and alternative fuels, which could open new market segments within the industry.

As the technology matures, ancillary markets are expected to develop, including specialized maintenance services, advanced simulation and training systems, and hypersonic-specific infrastructure. These secondary markets could significantly expand the overall economic footprint of the scramjet aircraft industry.

Hypersonic Lift Challenges and Limitations

Hypersonic lift optimization for scramjet-enabled aircraft faces numerous challenges and limitations due to the extreme conditions encountered at Mach 5 and above. The primary obstacle is the intense heat generated by air friction at such velocities, which can compromise the structural integrity of the aircraft and affect its aerodynamic performance.

One of the most significant challenges is the design of efficient airfoils that can generate sufficient lift while minimizing drag in the hypersonic regime. Traditional airfoil shapes become ineffective at these speeds, necessitating the development of novel geometries that can maintain lift under extreme conditions. The thin shock layers and high-temperature effects associated with hypersonic flight further complicate the aerodynamic design process.

Material limitations pose another critical constraint. Conventional aerospace materials cannot withstand the extreme temperatures encountered during sustained hypersonic flight. This necessitates the use of advanced materials such as ceramic matrix composites and refractory alloys, which are often expensive and difficult to manufacture at scale.

The integration of the scramjet engine with the airframe presents unique challenges for lift optimization. The engine inlet must be carefully designed to ensure efficient air compression while minimizing drag. Additionally, the exhaust from the scramjet can significantly affect the flow field around the aircraft, impacting lift generation and overall aerodynamic performance.

Control and stability issues become more pronounced at hypersonic speeds. The reduced effectiveness of conventional control surfaces and the potential for aeroelastic effects require innovative solutions for maintaining aircraft stability and maneuverability. This may involve the development of new control methodologies and adaptive structures capable of withstanding the harsh hypersonic environment.

Computational limitations also hinder progress in hypersonic lift optimization. Accurate modeling of hypersonic flows requires sophisticated computational fluid dynamics (CFD) simulations that are computationally intensive and time-consuming. The complex interactions between aerodynamics, thermodynamics, and chemistry at hypersonic speeds further complicate these simulations, making it challenging to predict and optimize lift performance accurately.

Experimental validation of hypersonic designs is extremely costly and limited by the availability of suitable test facilities. Wind tunnels capable of simulating hypersonic conditions are rare and can only operate for short durations, limiting the scope and fidelity of experimental data available for validation and optimization efforts.

One of the most significant challenges is the design of efficient airfoils that can generate sufficient lift while minimizing drag in the hypersonic regime. Traditional airfoil shapes become ineffective at these speeds, necessitating the development of novel geometries that can maintain lift under extreme conditions. The thin shock layers and high-temperature effects associated with hypersonic flight further complicate the aerodynamic design process.

Material limitations pose another critical constraint. Conventional aerospace materials cannot withstand the extreme temperatures encountered during sustained hypersonic flight. This necessitates the use of advanced materials such as ceramic matrix composites and refractory alloys, which are often expensive and difficult to manufacture at scale.

The integration of the scramjet engine with the airframe presents unique challenges for lift optimization. The engine inlet must be carefully designed to ensure efficient air compression while minimizing drag. Additionally, the exhaust from the scramjet can significantly affect the flow field around the aircraft, impacting lift generation and overall aerodynamic performance.

Control and stability issues become more pronounced at hypersonic speeds. The reduced effectiveness of conventional control surfaces and the potential for aeroelastic effects require innovative solutions for maintaining aircraft stability and maneuverability. This may involve the development of new control methodologies and adaptive structures capable of withstanding the harsh hypersonic environment.

Computational limitations also hinder progress in hypersonic lift optimization. Accurate modeling of hypersonic flows requires sophisticated computational fluid dynamics (CFD) simulations that are computationally intensive and time-consuming. The complex interactions between aerodynamics, thermodynamics, and chemistry at hypersonic speeds further complicate these simulations, making it challenging to predict and optimize lift performance accurately.

Experimental validation of hypersonic designs is extremely costly and limited by the availability of suitable test facilities. Wind tunnels capable of simulating hypersonic conditions are rare and can only operate for short durations, limiting the scope and fidelity of experimental data available for validation and optimization efforts.

Current Hypersonic Lift Enhancement Solutions

01 Integrated scramjet-airframe design for lift enhancement

Scramjet-enabled aircraft designs integrate the engine with the airframe to enhance lift generation. This approach utilizes the aircraft's body to compress incoming air and generate additional lift, improving overall aerodynamic performance at hypersonic speeds.- Scramjet integration with aircraft design: Scramjet engines are integrated into the aircraft design to optimize lift generation. The aircraft body is shaped to create compression surfaces and expansion nozzles, effectively utilizing the airflow for both propulsion and lift. This integration allows for improved aerodynamic performance at hypersonic speeds.

- Variable geometry for lift control: Scramjet-enabled aircraft employ variable geometry features to control lift at different flight regimes. Adjustable inlet ramps, movable surfaces, and adaptive nozzles allow for optimized lift generation from subsonic to hypersonic speeds. These systems can alter the aircraft's aerodynamic properties to maintain efficient lift throughout the flight envelope.

- Thermal management for lift surfaces: Advanced thermal management systems are crucial for maintaining the integrity of lift-generating surfaces in scramjet-powered aircraft. These systems protect against extreme temperatures encountered during hypersonic flight, ensuring consistent lift production and preventing structural failure of critical components.

- Fuel injection and combustion for lift augmentation: Innovative fuel injection and combustion techniques in scramjet engines are used to augment lift. Strategically placed fuel injectors and carefully designed combustion chambers can create pressure differentials that contribute to overall lift, especially during transonic and low hypersonic flight regimes.

- Computational fluid dynamics for lift optimization: Advanced computational fluid dynamics (CFD) models are employed to optimize lift generation in scramjet-enabled aircraft. These simulations help engineers design complex geometries and flow paths that maximize lift while maintaining efficient scramjet operation across a wide range of Mach numbers.

02 Variable geometry inlets and nozzles for lift control

Scramjet aircraft employ variable geometry inlets and nozzles to optimize airflow and thrust at different speeds. These adjustable components can be manipulated to influence lift characteristics, allowing for better control and performance across a wide range of flight conditions.Expand Specific Solutions03 Waverider configuration for lift generation

Waverider designs are utilized in scramjet-enabled aircraft to generate lift from shock waves produced at hypersonic speeds. This configuration allows the aircraft to 'ride' on its own shock wave, significantly increasing lift-to-drag ratios at high Mach numbers.Expand Specific Solutions04 Active flow control systems for lift enhancement

Scramjet aircraft incorporate active flow control systems to manipulate airflow over lifting surfaces. These systems may include plasma actuators, synthetic jets, or other devices to energize the boundary layer, delay flow separation, and enhance lift performance across various flight regimes.Expand Specific Solutions05 Thermal management integration for lift optimization

Advanced thermal management systems in scramjet aircraft are designed to not only protect the airframe from extreme temperatures but also to contribute to lift generation. By carefully managing heat distribution and utilizing it for boundary layer control, these systems can positively influence the aircraft's lift characteristics.Expand Specific Solutions

Key Players in Hypersonic Aircraft Industry

The hypersonic lift optimization for scramjet-enabled aircraft is a highly competitive and rapidly evolving field. The industry is in an early growth stage, with significant potential for market expansion as hypersonic technology matures. Major players like Boeing, Lockheed Martin, and Northrop Grumman are investing heavily in research and development. Academic institutions such as Nanjing University of Aeronautics & Astronautics and Beihang University are also contributing to technological advancements. The market size is expected to grow substantially as commercial applications emerge alongside military uses. While the technology is still in development, progress in materials science, propulsion systems, and aerodynamics is accelerating the path to practical implementation.

The Boeing Co.

Technical Solution: Boeing's approach to hypersonic lift optimization for scramjet-enabled aircraft involves advanced computational fluid dynamics (CFD) simulations and wind tunnel testing. They utilize a multi-disciplinary optimization (MDO) framework that integrates aerodynamics, propulsion, and structures to achieve optimal lift-to-drag ratios at hypersonic speeds[1]. Boeing's design incorporates a waverider configuration with a highly integrated airframe-propulsion system, featuring a carefully contoured underbody to capture and process the shock wave, enhancing lift generation[3]. The company has also developed innovative thermal management systems to address the extreme heating issues associated with hypersonic flight, using advanced materials and active cooling techniques[5].

Strengths: Extensive experience in aerospace engineering, access to advanced testing facilities, and a strong track record in developing cutting-edge aircraft. Weaknesses: High development costs and potential regulatory challenges for hypersonic technologies.

National University of Defense Technology

Technical Solution: The National University of Defense Technology (NUDT) has developed a novel approach to hypersonic lift optimization using a combination of machine learning algorithms and high-fidelity numerical simulations. Their method employs deep neural networks to predict aerodynamic performance, significantly reducing computational time compared to traditional CFD methods[2]. NUDT researchers have also introduced an innovative shape optimization technique that considers both external aerodynamics and internal flow paths of the scramjet engine simultaneously[4]. This integrated approach allows for more efficient design iterations and better overall performance of the hypersonic vehicle. Additionally, they have made advancements in plasma-assisted combustion technology to enhance scramjet efficiency at various flight conditions[6].

Strengths: Strong focus on cutting-edge computational methods and interdisciplinary research. Weaknesses: Potential limitations in full-scale testing capabilities and international collaboration due to defense-related nature of the institution.

Core Innovations in Hypersonic Aerodynamics

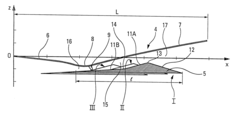

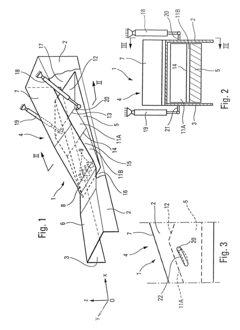

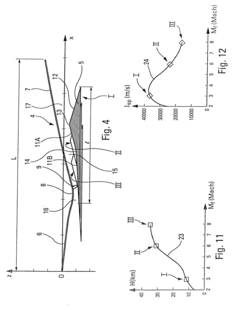

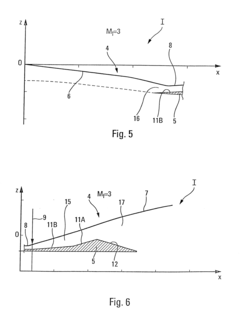

Ramjet for supersonic and hypersonic aircraft

PatentInactiveEP1288480A1

Innovation

- A ramjet engine design featuring a sliding lower wall that modifies the geometries of the oxidizer inlet and combustion chamber by translating one of the walls, allowing adaptation to different flight conditions, eliminating the need for a variable-geometry wall and simplifying the actuation system, while maintaining an optimal combustion chamber for both subsonic and supersonic conditions.

Ramjet for a supersonic and hypersonic aircraft

PatentInactiveUS6672068B1

Innovation

- A ramjet design featuring a sliding lower wall with a movable V-profiled structure that adjusts the oxidant inlet and combustion chamber geometry by translating one wall, eliminating the need for complex articulation systems and actuators, allowing for optimal combustion at both subsonic and supersonic speeds by modifying the cross-section and nozzle geometry in response to changing Mach numbers.

Materials Science for Hypersonic Flight

Materials science plays a crucial role in the development of hypersonic aircraft, particularly for scramjet-enabled vehicles. The extreme conditions encountered during hypersonic flight pose significant challenges to material selection and design. At hypersonic speeds, air friction generates intense heat, with temperatures reaching up to 2,000°C on leading edges and other critical surfaces. This necessitates the use of advanced materials capable of withstanding such extreme thermal loads while maintaining structural integrity.

Thermal protection systems (TPS) are essential components of hypersonic vehicles, designed to shield the aircraft's structure from excessive heat. Current TPS materials include ceramic matrix composites (CMCs), carbon-carbon composites, and refractory metals. CMCs, such as silicon carbide-based materials, offer excellent thermal resistance and low density. Carbon-carbon composites provide superior strength-to-weight ratios and thermal stability at high temperatures. Refractory metals like molybdenum and niobium alloys exhibit high melting points and good mechanical properties at elevated temperatures.

Oxidation resistance is a critical factor in material selection for hypersonic flight. The high-temperature oxidizing environment can rapidly degrade unprotected materials. Researchers are developing advanced coatings and surface treatments to enhance oxidation resistance. These include multi-layer ceramic coatings, self-healing materials, and nanostructured composites that form protective oxide scales under high-temperature conditions.

Lightweight materials are essential for optimizing the performance of scramjet-enabled aircraft. Advanced alloys, such as titanium aluminides and high-entropy alloys, offer promising combinations of low density, high strength, and temperature resistance. Nanocomposites and functionally graded materials are being explored to tailor material properties across different regions of the aircraft, optimizing weight distribution and thermal management.

The development of smart materials and structures is an emerging area in hypersonic materials science. These materials can adapt to changing flight conditions, potentially improving aerodynamic performance and thermal management. Shape memory alloys and piezoelectric materials are being investigated for their potential to enable active flow control and structural morphing in hypersonic environments.

Advancements in manufacturing techniques, such as additive manufacturing and advanced joining processes, are enabling the production of complex geometries and multi-material structures optimized for hypersonic flight. These technologies allow for the creation of intricate cooling channels, functionally graded structures, and novel material combinations that were previously impossible to manufacture.

Thermal protection systems (TPS) are essential components of hypersonic vehicles, designed to shield the aircraft's structure from excessive heat. Current TPS materials include ceramic matrix composites (CMCs), carbon-carbon composites, and refractory metals. CMCs, such as silicon carbide-based materials, offer excellent thermal resistance and low density. Carbon-carbon composites provide superior strength-to-weight ratios and thermal stability at high temperatures. Refractory metals like molybdenum and niobium alloys exhibit high melting points and good mechanical properties at elevated temperatures.

Oxidation resistance is a critical factor in material selection for hypersonic flight. The high-temperature oxidizing environment can rapidly degrade unprotected materials. Researchers are developing advanced coatings and surface treatments to enhance oxidation resistance. These include multi-layer ceramic coatings, self-healing materials, and nanostructured composites that form protective oxide scales under high-temperature conditions.

Lightweight materials are essential for optimizing the performance of scramjet-enabled aircraft. Advanced alloys, such as titanium aluminides and high-entropy alloys, offer promising combinations of low density, high strength, and temperature resistance. Nanocomposites and functionally graded materials are being explored to tailor material properties across different regions of the aircraft, optimizing weight distribution and thermal management.

The development of smart materials and structures is an emerging area in hypersonic materials science. These materials can adapt to changing flight conditions, potentially improving aerodynamic performance and thermal management. Shape memory alloys and piezoelectric materials are being investigated for their potential to enable active flow control and structural morphing in hypersonic environments.

Advancements in manufacturing techniques, such as additive manufacturing and advanced joining processes, are enabling the production of complex geometries and multi-material structures optimized for hypersonic flight. These technologies allow for the creation of intricate cooling channels, functionally graded structures, and novel material combinations that were previously impossible to manufacture.

Environmental Impact of Hypersonic Travel

The environmental impact of hypersonic travel, particularly for scramjet-enabled aircraft, is a critical consideration as this technology advances. Hypersonic flight, occurring at speeds above Mach 5, introduces unique environmental challenges that extend beyond those associated with conventional air travel.

One of the primary environmental concerns is the potential for increased stratospheric ozone depletion. Hypersonic aircraft operate at higher altitudes than traditional commercial planes, potentially releasing emissions directly into the stratosphere. The high temperatures generated during hypersonic flight can lead to the formation of nitrogen oxides (NOx), which are known to catalyze ozone destruction. This could exacerbate existing ozone depletion issues, particularly in polar regions.

The sonic boom generated by hypersonic aircraft presents another significant environmental challenge. Unlike conventional supersonic aircraft, hypersonic vehicles produce continuous sonic booms along their entire flight path. This persistent noise pollution could have far-reaching effects on both human populations and wildlife, potentially disrupting ecosystems and causing stress to various species.

Hypersonic flight also raises concerns about increased upper atmosphere pollution. The extreme speeds and temperatures involved in hypersonic travel may result in the production of unique pollutants or alter the chemical composition of existing emissions. These changes could have unforeseen consequences on atmospheric chemistry and climate patterns.

The energy requirements for hypersonic flight are substantially higher than those for conventional air travel, potentially leading to increased greenhouse gas emissions if not addressed through advanced propulsion technologies or sustainable fuel sources. The development of scramjet engines, while more efficient at hypersonic speeds, still faces challenges in terms of overall environmental sustainability.

Additionally, the thermal impact of hypersonic flight on the atmosphere is a growing area of concern. The heat generated by these aircraft could potentially alter local atmospheric conditions, with the cumulative effect of multiple flights potentially influencing weather patterns or contributing to atmospheric heating.

The materials used in hypersonic aircraft construction also present environmental considerations. Advanced heat-resistant materials may have complex manufacturing processes or contain elements that pose challenges for recycling or disposal at the end of the aircraft's lifecycle.

As research in hypersonic lift optimization for scramjet-enabled aircraft progresses, it is crucial to integrate environmental impact assessments into the design and development process. This proactive approach can help mitigate potential environmental risks and ensure that the advancement of hypersonic technology aligns with global sustainability goals.

One of the primary environmental concerns is the potential for increased stratospheric ozone depletion. Hypersonic aircraft operate at higher altitudes than traditional commercial planes, potentially releasing emissions directly into the stratosphere. The high temperatures generated during hypersonic flight can lead to the formation of nitrogen oxides (NOx), which are known to catalyze ozone destruction. This could exacerbate existing ozone depletion issues, particularly in polar regions.

The sonic boom generated by hypersonic aircraft presents another significant environmental challenge. Unlike conventional supersonic aircraft, hypersonic vehicles produce continuous sonic booms along their entire flight path. This persistent noise pollution could have far-reaching effects on both human populations and wildlife, potentially disrupting ecosystems and causing stress to various species.

Hypersonic flight also raises concerns about increased upper atmosphere pollution. The extreme speeds and temperatures involved in hypersonic travel may result in the production of unique pollutants or alter the chemical composition of existing emissions. These changes could have unforeseen consequences on atmospheric chemistry and climate patterns.

The energy requirements for hypersonic flight are substantially higher than those for conventional air travel, potentially leading to increased greenhouse gas emissions if not addressed through advanced propulsion technologies or sustainable fuel sources. The development of scramjet engines, while more efficient at hypersonic speeds, still faces challenges in terms of overall environmental sustainability.

Additionally, the thermal impact of hypersonic flight on the atmosphere is a growing area of concern. The heat generated by these aircraft could potentially alter local atmospheric conditions, with the cumulative effect of multiple flights potentially influencing weather patterns or contributing to atmospheric heating.

The materials used in hypersonic aircraft construction also present environmental considerations. Advanced heat-resistant materials may have complex manufacturing processes or contain elements that pose challenges for recycling or disposal at the end of the aircraft's lifecycle.

As research in hypersonic lift optimization for scramjet-enabled aircraft progresses, it is crucial to integrate environmental impact assessments into the design and development process. This proactive approach can help mitigate potential environmental risks and ensure that the advancement of hypersonic technology aligns with global sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!