Aerodynamic Lift Management in Scramjets During Extreme Maneuvers

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Lift Dynamics

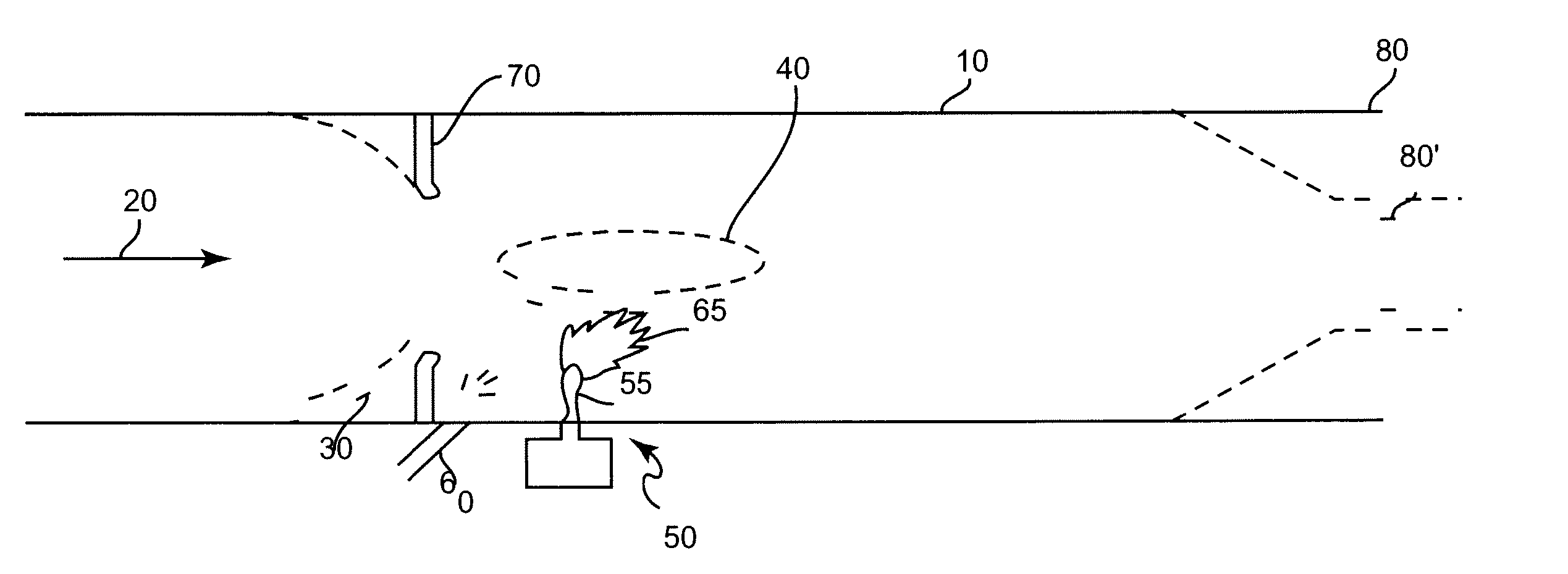

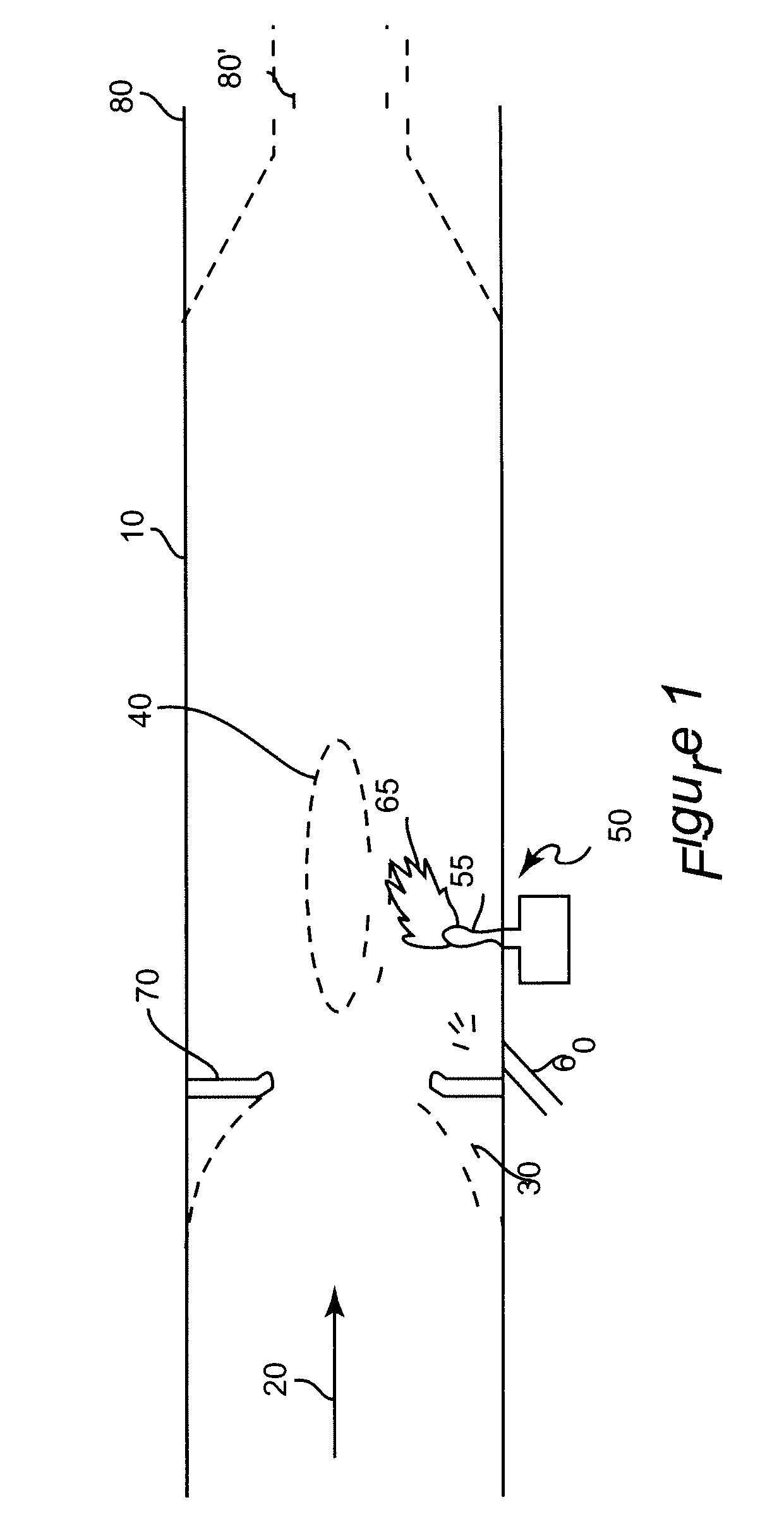

Scramjet lift dynamics play a crucial role in the performance and control of hypersonic vehicles during extreme maneuvers. The aerodynamic lift generated by a scramjet engine is a complex interplay of various factors, including the vehicle's geometry, flight conditions, and propulsion system characteristics.

At high Mach numbers, the flow entering the scramjet inlet undergoes significant compression, leading to increased pressure and temperature. This compression process contributes to the overall lift generation, as the high-pressure air on the lower surface of the vehicle creates an upward force. The forebody of the scramjet vehicle, typically designed with a wedge or ramp shape, further enhances this effect by creating a strong shock wave that increases the pressure differential between the upper and lower surfaces.

The combustion process within the scramjet engine also influences lift dynamics. As fuel is injected and burned in the supersonic airflow, it results in a rapid expansion of gases. This expansion, when properly managed, can contribute to additional lift generation through thrust vectoring and pressure distribution along the vehicle's aftbody.

During extreme maneuvers, such as rapid pitch or yaw movements, the scramjet lift dynamics become even more complex. The sudden changes in angle of attack or sideslip angle can lead to significant variations in the shock wave structure and flow field around the vehicle. These variations can cause abrupt changes in lift distribution, potentially leading to instabilities or loss of control if not properly managed.

The interaction between the vehicle's external aerodynamics and the internal flow of the scramjet engine presents unique challenges in lift management. The inlet shock system and boundary layer behavior are highly sensitive to changes in flight conditions, affecting the engine's performance and, consequently, the overall lift characteristics of the vehicle.

To effectively manage aerodynamic lift during extreme maneuvers, advanced control systems and adaptive structures are often employed. These systems may include variable geometry inlets, active flow control devices, and thrust vectoring mechanisms. By dynamically adjusting the vehicle's configuration and flow characteristics, these systems aim to maintain optimal lift performance across a wide range of flight conditions and maneuver scenarios.

Computational fluid dynamics (CFD) simulations and wind tunnel testing play vital roles in understanding and predicting scramjet lift dynamics. These tools allow engineers to analyze complex flow phenomena and optimize vehicle designs for enhanced lift management capabilities. Additionally, real-time flow sensing and adaptive control algorithms are being developed to provide rapid response to changing flight conditions, ensuring stable and efficient lift generation during extreme maneuvers.

At high Mach numbers, the flow entering the scramjet inlet undergoes significant compression, leading to increased pressure and temperature. This compression process contributes to the overall lift generation, as the high-pressure air on the lower surface of the vehicle creates an upward force. The forebody of the scramjet vehicle, typically designed with a wedge or ramp shape, further enhances this effect by creating a strong shock wave that increases the pressure differential between the upper and lower surfaces.

The combustion process within the scramjet engine also influences lift dynamics. As fuel is injected and burned in the supersonic airflow, it results in a rapid expansion of gases. This expansion, when properly managed, can contribute to additional lift generation through thrust vectoring and pressure distribution along the vehicle's aftbody.

During extreme maneuvers, such as rapid pitch or yaw movements, the scramjet lift dynamics become even more complex. The sudden changes in angle of attack or sideslip angle can lead to significant variations in the shock wave structure and flow field around the vehicle. These variations can cause abrupt changes in lift distribution, potentially leading to instabilities or loss of control if not properly managed.

The interaction between the vehicle's external aerodynamics and the internal flow of the scramjet engine presents unique challenges in lift management. The inlet shock system and boundary layer behavior are highly sensitive to changes in flight conditions, affecting the engine's performance and, consequently, the overall lift characteristics of the vehicle.

To effectively manage aerodynamic lift during extreme maneuvers, advanced control systems and adaptive structures are often employed. These systems may include variable geometry inlets, active flow control devices, and thrust vectoring mechanisms. By dynamically adjusting the vehicle's configuration and flow characteristics, these systems aim to maintain optimal lift performance across a wide range of flight conditions and maneuver scenarios.

Computational fluid dynamics (CFD) simulations and wind tunnel testing play vital roles in understanding and predicting scramjet lift dynamics. These tools allow engineers to analyze complex flow phenomena and optimize vehicle designs for enhanced lift management capabilities. Additionally, real-time flow sensing and adaptive control algorithms are being developed to provide rapid response to changing flight conditions, ensuring stable and efficient lift generation during extreme maneuvers.

Hypersonic Market Trends

The hypersonic market is experiencing rapid growth and transformation, driven by advancements in scramjet technology and the increasing demand for high-speed aerospace applications. This market segment is primarily fueled by defense and space exploration sectors, with emerging commercial applications on the horizon.

In the defense sector, hypersonic weapons and aircraft are becoming a top priority for major military powers. The United States, China, and Russia are investing heavily in hypersonic technology development, recognizing its potential to revolutionize warfare and strategic deterrence. This has led to a surge in government funding and research initiatives focused on scramjet propulsion systems and aerodynamic lift management.

The space exploration sector is also contributing significantly to the hypersonic market growth. As space agencies and private companies aim to reduce launch costs and improve spacecraft reusability, hypersonic technologies are becoming increasingly relevant. Scramjet-powered vehicles offer the potential for more efficient and cost-effective access to space, driving investment in this area.

Commercial applications of hypersonic technology are still in their infancy but show promising potential. The prospect of ultra-fast intercontinental travel has captured the imagination of the aviation industry, with several companies exploring the feasibility of hypersonic passenger aircraft. While significant technical and regulatory challenges remain, this sector could represent a substantial market opportunity in the coming decades.

The global hypersonic market is expected to grow substantially in the next decade. This growth is attributed to increased military spending, advancements in materials science, and breakthroughs in propulsion technology. The focus on aerodynamic lift management in scramjets during extreme maneuvers is a critical aspect of this market trend, as it directly impacts the performance and viability of hypersonic vehicles.

Key players in the hypersonic market include established aerospace and defense companies as well as innovative startups. These organizations are investing in research and development to overcome technical challenges, such as thermal management, propulsion efficiency, and control systems for extreme flight conditions.

As the hypersonic market evolves, there is a growing emphasis on international collaboration and competition. While national security concerns often limit information sharing, there is recognition that advancing hypersonic technology requires a global pool of expertise and resources. This dynamic is shaping the market landscape and influencing strategic partnerships within the industry.

In the defense sector, hypersonic weapons and aircraft are becoming a top priority for major military powers. The United States, China, and Russia are investing heavily in hypersonic technology development, recognizing its potential to revolutionize warfare and strategic deterrence. This has led to a surge in government funding and research initiatives focused on scramjet propulsion systems and aerodynamic lift management.

The space exploration sector is also contributing significantly to the hypersonic market growth. As space agencies and private companies aim to reduce launch costs and improve spacecraft reusability, hypersonic technologies are becoming increasingly relevant. Scramjet-powered vehicles offer the potential for more efficient and cost-effective access to space, driving investment in this area.

Commercial applications of hypersonic technology are still in their infancy but show promising potential. The prospect of ultra-fast intercontinental travel has captured the imagination of the aviation industry, with several companies exploring the feasibility of hypersonic passenger aircraft. While significant technical and regulatory challenges remain, this sector could represent a substantial market opportunity in the coming decades.

The global hypersonic market is expected to grow substantially in the next decade. This growth is attributed to increased military spending, advancements in materials science, and breakthroughs in propulsion technology. The focus on aerodynamic lift management in scramjets during extreme maneuvers is a critical aspect of this market trend, as it directly impacts the performance and viability of hypersonic vehicles.

Key players in the hypersonic market include established aerospace and defense companies as well as innovative startups. These organizations are investing in research and development to overcome technical challenges, such as thermal management, propulsion efficiency, and control systems for extreme flight conditions.

As the hypersonic market evolves, there is a growing emphasis on international collaboration and competition. While national security concerns often limit information sharing, there is recognition that advancing hypersonic technology requires a global pool of expertise and resources. This dynamic is shaping the market landscape and influencing strategic partnerships within the industry.

Aerodynamic Challenges

Scramjet engines face significant aerodynamic challenges during extreme maneuvers, particularly in managing lift forces. These challenges stem from the complex interactions between the vehicle's high-speed airflow and its rapidly changing orientation relative to the freestream.

One of the primary aerodynamic challenges is maintaining stable and efficient combustion within the scramjet engine during extreme maneuvers. As the vehicle undergoes rapid changes in pitch, yaw, or roll, the airflow entering the engine inlet can become distorted, leading to uneven pressure distribution and potential flame instability. This can result in reduced engine performance or even flame-out in severe cases.

Another critical challenge is managing the distribution of lift forces across the vehicle during maneuvers. Scramjets typically rely on the forebody to generate a significant portion of the vehicle's lift. However, during extreme maneuvers, the angle of attack can change dramatically, altering the pressure distribution and potentially causing flow separation. This can lead to sudden changes in lift, potentially compromising vehicle stability and control.

The high-speed nature of scramjet flight also introduces challenges related to shock wave interactions. During maneuvers, the vehicle's changing orientation can cause complex shock wave patterns to form and interact with the vehicle's surfaces. These interactions can lead to localized areas of high pressure and temperature, potentially causing structural stress and heat transfer issues.

Furthermore, the thin atmosphere at typical scramjet operating altitudes presents challenges in generating sufficient lift during maneuvers. The reduced air density limits the available dynamic pressure, making it more difficult to generate the necessary lift forces for rapid changes in trajectory or orientation.

Control surface effectiveness is another critical aerodynamic challenge during extreme maneuvers. The high-speed, low-density environment in which scramjets operate can reduce the effectiveness of traditional control surfaces. This necessitates innovative approaches to vehicle control, such as thrust vectoring or reaction control systems, which must be carefully integrated with the overall aerodynamic design.

Lastly, the interaction between the vehicle's external aerodynamics and the internal flow of the scramjet engine presents a unique challenge. Changes in external flow conditions during maneuvers can affect the engine's performance, while variations in engine thrust can influence the vehicle's overall aerodynamic behavior. Balancing these interdependent systems during extreme maneuvers requires sophisticated modeling and control strategies.

One of the primary aerodynamic challenges is maintaining stable and efficient combustion within the scramjet engine during extreme maneuvers. As the vehicle undergoes rapid changes in pitch, yaw, or roll, the airflow entering the engine inlet can become distorted, leading to uneven pressure distribution and potential flame instability. This can result in reduced engine performance or even flame-out in severe cases.

Another critical challenge is managing the distribution of lift forces across the vehicle during maneuvers. Scramjets typically rely on the forebody to generate a significant portion of the vehicle's lift. However, during extreme maneuvers, the angle of attack can change dramatically, altering the pressure distribution and potentially causing flow separation. This can lead to sudden changes in lift, potentially compromising vehicle stability and control.

The high-speed nature of scramjet flight also introduces challenges related to shock wave interactions. During maneuvers, the vehicle's changing orientation can cause complex shock wave patterns to form and interact with the vehicle's surfaces. These interactions can lead to localized areas of high pressure and temperature, potentially causing structural stress and heat transfer issues.

Furthermore, the thin atmosphere at typical scramjet operating altitudes presents challenges in generating sufficient lift during maneuvers. The reduced air density limits the available dynamic pressure, making it more difficult to generate the necessary lift forces for rapid changes in trajectory or orientation.

Control surface effectiveness is another critical aerodynamic challenge during extreme maneuvers. The high-speed, low-density environment in which scramjets operate can reduce the effectiveness of traditional control surfaces. This necessitates innovative approaches to vehicle control, such as thrust vectoring or reaction control systems, which must be carefully integrated with the overall aerodynamic design.

Lastly, the interaction between the vehicle's external aerodynamics and the internal flow of the scramjet engine presents a unique challenge. Changes in external flow conditions during maneuvers can affect the engine's performance, while variations in engine thrust can influence the vehicle's overall aerodynamic behavior. Balancing these interdependent systems during extreme maneuvers requires sophisticated modeling and control strategies.

Current Lift Solutions

01 Scramjet engine design for improved aerodynamic lift

Innovative scramjet engine designs incorporate features to enhance aerodynamic lift. These designs may include specialized inlet configurations, combustion chamber geometries, and nozzle shapes that contribute to lift generation while maintaining efficient supersonic combustion. The integration of lift-enhancing elements in the engine structure allows for improved vehicle performance and maneuverability at hypersonic speeds.- Scramjet engine design for improved aerodynamic lift: Innovative scramjet engine designs incorporate features to enhance aerodynamic lift. These designs may include specialized inlet configurations, combustion chamber shapes, and nozzle geometries that contribute to the overall lift generation of the vehicle while maintaining efficient supersonic combustion.

- Integration of lifting surfaces with scramjet propulsion: Advanced scramjet-powered vehicles integrate lifting surfaces directly with the propulsion system. This approach combines the functions of lift generation and propulsion, optimizing the vehicle's aerodynamic performance at hypersonic speeds while reducing overall drag and improving efficiency.

- Waverider configurations for scramjet-powered vehicles: Waverider configurations are employed in scramjet-powered vehicles to generate lift from shock waves at hypersonic speeds. These designs utilize the compressed air flow beneath the vehicle to create a high-pressure region, enhancing lift and reducing drag in the hypersonic flight regime.

- Active flow control techniques for scramjet aerodynamics: Active flow control techniques are implemented in scramjet-powered vehicles to manipulate airflow and enhance aerodynamic performance. These may include plasma actuators, synthetic jets, or other methods to influence boundary layer behavior, reduce drag, and increase lift at various flight conditions.

- Multi-mode propulsion systems with scramjet integration: Advanced aerospace vehicles incorporate multi-mode propulsion systems that seamlessly integrate scramjet engines with other propulsion types. These systems are designed to provide optimal performance across a wide range of flight speeds, from subsonic to hypersonic, while maintaining efficient lift generation throughout the flight envelope.

02 Airframe-integrated scramjet configurations

Airframe-integrated scramjet designs optimize the vehicle's overall aerodynamic performance. These configurations seamlessly blend the engine with the aircraft body, utilizing the entire underside of the vehicle as part of the propulsion system. This approach maximizes lift generation while minimizing drag, resulting in improved efficiency and performance at high Mach numbers.Expand Specific Solutions03 Waverider concepts for scramjet-powered vehicles

Waverider designs are applied to scramjet-powered vehicles to generate lift from shock waves. These configurations utilize the compressed air flow beneath the vehicle to create a lifting surface, enhancing overall aerodynamic performance. The integration of waverider principles with scramjet propulsion systems results in highly efficient hypersonic aircraft designs.Expand Specific Solutions04 Active flow control techniques for scramjet lift enhancement

Advanced flow control methods are employed to manipulate airflow around scramjet-powered vehicles, enhancing lift and overall aerodynamic performance. These techniques may include plasma actuators, synthetic jets, or other active flow control devices strategically placed on the vehicle's surface. By influencing boundary layer behavior and shock wave interactions, these methods can significantly improve lift-to-drag ratios at hypersonic speeds.Expand Specific Solutions05 Multifunctional lifting body designs for scramjet vehicles

Innovative lifting body configurations are developed for scramjet-powered vehicles, integrating multiple functions into the airframe design. These concepts may incorporate fuel storage, payload capacity, and thermal management systems while maintaining optimal aerodynamic lift characteristics. The multifunctional approach results in more efficient and versatile hypersonic vehicle designs, capable of extended range and improved mission flexibility.Expand Specific Solutions

Key Scramjet Developers

The competition in Aerodynamic Lift Management for Scramjets during Extreme Maneuvers is at an advanced stage, with significant market potential due to its critical role in hypersonic flight. The global market for this technology is expanding, driven by increasing investments in defense and aerospace sectors. Key players like Boeing, Airbus, and Northrop Grumman are at the forefront, leveraging their extensive aerospace expertise. Academic institutions such as MIT and Beihang University contribute cutting-edge research, while government agencies like NASA provide crucial support. The technology's maturity varies, with established companies having more developed solutions, while newer entrants and research institutions focus on innovative approaches to enhance performance and efficiency in extreme flight conditions.

The Boeing Co.

Technical Solution: Boeing's approach to aerodynamic lift management in scramjets during extreme maneuvers involves advanced computational fluid dynamics (CFD) simulations and wind tunnel testing. They have developed a proprietary software suite that combines real-time flight data with predictive modeling to optimize scramjet performance during high-speed, high-altitude maneuvers. This system utilizes adaptive control algorithms to adjust inlet geometry and fuel injection rates, maintaining optimal combustion efficiency across a wide range of flight conditions[1][3]. Boeing has also implemented innovative materials in scramjet design, such as ceramic matrix composites, to withstand extreme temperatures and reduce overall weight[5]. Their research includes the integration of artificial intelligence to predict and mitigate potential flow separation and shock wave interactions during rapid attitude changes[2].

Strengths: Extensive experience in aerospace engineering, access to advanced testing facilities, and strong computational capabilities. Weaknesses: High development costs and potential challenges in scaling technology for commercial applications.

National University of Defense Technology

Technical Solution: The National University of Defense Technology (NUDT) has developed a novel approach to aerodynamic lift management in scramjets during extreme maneuvers, focusing on adaptive flow control techniques. Their research utilizes plasma actuators strategically placed along the scramjet inlet and combustor to manipulate the boundary layer and shock wave interactions[4]. NUDT has also pioneered the use of magnetohydrodynamic (MHD) flow control systems, which can rapidly adjust the airflow characteristics without moving parts, crucial for maintaining stability during high-g maneuvers[6]. Their scramjet designs incorporate variable geometry inlets with shape memory alloys, allowing for real-time optimization of airflow compression ratios[8]. Additionally, NUDT has developed advanced sensors and control systems that can detect and respond to flow instabilities within milliseconds, ensuring consistent performance across a wide range of flight conditions[7].

Strengths: Cutting-edge research in plasma and MHD flow control, strong focus on military applications. Weaknesses: Potential limitations in international collaboration due to defense-related nature of research.

Innovative Lift Control

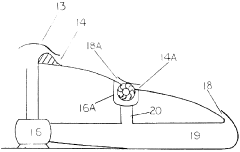

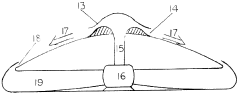

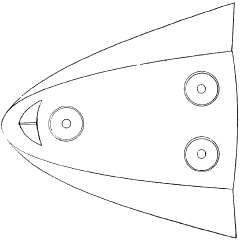

Aerodynamic lift apparatus

PatentInactiveUS6073881A

Innovation

- A lift apparatus using the pressure force method with a high pressure jet engine that recycles air as the working substance, employing a supersonic gas stream in a divergent space to create a low-pressure zone above the upper surface, and utilizing a hybrid internal combustion engine to efficiently generate and recycle the air stream, thereby reducing energy waste and maintaining stream attachment.

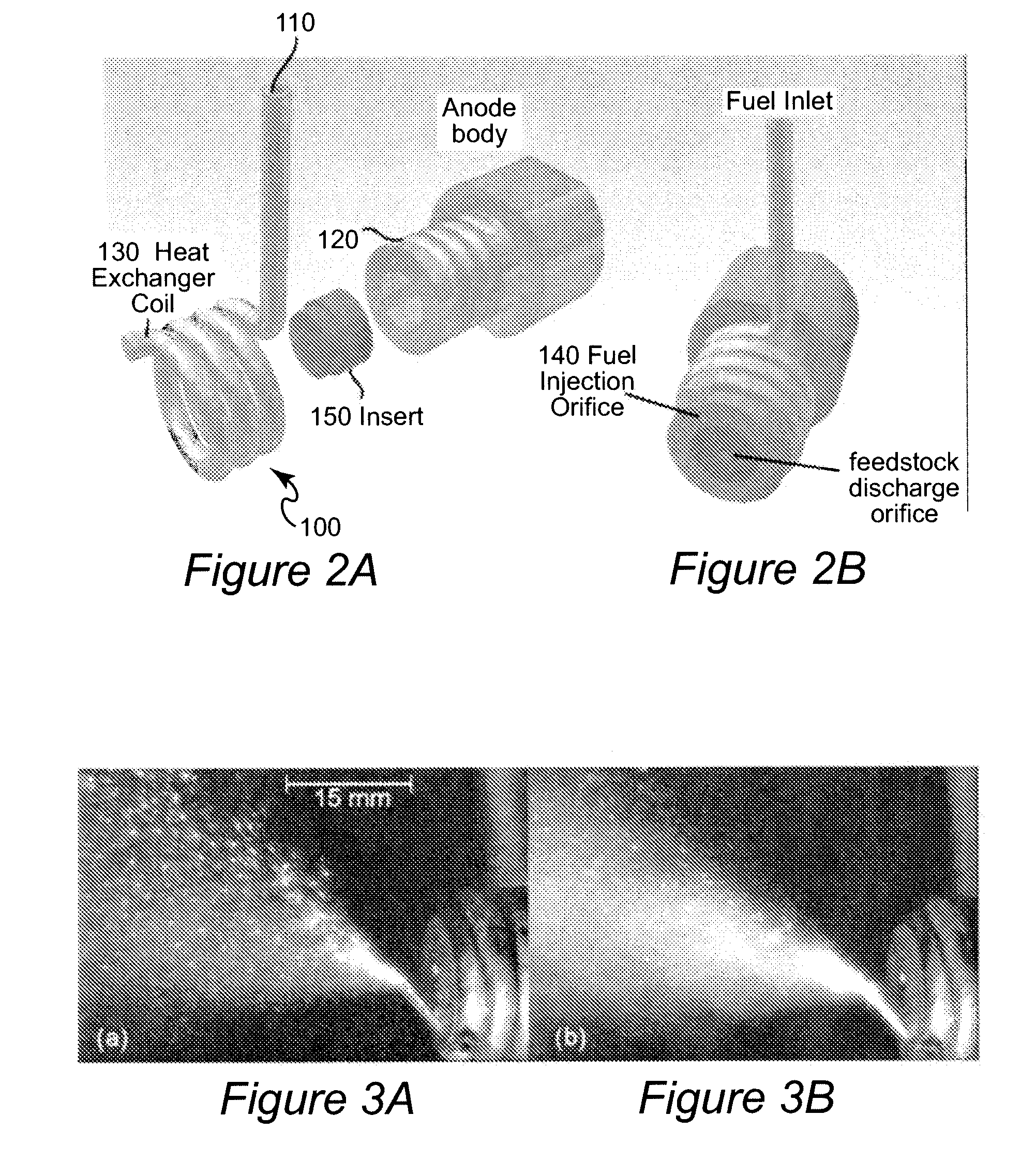

Improved Plasma Torch for Ignition, Flameholding and Enhancement of Combustion in High Speed Flows

PatentInactiveUS20070044449A1

Innovation

- A plasma torch with a fuel injector and heat exchanger is integrated or retrofitted to improve fuel mixing and atomization, providing controllable ignition and flameholding, with features like unsteady energization and the use of nitrogen as a feedstock gas to enhance combustion efficiency.

Material Advancements

Material advancements play a crucial role in enhancing the performance and durability of scramjet engines, particularly during extreme maneuvers where aerodynamic lift management is critical. Recent developments in high-temperature materials have significantly improved the ability of scramjets to withstand the intense heat and pressure generated during hypersonic flight.

One of the most promising advancements is in the field of ceramic matrix composites (CMCs). These materials offer exceptional heat resistance and strength-to-weight ratios, making them ideal for use in scramjet combustion chambers and nozzles. Silicon carbide (SiC) and carbon fiber reinforced silicon carbide (C/SiC) composites have shown remarkable performance in maintaining structural integrity under extreme thermal and mechanical loads.

Thermal barrier coatings (TBCs) have also seen significant improvements. Advanced zirconia-based TBCs, incorporating rare earth elements such as yttrium and gadolinium, have demonstrated enhanced thermal insulation properties. These coatings help protect the underlying metal structures from the extreme temperatures experienced during scramjet operation, particularly during high-g maneuvers where aerodynamic heating is intensified.

In the realm of metallic materials, nickel-based superalloys continue to evolve. New alloy compositions with improved creep resistance and oxidation protection have been developed, allowing for higher operating temperatures in scramjet engines. Additionally, advanced manufacturing techniques such as additive manufacturing have enabled the creation of complex cooling channels within these alloys, further enhancing their heat management capabilities.

Shape memory alloys (SMAs) are emerging as potential candidates for adaptive structures in scramjets. These materials can change their shape in response to temperature variations, offering the possibility of real-time adjustment of engine geometry to optimize performance during different flight regimes and maneuvers.

Carbon-carbon (C/C) composites have also seen advancements in their fabrication and properties. These materials offer excellent thermal shock resistance and low thermal expansion, making them suitable for leading edges and other critical components exposed to extreme aerodynamic heating during maneuvers.

Nanotechnology has opened new avenues for material enhancement. Nanostructured coatings and nanocomposites are being developed to improve wear resistance, reduce friction, and enhance thermal management in scramjet engines. These materials show promise in mitigating the effects of extreme conditions encountered during high-speed maneuvers.

The integration of smart materials and sensors into scramjet structures is another area of advancement. Piezoelectric materials and fiber optic sensors embedded within composite structures allow for real-time monitoring of structural health and temperature distribution, enabling more precise control of aerodynamic lift during extreme maneuvers.

One of the most promising advancements is in the field of ceramic matrix composites (CMCs). These materials offer exceptional heat resistance and strength-to-weight ratios, making them ideal for use in scramjet combustion chambers and nozzles. Silicon carbide (SiC) and carbon fiber reinforced silicon carbide (C/SiC) composites have shown remarkable performance in maintaining structural integrity under extreme thermal and mechanical loads.

Thermal barrier coatings (TBCs) have also seen significant improvements. Advanced zirconia-based TBCs, incorporating rare earth elements such as yttrium and gadolinium, have demonstrated enhanced thermal insulation properties. These coatings help protect the underlying metal structures from the extreme temperatures experienced during scramjet operation, particularly during high-g maneuvers where aerodynamic heating is intensified.

In the realm of metallic materials, nickel-based superalloys continue to evolve. New alloy compositions with improved creep resistance and oxidation protection have been developed, allowing for higher operating temperatures in scramjet engines. Additionally, advanced manufacturing techniques such as additive manufacturing have enabled the creation of complex cooling channels within these alloys, further enhancing their heat management capabilities.

Shape memory alloys (SMAs) are emerging as potential candidates for adaptive structures in scramjets. These materials can change their shape in response to temperature variations, offering the possibility of real-time adjustment of engine geometry to optimize performance during different flight regimes and maneuvers.

Carbon-carbon (C/C) composites have also seen advancements in their fabrication and properties. These materials offer excellent thermal shock resistance and low thermal expansion, making them suitable for leading edges and other critical components exposed to extreme aerodynamic heating during maneuvers.

Nanotechnology has opened new avenues for material enhancement. Nanostructured coatings and nanocomposites are being developed to improve wear resistance, reduce friction, and enhance thermal management in scramjet engines. These materials show promise in mitigating the effects of extreme conditions encountered during high-speed maneuvers.

The integration of smart materials and sensors into scramjet structures is another area of advancement. Piezoelectric materials and fiber optic sensors embedded within composite structures allow for real-time monitoring of structural health and temperature distribution, enabling more precise control of aerodynamic lift during extreme maneuvers.

Thermal Management

Thermal management is a critical aspect of scramjet operation, particularly during extreme maneuvers where aerodynamic lift management becomes challenging. The intense heat generated by hypersonic flight and combustion processes necessitates advanced cooling strategies to maintain structural integrity and ensure optimal performance.

Scramjet engines operate at extremely high temperatures, often exceeding 2000°C in the combustion chamber. During extreme maneuvers, the thermal loads can increase significantly due to changes in airflow and pressure distribution. This presents a unique challenge for thermal management systems, which must adapt to rapidly changing conditions while maintaining engine efficiency and structural stability.

One of the primary thermal management techniques employed in scramjets is regenerative cooling. This method utilizes the fuel as a coolant before it enters the combustion chamber. The fuel flows through channels in the engine walls, absorbing heat and simultaneously preheating itself for more efficient combustion. During extreme maneuvers, the fuel flow rates and pathways may need to be dynamically adjusted to compensate for localized heating effects.

Active cooling systems, such as transpiration cooling, are also crucial for managing thermal loads during high-stress maneuvers. These systems involve injecting a coolant (often water or a cryogenic fluid) through porous materials in high-temperature regions. The coolant forms a protective layer, reducing heat transfer to the engine structure. Advanced control systems are required to modulate coolant flow rates in response to changing thermal conditions during maneuvers.

Material selection plays a vital role in thermal management for scramjets. High-temperature alloys, ceramics, and composite materials are employed to withstand the extreme thermal environments. During extreme maneuvers, these materials must maintain their structural properties under varying thermal stresses and strains. Thermal barrier coatings are often applied to critical components to further enhance heat resistance and prolong component life.

Innovative thermal management solutions for scramjets undergoing extreme maneuvers include the use of phase change materials (PCMs) and thermoelectric devices. PCMs can absorb large amounts of heat during phase transitions, providing a passive cooling mechanism. Thermoelectric devices can convert thermal gradients into electrical power, potentially offering dual benefits of cooling and energy recovery.

The integration of thermal management systems with aerodynamic control surfaces presents both challenges and opportunities. Heat exchangers embedded in control surfaces can help dissipate heat while also contributing to lift management. However, careful design is necessary to ensure that thermal expansion and contraction do not compromise the aerodynamic performance of these surfaces during extreme maneuvers.

Scramjet engines operate at extremely high temperatures, often exceeding 2000°C in the combustion chamber. During extreme maneuvers, the thermal loads can increase significantly due to changes in airflow and pressure distribution. This presents a unique challenge for thermal management systems, which must adapt to rapidly changing conditions while maintaining engine efficiency and structural stability.

One of the primary thermal management techniques employed in scramjets is regenerative cooling. This method utilizes the fuel as a coolant before it enters the combustion chamber. The fuel flows through channels in the engine walls, absorbing heat and simultaneously preheating itself for more efficient combustion. During extreme maneuvers, the fuel flow rates and pathways may need to be dynamically adjusted to compensate for localized heating effects.

Active cooling systems, such as transpiration cooling, are also crucial for managing thermal loads during high-stress maneuvers. These systems involve injecting a coolant (often water or a cryogenic fluid) through porous materials in high-temperature regions. The coolant forms a protective layer, reducing heat transfer to the engine structure. Advanced control systems are required to modulate coolant flow rates in response to changing thermal conditions during maneuvers.

Material selection plays a vital role in thermal management for scramjets. High-temperature alloys, ceramics, and composite materials are employed to withstand the extreme thermal environments. During extreme maneuvers, these materials must maintain their structural properties under varying thermal stresses and strains. Thermal barrier coatings are often applied to critical components to further enhance heat resistance and prolong component life.

Innovative thermal management solutions for scramjets undergoing extreme maneuvers include the use of phase change materials (PCMs) and thermoelectric devices. PCMs can absorb large amounts of heat during phase transitions, providing a passive cooling mechanism. Thermoelectric devices can convert thermal gradients into electrical power, potentially offering dual benefits of cooling and energy recovery.

The integration of thermal management systems with aerodynamic control surfaces presents both challenges and opportunities. Heat exchangers embedded in control surfaces can help dissipate heat while also contributing to lift management. However, careful design is necessary to ensure that thermal expansion and contraction do not compromise the aerodynamic performance of these surfaces during extreme maneuvers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!