Fuel Flow Dynamics in Scramjet Engine Optimizations

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Fuel Flow Dynamics Background and Objectives

Scramjet engines represent a revolutionary advancement in aerospace propulsion technology, offering the potential for hypersonic flight and more efficient high-speed travel. The development of scramjet technology can be traced back to the 1950s, with significant progress made in the following decades. The primary objective of scramjet engine optimization is to achieve sustained hypersonic flight by efficiently managing fuel flow dynamics within the engine.

The evolution of scramjet technology has been driven by the need for faster and more efficient propulsion systems capable of operating at hypersonic speeds. Unlike traditional jet engines, scramjets rely on supersonic airflow throughout the engine, presenting unique challenges in fuel injection, mixing, and combustion. The goal is to achieve optimal fuel-air mixing and combustion within extremely short timeframes, typically measured in milliseconds.

Current technological trends in scramjet fuel flow dynamics focus on advanced fuel injection techniques, innovative combustor designs, and sophisticated flow control mechanisms. Researchers are exploring novel approaches to enhance fuel atomization, improve mixing efficiency, and maintain stable combustion under extreme conditions. The development of advanced materials capable of withstanding high temperatures and pressures is also crucial for the progression of scramjet technology.

One of the primary objectives in scramjet fuel flow optimization is to minimize total pressure loss while maximizing thrust production. This involves careful consideration of fuel injection timing, location, and distribution to ensure efficient mixing and combustion across a wide range of flight conditions. Additionally, researchers aim to develop robust control systems capable of adapting to rapidly changing flow conditions and maintaining optimal performance throughout the flight envelope.

Another key objective is to improve the overall efficiency of scramjet engines by reducing fuel consumption and increasing specific impulse. This requires a deep understanding of the complex interactions between fuel flow, airflow, and combustion dynamics within the engine. Researchers are employing advanced computational fluid dynamics (CFD) simulations and experimental techniques to gain insights into these phenomena and develop innovative solutions.

The ultimate goal of scramjet fuel flow dynamics research is to enable practical applications of hypersonic technology in both civilian and military sectors. This includes the development of hypersonic aircraft capable of drastically reducing long-distance travel times, as well as advanced missile systems and space launch vehicles. Achieving these objectives requires overcoming significant technical challenges and pushing the boundaries of aerospace engineering and propulsion technology.

The evolution of scramjet technology has been driven by the need for faster and more efficient propulsion systems capable of operating at hypersonic speeds. Unlike traditional jet engines, scramjets rely on supersonic airflow throughout the engine, presenting unique challenges in fuel injection, mixing, and combustion. The goal is to achieve optimal fuel-air mixing and combustion within extremely short timeframes, typically measured in milliseconds.

Current technological trends in scramjet fuel flow dynamics focus on advanced fuel injection techniques, innovative combustor designs, and sophisticated flow control mechanisms. Researchers are exploring novel approaches to enhance fuel atomization, improve mixing efficiency, and maintain stable combustion under extreme conditions. The development of advanced materials capable of withstanding high temperatures and pressures is also crucial for the progression of scramjet technology.

One of the primary objectives in scramjet fuel flow optimization is to minimize total pressure loss while maximizing thrust production. This involves careful consideration of fuel injection timing, location, and distribution to ensure efficient mixing and combustion across a wide range of flight conditions. Additionally, researchers aim to develop robust control systems capable of adapting to rapidly changing flow conditions and maintaining optimal performance throughout the flight envelope.

Another key objective is to improve the overall efficiency of scramjet engines by reducing fuel consumption and increasing specific impulse. This requires a deep understanding of the complex interactions between fuel flow, airflow, and combustion dynamics within the engine. Researchers are employing advanced computational fluid dynamics (CFD) simulations and experimental techniques to gain insights into these phenomena and develop innovative solutions.

The ultimate goal of scramjet fuel flow dynamics research is to enable practical applications of hypersonic technology in both civilian and military sectors. This includes the development of hypersonic aircraft capable of drastically reducing long-distance travel times, as well as advanced missile systems and space launch vehicles. Achieving these objectives requires overcoming significant technical challenges and pushing the boundaries of aerospace engineering and propulsion technology.

Market Analysis for Hypersonic Propulsion Systems

The market for hypersonic propulsion systems, particularly those utilizing scramjet technology, is experiencing rapid growth and attracting significant investment. This surge is driven by the increasing demand for high-speed transportation and advanced defense capabilities. The global hypersonic technology market, which includes propulsion systems, is projected to reach substantial value in the coming years, with a compound annual growth rate exceeding industry averages.

Military applications currently dominate the market for hypersonic propulsion systems. Major defense contractors and government agencies are investing heavily in research and development to gain strategic advantages in hypersonic weapons and aircraft. The United States, China, and Russia are at the forefront of this technological race, allocating substantial budgets to hypersonic programs.

Commercial applications, while still in nascent stages, show promising potential. The aerospace industry is exploring hypersonic propulsion for next-generation aircraft capable of drastically reducing long-distance travel times. Several major airlines and aerospace companies have expressed interest in developing hypersonic passenger aircraft, which could revolutionize international travel.

The space industry also presents a growing market for hypersonic propulsion systems. As space exploration and commercial space activities expand, there is an increasing need for efficient and powerful propulsion technologies. Scramjet engines are being considered for use in space launch vehicles and high-altitude research platforms.

Key market drivers include advancements in materials science, computational fluid dynamics, and additive manufacturing. These technological improvements are making scramjet engines more feasible and cost-effective to produce. Additionally, the growing emphasis on reducing carbon emissions in the aviation sector is spurring interest in alternative propulsion technologies, including hydrogen-powered scramjets.

However, the market faces significant challenges. The complexity of fuel flow dynamics in scramjet engines presents technical hurdles that require ongoing research and development. Regulatory frameworks for hypersonic flight are still evolving, which could impact market growth. Moreover, the high costs associated with developing and testing hypersonic technologies remain a barrier to widespread adoption.

Despite these challenges, the market outlook for hypersonic propulsion systems remains positive. As technologies mature and costs decrease, we can expect to see increased commercial interest and investment in this field. The potential for dual-use applications in both military and civilian sectors further enhances the market's attractiveness to investors and industry players.

Military applications currently dominate the market for hypersonic propulsion systems. Major defense contractors and government agencies are investing heavily in research and development to gain strategic advantages in hypersonic weapons and aircraft. The United States, China, and Russia are at the forefront of this technological race, allocating substantial budgets to hypersonic programs.

Commercial applications, while still in nascent stages, show promising potential. The aerospace industry is exploring hypersonic propulsion for next-generation aircraft capable of drastically reducing long-distance travel times. Several major airlines and aerospace companies have expressed interest in developing hypersonic passenger aircraft, which could revolutionize international travel.

The space industry also presents a growing market for hypersonic propulsion systems. As space exploration and commercial space activities expand, there is an increasing need for efficient and powerful propulsion technologies. Scramjet engines are being considered for use in space launch vehicles and high-altitude research platforms.

Key market drivers include advancements in materials science, computational fluid dynamics, and additive manufacturing. These technological improvements are making scramjet engines more feasible and cost-effective to produce. Additionally, the growing emphasis on reducing carbon emissions in the aviation sector is spurring interest in alternative propulsion technologies, including hydrogen-powered scramjets.

However, the market faces significant challenges. The complexity of fuel flow dynamics in scramjet engines presents technical hurdles that require ongoing research and development. Regulatory frameworks for hypersonic flight are still evolving, which could impact market growth. Moreover, the high costs associated with developing and testing hypersonic technologies remain a barrier to widespread adoption.

Despite these challenges, the market outlook for hypersonic propulsion systems remains positive. As technologies mature and costs decrease, we can expect to see increased commercial interest and investment in this field. The potential for dual-use applications in both military and civilian sectors further enhances the market's attractiveness to investors and industry players.

Current Challenges in Scramjet Fuel Flow Optimization

Scramjet fuel flow optimization faces several significant challenges that hinder the development and performance of these advanced propulsion systems. One of the primary issues is the extremely short residence time of fuel in the combustion chamber. Due to the supersonic airflow, fuel has only milliseconds to mix, vaporize, and combust efficiently. This rapid process demands precise control and innovative injection strategies to ensure complete combustion and optimal thrust generation.

Another major challenge is the complex and highly turbulent flow field within the scramjet engine. The supersonic airflow creates shock waves, boundary layers, and regions of recirculation, which significantly affect fuel distribution and mixing. These flow structures can lead to uneven fuel-air ratios across the combustion chamber, resulting in reduced efficiency and potential engine instabilities.

The extreme temperatures and pressures encountered in scramjet engines pose additional difficulties for fuel flow optimization. These harsh conditions can cause fuel decomposition or coking, leading to injector clogging and reduced performance. Moreover, the high-speed flow can result in fuel atomization issues, where larger droplets may not have sufficient time to vaporize completely before exiting the engine.

Fuel injection timing and location present another set of challenges. The optimal injection points and timing can vary significantly based on flight conditions, making it difficult to design a system that performs well across a wide range of operating parameters. Additionally, the need for rapid and precise fuel flow modulation to accommodate changing flight conditions adds complexity to the fuel delivery system.

The interaction between fuel injection and the engine's thermal management system is also a critical concern. Fuel is often used as a coolant for engine components before combustion, but this preheating can affect its chemical properties and combustion characteristics. Balancing the cooling requirements with optimal fuel preparation for combustion is a delicate and challenging task.

Furthermore, the development of accurate computational models for scramjet fuel flow dynamics remains an ongoing challenge. The complex, multiphase, and reactive nature of the flow makes it difficult to create simulations that reliably predict performance across all operating conditions. This limitation hampers the design optimization process and necessitates extensive experimental testing, which is both costly and time-consuming.

Lastly, the integration of advanced materials and manufacturing techniques for fuel injection systems presents both opportunities and challenges. While new materials may offer improved durability and performance, their behavior under extreme scramjet conditions is not always well understood, requiring extensive research and testing before implementation.

Another major challenge is the complex and highly turbulent flow field within the scramjet engine. The supersonic airflow creates shock waves, boundary layers, and regions of recirculation, which significantly affect fuel distribution and mixing. These flow structures can lead to uneven fuel-air ratios across the combustion chamber, resulting in reduced efficiency and potential engine instabilities.

The extreme temperatures and pressures encountered in scramjet engines pose additional difficulties for fuel flow optimization. These harsh conditions can cause fuel decomposition or coking, leading to injector clogging and reduced performance. Moreover, the high-speed flow can result in fuel atomization issues, where larger droplets may not have sufficient time to vaporize completely before exiting the engine.

Fuel injection timing and location present another set of challenges. The optimal injection points and timing can vary significantly based on flight conditions, making it difficult to design a system that performs well across a wide range of operating parameters. Additionally, the need for rapid and precise fuel flow modulation to accommodate changing flight conditions adds complexity to the fuel delivery system.

The interaction between fuel injection and the engine's thermal management system is also a critical concern. Fuel is often used as a coolant for engine components before combustion, but this preheating can affect its chemical properties and combustion characteristics. Balancing the cooling requirements with optimal fuel preparation for combustion is a delicate and challenging task.

Furthermore, the development of accurate computational models for scramjet fuel flow dynamics remains an ongoing challenge. The complex, multiphase, and reactive nature of the flow makes it difficult to create simulations that reliably predict performance across all operating conditions. This limitation hampers the design optimization process and necessitates extensive experimental testing, which is both costly and time-consuming.

Lastly, the integration of advanced materials and manufacturing techniques for fuel injection systems presents both opportunities and challenges. While new materials may offer improved durability and performance, their behavior under extreme scramjet conditions is not always well understood, requiring extensive research and testing before implementation.

Existing Fuel Flow Optimization Techniques

01 Fuel injection and mixing optimization

Scramjet engines require efficient fuel injection and mixing systems to achieve optimal combustion. This involves designing advanced injectors and mixing devices that can effectively distribute fuel in the supersonic airflow. Techniques such as angled injection, multiple injection points, and turbulence-inducing structures are employed to enhance fuel-air mixing and improve overall engine performance.- Fuel injection and mixing optimization: Scramjet engines require efficient fuel injection and mixing systems to achieve optimal combustion. This involves designing injectors and mixing chambers that promote rapid and uniform fuel-air mixing at supersonic speeds. Advanced techniques such as angled injection, multiple injection points, and turbulence-enhancing structures are employed to improve fuel atomization and distribution within the combustion chamber.

- Fuel flow control and metering: Precise control of fuel flow is crucial for maintaining stable combustion and engine performance across various flight conditions. This involves developing sophisticated fuel metering systems, variable-geometry injectors, and adaptive control algorithms that can adjust fuel flow rates based on real-time engine parameters and flight conditions. These systems help optimize fuel consumption and maintain the desired air-fuel ratio throughout the flight envelope.

- Thermal management of fuel systems: The extreme temperatures encountered in scramjet engines necessitate effective thermal management of fuel systems. This includes developing heat-resistant materials for fuel lines and injectors, implementing active cooling systems, and utilizing the fuel as a heat sink to cool engine components. Advanced thermal management techniques help prevent fuel coking, maintain fuel stability, and protect sensitive engine components from thermal damage.

- Fuel-air mixing enhancement techniques: Enhancing fuel-air mixing is critical for achieving efficient combustion in scramjet engines. Various techniques are employed, such as using plasma actuators, acoustic excitation, and vortex generators to promote turbulence and improve mixing. Additionally, novel injector designs and flow control devices are developed to create more uniform fuel distribution and increase the residence time of fuel in the combustion chamber.

- Computational modeling and simulation of fuel dynamics: Advanced computational fluid dynamics (CFD) models and simulation techniques are used to analyze and optimize fuel flow dynamics in scramjet engines. These tools help predict fuel distribution patterns, mixing efficiencies, and combustion characteristics under various operating conditions. High-fidelity simulations enable engineers to evaluate different injector designs, fuel compositions, and flow control strategies without the need for extensive physical testing, accelerating the development process and reducing costs.

02 Fuel flow control and regulation

Precise control of fuel flow is crucial for maintaining stable combustion and thrust in scramjet engines. This involves developing sophisticated fuel management systems that can adjust fuel flow rates based on flight conditions, engine parameters, and mission requirements. Advanced control algorithms and sensors are utilized to ensure optimal fuel delivery across various operating regimes.Expand Specific Solutions03 Thermal management of fuel systems

Scramjet engines operate at extremely high temperatures, necessitating effective thermal management of fuel systems. This includes developing heat-resistant materials, cooling techniques, and thermal protection systems to prevent fuel degradation and ensure reliable engine operation. Regenerative cooling systems and fuel preheating methods are often employed to improve overall system efficiency.Expand Specific Solutions04 Fuel-cooled structures and heat exchangers

Utilizing fuel as a coolant for engine structures and components is a common approach in scramjet design. This involves integrating fuel passages and heat exchangers into engine walls and other critical areas to absorb excess heat and improve overall thermal efficiency. Advanced materials and manufacturing techniques are employed to create these complex fuel-cooled structures.Expand Specific Solutions05 Supersonic combustion stability

Maintaining stable combustion in supersonic flow conditions is a significant challenge in scramjet engines. Research focuses on developing techniques to enhance flame stability, reduce combustion instabilities, and prevent flame blowout. This includes investigating various fuel injection patterns, flame holding mechanisms, and combustor geometries to achieve reliable and efficient supersonic combustion.Expand Specific Solutions

Key Players in Scramjet Engine Development

The scramjet engine optimization field is in a dynamic phase of development, with significant market growth potential as aerospace technologies advance. The market size is expanding, driven by increasing interest in hypersonic flight applications. Technologically, scramjet engines are still maturing, with ongoing research to improve efficiency and reliability. Key players like Aerojet Rocketdyne, Mitsubishi Heavy Industries, and MBDA UK are at the forefront of development, while academic institutions such as the National University of Defense Technology and Beihang University contribute valuable research. Government entities like NASA and China's CARDC also play crucial roles in advancing scramjet technology, indicating its strategic importance in both civilian and military sectors.

National University of Defense Technology

Technical Solution: The National University of Defense Technology (NUDT) has made significant contributions to scramjet fuel flow dynamics research, focusing on advanced numerical modeling and experimental techniques. NUDT researchers have developed high-fidelity computational models that incorporate detailed chemical kinetics and turbulence-chemistry interactions to accurately predict fuel mixing and combustion behavior in supersonic flows[13]. The university has also pioneered the use of laser-based diagnostics, such as planar laser-induced fluorescence (PLIF) and coherent anti-Stokes Raman spectroscopy (CARS), to study fuel distribution and reaction zones in scramjet combustors[15]. Additionally, NUDT has explored novel fuel injection concepts, including transverse jet injection with shock-induced vortices to enhance mixing efficiency and reduce total pressure losses[17].

Strengths: Strong theoretical foundation, advanced computational capabilities, and access to state-of-the-art experimental facilities. Weaknesses: Potential limitations in full-scale engine testing and international collaboration due to defense-related research restrictions.

Aerojet Rocketdyne, Inc.

Technical Solution: Aerojet Rocketdyne has developed advanced fuel injection systems for scramjet engines, focusing on optimizing fuel flow dynamics. Their approach involves using a combination of computational fluid dynamics (CFD) simulations and experimental testing to design fuel injectors that promote rapid fuel-air mixing and efficient combustion[1]. The company has implemented a staged injection strategy, where fuel is introduced at multiple points along the engine, allowing for better control of the combustion process and improved performance across a wide range of flight conditions[3]. Additionally, Aerojet Rocketdyne has explored the use of supercritical fuel injection, which takes advantage of the unique properties of fuels at high pressures and temperatures to enhance atomization and mixing[5].

Strengths: Extensive experience in propulsion systems, advanced simulation capabilities, and access to high-fidelity testing facilities. Weaknesses: High development costs and long lead times for new technologies.

Innovative Fuel Dynamics Control Strategies

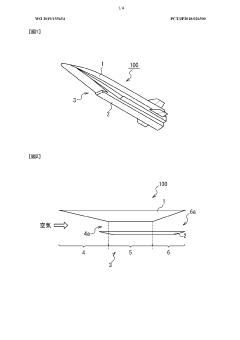

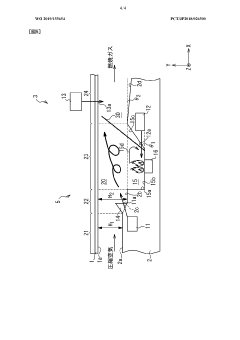

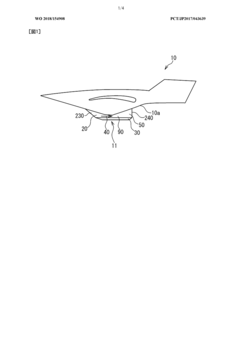

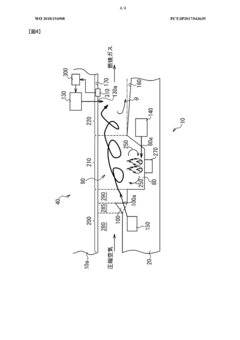

Scramjet engine and flying object

PatentWO2019155654A1

Innovation

- The scramjet engine design incorporates a dual fuel injection system with a protrusion in the turbulence forming region and a cavity with an inclined surface to generate shock waves, optimizing fuel injection and airflow for improved combustion efficiency, featuring a first fuel nozzle injecting fuel into turbulent air and a second nozzle injecting across a discontinuous surface to promote mixing and flame stabilization.

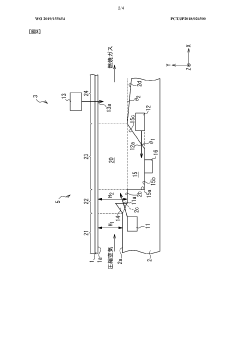

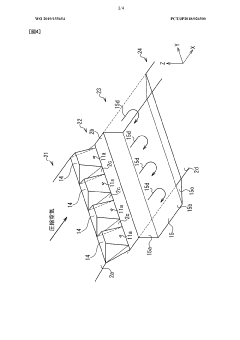

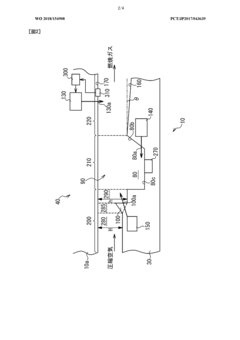

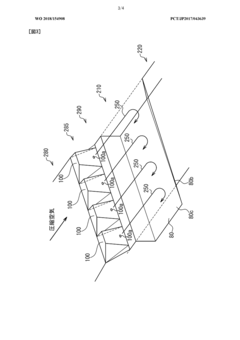

Scramjet engine

PatentWO2018154908A1

Innovation

- The scramjet engine design incorporates a flow path with convex portions on the first surface to create turbulence, a cavity for flame holding, and multiple fuel injection sections to efficiently mix and combust air and fuel, ensuring complete combustion by controlling the fuel injection amount and direction.

Environmental Impact of Scramjet Propulsion

The environmental impact of scramjet propulsion is a critical consideration in the development and deployment of this advanced aerospace technology. Scramjet engines, designed to operate at hypersonic speeds, offer significant advantages in terms of efficiency and performance. However, their potential environmental effects must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with scramjet propulsion is the emission of pollutants. Unlike conventional jet engines, scramjets operate at extremely high temperatures and pressures, which can lead to the formation of nitrogen oxides (NOx) in greater quantities. These compounds contribute to air pollution and can have detrimental effects on the ozone layer and climate change.

Additionally, the high-altitude operation of scramjet-powered vehicles raises questions about their impact on the upper atmosphere. The release of water vapor and other combustion products at these altitudes could potentially affect cloud formation and atmospheric chemistry in ways that are not yet fully understood.

The sonic boom generated by hypersonic vehicles powered by scramjet engines is another environmental consideration. These intense pressure waves can cause disturbances to both human populations and wildlife, particularly in areas beneath flight paths. Mitigating the effects of sonic booms remains a significant challenge for the widespread adoption of scramjet technology.

Fuel consumption and efficiency are key factors in assessing the environmental footprint of scramjet propulsion. While scramjets offer improved fuel efficiency at high speeds compared to traditional rocket engines, the overall environmental impact of their fuel usage must be evaluated across the entire flight profile, including takeoff and landing phases.

The manufacturing and testing of scramjet engines also have environmental implications. The production of specialized materials and components required for these advanced propulsion systems may involve energy-intensive processes and the use of rare or hazardous materials. Furthermore, ground testing of scramjet engines can result in localized environmental impacts, including noise pollution and the release of combustion products.

As research and development in scramjet technology progress, efforts are being made to address these environmental concerns. This includes the exploration of alternative fuels, such as hydrogen, which could potentially reduce certain emissions. Additionally, advancements in materials science and engine design are aimed at improving efficiency and reducing the overall environmental impact of scramjet propulsion systems.

One of the primary environmental concerns associated with scramjet propulsion is the emission of pollutants. Unlike conventional jet engines, scramjets operate at extremely high temperatures and pressures, which can lead to the formation of nitrogen oxides (NOx) in greater quantities. These compounds contribute to air pollution and can have detrimental effects on the ozone layer and climate change.

Additionally, the high-altitude operation of scramjet-powered vehicles raises questions about their impact on the upper atmosphere. The release of water vapor and other combustion products at these altitudes could potentially affect cloud formation and atmospheric chemistry in ways that are not yet fully understood.

The sonic boom generated by hypersonic vehicles powered by scramjet engines is another environmental consideration. These intense pressure waves can cause disturbances to both human populations and wildlife, particularly in areas beneath flight paths. Mitigating the effects of sonic booms remains a significant challenge for the widespread adoption of scramjet technology.

Fuel consumption and efficiency are key factors in assessing the environmental footprint of scramjet propulsion. While scramjets offer improved fuel efficiency at high speeds compared to traditional rocket engines, the overall environmental impact of their fuel usage must be evaluated across the entire flight profile, including takeoff and landing phases.

The manufacturing and testing of scramjet engines also have environmental implications. The production of specialized materials and components required for these advanced propulsion systems may involve energy-intensive processes and the use of rare or hazardous materials. Furthermore, ground testing of scramjet engines can result in localized environmental impacts, including noise pollution and the release of combustion products.

As research and development in scramjet technology progress, efforts are being made to address these environmental concerns. This includes the exploration of alternative fuels, such as hydrogen, which could potentially reduce certain emissions. Additionally, advancements in materials science and engine design are aimed at improving efficiency and reducing the overall environmental impact of scramjet propulsion systems.

International Collaboration in Hypersonic Research

International collaboration in hypersonic research has become increasingly crucial for advancing fuel flow dynamics in scramjet engine optimizations. The complex nature of hypersonic flight and the associated technological challenges necessitate a global effort to pool resources, expertise, and facilities. Collaborative initiatives between leading aerospace nations have led to significant breakthroughs in understanding and optimizing fuel flow dynamics within scramjet engines.

The United States, Russia, China, and Australia have emerged as key players in hypersonic research, each contributing unique capabilities and knowledge to the field. Joint research programs, such as the HIFiRE (Hypersonic International Flight Research Experimentation) program, have facilitated the exchange of data and insights on scramjet propulsion systems. These collaborations have accelerated progress in areas such as fuel injection strategies, combustion stability, and thermal management.

International partnerships have also enabled the sharing of specialized testing facilities, which are essential for validating theoretical models and simulations of fuel flow dynamics. Wind tunnels capable of simulating hypersonic conditions are scarce and expensive, making international cooperation vital for comprehensive experimental studies. The von Karman Institute for Fluid Dynamics in Belgium, for instance, has hosted researchers from various countries to conduct experiments on scramjet fuel flow optimization.

Collaborative efforts have led to the development of advanced computational fluid dynamics (CFD) models that accurately simulate fuel flow behavior in scramjet engines. These models incorporate data from multiple international sources, enhancing their reliability and predictive capabilities. The exchange of CFD methodologies and validation techniques has significantly improved the global understanding of fuel-air mixing, combustion processes, and flow field interactions in hypersonic conditions.

Joint research initiatives have also focused on innovative fuel injection concepts and combustion chamber designs. International teams have explored various fuel types, injection patterns, and mixing enhancement techniques to optimize scramjet performance across a wide range of flight conditions. The cross-pollination of ideas has resulted in novel approaches to fuel flow control and combustion efficiency improvement.

Despite the benefits of international collaboration, challenges remain in balancing cooperation with national security concerns and intellectual property rights. Nonetheless, the global hypersonic research community continues to find ways to share non-sensitive information and collaborate on fundamental scientific principles. This ongoing international dialogue is crucial for overcoming the formidable challenges associated with fuel flow dynamics in scramjet engine optimizations and advancing the field of hypersonic propulsion.

The United States, Russia, China, and Australia have emerged as key players in hypersonic research, each contributing unique capabilities and knowledge to the field. Joint research programs, such as the HIFiRE (Hypersonic International Flight Research Experimentation) program, have facilitated the exchange of data and insights on scramjet propulsion systems. These collaborations have accelerated progress in areas such as fuel injection strategies, combustion stability, and thermal management.

International partnerships have also enabled the sharing of specialized testing facilities, which are essential for validating theoretical models and simulations of fuel flow dynamics. Wind tunnels capable of simulating hypersonic conditions are scarce and expensive, making international cooperation vital for comprehensive experimental studies. The von Karman Institute for Fluid Dynamics in Belgium, for instance, has hosted researchers from various countries to conduct experiments on scramjet fuel flow optimization.

Collaborative efforts have led to the development of advanced computational fluid dynamics (CFD) models that accurately simulate fuel flow behavior in scramjet engines. These models incorporate data from multiple international sources, enhancing their reliability and predictive capabilities. The exchange of CFD methodologies and validation techniques has significantly improved the global understanding of fuel-air mixing, combustion processes, and flow field interactions in hypersonic conditions.

Joint research initiatives have also focused on innovative fuel injection concepts and combustion chamber designs. International teams have explored various fuel types, injection patterns, and mixing enhancement techniques to optimize scramjet performance across a wide range of flight conditions. The cross-pollination of ideas has resulted in novel approaches to fuel flow control and combustion efficiency improvement.

Despite the benefits of international collaboration, challenges remain in balancing cooperation with national security concerns and intellectual property rights. Nonetheless, the global hypersonic research community continues to find ways to share non-sensitive information and collaborate on fundamental scientific principles. This ongoing international dialogue is crucial for overcoming the formidable challenges associated with fuel flow dynamics in scramjet engine optimizations and advancing the field of hypersonic propulsion.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!