Workforce Realignments in Scramjet-based Aerospace Firms

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Tech Evolution

The evolution of scramjet technology has been marked by significant milestones and breakthroughs over the past several decades. Initially conceived in the 1950s, scramjet engines represented a revolutionary approach to hypersonic propulsion, promising to overcome the limitations of traditional jet engines at extreme speeds.

In the 1960s and 1970s, theoretical work laid the foundation for scramjet development, with researchers focusing on understanding the complex fluid dynamics and combustion processes involved. The 1980s saw the first successful ground tests of scramjet engines, demonstrating the feasibility of sustained hypersonic combustion.

The 1990s marked a pivotal era with the initiation of major research programs like NASA's Hyper-X, which aimed to validate scramjet technology in actual flight conditions. This decade also witnessed increased international interest, with countries like Russia and Australia launching their own scramjet research initiatives.

The early 2000s brought about groundbreaking achievements, including the successful flight of NASA's X-43A in 2004, which reached Mach 9.6, setting a new speed record for air-breathing engines. This was followed by the X-51 WaveRider program, which demonstrated longer duration scramjet flight in 2010.

Recent years have seen a shift towards more practical applications of scramjet technology. Defense agencies worldwide have intensified efforts to develop hypersonic weapons systems utilizing scramjet propulsion. Simultaneously, aerospace firms have begun exploring the potential for scramjet-powered aircraft in both military and civilian sectors.

The evolution of materials science and manufacturing techniques has played a crucial role in advancing scramjet technology. High-temperature materials capable of withstanding the extreme conditions in scramjet engines have been developed, enabling longer and more stable flights.

Computational fluid dynamics and advanced simulation tools have significantly accelerated the design and testing processes, reducing the need for costly physical prototypes. This has allowed for rapid iteration and optimization of scramjet designs, leading to improved performance and reliability.

As scramjet technology continues to mature, the focus is shifting towards integration with other systems and practical implementation. This evolution is driving workforce realignments within aerospace firms, necessitating a blend of traditional aerospace engineering skills with specialized knowledge in hypersonic propulsion, advanced materials, and complex systems integration.

In the 1960s and 1970s, theoretical work laid the foundation for scramjet development, with researchers focusing on understanding the complex fluid dynamics and combustion processes involved. The 1980s saw the first successful ground tests of scramjet engines, demonstrating the feasibility of sustained hypersonic combustion.

The 1990s marked a pivotal era with the initiation of major research programs like NASA's Hyper-X, which aimed to validate scramjet technology in actual flight conditions. This decade also witnessed increased international interest, with countries like Russia and Australia launching their own scramjet research initiatives.

The early 2000s brought about groundbreaking achievements, including the successful flight of NASA's X-43A in 2004, which reached Mach 9.6, setting a new speed record for air-breathing engines. This was followed by the X-51 WaveRider program, which demonstrated longer duration scramjet flight in 2010.

Recent years have seen a shift towards more practical applications of scramjet technology. Defense agencies worldwide have intensified efforts to develop hypersonic weapons systems utilizing scramjet propulsion. Simultaneously, aerospace firms have begun exploring the potential for scramjet-powered aircraft in both military and civilian sectors.

The evolution of materials science and manufacturing techniques has played a crucial role in advancing scramjet technology. High-temperature materials capable of withstanding the extreme conditions in scramjet engines have been developed, enabling longer and more stable flights.

Computational fluid dynamics and advanced simulation tools have significantly accelerated the design and testing processes, reducing the need for costly physical prototypes. This has allowed for rapid iteration and optimization of scramjet designs, leading to improved performance and reliability.

As scramjet technology continues to mature, the focus is shifting towards integration with other systems and practical implementation. This evolution is driving workforce realignments within aerospace firms, necessitating a blend of traditional aerospace engineering skills with specialized knowledge in hypersonic propulsion, advanced materials, and complex systems integration.

Aerospace Market Trends

The aerospace market has been experiencing significant shifts in recent years, driven by technological advancements, changing geopolitical landscapes, and evolving consumer demands. The scramjet-based aerospace sector, in particular, has seen a surge in interest and investment due to its potential to revolutionize high-speed air travel and space exploration.

Global aerospace market trends indicate a growing emphasis on sustainable aviation technologies, with major players investing heavily in research and development of more fuel-efficient and environmentally friendly propulsion systems. This shift has created new opportunities for scramjet technology, which offers the promise of hypersonic travel with reduced environmental impact compared to traditional rocket propulsion.

The commercial space industry has also been a key driver of growth in the aerospace market. Private companies are increasingly entering the space race, leading to increased competition and innovation in launch technologies. Scramjet-based systems are being explored as a potential solution for more cost-effective and reusable space launch vehicles, further fueling market growth in this sector.

Defense spending continues to be a significant factor in the aerospace market, with many nations investing in advanced military aircraft and missile systems. Scramjet technology is of particular interest in this domain due to its potential applications in hypersonic weapons and reconnaissance platforms. This has led to increased government funding for scramjet research and development programs.

The urban air mobility market is another emerging trend that is reshaping the aerospace landscape. While not directly related to scramjet technology, the growth in this sector is indicative of the broader shifts occurring in aerospace, with a focus on new forms of transportation and increased connectivity.

Workforce trends in the aerospace industry reflect these market shifts, with a growing demand for skilled professionals in areas such as hypersonics, advanced materials, and computational fluid dynamics. Companies involved in scramjet development are actively seeking to realign their workforce to meet these new technological challenges, often competing for talent with other high-tech sectors.

The COVID-19 pandemic has had a significant impact on the aerospace market, particularly in the commercial aviation sector. However, the defense and space segments have shown resilience, with continued investment in advanced technologies like scramjets. As the industry recovers, there is an increased focus on digital transformation and automation, which is likely to influence workforce requirements and skill sets in scramjet-based firms.

Global aerospace market trends indicate a growing emphasis on sustainable aviation technologies, with major players investing heavily in research and development of more fuel-efficient and environmentally friendly propulsion systems. This shift has created new opportunities for scramjet technology, which offers the promise of hypersonic travel with reduced environmental impact compared to traditional rocket propulsion.

The commercial space industry has also been a key driver of growth in the aerospace market. Private companies are increasingly entering the space race, leading to increased competition and innovation in launch technologies. Scramjet-based systems are being explored as a potential solution for more cost-effective and reusable space launch vehicles, further fueling market growth in this sector.

Defense spending continues to be a significant factor in the aerospace market, with many nations investing in advanced military aircraft and missile systems. Scramjet technology is of particular interest in this domain due to its potential applications in hypersonic weapons and reconnaissance platforms. This has led to increased government funding for scramjet research and development programs.

The urban air mobility market is another emerging trend that is reshaping the aerospace landscape. While not directly related to scramjet technology, the growth in this sector is indicative of the broader shifts occurring in aerospace, with a focus on new forms of transportation and increased connectivity.

Workforce trends in the aerospace industry reflect these market shifts, with a growing demand for skilled professionals in areas such as hypersonics, advanced materials, and computational fluid dynamics. Companies involved in scramjet development are actively seeking to realign their workforce to meet these new technological challenges, often competing for talent with other high-tech sectors.

The COVID-19 pandemic has had a significant impact on the aerospace market, particularly in the commercial aviation sector. However, the defense and space segments have shown resilience, with continued investment in advanced technologies like scramjets. As the industry recovers, there is an increased focus on digital transformation and automation, which is likely to influence workforce requirements and skill sets in scramjet-based firms.

Scramjet Challenges

Scramjet technology presents several significant challenges that aerospace firms must address to achieve successful implementation and commercialization. One of the primary obstacles is the extreme operating conditions required for scramjet engines. These engines function at hypersonic speeds, typically above Mach 5, which subjects materials and components to intense heat and pressure. Developing materials that can withstand these conditions while maintaining structural integrity and performance is a critical challenge.

Another major hurdle is the complexity of fuel injection and combustion at hypersonic speeds. The airflow through a scramjet engine moves faster than the speed of sound, leaving extremely limited time for fuel mixing and combustion. Engineers must design innovative fuel injection systems and combustion chamber geometries to ensure efficient and stable combustion under these conditions.

The integration of scramjet propulsion systems with aircraft or spacecraft designs poses additional challenges. The transition from conventional propulsion to scramjet operation, known as the "dual-mode" problem, requires careful engineering to maintain vehicle stability and control throughout the flight envelope. Furthermore, the aerodynamic design of the entire vehicle must be optimized to work in conjunction with the scramjet engine, as the forebody of the aircraft serves as part of the engine's compression system.

Control and stability of scramjet-powered vehicles present another set of challenges. At hypersonic speeds, even minor perturbations can have significant effects on vehicle performance and trajectory. Developing robust control systems that can rapidly adjust to changing flight conditions is essential for safe and reliable operation.

The testing and validation of scramjet technology also pose unique difficulties. Ground-based testing facilities capable of simulating hypersonic flight conditions are limited and expensive to operate. Flight testing of scramjet vehicles is equally challenging, requiring specialized launch systems and extensive safety precautions.

Lastly, the economic viability of scramjet technology remains a significant challenge. The high costs associated with research, development, and testing of scramjet systems, coupled with the limited current applications, make it difficult to justify large-scale investments. Aerospace firms must carefully balance the potential long-term benefits of scramjet technology against the substantial short-term costs and risks involved in its development.

Another major hurdle is the complexity of fuel injection and combustion at hypersonic speeds. The airflow through a scramjet engine moves faster than the speed of sound, leaving extremely limited time for fuel mixing and combustion. Engineers must design innovative fuel injection systems and combustion chamber geometries to ensure efficient and stable combustion under these conditions.

The integration of scramjet propulsion systems with aircraft or spacecraft designs poses additional challenges. The transition from conventional propulsion to scramjet operation, known as the "dual-mode" problem, requires careful engineering to maintain vehicle stability and control throughout the flight envelope. Furthermore, the aerodynamic design of the entire vehicle must be optimized to work in conjunction with the scramjet engine, as the forebody of the aircraft serves as part of the engine's compression system.

Control and stability of scramjet-powered vehicles present another set of challenges. At hypersonic speeds, even minor perturbations can have significant effects on vehicle performance and trajectory. Developing robust control systems that can rapidly adjust to changing flight conditions is essential for safe and reliable operation.

The testing and validation of scramjet technology also pose unique difficulties. Ground-based testing facilities capable of simulating hypersonic flight conditions are limited and expensive to operate. Flight testing of scramjet vehicles is equally challenging, requiring specialized launch systems and extensive safety precautions.

Lastly, the economic viability of scramjet technology remains a significant challenge. The high costs associated with research, development, and testing of scramjet systems, coupled with the limited current applications, make it difficult to justify large-scale investments. Aerospace firms must carefully balance the potential long-term benefits of scramjet technology against the substantial short-term costs and risks involved in its development.

Current Workforce Models

01 Workforce management in scramjet-based aerospace firms

Specialized systems and methods for managing the workforce in scramjet-based aerospace companies. These include tools for scheduling, skill tracking, and resource allocation tailored to the unique needs of hypersonic technology development and production.- Workforce management in aerospace firms: Aerospace companies, including those focused on scramjet technology, require specialized workforce management systems. These systems help in scheduling, skill tracking, and resource allocation for complex projects. They often incorporate features for managing highly skilled technical personnel and ensuring compliance with industry regulations.

- Scramjet engine design and development: Scramjet-based aerospace firms focus on the design and development of supersonic combustion ramjet engines. This involves specialized engineering teams working on advanced propulsion systems, aerodynamics, and materials science. The workforce in these firms requires expertise in high-speed flight and hypersonic technologies.

- Training and skill development for aerospace workforce: Aerospace companies invest in continuous training and skill development programs for their workforce. This includes specialized training in scramjet technologies, simulation-based learning, and cross-functional skill development. The focus is on maintaining a highly skilled workforce capable of innovating in cutting-edge aerospace technologies.

- Project management in scramjet development: Scramjet-based firms employ advanced project management techniques to handle complex, long-term aerospace projects. This involves coordinating multidisciplinary teams, managing research and development timelines, and integrating various technological components. Specialized software and methodologies are used to oversee these high-tech projects.

- Collaboration and knowledge sharing in aerospace industry: Scramjet-based aerospace firms often engage in collaborative efforts with other companies, research institutions, and government agencies. This requires effective knowledge sharing systems and collaborative platforms to facilitate the exchange of ideas and expertise across organizational boundaries, enhancing innovation in scramjet technology.

02 Scramjet engine design and workforce implications

Innovations in scramjet engine design that impact workforce requirements. This includes advancements in propulsion systems, materials, and manufacturing processes that necessitate specific skill sets and training programs for aerospace employees.Expand Specific Solutions03 Training and simulation for scramjet technology workforce

Development of training programs and simulation technologies to prepare the workforce for the challenges of scramjet-based aerospace projects. This includes virtual reality training, advanced modeling software, and hands-on experience with prototype systems.Expand Specific Solutions04 Talent acquisition and retention in hypersonic aerospace

Strategies and systems for attracting and retaining skilled professionals in the highly competitive field of hypersonic aerospace. This includes specialized recruitment platforms, career development programs, and incentive structures tailored to the industry.Expand Specific Solutions05 Collaborative workforce solutions for scramjet projects

Innovative approaches to fostering collaboration among diverse teams working on scramjet technology. This includes cross-functional project management tools, communication platforms, and methodologies for integrating multidisciplinary expertise in aerospace projects.Expand Specific Solutions

Key Aerospace Players

The workforce realignment in scramjet-based aerospace firms is occurring in an industry still in its early development stages. The market for scramjet technology remains relatively small but is expected to grow significantly in the coming years. Technologically, scramjets are still in the experimental phase, with only a few successful test flights conducted. Companies like Boeing, Airbus, and National University of Defense Technology are at the forefront of research and development in this field. However, the technology's maturity level is still low, requiring substantial investment in R&D and skilled personnel. As the industry evolves, workforce realignments are likely to focus on acquiring specialized talent and optimizing existing teams to meet the unique challenges of scramjet development and commercialization.

The Boeing Co.

Technical Solution: Boeing has been actively involved in scramjet technology development for aerospace applications. Their approach focuses on integrating scramjet propulsion systems into hypersonic vehicles. Boeing's X-51A Waverider program demonstrated sustained scramjet-powered hypersonic flight, reaching speeds of Mach 5.1 for 210 seconds in 2013[1]. The company has been working on workforce realignment to support these advanced propulsion technologies, including cross-training engineers from traditional jet engine backgrounds in hypersonic propulsion systems. Boeing is also investing in advanced manufacturing techniques and materials to support scramjet production, such as 3D printing of complex engine components and developing heat-resistant materials capable of withstanding extreme temperatures encountered during hypersonic flight[2].

Strengths: Extensive experience in aerospace engineering, strong R&D capabilities, and successful demonstration of scramjet technology. Weaknesses: High development costs and long lead times for new technology implementation.

Airbus Operations GmbH

Technical Solution: Airbus is actively pursuing scramjet technology through its SABRE (Synergetic Air-Breathing Rocket Engine) program in collaboration with Reaction Engines Limited. This hybrid engine design combines elements of a jet engine and a rocket, capable of operating in air-breathing mode up to Mach 5.5 before transitioning to rocket mode for space access[3]. Airbus has been realigning its workforce to support this technology, focusing on developing expertise in high-temperature materials, advanced cooling systems, and hypersonic aerodynamics. The company is also investing in digital twin technology to simulate and optimize scramjet engine performance, reducing development time and costs. Airbus's approach includes a significant emphasis on sustainable aviation, exploring the potential of hydrogen as a fuel for scramjet engines to reduce environmental impact[4].

Strengths: Strong aerospace engineering capabilities, innovative hybrid engine design, and focus on sustainability. Weaknesses: Complex technology integration challenges and high initial investment costs.

Skill Gap Analysis

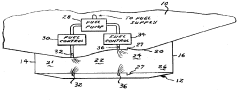

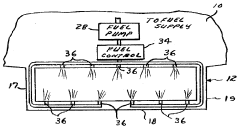

Dual mode supersonic combustion ramjet engine

PatentInactiveUS3667233A

Innovation

- A dual-mode combustion system with a combustor featuring a fixed geometry and parallel combustion section with uniform cross-section, utilizing fuel injection to stabilize flames and create choked flow, transitioning from subsonic to supersonic mode by manipulating shock waves through diverging sections and fuel distribution.

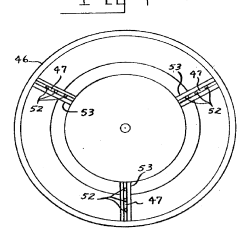

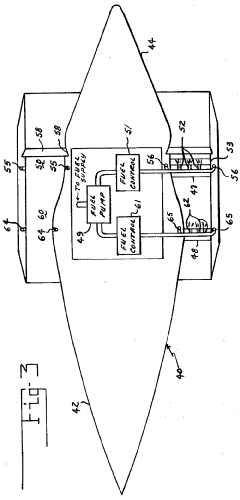

Step cylinder combustor design

PatentInactiveUS3864907A

Innovation

- A combustor chamber design with multiple stabilizing steps followed by constant area cylindrical sections allows for selective heat addition, avoiding divergent flow issues and enabling greater heat and energy input through progressively increasing diameter chambers.

Regulatory Framework

The regulatory framework surrounding workforce realignments in scramjet-based aerospace firms is complex and multifaceted, reflecting the cutting-edge nature of the technology and its potential impact on national security and economic competitiveness. At the federal level, the Department of Defense (DoD) and the Federal Aviation Administration (FAA) play crucial roles in shaping the regulatory landscape for scramjet technology development and implementation.

The DoD, through its various agencies such as DARPA and the Air Force Research Laboratory, has established guidelines for the development and testing of hypersonic technologies, including scramjets. These regulations often emphasize the need for maintaining a skilled workforce capable of advancing this critical technology. Consequently, firms engaged in scramjet development must adhere to strict security clearance requirements for their personnel, which can significantly impact hiring practices and workforce management.

The FAA, while primarily focused on commercial aviation, has begun to develop regulatory frameworks for hypersonic flight, which will inevitably affect scramjet-based aerospace firms. These emerging regulations are likely to address issues such as airspace integration, safety standards, and certification processes for hypersonic vehicles, all of which will require specialized workforce expertise.

On the labor front, the National Labor Relations Board (NLRB) oversees workforce-related issues, including those pertaining to high-tech industries like aerospace. The NLRB's regulations on collective bargaining, worker classifications, and employment terms may influence how scramjet-based firms manage their workforce realignments. Additionally, the Department of Labor's Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, which are particularly relevant given the potentially hazardous nature of scramjet development and testing.

International regulations also play a role, particularly those related to the Missile Technology Control Regime (MTCR) and the Wassenaar Arrangement on Export Controls for Conventional Arms and Dual-Use Goods and Technologies. These agreements can affect the ability of scramjet-based firms to collaborate internationally or share technology, potentially impacting workforce composition and knowledge transfer.

State-level regulations further complicate the landscape, with some states offering incentives for aerospace companies to relocate or expand, while others impose additional environmental or labor requirements. These varying state regulations can influence decisions on where to locate facilities and how to structure workforce realignments.

As the scramjet technology sector evolves, it is likely that new regulations will emerge to address novel challenges. Firms in this space must remain vigilant and adaptable, ensuring their workforce strategies align with both current and anticipated regulatory requirements.

The DoD, through its various agencies such as DARPA and the Air Force Research Laboratory, has established guidelines for the development and testing of hypersonic technologies, including scramjets. These regulations often emphasize the need for maintaining a skilled workforce capable of advancing this critical technology. Consequently, firms engaged in scramjet development must adhere to strict security clearance requirements for their personnel, which can significantly impact hiring practices and workforce management.

The FAA, while primarily focused on commercial aviation, has begun to develop regulatory frameworks for hypersonic flight, which will inevitably affect scramjet-based aerospace firms. These emerging regulations are likely to address issues such as airspace integration, safety standards, and certification processes for hypersonic vehicles, all of which will require specialized workforce expertise.

On the labor front, the National Labor Relations Board (NLRB) oversees workforce-related issues, including those pertaining to high-tech industries like aerospace. The NLRB's regulations on collective bargaining, worker classifications, and employment terms may influence how scramjet-based firms manage their workforce realignments. Additionally, the Department of Labor's Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, which are particularly relevant given the potentially hazardous nature of scramjet development and testing.

International regulations also play a role, particularly those related to the Missile Technology Control Regime (MTCR) and the Wassenaar Arrangement on Export Controls for Conventional Arms and Dual-Use Goods and Technologies. These agreements can affect the ability of scramjet-based firms to collaborate internationally or share technology, potentially impacting workforce composition and knowledge transfer.

State-level regulations further complicate the landscape, with some states offering incentives for aerospace companies to relocate or expand, while others impose additional environmental or labor requirements. These varying state regulations can influence decisions on where to locate facilities and how to structure workforce realignments.

As the scramjet technology sector evolves, it is likely that new regulations will emerge to address novel challenges. Firms in this space must remain vigilant and adaptable, ensuring their workforce strategies align with both current and anticipated regulatory requirements.

Economic Impact

The economic impact of workforce realignments in scramjet-based aerospace firms is multifaceted and far-reaching. As the industry transitions towards more advanced propulsion technologies, there is a significant shift in the skills and expertise required from the workforce. This realignment process has both immediate and long-term economic consequences for the firms, their employees, and the broader aerospace sector.

In the short term, aerospace firms investing in scramjet technology may face increased labor costs as they compete for a limited pool of highly specialized engineers and technicians. The demand for professionals with expertise in hypersonic propulsion, advanced materials, and complex fluid dynamics is likely to drive up wages in these niche areas. Simultaneously, there may be a reduction in workforce in traditional rocket propulsion departments, potentially leading to temporary unemployment or retraining costs.

The realignment process also necessitates substantial investments in employee training and development programs. Firms must allocate resources to upskill their existing workforce and attract new talent capable of working with cutting-edge scramjet technologies. This investment in human capital, while initially costly, is crucial for maintaining competitiveness and driving innovation in the long run.

From a macroeconomic perspective, the shift towards scramjet technology in aerospace firms can stimulate economic growth in several ways. The development of new technologies often leads to the creation of high-value jobs, not only within the aerospace sector but also in supporting industries such as advanced manufacturing, materials science, and software engineering. This can contribute to overall economic productivity and potentially lead to the establishment of new industry clusters around scramjet technology hubs.

Moreover, the successful development and commercialization of scramjet-based aerospace technologies have the potential to open up new markets and revenue streams. Hypersonic travel and advanced space exploration capabilities enabled by scramjets could create entirely new economic sectors, driving growth and innovation across multiple industries.

However, the economic impact is not uniformly positive. Regions heavily dependent on traditional aerospace manufacturing may experience economic disruption as firms realign their workforce. This could lead to localized economic challenges, requiring targeted economic development initiatives and support for affected communities.

The realignment also has implications for the global competitiveness of nations investing in scramjet technology. Countries that successfully navigate this transition may gain significant economic advantages in the form of export opportunities, technological leadership, and strategic military capabilities. This could reshape global economic dynamics in the aerospace and defense sectors.

In the short term, aerospace firms investing in scramjet technology may face increased labor costs as they compete for a limited pool of highly specialized engineers and technicians. The demand for professionals with expertise in hypersonic propulsion, advanced materials, and complex fluid dynamics is likely to drive up wages in these niche areas. Simultaneously, there may be a reduction in workforce in traditional rocket propulsion departments, potentially leading to temporary unemployment or retraining costs.

The realignment process also necessitates substantial investments in employee training and development programs. Firms must allocate resources to upskill their existing workforce and attract new talent capable of working with cutting-edge scramjet technologies. This investment in human capital, while initially costly, is crucial for maintaining competitiveness and driving innovation in the long run.

From a macroeconomic perspective, the shift towards scramjet technology in aerospace firms can stimulate economic growth in several ways. The development of new technologies often leads to the creation of high-value jobs, not only within the aerospace sector but also in supporting industries such as advanced manufacturing, materials science, and software engineering. This can contribute to overall economic productivity and potentially lead to the establishment of new industry clusters around scramjet technology hubs.

Moreover, the successful development and commercialization of scramjet-based aerospace technologies have the potential to open up new markets and revenue streams. Hypersonic travel and advanced space exploration capabilities enabled by scramjets could create entirely new economic sectors, driving growth and innovation across multiple industries.

However, the economic impact is not uniformly positive. Regions heavily dependent on traditional aerospace manufacturing may experience economic disruption as firms realign their workforce. This could lead to localized economic challenges, requiring targeted economic development initiatives and support for affected communities.

The realignment also has implications for the global competitiveness of nations investing in scramjet technology. Countries that successfully navigate this transition may gain significant economic advantages in the form of export opportunities, technological leadership, and strategic military capabilities. This could reshape global economic dynamics in the aerospace and defense sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!