Impact of mild hybrids on automotive manufacturing supply chains

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Evolution and Objectives

Mild hybrid technology has emerged as a significant evolutionary step in the automotive industry, bridging the gap between conventional internal combustion engines and fully electric vehicles. The development of mild hybrid systems can be traced back to the early 2000s, with initial implementations focusing on improving fuel efficiency and reducing emissions in urban driving conditions.

As environmental concerns and stringent regulations have intensified, the automotive industry has accelerated its efforts to develop and refine mild hybrid technologies. The evolution of these systems has been characterized by increasing sophistication in energy recovery and power assist capabilities, as well as the integration of more advanced electronic control units and power management systems.

The primary objectives of mild hybrid technology are multifaceted. Firstly, it aims to enhance fuel efficiency by recuperating energy during deceleration and braking, which is then stored in a small battery for later use. This stored energy can be utilized to assist the internal combustion engine during acceleration, reducing the overall fuel consumption and emissions.

Secondly, mild hybrid systems seek to improve vehicle performance by providing additional torque during acceleration, effectively filling the power gaps typically experienced in conventional powertrains. This results in smoother acceleration and improved drivability, enhancing the overall driving experience.

Another key objective is to enable more efficient engine operation by allowing for extended start-stop functionality. Mild hybrid systems can shut off the engine during coasting or when the vehicle is stationary, seamlessly restarting it when power is needed. This feature significantly reduces idle fuel consumption and emissions, particularly in urban driving scenarios.

As the technology has matured, the focus has shifted towards cost-effective implementation and scalability across various vehicle segments. Automotive manufacturers are now aiming to integrate mild hybrid systems into a wider range of models, from compact cars to larger SUVs and trucks, to meet increasingly stringent emissions standards and consumer demands for improved fuel economy.

Looking ahead, the evolution of mild hybrid technology is expected to continue, with objectives centered on further improving system efficiency, reducing costs, and enhancing integration with other advanced powertrain technologies. This includes the development of more powerful and compact electric motors, higher-capacity batteries, and more sophisticated power electronics to maximize energy recovery and utilization.

As environmental concerns and stringent regulations have intensified, the automotive industry has accelerated its efforts to develop and refine mild hybrid technologies. The evolution of these systems has been characterized by increasing sophistication in energy recovery and power assist capabilities, as well as the integration of more advanced electronic control units and power management systems.

The primary objectives of mild hybrid technology are multifaceted. Firstly, it aims to enhance fuel efficiency by recuperating energy during deceleration and braking, which is then stored in a small battery for later use. This stored energy can be utilized to assist the internal combustion engine during acceleration, reducing the overall fuel consumption and emissions.

Secondly, mild hybrid systems seek to improve vehicle performance by providing additional torque during acceleration, effectively filling the power gaps typically experienced in conventional powertrains. This results in smoother acceleration and improved drivability, enhancing the overall driving experience.

Another key objective is to enable more efficient engine operation by allowing for extended start-stop functionality. Mild hybrid systems can shut off the engine during coasting or when the vehicle is stationary, seamlessly restarting it when power is needed. This feature significantly reduces idle fuel consumption and emissions, particularly in urban driving scenarios.

As the technology has matured, the focus has shifted towards cost-effective implementation and scalability across various vehicle segments. Automotive manufacturers are now aiming to integrate mild hybrid systems into a wider range of models, from compact cars to larger SUVs and trucks, to meet increasingly stringent emissions standards and consumer demands for improved fuel economy.

Looking ahead, the evolution of mild hybrid technology is expected to continue, with objectives centered on further improving system efficiency, reducing costs, and enhancing integration with other advanced powertrain technologies. This includes the development of more powerful and compact electric motors, higher-capacity batteries, and more sophisticated power electronics to maximize energy recovery and utilization.

Market Demand Analysis for Mild Hybrids

The market demand for mild hybrid vehicles has been steadily increasing in recent years, driven by several key factors. Stringent emissions regulations worldwide have pushed automakers to adopt more fuel-efficient technologies, with mild hybrids offering a cost-effective solution to meet these standards. Consumer awareness of environmental issues and the desire for improved fuel economy have also contributed to the growing demand for mild hybrid vehicles.

In terms of market size, the global mild hybrid market was valued at approximately $20 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 12% from 2021 to 2026. This growth is expected to be particularly strong in regions such as Europe and Asia-Pacific, where emissions regulations are becoming increasingly strict.

The automotive industry has seen a shift towards electrification, with mild hybrids serving as a transitional technology between conventional internal combustion engines and fully electric vehicles. This positioning has made mild hybrids an attractive option for both manufacturers and consumers, as they offer improved fuel efficiency and reduced emissions without the range anxiety associated with fully electric vehicles.

Market trends indicate that mild hybrid systems are being adopted across various vehicle segments, from compact cars to luxury SUVs. This widespread adoption is driven by the technology's versatility and its ability to be integrated into existing vehicle platforms with relatively minor modifications. As a result, many automakers are incorporating mild hybrid systems into their product lineups to meet emissions targets and consumer demands.

The impact on the automotive manufacturing supply chain has been significant. Suppliers of electrical components, such as batteries, electric motors, and power electronics, have seen increased demand for their products. Traditional suppliers of internal combustion engine components have had to adapt their offerings to include parts compatible with mild hybrid systems. This shift has led to new partnerships and collaborations within the industry, as well as investments in research and development to improve mild hybrid technologies.

Consumer preferences are also shaping the market demand for mild hybrids. While there is growing interest in fully electric vehicles, many consumers still prefer the familiarity and convenience of conventional powertrains. Mild hybrids offer a compromise, providing improved efficiency and reduced emissions without requiring significant changes in driving habits or infrastructure.

Looking ahead, the market demand for mild hybrids is expected to continue growing in the short to medium term. However, as battery technology improves and the cost of fully electric vehicles decreases, the long-term outlook for mild hybrids may shift. Automakers and suppliers will need to carefully monitor market trends and adjust their strategies accordingly to remain competitive in the evolving automotive landscape.

In terms of market size, the global mild hybrid market was valued at approximately $20 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of around 12% from 2021 to 2026. This growth is expected to be particularly strong in regions such as Europe and Asia-Pacific, where emissions regulations are becoming increasingly strict.

The automotive industry has seen a shift towards electrification, with mild hybrids serving as a transitional technology between conventional internal combustion engines and fully electric vehicles. This positioning has made mild hybrids an attractive option for both manufacturers and consumers, as they offer improved fuel efficiency and reduced emissions without the range anxiety associated with fully electric vehicles.

Market trends indicate that mild hybrid systems are being adopted across various vehicle segments, from compact cars to luxury SUVs. This widespread adoption is driven by the technology's versatility and its ability to be integrated into existing vehicle platforms with relatively minor modifications. As a result, many automakers are incorporating mild hybrid systems into their product lineups to meet emissions targets and consumer demands.

The impact on the automotive manufacturing supply chain has been significant. Suppliers of electrical components, such as batteries, electric motors, and power electronics, have seen increased demand for their products. Traditional suppliers of internal combustion engine components have had to adapt their offerings to include parts compatible with mild hybrid systems. This shift has led to new partnerships and collaborations within the industry, as well as investments in research and development to improve mild hybrid technologies.

Consumer preferences are also shaping the market demand for mild hybrids. While there is growing interest in fully electric vehicles, many consumers still prefer the familiarity and convenience of conventional powertrains. Mild hybrids offer a compromise, providing improved efficiency and reduced emissions without requiring significant changes in driving habits or infrastructure.

Looking ahead, the market demand for mild hybrids is expected to continue growing in the short to medium term. However, as battery technology improves and the cost of fully electric vehicles decreases, the long-term outlook for mild hybrids may shift. Automakers and suppliers will need to carefully monitor market trends and adjust their strategies accordingly to remain competitive in the evolving automotive landscape.

Mild Hybrid Technology Landscape

Mild hybrid technology represents a significant evolution in automotive engineering, blending conventional internal combustion engines with electric propulsion systems. This technology landscape has been rapidly developing over the past decade, driven by the automotive industry's need to meet increasingly stringent emissions regulations while maintaining vehicle performance and consumer appeal.

The core of mild hybrid systems typically consists of a 48-volt electrical system, which supplements the traditional 12-volt system. This higher voltage allows for the integration of more powerful electric motors and generators, capable of providing assistance to the combustion engine during acceleration and recovering energy during deceleration through regenerative braking.

Several key components define the mild hybrid technology landscape. These include the Belt-Driven Starter Generator (BSG) or Integrated Starter Generator (ISG), which replaces the traditional alternator and starter motor. This component enables quick and smooth engine start-stop functionality, as well as power assist during acceleration. Another crucial element is the lithium-ion battery pack, which stores recovered energy and powers the electric systems.

The mild hybrid technology landscape has seen a proliferation of different architectures and configurations. P0, P1, and P2 configurations represent varying levels of integration between the electric motor and the combustion engine, each offering different trade-offs between complexity, cost, and efficiency gains.

Advancements in power electronics and control systems have been pivotal in the evolution of mild hybrid technology. These improvements have enabled more sophisticated energy management strategies, optimizing the interplay between electric and combustion power sources to maximize efficiency and performance.

The mild hybrid landscape has also witnessed a trend towards increased electrification of auxiliary systems. This includes electric power steering, electric air conditioning compressors, and electric water pumps, all of which contribute to reduced parasitic losses and improved overall vehicle efficiency.

As the technology matures, we are seeing a convergence of mild hybrid systems with other advanced powertrain technologies. This includes integration with advanced combustion strategies like homogeneous charge compression ignition (HCCI) and variable compression ratio engines, further pushing the boundaries of efficiency and emissions reduction.

The impact of mild hybrid technology on manufacturing supply chains has been significant. It has necessitated the development of new supplier relationships, particularly in the areas of battery technology, power electronics, and electric motor manufacturing. This shift has also driven changes in traditional automotive supply chains, with increased emphasis on electrical and electronic components.

The core of mild hybrid systems typically consists of a 48-volt electrical system, which supplements the traditional 12-volt system. This higher voltage allows for the integration of more powerful electric motors and generators, capable of providing assistance to the combustion engine during acceleration and recovering energy during deceleration through regenerative braking.

Several key components define the mild hybrid technology landscape. These include the Belt-Driven Starter Generator (BSG) or Integrated Starter Generator (ISG), which replaces the traditional alternator and starter motor. This component enables quick and smooth engine start-stop functionality, as well as power assist during acceleration. Another crucial element is the lithium-ion battery pack, which stores recovered energy and powers the electric systems.

The mild hybrid technology landscape has seen a proliferation of different architectures and configurations. P0, P1, and P2 configurations represent varying levels of integration between the electric motor and the combustion engine, each offering different trade-offs between complexity, cost, and efficiency gains.

Advancements in power electronics and control systems have been pivotal in the evolution of mild hybrid technology. These improvements have enabled more sophisticated energy management strategies, optimizing the interplay between electric and combustion power sources to maximize efficiency and performance.

The mild hybrid landscape has also witnessed a trend towards increased electrification of auxiliary systems. This includes electric power steering, electric air conditioning compressors, and electric water pumps, all of which contribute to reduced parasitic losses and improved overall vehicle efficiency.

As the technology matures, we are seeing a convergence of mild hybrid systems with other advanced powertrain technologies. This includes integration with advanced combustion strategies like homogeneous charge compression ignition (HCCI) and variable compression ratio engines, further pushing the boundaries of efficiency and emissions reduction.

The impact of mild hybrid technology on manufacturing supply chains has been significant. It has necessitated the development of new supplier relationships, particularly in the areas of battery technology, power electronics, and electric motor manufacturing. This shift has also driven changes in traditional automotive supply chains, with increased emphasis on electrical and electronic components.

Current Mild Hybrid System Architectures

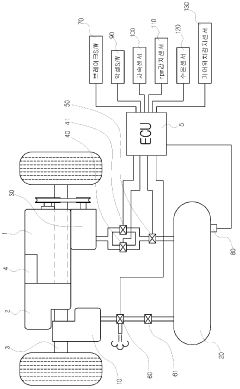

01 Hybrid powertrain systems

Mild hybrid systems integrate electric motors with conventional internal combustion engines to improve fuel efficiency and reduce emissions. These systems typically use a small electric motor to assist the engine during acceleration and recover energy during braking. The electric motor can also enable start-stop functionality, further enhancing fuel economy in urban driving conditions.- Hybrid powertrain systems: Mild hybrid systems integrate electric motors with conventional internal combustion engines to improve fuel efficiency and reduce emissions. These systems typically use a small electric motor to assist the engine during acceleration and recover energy during braking, without the capability of full electric-only operation.

- Energy storage and management: Mild hybrids employ advanced energy storage systems, such as lithium-ion batteries or supercapacitors, to store and deliver electrical energy efficiently. Sophisticated energy management systems optimize the use of stored energy to maximize fuel economy and performance.

- Regenerative braking systems: Regenerative braking is a key feature in mild hybrid vehicles, allowing the electric motor to act as a generator during deceleration. This system captures kinetic energy that would otherwise be lost as heat and converts it into electrical energy, which is then stored for later use.

- Start-stop technology: Mild hybrid systems often incorporate start-stop technology, which automatically shuts off the engine when the vehicle comes to a stop and restarts it when the accelerator is pressed. This feature helps reduce fuel consumption and emissions, particularly in urban driving conditions.

- Electric boost and torque assist: Mild hybrid powertrains provide electric boost and torque assist to the internal combustion engine. This allows for improved acceleration and performance while reducing the load on the engine, resulting in better fuel efficiency and reduced emissions during high-demand situations.

02 Energy storage and management

Mild hybrid vehicles employ advanced energy storage systems, such as lithium-ion batteries or supercapacitors, to store and deliver electrical energy efficiently. Sophisticated energy management systems optimize the distribution of power between the electric motor and the internal combustion engine, maximizing overall system efficiency and performance.Expand Specific Solutions03 Regenerative braking systems

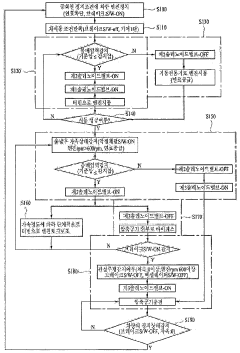

Regenerative braking is a key feature of mild hybrid vehicles, allowing the electric motor to act as a generator during deceleration. This process recovers kinetic energy that would otherwise be lost as heat in conventional braking systems, converting it into electrical energy to recharge the battery. The recovered energy can then be used to power the electric motor during acceleration or other vehicle operations.Expand Specific Solutions04 Mild hybrid control strategies

Advanced control strategies are implemented in mild hybrid vehicles to optimize the interaction between the electric motor and the internal combustion engine. These strategies may include predictive energy management, adaptive control algorithms, and real-time optimization techniques to maximize fuel efficiency and performance based on driving conditions and driver behavior.Expand Specific Solutions05 Integration with vehicle systems

Mild hybrid technology is integrated with various vehicle systems to enhance overall performance and efficiency. This integration may include electric power steering, electric air conditioning compressors, and other auxiliary systems. By electrifying these components, the mild hybrid system can reduce the load on the internal combustion engine and improve fuel economy across a wide range of operating conditions.Expand Specific Solutions

Key Automotive Manufacturers and Suppliers

The impact of mild hybrids on automotive manufacturing supply chains is at a transitional stage, with the market showing significant growth potential. The technology is maturing rapidly, driven by stringent emissions regulations and consumer demand for fuel efficiency. Key players like Johnson Controls, GM Global Technology, and Hyundai Motor Co. are investing heavily in mild hybrid systems. The market size is expanding, with projections indicating substantial growth over the next decade. Companies such as Schaeffler Technologies and Robert Bosch GmbH are developing innovative solutions to meet the increasing demand, while traditional automakers like Volkswagen AG and AUDI AG are integrating mild hybrid technology across their product lines to comply with environmental standards and improve vehicle performance.

GM Global Technology Operations LLC

Technical Solution: GM has developed a sophisticated mild hybrid system called eAssist, which integrates a compact lithium-ion battery and electric motor-generator to aid the internal combustion engine. This system allows for regenerative braking, electric power assist, and improved fuel economy. GM's approach focuses on seamless integration with existing powertrains, minimizing disruption to current manufacturing processes[1]. The company has also invested in flexible manufacturing lines that can produce both conventional and mild hybrid vehicles, allowing for rapid adaptation to market demands[2].

Strengths: Seamless integration with existing powertrains, flexible manufacturing capabilities. Weaknesses: May not offer as significant fuel economy improvements as full hybrids.

FCA US LLC

Technical Solution: FCA (now part of Stellantis) has implemented a Belt Starter Generator (BSG) mild hybrid system in several of its vehicles. This 48V system provides electric assist, regenerative braking, and improved start-stop functionality. FCA's approach emphasizes cost-effectiveness and ease of integration into existing vehicle platforms. The company has also focused on localizing the production of key components, such as the BSG units, to reduce supply chain complexity and costs[3]. FCA has worked closely with suppliers to develop standardized mild hybrid components that can be used across multiple vehicle models, streamlining the supply chain[4].

Strengths: Cost-effective solution, easy integration into existing platforms. Weaknesses: Limited electric-only operation compared to more advanced hybrid systems.

Core Innovations in Mild Hybrid Technology

Mild hybrid system

PatentWO2011152619A2

Innovation

- A hybrid engine system utilizing a compressor, compressed air cylinder, turbine, and solenoid valves to control compressed air supply for smooth engine start and acceleration, reducing engine load and maintaining efficient operation without design changes to existing engines.

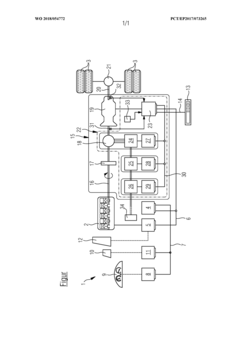

Hybrid vehicle

PatentWO2018054772A1

Innovation

- A hybrid vehicle with a simplified transmission system that integrates an electric machine, energy storage device, and main control via a data bus, allowing the main transmission control to manage all components, reducing complexity and enhancing reliability, and using a mild hybrid configuration with a 12V or 24V electrical system to eliminate the need for alternators and reduce battery size.

Supply Chain Restructuring for Mild Hybrids

The integration of mild hybrid technology into automotive manufacturing supply chains necessitates significant restructuring to accommodate the new components and processes required. This shift impacts various aspects of the supply chain, from sourcing to production and distribution.

Suppliers must adapt to produce new components specific to mild hybrid systems, such as electric motors, batteries, and power electronics. This adaptation often requires substantial investments in research and development, as well as retooling of production facilities. Tier 1 suppliers are particularly affected, as they need to develop expertise in both traditional combustion engine components and electrical systems.

Original Equipment Manufacturers (OEMs) face the challenge of redesigning their production lines to incorporate mild hybrid technology. This involves modifying assembly processes to integrate electric motors and batteries alongside conventional powertrains. The complexity of managing dual powertrain systems increases inventory management challenges and requires more sophisticated just-in-time delivery systems.

Logistics networks must evolve to handle the transportation and storage of new components, particularly batteries, which require special handling due to safety regulations. This may lead to the emergence of specialized logistics providers equipped to manage these unique requirements.

Quality control processes need to be updated to ensure the reliability and safety of mild hybrid systems. This includes developing new testing procedures and equipment to validate the performance of electrical components and their integration with mechanical systems.

The shift towards mild hybrids also impacts the aftermarket supply chain. Service centers and spare parts distributors must stock a wider range of components and train technicians to maintain and repair these more complex vehicles.

Collaboration between OEMs, suppliers, and technology providers becomes increasingly crucial. Joint ventures and strategic partnerships are likely to form, fostering innovation and sharing the risks associated with developing new technologies.

As the demand for mild hybrid vehicles grows, supply chains must become more agile and responsive to market fluctuations. This may lead to the adoption of advanced forecasting tools and data analytics to better predict and manage supply and demand dynamics.

Overall, the restructuring of supply chains for mild hybrids represents a significant transformation in the automotive industry, requiring substantial investments, new skills, and a reimagining of traditional supply chain models.

Suppliers must adapt to produce new components specific to mild hybrid systems, such as electric motors, batteries, and power electronics. This adaptation often requires substantial investments in research and development, as well as retooling of production facilities. Tier 1 suppliers are particularly affected, as they need to develop expertise in both traditional combustion engine components and electrical systems.

Original Equipment Manufacturers (OEMs) face the challenge of redesigning their production lines to incorporate mild hybrid technology. This involves modifying assembly processes to integrate electric motors and batteries alongside conventional powertrains. The complexity of managing dual powertrain systems increases inventory management challenges and requires more sophisticated just-in-time delivery systems.

Logistics networks must evolve to handle the transportation and storage of new components, particularly batteries, which require special handling due to safety regulations. This may lead to the emergence of specialized logistics providers equipped to manage these unique requirements.

Quality control processes need to be updated to ensure the reliability and safety of mild hybrid systems. This includes developing new testing procedures and equipment to validate the performance of electrical components and their integration with mechanical systems.

The shift towards mild hybrids also impacts the aftermarket supply chain. Service centers and spare parts distributors must stock a wider range of components and train technicians to maintain and repair these more complex vehicles.

Collaboration between OEMs, suppliers, and technology providers becomes increasingly crucial. Joint ventures and strategic partnerships are likely to form, fostering innovation and sharing the risks associated with developing new technologies.

As the demand for mild hybrid vehicles grows, supply chains must become more agile and responsive to market fluctuations. This may lead to the adoption of advanced forecasting tools and data analytics to better predict and manage supply and demand dynamics.

Overall, the restructuring of supply chains for mild hybrids represents a significant transformation in the automotive industry, requiring substantial investments, new skills, and a reimagining of traditional supply chain models.

Environmental Impact Assessment

The introduction of mild hybrid technology in automotive manufacturing has significant implications for environmental impact assessment. This technology, which combines a conventional internal combustion engine with an electric motor, offers potential benefits in terms of reduced emissions and improved fuel efficiency. However, its implementation also presents challenges that need to be carefully evaluated.

Mild hybrid systems contribute to a reduction in greenhouse gas emissions by enabling the engine to shut off during coasting, braking, and stopping, while the electric motor provides power assistance during acceleration. This results in lower fuel consumption and, consequently, decreased carbon dioxide emissions. Studies have shown that mild hybrid vehicles can reduce CO2 emissions by 15-20% compared to conventional vehicles, depending on driving conditions and vehicle specifications.

The manufacturing process of mild hybrid components, particularly the electric motor and battery systems, introduces new environmental considerations. The production of these components requires additional resources and energy, potentially offsetting some of the environmental gains achieved during vehicle operation. However, advancements in manufacturing techniques and materials science are continually improving the sustainability of these processes.

The impact on supply chains is notable, as the shift towards mild hybrid technology necessitates changes in sourcing strategies. Suppliers are required to adapt their production lines to accommodate new components, which may lead to temporary increases in energy consumption and waste generation during the transition period. However, in the long term, this transition is expected to drive innovation in more sustainable manufacturing practices.

Recycling and end-of-life management of mild hybrid vehicles present both challenges and opportunities. The addition of electric components, particularly batteries, requires the development of specialized recycling processes. While this initially poses a challenge, it also stimulates the growth of a new recycling industry, potentially creating jobs and fostering technological innovation in waste management.

The overall lifecycle assessment of mild hybrid vehicles indicates a net positive environmental impact when compared to conventional vehicles. The reduced emissions and improved fuel efficiency during the operational phase outweigh the additional environmental costs associated with manufacturing and end-of-life processing. However, continuous monitoring and assessment are necessary to ensure that these benefits are realized and maximized as the technology evolves and becomes more widespread in the automotive industry.

In conclusion, while the adoption of mild hybrid technology in automotive manufacturing introduces new environmental considerations, its overall impact is generally positive. The key to maximizing these benefits lies in ongoing research and development to improve manufacturing processes, enhance recycling capabilities, and further optimize the efficiency of mild hybrid systems.

Mild hybrid systems contribute to a reduction in greenhouse gas emissions by enabling the engine to shut off during coasting, braking, and stopping, while the electric motor provides power assistance during acceleration. This results in lower fuel consumption and, consequently, decreased carbon dioxide emissions. Studies have shown that mild hybrid vehicles can reduce CO2 emissions by 15-20% compared to conventional vehicles, depending on driving conditions and vehicle specifications.

The manufacturing process of mild hybrid components, particularly the electric motor and battery systems, introduces new environmental considerations. The production of these components requires additional resources and energy, potentially offsetting some of the environmental gains achieved during vehicle operation. However, advancements in manufacturing techniques and materials science are continually improving the sustainability of these processes.

The impact on supply chains is notable, as the shift towards mild hybrid technology necessitates changes in sourcing strategies. Suppliers are required to adapt their production lines to accommodate new components, which may lead to temporary increases in energy consumption and waste generation during the transition period. However, in the long term, this transition is expected to drive innovation in more sustainable manufacturing practices.

Recycling and end-of-life management of mild hybrid vehicles present both challenges and opportunities. The addition of electric components, particularly batteries, requires the development of specialized recycling processes. While this initially poses a challenge, it also stimulates the growth of a new recycling industry, potentially creating jobs and fostering technological innovation in waste management.

The overall lifecycle assessment of mild hybrid vehicles indicates a net positive environmental impact when compared to conventional vehicles. The reduced emissions and improved fuel efficiency during the operational phase outweigh the additional environmental costs associated with manufacturing and end-of-life processing. However, continuous monitoring and assessment are necessary to ensure that these benefits are realized and maximized as the technology evolves and becomes more widespread in the automotive industry.

In conclusion, while the adoption of mild hybrid technology in automotive manufacturing introduces new environmental considerations, its overall impact is generally positive. The key to maximizing these benefits lies in ongoing research and development to improve manufacturing processes, enhance recycling capabilities, and further optimize the efficiency of mild hybrid systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!