Implementations of LTPO in AMOLED panels for energy efficiency.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LTPO AMOLED Evolution

The evolution of LTPO (Low-Temperature Polycrystalline Oxide) technology in AMOLED (Active-Matrix Organic Light-Emitting Diode) displays represents a significant advancement in energy-efficient display technology. This progression has been driven by the increasing demand for longer battery life in mobile devices and the need for more power-efficient displays in various applications.

LTPO technology emerged as a hybrid solution, combining the benefits of LTPS (Low-Temperature Polycrystalline Silicon) and IGZO (Indium Gallium Zinc Oxide) technologies. The development of LTPO can be traced back to the early 2010s when display manufacturers began exploring ways to reduce power consumption in OLED panels without compromising performance.

The first generation of LTPO displays, introduced around 2015, focused on integrating LTPS and IGZO technologies to create a more energy-efficient backplane. This initial implementation allowed for variable refresh rates, ranging from 1Hz to 60Hz, which significantly reduced power consumption during static image display.

As the technology matured, second-generation LTPO displays emerged around 2018, offering improved performance and wider refresh rate ranges. These displays could dynamically adjust refresh rates from 1Hz to 120Hz, providing smoother animations and further enhancing energy efficiency. This generation also saw improvements in pixel density and color accuracy.

The third generation of LTPO technology, introduced in 2020, brought about even more sophisticated power management capabilities. These displays could seamlessly switch between refresh rates, from as low as 1Hz to as high as 144Hz, adapting in real-time to the content being displayed. This generation also introduced advanced dimming techniques and improved color management systems.

Recent developments in LTPO technology have focused on expanding its application beyond smartphones to other devices such as smartwatches, tablets, and laptops. The latest iterations have also addressed challenges related to manufacturing costs and yield rates, making LTPO more accessible for a wider range of products.

Looking ahead, the evolution of LTPO AMOLED technology is expected to continue, with future generations likely to offer even wider refresh rate ranges, potentially reaching 240Hz or higher. Researchers are also exploring ways to further reduce power consumption and improve display quality, including advancements in materials science and pixel architectures.

LTPO technology emerged as a hybrid solution, combining the benefits of LTPS (Low-Temperature Polycrystalline Silicon) and IGZO (Indium Gallium Zinc Oxide) technologies. The development of LTPO can be traced back to the early 2010s when display manufacturers began exploring ways to reduce power consumption in OLED panels without compromising performance.

The first generation of LTPO displays, introduced around 2015, focused on integrating LTPS and IGZO technologies to create a more energy-efficient backplane. This initial implementation allowed for variable refresh rates, ranging from 1Hz to 60Hz, which significantly reduced power consumption during static image display.

As the technology matured, second-generation LTPO displays emerged around 2018, offering improved performance and wider refresh rate ranges. These displays could dynamically adjust refresh rates from 1Hz to 120Hz, providing smoother animations and further enhancing energy efficiency. This generation also saw improvements in pixel density and color accuracy.

The third generation of LTPO technology, introduced in 2020, brought about even more sophisticated power management capabilities. These displays could seamlessly switch between refresh rates, from as low as 1Hz to as high as 144Hz, adapting in real-time to the content being displayed. This generation also introduced advanced dimming techniques and improved color management systems.

Recent developments in LTPO technology have focused on expanding its application beyond smartphones to other devices such as smartwatches, tablets, and laptops. The latest iterations have also addressed challenges related to manufacturing costs and yield rates, making LTPO more accessible for a wider range of products.

Looking ahead, the evolution of LTPO AMOLED technology is expected to continue, with future generations likely to offer even wider refresh rate ranges, potentially reaching 240Hz or higher. Researchers are also exploring ways to further reduce power consumption and improve display quality, including advancements in materials science and pixel architectures.

Energy Efficiency Demand

The demand for energy efficiency in electronic devices, particularly in mobile and wearable technologies, has become a critical factor driving innovation in display technologies. As consumers increasingly rely on smartphones, tablets, and smartwatches for daily activities, the need for longer battery life and reduced power consumption has intensified. This market demand has led to the development and implementation of Low-Temperature Polycrystalline Oxide (LTPO) technology in Active-Matrix Organic Light-Emitting Diode (AMOLED) panels.

LTPO technology addresses the energy efficiency challenge by enabling dynamic refresh rates in displays. Traditional displays operate at fixed refresh rates, typically 60Hz, regardless of the content being displayed. This constant refreshing consumes unnecessary power, especially when displaying static content. LTPO allows displays to adjust their refresh rates in real-time, ranging from as low as 1Hz for static content to high refresh rates of 120Hz or more for smooth animations and video playback.

The market demand for LTPO AMOLED panels is driven by several factors. Firstly, smartphone manufacturers are under pressure to improve battery life without increasing device thickness or weight. LTPO technology offers a solution by reducing display power consumption, which accounts for a significant portion of overall device energy use. Secondly, the growing popularity of always-on display features in smartphones and smartwatches requires efficient display technologies that can maintain functionality without rapidly draining the battery.

In the wearable technology sector, particularly smartwatches, LTPO AMOLED panels have become increasingly important. These devices have limited battery capacity due to their small form factor, making energy efficiency crucial for extending usage time between charges. The ability of LTPO displays to operate at very low refresh rates is particularly beneficial for smartwatch applications, where the display often shows static information for extended periods.

The automotive industry is another sector driving demand for energy-efficient display technologies. As vehicles incorporate more digital displays for infotainment systems and instrument clusters, the need for power-efficient solutions becomes more pressing, especially in electric vehicles where energy conservation directly impacts driving range.

Market research indicates a growing adoption of LTPO AMOLED panels across various device categories. This trend is expected to continue as manufacturers seek to differentiate their products through improved battery life and display performance. The demand for energy-efficient displays is also aligned with broader environmental concerns and regulatory pressures to reduce electronic waste and improve the overall sustainability of consumer electronics.

LTPO technology addresses the energy efficiency challenge by enabling dynamic refresh rates in displays. Traditional displays operate at fixed refresh rates, typically 60Hz, regardless of the content being displayed. This constant refreshing consumes unnecessary power, especially when displaying static content. LTPO allows displays to adjust their refresh rates in real-time, ranging from as low as 1Hz for static content to high refresh rates of 120Hz or more for smooth animations and video playback.

The market demand for LTPO AMOLED panels is driven by several factors. Firstly, smartphone manufacturers are under pressure to improve battery life without increasing device thickness or weight. LTPO technology offers a solution by reducing display power consumption, which accounts for a significant portion of overall device energy use. Secondly, the growing popularity of always-on display features in smartphones and smartwatches requires efficient display technologies that can maintain functionality without rapidly draining the battery.

In the wearable technology sector, particularly smartwatches, LTPO AMOLED panels have become increasingly important. These devices have limited battery capacity due to their small form factor, making energy efficiency crucial for extending usage time between charges. The ability of LTPO displays to operate at very low refresh rates is particularly beneficial for smartwatch applications, where the display often shows static information for extended periods.

The automotive industry is another sector driving demand for energy-efficient display technologies. As vehicles incorporate more digital displays for infotainment systems and instrument clusters, the need for power-efficient solutions becomes more pressing, especially in electric vehicles where energy conservation directly impacts driving range.

Market research indicates a growing adoption of LTPO AMOLED panels across various device categories. This trend is expected to continue as manufacturers seek to differentiate their products through improved battery life and display performance. The demand for energy-efficient displays is also aligned with broader environmental concerns and regulatory pressures to reduce electronic waste and improve the overall sustainability of consumer electronics.

LTPO Challenges

Despite the promising potential of LTPO technology in AMOLED panels for energy efficiency, several significant challenges hinder its widespread adoption and optimal implementation. One of the primary obstacles is the complexity of the manufacturing process. LTPO requires the integration of both LTPS (Low-Temperature Polycrystalline Silicon) and IGZO (Indium Gallium Zinc Oxide) technologies, which demands sophisticated production techniques and specialized equipment. This complexity not only increases production costs but also impacts yield rates, making it difficult for manufacturers to achieve economies of scale.

Another critical challenge lies in the design and optimization of LTPO backplanes. Engineers must carefully balance the trade-offs between power efficiency, display performance, and production feasibility. The variable refresh rate capability of LTPO, while beneficial for energy savings, introduces additional complexities in terms of timing control and power management circuitry. Ensuring smooth transitions between different refresh rates without compromising image quality or introducing artifacts remains a significant technical hurdle.

The integration of LTPO technology with existing AMOLED panel designs also presents challenges. Manufacturers must adapt their current production lines and processes to accommodate the new technology, which often requires substantial investments in research, development, and retooling. Furthermore, the compatibility of LTPO with various display sizes and form factors needs to be addressed, as different applications may require tailored solutions.

Power management and optimization pose another set of challenges for LTPO implementation. While the technology offers improved energy efficiency, realizing its full potential requires sophisticated power control algorithms and hardware. Developing these systems to dynamically adjust refresh rates based on content and user interaction, while maintaining optimal power consumption, demands extensive research and fine-tuning.

Lastly, the cost factor remains a significant barrier to widespread LTPO adoption. The increased complexity and specialized materials required for LTPO production result in higher manufacturing costs compared to traditional AMOLED panels. This cost premium can be a deterrent for both manufacturers and consumers, particularly in price-sensitive market segments. Balancing the benefits of energy efficiency against the increased production costs presents a ongoing challenge for the industry.

Another critical challenge lies in the design and optimization of LTPO backplanes. Engineers must carefully balance the trade-offs between power efficiency, display performance, and production feasibility. The variable refresh rate capability of LTPO, while beneficial for energy savings, introduces additional complexities in terms of timing control and power management circuitry. Ensuring smooth transitions between different refresh rates without compromising image quality or introducing artifacts remains a significant technical hurdle.

The integration of LTPO technology with existing AMOLED panel designs also presents challenges. Manufacturers must adapt their current production lines and processes to accommodate the new technology, which often requires substantial investments in research, development, and retooling. Furthermore, the compatibility of LTPO with various display sizes and form factors needs to be addressed, as different applications may require tailored solutions.

Power management and optimization pose another set of challenges for LTPO implementation. While the technology offers improved energy efficiency, realizing its full potential requires sophisticated power control algorithms and hardware. Developing these systems to dynamically adjust refresh rates based on content and user interaction, while maintaining optimal power consumption, demands extensive research and fine-tuning.

Lastly, the cost factor remains a significant barrier to widespread LTPO adoption. The increased complexity and specialized materials required for LTPO production result in higher manufacturing costs compared to traditional AMOLED panels. This cost premium can be a deterrent for both manufacturers and consumers, particularly in price-sensitive market segments. Balancing the benefits of energy efficiency against the increased production costs presents a ongoing challenge for the industry.

Current LTPO Solutions

01 LTPO backplane technology for energy efficiency

LTPO (Low-Temperature Polycrystalline Oxide) backplane technology combines the benefits of LTPS and oxide TFTs to achieve high energy efficiency in AMOLED displays. This technology allows for dynamic refresh rate adjustment, significantly reducing power consumption when displaying static content.- LTPO backplane technology for energy efficiency: LTPO (Low-Temperature Polycrystalline Oxide) backplane technology is used in AMOLED panels to improve energy efficiency. This technology allows for dynamic refresh rate adjustment, reducing power consumption when displaying static content. LTPO combines the advantages of LTPS and IGZO technologies, offering high electron mobility and low leakage current.

- Variable refresh rate implementation: LTPO AMOLED panels implement variable refresh rate technology to optimize power consumption. The display can dynamically adjust its refresh rate based on the content being displayed, ranging from low rates for static images to high rates for fast-moving content. This adaptive approach significantly reduces energy usage compared to fixed refresh rate displays.

- Pixel circuit design for power efficiency: Advanced pixel circuit designs are employed in LTPO AMOLED panels to enhance energy efficiency. These circuits incorporate features such as improved charge holding capabilities, optimized transistor layouts, and reduced parasitic capacitances. Such designs minimize power leakage and improve overall panel efficiency.

- Power management techniques: LTPO AMOLED panels utilize sophisticated power management techniques to reduce energy consumption. These include selective pixel dimming, local dimming for dark areas, and intelligent power distribution across the display. Advanced algorithms are used to optimize power usage based on displayed content and ambient lighting conditions.

- Integration of energy-efficient materials: The incorporation of energy-efficient materials in LTPO AMOLED panels contributes to improved power efficiency. This includes the use of advanced organic light-emitting materials with higher quantum efficiency, as well as optimized thin-film transistor materials. These materials help reduce power consumption while maintaining or enhancing display performance.

02 Variable refresh rate implementation

LTPO AMOLED panels can dynamically adjust their refresh rates based on the content being displayed. This feature allows the display to lower its refresh rate for static content, thereby reducing power consumption and improving overall energy efficiency.Expand Specific Solutions03 Pixel circuit design optimization

Advanced pixel circuit designs are implemented in LTPO AMOLED panels to minimize power consumption. These designs include improved transistor configurations and compensation circuits that enhance the overall energy efficiency of the display.Expand Specific Solutions04 Power management techniques

LTPO AMOLED panels incorporate various power management techniques to optimize energy consumption. These include adaptive brightness control, selective pixel activation, and intelligent power distribution across the display, contributing to improved energy efficiency.Expand Specific Solutions05 Integration of energy-efficient materials

The use of advanced materials in LTPO AMOLED panels, such as high-mobility semiconductors and low-resistance electrodes, contributes to improved energy efficiency. These materials enhance charge carrier mobility and reduce power losses, resulting in lower overall power consumption.Expand Specific Solutions

LTPO Market Players

The implementation of LTPO in AMOLED panels for energy efficiency is in a growth phase, with increasing market demand driven by the need for power-efficient displays in mobile devices. The market size is expanding rapidly, with major players like BOE Technology Group, Tianma Microelectronics, and China Star Optoelectronics investing heavily in LTPO technology. The technology's maturity is advancing, with companies like Visionox and Novatek Microelectronics making significant strides in LTPO development. However, challenges remain in mass production and cost-effectiveness, indicating that the technology is still evolving. The competitive landscape is intensifying as more manufacturers enter the market, driving innovation and potentially leading to wider adoption of LTPO AMOLED panels in various consumer electronics.

Wuhan China Star Optoelectronics Semicon Display Tech Co.

Technical Solution: CSOT has implemented LTPO technology in their AMOLED panels, focusing on achieving high energy efficiency without compromising display quality. Their approach involves a novel backplane design that combines the benefits of LTPS and oxide TFTs. CSOT's LTPO panels can dynamically adjust refresh rates from 1Hz to 120Hz, with a particular emphasis on minimizing power consumption during low refresh rate operations[10]. The company has also developed proprietary compensation techniques to maintain color accuracy and brightness uniformity across different refresh rates, addressing common challenges in variable refresh rate displays[11].

Strengths: Balanced performance between power efficiency and display quality, robust compensation techniques. Weaknesses: Relatively new to LTPO technology, may face challenges in mass production and yield rates initially.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced LTPO AMOLED panels incorporating a hybrid oxide and LTPS backplane technology. Their implementation allows for variable refresh rates from 1Hz to 120Hz, significantly reducing power consumption. BOE's LTPO technology utilizes a two-layer transistor structure, combining the advantages of LTPS for high electron mobility and oxide TFTs for low leakage current[1][3]. This design enables precise control over pixel switching, allowing for dynamic adjustment of refresh rates based on displayed content. BOE has also integrated advanced compensation circuits to maintain color accuracy and brightness consistency across different refresh rates[5].

Strengths: Highly efficient power management, wide refresh rate range, and color consistency. Weaknesses: Complex manufacturing process may impact yield rates and production costs.

LTPO Core Innovations

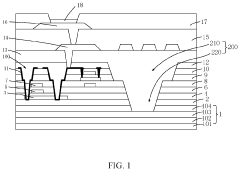

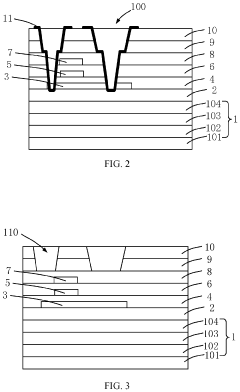

Array substrate and manufacturing method thereof

PatentActiveUS11997878B2

Innovation

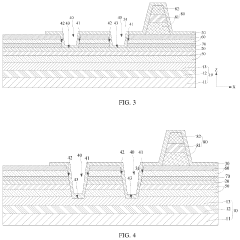

- The array substrate design includes a first recess extending through multiple layers with a bottom surface inside the barrier layer, allowing the source/drain electrode to cover the inner sidewall and bottom surface, and a passivation layer that fills the recess, increasing the contact area and reducing resistance, while a stepped surface on the sidewall provides a buffering effect to prevent electrode breakage.

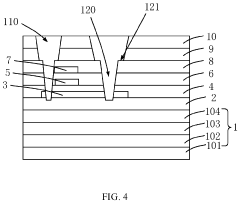

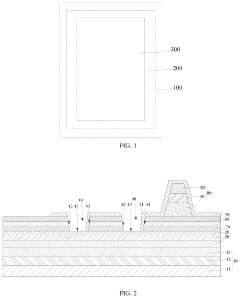

Display panel and display device

PatentPendingUS20230071744A1

Innovation

- A display panel design featuring a blocking groove in the non-display area that surrounds the pixel and drive areas, with the groove extending to a blocking layer in the thickness direction, and an extension portion of the encapsulation layer covering the side surfaces, forming a sealed space to prevent water vapor and oxygen ingress.

LTPO Manufacturing Process

The manufacturing process of Low-Temperature Polycrystalline Oxide (LTPO) for AMOLED panels involves several intricate steps, each crucial for achieving the desired energy efficiency and performance characteristics. The process begins with the deposition of a thin layer of amorphous silicon on a glass substrate using plasma-enhanced chemical vapor deposition (PECVD). This layer is then subjected to laser annealing, which transforms the amorphous silicon into polycrystalline silicon, forming the foundation for the LTPO backplane.

Following the laser annealing, a layer of oxide semiconductor material, typically indium gallium zinc oxide (IGZO), is deposited onto the polycrystalline silicon layer. This step is critical as it combines the benefits of both LTPS and oxide TFT technologies. The IGZO layer is deposited using sputtering techniques, ensuring uniform coverage and optimal electrical properties.

The next phase involves the patterning of the LTPO layers using photolithography and etching processes. This step defines the transistor structures and interconnects that form the active matrix backplane. Precise control over the etching process is essential to achieve the desired transistor characteristics and minimize defects.

After patterning, a series of ion implantation steps are performed to create the source, drain, and channel regions of the transistors. This process allows for fine-tuning of the electrical properties of the LTPO transistors, enabling the variable refresh rate functionality that is key to the energy efficiency of LTPO displays.

The manufacturing process then proceeds with the deposition of insulating and passivation layers. These layers protect the transistor structures and provide electrical isolation between different components of the display. High-quality dielectric materials are used to ensure minimal leakage currents and optimal transistor performance.

Following the passivation, contact holes are etched to allow for electrical connections between the transistors and subsequent layers. Metal deposition and patterning steps are then carried out to create the electrodes and interconnects necessary for driving the OLED pixels.

The final stages of the LTPO manufacturing process involve the integration of the OLED layers. This includes the deposition of the hole injection layer, hole transport layer, emissive layer, electron transport layer, and electron injection layer. These organic layers are typically deposited using vacuum thermal evaporation or inkjet printing techniques, depending on the specific materials and desired performance characteristics.

Throughout the entire manufacturing process, strict quality control measures are implemented to ensure consistency and reliability. Advanced inspection and testing equipment is used at various stages to detect defects and verify the electrical properties of the LTPO backplane and OLED layers.

Following the laser annealing, a layer of oxide semiconductor material, typically indium gallium zinc oxide (IGZO), is deposited onto the polycrystalline silicon layer. This step is critical as it combines the benefits of both LTPS and oxide TFT technologies. The IGZO layer is deposited using sputtering techniques, ensuring uniform coverage and optimal electrical properties.

The next phase involves the patterning of the LTPO layers using photolithography and etching processes. This step defines the transistor structures and interconnects that form the active matrix backplane. Precise control over the etching process is essential to achieve the desired transistor characteristics and minimize defects.

After patterning, a series of ion implantation steps are performed to create the source, drain, and channel regions of the transistors. This process allows for fine-tuning of the electrical properties of the LTPO transistors, enabling the variable refresh rate functionality that is key to the energy efficiency of LTPO displays.

The manufacturing process then proceeds with the deposition of insulating and passivation layers. These layers protect the transistor structures and provide electrical isolation between different components of the display. High-quality dielectric materials are used to ensure minimal leakage currents and optimal transistor performance.

Following the passivation, contact holes are etched to allow for electrical connections between the transistors and subsequent layers. Metal deposition and patterning steps are then carried out to create the electrodes and interconnects necessary for driving the OLED pixels.

The final stages of the LTPO manufacturing process involve the integration of the OLED layers. This includes the deposition of the hole injection layer, hole transport layer, emissive layer, electron transport layer, and electron injection layer. These organic layers are typically deposited using vacuum thermal evaporation or inkjet printing techniques, depending on the specific materials and desired performance characteristics.

Throughout the entire manufacturing process, strict quality control measures are implemented to ensure consistency and reliability. Advanced inspection and testing equipment is used at various stages to detect defects and verify the electrical properties of the LTPO backplane and OLED layers.

LTPO Cost-Benefit Analysis

The implementation of Low-Temperature Polycrystalline Oxide (LTPO) technology in AMOLED panels presents a significant opportunity for improving energy efficiency in mobile devices. However, to fully understand its potential impact, a comprehensive cost-benefit analysis is essential.

From a cost perspective, the integration of LTPO technology into AMOLED panels requires substantial initial investment. Manufacturers need to modify their production lines and processes to accommodate the new technology. This includes the acquisition of specialized equipment and the development of new manufacturing techniques. Additionally, there may be increased material costs associated with the production of LTPO backplanes.

The complexity of LTPO manufacturing also contributes to higher production costs in the short term. The process involves more steps and requires greater precision compared to traditional LTFT (Low-Temperature Polycrystalline Silicon) technology. This complexity can lead to lower yields initially, further increasing the cost per unit.

However, these increased costs must be weighed against the significant benefits that LTPO technology offers. The primary advantage is the substantial improvement in energy efficiency. LTPO allows for more precise control of refresh rates, enabling dynamic adjustments from as low as 1Hz to 120Hz or higher. This capability can result in power savings of up to 20-30% compared to conventional OLED displays.

The energy efficiency gains translate directly into extended battery life for mobile devices, a key selling point for consumers. This improvement can lead to increased customer satisfaction and potentially higher sales volumes, offsetting the initial production costs over time.

Furthermore, LTPO technology enables smoother display performance and reduced motion blur, enhancing the overall user experience. These qualitative improvements can justify premium pricing for devices incorporating LTPO displays, potentially increasing profit margins.

In the long term, as manufacturing processes mature and economies of scale come into play, the production costs for LTPO panels are expected to decrease. This trend will further improve the cost-benefit ratio, making the technology more accessible to a wider range of devices and market segments.

It's also worth considering the potential for reduced warranty claims and customer support costs. The improved energy efficiency and display performance may lead to fewer issues related to battery life and display quality, resulting in cost savings for manufacturers in after-sales support.

In conclusion, while the implementation of LTPO in AMOLED panels does involve significant upfront costs, the long-term benefits in terms of energy efficiency, user experience, and potential market advantages make it a compelling investment for manufacturers looking to stay competitive in the mobile device market.

From a cost perspective, the integration of LTPO technology into AMOLED panels requires substantial initial investment. Manufacturers need to modify their production lines and processes to accommodate the new technology. This includes the acquisition of specialized equipment and the development of new manufacturing techniques. Additionally, there may be increased material costs associated with the production of LTPO backplanes.

The complexity of LTPO manufacturing also contributes to higher production costs in the short term. The process involves more steps and requires greater precision compared to traditional LTFT (Low-Temperature Polycrystalline Silicon) technology. This complexity can lead to lower yields initially, further increasing the cost per unit.

However, these increased costs must be weighed against the significant benefits that LTPO technology offers. The primary advantage is the substantial improvement in energy efficiency. LTPO allows for more precise control of refresh rates, enabling dynamic adjustments from as low as 1Hz to 120Hz or higher. This capability can result in power savings of up to 20-30% compared to conventional OLED displays.

The energy efficiency gains translate directly into extended battery life for mobile devices, a key selling point for consumers. This improvement can lead to increased customer satisfaction and potentially higher sales volumes, offsetting the initial production costs over time.

Furthermore, LTPO technology enables smoother display performance and reduced motion blur, enhancing the overall user experience. These qualitative improvements can justify premium pricing for devices incorporating LTPO displays, potentially increasing profit margins.

In the long term, as manufacturing processes mature and economies of scale come into play, the production costs for LTPO panels are expected to decrease. This trend will further improve the cost-benefit ratio, making the technology more accessible to a wider range of devices and market segments.

It's also worth considering the potential for reduced warranty claims and customer support costs. The improved energy efficiency and display performance may lead to fewer issues related to battery life and display quality, resulting in cost savings for manufacturers in after-sales support.

In conclusion, while the implementation of LTPO in AMOLED panels does involve significant upfront costs, the long-term benefits in terms of energy efficiency, user experience, and potential market advantages make it a compelling investment for manufacturers looking to stay competitive in the mobile device market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!