Internet of Things (IoT) Integration in Monitoring Solenoid Valve Performance

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IoT and Solenoid Valve Monitoring: Background and Objectives

The Internet of Things (IoT) has revolutionized various industries by enabling seamless connectivity and data exchange between devices. In the context of solenoid valve performance monitoring, IoT integration represents a significant technological advancement. This convergence of IoT and industrial valve systems aims to enhance operational efficiency, reduce downtime, and optimize maintenance processes.

Solenoid valves, widely used in fluid control applications across multiple sectors, play a crucial role in regulating the flow of liquids or gases. Traditionally, monitoring these valves relied on periodic manual inspections or basic sensors, often resulting in delayed detection of issues and suboptimal performance. The integration of IoT technology in solenoid valve monitoring addresses these limitations by providing real-time data collection, analysis, and predictive maintenance capabilities.

The evolution of IoT technology has been marked by increasing miniaturization of sensors, improved wireless communication protocols, and advancements in data analytics. These developments have paved the way for more sophisticated monitoring solutions in industrial settings. In the case of solenoid valves, IoT integration allows for continuous monitoring of various parameters such as valve position, temperature, pressure, and flow rates.

The primary objective of incorporating IoT in solenoid valve monitoring is to achieve a comprehensive and proactive approach to valve management. This includes early detection of potential failures, optimization of valve performance, and extension of valve lifespan. By leveraging IoT capabilities, organizations can transition from reactive maintenance strategies to predictive and prescriptive maintenance models, significantly reducing operational costs and improving overall system reliability.

Another key goal is to enhance decision-making processes through data-driven insights. IoT-enabled solenoid valve monitoring systems generate vast amounts of operational data, which can be analyzed to identify patterns, trends, and anomalies. This information empowers engineers and maintenance personnel to make informed decisions regarding valve maintenance, replacement, and system optimization.

Furthermore, the integration of IoT in solenoid valve monitoring aligns with broader industry trends towards digital transformation and Industry 4.0 initiatives. It represents a step towards creating more intelligent and interconnected industrial ecosystems, where various components communicate and collaborate seamlessly. This integration also supports sustainability goals by optimizing resource usage and reducing energy consumption through more efficient valve operation.

As we delve deeper into the technological landscape of IoT and solenoid valve monitoring, it becomes evident that this integration holds immense potential for revolutionizing industrial processes. The subsequent sections of this report will explore the market demands, technical challenges, and innovative solutions emerging in this dynamic field.

Solenoid valves, widely used in fluid control applications across multiple sectors, play a crucial role in regulating the flow of liquids or gases. Traditionally, monitoring these valves relied on periodic manual inspections or basic sensors, often resulting in delayed detection of issues and suboptimal performance. The integration of IoT technology in solenoid valve monitoring addresses these limitations by providing real-time data collection, analysis, and predictive maintenance capabilities.

The evolution of IoT technology has been marked by increasing miniaturization of sensors, improved wireless communication protocols, and advancements in data analytics. These developments have paved the way for more sophisticated monitoring solutions in industrial settings. In the case of solenoid valves, IoT integration allows for continuous monitoring of various parameters such as valve position, temperature, pressure, and flow rates.

The primary objective of incorporating IoT in solenoid valve monitoring is to achieve a comprehensive and proactive approach to valve management. This includes early detection of potential failures, optimization of valve performance, and extension of valve lifespan. By leveraging IoT capabilities, organizations can transition from reactive maintenance strategies to predictive and prescriptive maintenance models, significantly reducing operational costs and improving overall system reliability.

Another key goal is to enhance decision-making processes through data-driven insights. IoT-enabled solenoid valve monitoring systems generate vast amounts of operational data, which can be analyzed to identify patterns, trends, and anomalies. This information empowers engineers and maintenance personnel to make informed decisions regarding valve maintenance, replacement, and system optimization.

Furthermore, the integration of IoT in solenoid valve monitoring aligns with broader industry trends towards digital transformation and Industry 4.0 initiatives. It represents a step towards creating more intelligent and interconnected industrial ecosystems, where various components communicate and collaborate seamlessly. This integration also supports sustainability goals by optimizing resource usage and reducing energy consumption through more efficient valve operation.

As we delve deeper into the technological landscape of IoT and solenoid valve monitoring, it becomes evident that this integration holds immense potential for revolutionizing industrial processes. The subsequent sections of this report will explore the market demands, technical challenges, and innovative solutions emerging in this dynamic field.

Market Demand Analysis for IoT-Enabled Valve Monitoring

The integration of IoT technology in monitoring solenoid valve performance has sparked significant market interest across various industries. This growing demand is driven by the increasing need for real-time monitoring, predictive maintenance, and improved operational efficiency in industrial processes.

The global market for IoT-enabled valve monitoring systems is experiencing robust growth, with a projected compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily fueled by the rising adoption of Industry 4.0 technologies and the increasing focus on reducing downtime and maintenance costs in manufacturing and process industries.

Key sectors driving the demand for IoT-enabled valve monitoring include oil and gas, water and wastewater management, chemical processing, and power generation. These industries are increasingly recognizing the value of continuous monitoring and data-driven decision-making in optimizing valve performance and preventing costly failures.

In the oil and gas sector, the need for remote monitoring of valves in harsh and hazardous environments has led to a surge in demand for IoT-enabled solutions. The ability to detect early signs of valve degradation and predict potential failures has become crucial for maintaining operational integrity and safety in offshore platforms and pipelines.

The water and wastewater management industry is another significant market for IoT-enabled valve monitoring. With increasing pressure to improve water conservation and reduce leakage, utilities are turning to smart valve monitoring systems to detect anomalies and optimize distribution networks. This trend is particularly pronounced in regions facing water scarcity and aging infrastructure challenges.

In the chemical processing industry, the demand for IoT-enabled valve monitoring is driven by the need for precise control of fluid flow and pressure in complex manufacturing processes. Real-time monitoring and analytics capabilities offered by IoT solutions enable plant operators to maintain optimal production conditions and ensure product quality.

The power generation sector is also showing increased interest in IoT-enabled valve monitoring, particularly in thermal and nuclear power plants. The ability to continuously monitor critical valves and predict maintenance needs helps improve plant reliability and reduce the risk of unplanned shutdowns.

Market analysis indicates that end-users are particularly interested in IoT solutions that offer seamless integration with existing industrial control systems, advanced analytics capabilities, and user-friendly interfaces for data visualization and reporting. There is also a growing demand for edge computing solutions that can process valve performance data locally, reducing latency and enhancing real-time decision-making capabilities.

As the market for IoT-enabled valve monitoring continues to evolve, there is an emerging trend towards the development of more sophisticated predictive maintenance algorithms and machine learning models. These advanced analytics capabilities are expected to further enhance the value proposition of IoT solutions in valve monitoring, driving adoption across a wider range of industries and applications.

The global market for IoT-enabled valve monitoring systems is experiencing robust growth, with a projected compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily fueled by the rising adoption of Industry 4.0 technologies and the increasing focus on reducing downtime and maintenance costs in manufacturing and process industries.

Key sectors driving the demand for IoT-enabled valve monitoring include oil and gas, water and wastewater management, chemical processing, and power generation. These industries are increasingly recognizing the value of continuous monitoring and data-driven decision-making in optimizing valve performance and preventing costly failures.

In the oil and gas sector, the need for remote monitoring of valves in harsh and hazardous environments has led to a surge in demand for IoT-enabled solutions. The ability to detect early signs of valve degradation and predict potential failures has become crucial for maintaining operational integrity and safety in offshore platforms and pipelines.

The water and wastewater management industry is another significant market for IoT-enabled valve monitoring. With increasing pressure to improve water conservation and reduce leakage, utilities are turning to smart valve monitoring systems to detect anomalies and optimize distribution networks. This trend is particularly pronounced in regions facing water scarcity and aging infrastructure challenges.

In the chemical processing industry, the demand for IoT-enabled valve monitoring is driven by the need for precise control of fluid flow and pressure in complex manufacturing processes. Real-time monitoring and analytics capabilities offered by IoT solutions enable plant operators to maintain optimal production conditions and ensure product quality.

The power generation sector is also showing increased interest in IoT-enabled valve monitoring, particularly in thermal and nuclear power plants. The ability to continuously monitor critical valves and predict maintenance needs helps improve plant reliability and reduce the risk of unplanned shutdowns.

Market analysis indicates that end-users are particularly interested in IoT solutions that offer seamless integration with existing industrial control systems, advanced analytics capabilities, and user-friendly interfaces for data visualization and reporting. There is also a growing demand for edge computing solutions that can process valve performance data locally, reducing latency and enhancing real-time decision-making capabilities.

As the market for IoT-enabled valve monitoring continues to evolve, there is an emerging trend towards the development of more sophisticated predictive maintenance algorithms and machine learning models. These advanced analytics capabilities are expected to further enhance the value proposition of IoT solutions in valve monitoring, driving adoption across a wider range of industries and applications.

Current Challenges in IoT Integration for Valve Performance

The integration of IoT in monitoring solenoid valve performance faces several significant challenges. One of the primary obstacles is the lack of standardization across IoT devices and protocols. This heterogeneity makes it difficult to establish seamless communication between various sensors, actuators, and control systems, often resulting in compatibility issues and increased complexity in system design and implementation.

Data security and privacy concerns pose another major challenge. As solenoid valves are often used in critical industrial processes, the data collected and transmitted through IoT networks can be sensitive and valuable. Ensuring robust encryption, secure data transmission, and protection against cyber-attacks is crucial but remains a complex task, especially in large-scale industrial environments with numerous connected devices.

The reliability and durability of IoT sensors in harsh industrial environments present additional hurdles. Solenoid valves are frequently deployed in conditions with extreme temperatures, high pressure, or corrosive substances. Developing IoT devices that can withstand these conditions while maintaining accurate and consistent performance over extended periods is technically challenging and often costly.

Power management is another significant issue, particularly for remote or hard-to-reach valve installations. Many IoT devices rely on batteries, and frequent battery replacements can be impractical and expensive. Developing energy-efficient sensors and communication protocols, or implementing energy harvesting technologies, remains an ongoing challenge in the field.

The sheer volume of data generated by IoT-enabled valve monitoring systems presents challenges in data management and analysis. Real-time processing of large datasets to extract meaningful insights and make timely decisions requires sophisticated analytics capabilities and often edge computing solutions. Balancing the need for comprehensive data collection with efficient data processing and storage is a complex task.

Scalability and interoperability issues also emerge as organizations attempt to implement IoT solutions across large valve networks. Ensuring that IoT systems can seamlessly integrate with existing industrial control systems, enterprise resource planning (ERP) software, and other business applications is crucial for realizing the full potential of IoT in valve performance monitoring.

Lastly, the skills gap in the workforce presents a human resource challenge. The implementation and maintenance of IoT systems for valve monitoring require personnel with expertise in both traditional industrial processes and modern IoT technologies. Training existing staff and recruiting skilled professionals who can bridge this knowledge gap remains a significant hurdle for many organizations.

Data security and privacy concerns pose another major challenge. As solenoid valves are often used in critical industrial processes, the data collected and transmitted through IoT networks can be sensitive and valuable. Ensuring robust encryption, secure data transmission, and protection against cyber-attacks is crucial but remains a complex task, especially in large-scale industrial environments with numerous connected devices.

The reliability and durability of IoT sensors in harsh industrial environments present additional hurdles. Solenoid valves are frequently deployed in conditions with extreme temperatures, high pressure, or corrosive substances. Developing IoT devices that can withstand these conditions while maintaining accurate and consistent performance over extended periods is technically challenging and often costly.

Power management is another significant issue, particularly for remote or hard-to-reach valve installations. Many IoT devices rely on batteries, and frequent battery replacements can be impractical and expensive. Developing energy-efficient sensors and communication protocols, or implementing energy harvesting technologies, remains an ongoing challenge in the field.

The sheer volume of data generated by IoT-enabled valve monitoring systems presents challenges in data management and analysis. Real-time processing of large datasets to extract meaningful insights and make timely decisions requires sophisticated analytics capabilities and often edge computing solutions. Balancing the need for comprehensive data collection with efficient data processing and storage is a complex task.

Scalability and interoperability issues also emerge as organizations attempt to implement IoT solutions across large valve networks. Ensuring that IoT systems can seamlessly integrate with existing industrial control systems, enterprise resource planning (ERP) software, and other business applications is crucial for realizing the full potential of IoT in valve performance monitoring.

Lastly, the skills gap in the workforce presents a human resource challenge. The implementation and maintenance of IoT systems for valve monitoring require personnel with expertise in both traditional industrial processes and modern IoT technologies. Training existing staff and recruiting skilled professionals who can bridge this knowledge gap remains a significant hurdle for many organizations.

Existing IoT Solutions for Solenoid Valve Monitoring

01 Improved valve design for enhanced performance

Solenoid valve performance can be improved through innovative design features. These may include optimized flow paths, reduced friction, and enhanced sealing mechanisms. Such designs can lead to better response times, increased efficiency, and improved overall valve performance.- Improved valve design for enhanced performance: Solenoid valve performance can be improved through innovative design features. These may include optimized flow paths, reduced friction in moving parts, and enhanced sealing mechanisms. Such designs can lead to faster response times, increased reliability, and improved overall efficiency of the valve.

- Advanced materials for solenoid valve components: The use of advanced materials in solenoid valve construction can significantly enhance performance. Materials with superior magnetic properties can improve the valve's response to electrical signals, while corrosion-resistant and wear-resistant materials can extend the valve's lifespan and maintain consistent performance over time.

- Electronic control systems for precise valve operation: Integration of sophisticated electronic control systems can greatly enhance solenoid valve performance. These systems can provide precise timing and control of valve operations, allow for adaptive responses to changing conditions, and enable real-time monitoring and diagnostics of valve performance.

- Energy-efficient solenoid valve designs: Improving the energy efficiency of solenoid valves is crucial for enhancing overall performance. This can be achieved through designs that minimize power consumption during operation, utilize energy recovery mechanisms, or incorporate low-power holding circuits to maintain valve position with reduced energy input.

- Performance testing and quality control methods: Developing and implementing rigorous performance testing and quality control methods is essential for ensuring consistent and reliable solenoid valve performance. This includes advanced testing procedures, automated inspection systems, and data-driven analysis techniques to identify and address potential performance issues.

02 Advanced materials for solenoid valve components

The use of advanced materials in solenoid valve construction can significantly impact performance. Materials with improved magnetic properties, wear resistance, and thermal stability can enhance valve longevity, reduce power consumption, and improve operational reliability across various conditions.Expand Specific Solutions03 Electronic control and monitoring systems

Integration of sophisticated electronic control and monitoring systems can optimize solenoid valve performance. These systems can provide precise actuation timing, real-time performance feedback, and predictive maintenance capabilities, leading to improved efficiency and reduced downtime.Expand Specific Solutions04 Energy-efficient solenoid valve designs

Developing energy-efficient solenoid valve designs is crucial for improving overall performance. This can involve optimizing coil designs, implementing power-saving modes, and utilizing energy recovery mechanisms. Such innovations can lead to reduced power consumption and heat generation, enhancing valve longevity and reliability.Expand Specific Solutions05 Performance testing and quality control methods

Implementing advanced performance testing and quality control methods can ensure consistent and reliable solenoid valve operation. This may include automated testing procedures, precision measurement techniques, and rigorous quality assurance protocols to identify and address potential performance issues before valve deployment.Expand Specific Solutions

Key Players in IoT and Valve Monitoring Industries

The Internet of Things (IoT) integration in monitoring solenoid valve performance is in a growth phase, with increasing market size and technological advancements. The global IoT in manufacturing market is expected to expand significantly, driven by the need for real-time monitoring and predictive maintenance. Companies like Hangzhou Innover Technology, Chengdu Qinchuan IoT Technology, and IBM are at the forefront, developing sophisticated IoT solutions for industrial applications. These firms are leveraging their expertise in sensor technology, data analytics, and cloud computing to enhance solenoid valve monitoring capabilities, indicating a moderate to high level of technological maturity in this specific application area.

International Business Machines Corp.

Technical Solution: IBM's IoT integration for monitoring solenoid valve performance leverages their Watson IoT platform. This cloud-based solution utilizes advanced analytics and machine learning to process real-time data from sensors attached to solenoid valves. The system employs edge computing for immediate data processing, reducing latency and enabling rapid response to potential issues. IBM's solution incorporates predictive maintenance algorithms that analyze valve operation patterns, predicting failures before they occur[1]. The platform also integrates with IBM's Maximo Asset Management system, providing a comprehensive view of valve health and performance across entire industrial operations[2].

Strengths: Robust analytics capabilities, seamless integration with existing IBM ecosystems, and scalability for large-scale industrial applications. Weaknesses: Potential complexity for smaller operations and dependence on cloud connectivity for full functionality.

Hitachi Industrial Equipment Systems Co., Ltd.

Technical Solution: Hitachi's IoT integration for solenoid valve monitoring is part of their broader Lumada IoT platform. Their solution combines advanced sensing technologies with AI-driven analytics to provide comprehensive valve health monitoring. Hitachi employs a combination of vibration sensors, temperature sensors, and electromagnetic field sensors to capture a wide range of valve performance data. The system utilizes edge computing devices to perform initial data processing and anomaly detection, reducing data transmission loads and enabling rapid response to critical issues[7]. Hitachi's AI algorithms analyze historical and real-time data to predict valve lifespan, optimize maintenance schedules, and identify potential failure modes. The solution also integrates with Hitachi's manufacturing execution systems (MES) for seamless incorporation into existing industrial processes[8].

Strengths: Comprehensive industrial expertise, strong AI capabilities, and integration with broader manufacturing systems. Weaknesses: Potentially higher cost for full system implementation and possible vendor lock-in.

Core Innovations in IoT-Based Valve Performance Tracking

Device for monitoring the operation of a solenoid valve and method for monitoring the operation of solenoid valve operation

PatentActivePL438382A1

Innovation

- Dual-channel current measurement system with a regular channel (K2) and an amplified channel (K3) for improved accuracy and range.

- Adaptive gain control of the regulated amplifier to ensure the amplified signal stays within the measuring range of channel K3.

- Automatic power cut-off mechanism when the current drawn exceeds a threshold value, providing protection against overcurrent.

Web dashboard-monitored and operated control valves in the automotive industry with add-on IoT system

PatentPendingIN202411024438A

Innovation

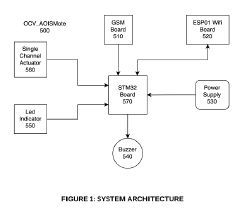

- The integration of IoT technologies, specifically using an STM32 Board as the microcontroller, ESP01 Wifi Board for wireless connectivity, GSM Board for network communication, and a Single Channel Actuator for remote operation, along with a customized web dashboard for monitoring and control, enables remote monitoring and operation of control valves.

Cybersecurity Considerations for IoT-Enabled Valve Systems

The integration of IoT technologies in valve systems has revolutionized monitoring and control capabilities, but it has also introduced significant cybersecurity risks. As these systems become more interconnected, they present an expanded attack surface for malicious actors. Cybersecurity considerations for IoT-enabled valve systems must address vulnerabilities at multiple levels, including device hardware, firmware, network communications, and cloud infrastructure.

At the device level, secure hardware design is crucial. Implementing tamper-resistant components, secure boot processes, and hardware-based encryption can protect against physical attacks and unauthorized access. Firmware security is equally important, requiring regular updates, secure coding practices, and robust authentication mechanisms to prevent exploitation of software vulnerabilities.

Network security is a critical concern for IoT-enabled valve systems. Implementing end-to-end encryption for all data transmissions, using secure protocols, and segmenting networks can help protect against eavesdropping and man-in-the-middle attacks. Additionally, strong access controls, including multi-factor authentication and role-based access, should be enforced to ensure that only authorized personnel can interact with the system.

Cloud infrastructure security is essential for protecting the vast amounts of data generated by IoT-enabled valve systems. Implementing robust data encryption, both in transit and at rest, along with secure APIs and regular security audits, can help safeguard sensitive information and prevent unauthorized access to control systems.

Continuous monitoring and threat detection are vital components of a comprehensive cybersecurity strategy for IoT-enabled valve systems. Implementing intrusion detection systems, security information and event management (SIEM) solutions, and conducting regular vulnerability assessments can help identify and mitigate potential threats before they can cause significant damage.

Supply chain security is another critical consideration. Ensuring that all components and software used in IoT-enabled valve systems come from trusted sources and have not been compromised during manufacturing or distribution is essential for maintaining overall system integrity.

As the regulatory landscape evolves, compliance with industry standards and government regulations becomes increasingly important. Adhering to frameworks such as IEC 62443 for industrial control systems and the NIST Cybersecurity Framework can provide a solid foundation for securing IoT-enabled valve systems.

At the device level, secure hardware design is crucial. Implementing tamper-resistant components, secure boot processes, and hardware-based encryption can protect against physical attacks and unauthorized access. Firmware security is equally important, requiring regular updates, secure coding practices, and robust authentication mechanisms to prevent exploitation of software vulnerabilities.

Network security is a critical concern for IoT-enabled valve systems. Implementing end-to-end encryption for all data transmissions, using secure protocols, and segmenting networks can help protect against eavesdropping and man-in-the-middle attacks. Additionally, strong access controls, including multi-factor authentication and role-based access, should be enforced to ensure that only authorized personnel can interact with the system.

Cloud infrastructure security is essential for protecting the vast amounts of data generated by IoT-enabled valve systems. Implementing robust data encryption, both in transit and at rest, along with secure APIs and regular security audits, can help safeguard sensitive information and prevent unauthorized access to control systems.

Continuous monitoring and threat detection are vital components of a comprehensive cybersecurity strategy for IoT-enabled valve systems. Implementing intrusion detection systems, security information and event management (SIEM) solutions, and conducting regular vulnerability assessments can help identify and mitigate potential threats before they can cause significant damage.

Supply chain security is another critical consideration. Ensuring that all components and software used in IoT-enabled valve systems come from trusted sources and have not been compromised during manufacturing or distribution is essential for maintaining overall system integrity.

As the regulatory landscape evolves, compliance with industry standards and government regulations becomes increasingly important. Adhering to frameworks such as IEC 62443 for industrial control systems and the NIST Cybersecurity Framework can provide a solid foundation for securing IoT-enabled valve systems.

Environmental Impact of IoT-Enhanced Valve Monitoring

The integration of IoT technology in monitoring solenoid valve performance has significant environmental implications. By enhancing the efficiency and accuracy of valve monitoring systems, IoT solutions contribute to reduced resource consumption and minimized environmental impact across various industries.

One of the primary environmental benefits of IoT-enhanced valve monitoring is the optimization of energy consumption. Smart sensors and real-time data analytics enable precise control of valve operations, reducing unnecessary energy expenditure. This leads to lower electricity consumption in industrial processes, contributing to decreased carbon emissions and a smaller overall carbon footprint.

Water conservation is another crucial environmental aspect improved by IoT-enabled valve monitoring. In water management systems, smart valves can detect leaks, monitor flow rates, and adjust water distribution based on real-time demand. This results in significant water savings, particularly in agriculture and urban water supply networks, helping to preserve this vital natural resource.

The implementation of IoT in valve monitoring also contributes to waste reduction. By providing early detection of valve malfunctions or wear, maintenance can be performed proactively, extending the lifespan of equipment and reducing the need for premature replacements. This approach minimizes the production of industrial waste and conserves raw materials used in manufacturing replacement parts.

Furthermore, IoT-enhanced valve monitoring plays a crucial role in preventing environmental accidents. In industries dealing with hazardous materials, such as chemical processing or oil and gas, advanced monitoring systems can quickly detect and respond to potential leaks or failures, significantly reducing the risk of environmental contamination.

The environmental impact extends to air quality improvement as well. In HVAC systems and industrial processes involving gas flow control, IoT-enabled valves can optimize air circulation and filtration, leading to better indoor air quality and reduced emissions of pollutants into the atmosphere.

Lastly, the data collected through IoT valve monitoring systems contributes to more sustainable practices in the long term. By analyzing patterns and trends in valve performance, industries can make informed decisions about process improvements, leading to more efficient resource utilization and reduced environmental impact over time.

In conclusion, the environmental impact of IoT-enhanced valve monitoring is multifaceted and predominantly positive. From energy and water conservation to waste reduction and pollution prevention, this technology plays a significant role in promoting sustainability across various sectors. As IoT solutions continue to evolve, their potential for further environmental benefits in valve monitoring applications is likely to expand, contributing to global efforts in environmental protection and resource conservation.

One of the primary environmental benefits of IoT-enhanced valve monitoring is the optimization of energy consumption. Smart sensors and real-time data analytics enable precise control of valve operations, reducing unnecessary energy expenditure. This leads to lower electricity consumption in industrial processes, contributing to decreased carbon emissions and a smaller overall carbon footprint.

Water conservation is another crucial environmental aspect improved by IoT-enabled valve monitoring. In water management systems, smart valves can detect leaks, monitor flow rates, and adjust water distribution based on real-time demand. This results in significant water savings, particularly in agriculture and urban water supply networks, helping to preserve this vital natural resource.

The implementation of IoT in valve monitoring also contributes to waste reduction. By providing early detection of valve malfunctions or wear, maintenance can be performed proactively, extending the lifespan of equipment and reducing the need for premature replacements. This approach minimizes the production of industrial waste and conserves raw materials used in manufacturing replacement parts.

Furthermore, IoT-enhanced valve monitoring plays a crucial role in preventing environmental accidents. In industries dealing with hazardous materials, such as chemical processing or oil and gas, advanced monitoring systems can quickly detect and respond to potential leaks or failures, significantly reducing the risk of environmental contamination.

The environmental impact extends to air quality improvement as well. In HVAC systems and industrial processes involving gas flow control, IoT-enabled valves can optimize air circulation and filtration, leading to better indoor air quality and reduced emissions of pollutants into the atmosphere.

Lastly, the data collected through IoT valve monitoring systems contributes to more sustainable practices in the long term. By analyzing patterns and trends in valve performance, industries can make informed decisions about process improvements, leading to more efficient resource utilization and reduced environmental impact over time.

In conclusion, the environmental impact of IoT-enhanced valve monitoring is multifaceted and predominantly positive. From energy and water conservation to waste reduction and pollution prevention, this technology plays a significant role in promoting sustainability across various sectors. As IoT solutions continue to evolve, their potential for further environmental benefits in valve monitoring applications is likely to expand, contributing to global efforts in environmental protection and resource conservation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!