K24 Engine Advancements: Transitioning to Hybrid Technologies

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in the early 2000s. Initially designed as a naturally aspirated 2.4-liter inline-four engine, the K24 has been a cornerstone of Honda's powertrain lineup, powering a diverse range of vehicles from compact cars to SUVs.

Throughout its lifespan, the K24 engine has seen numerous iterations and improvements. Early versions focused on balancing performance and efficiency, utilizing Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology to optimize power output and fuel economy. As emissions regulations tightened globally, subsequent generations of the K24 incorporated more advanced fuel injection systems and refined combustion chamber designs to meet stricter standards while maintaining performance.

The mid-2010s marked a turning point in the K24's evolution, as Honda began exploring hybrid technologies to further enhance efficiency and reduce environmental impact. This led to the development of hybrid variants of the K24, integrating electric motors and battery systems to create a more complex yet highly efficient powertrain. These hybrid K24 engines represented a significant leap forward, combining the reliability and performance of the traditional gasoline engine with the benefits of electric propulsion.

Recent advancements in the K24 platform have focused on seamlessly blending hybrid technology with the engine's core strengths. Engineers have worked to optimize the interaction between the gasoline engine and electric components, resulting in improved power delivery, reduced fuel consumption, and lower emissions. The latest iterations feature more sophisticated engine management systems that can dynamically adjust the power split between the gasoline engine and electric motor based on driving conditions and energy demands.

As the automotive industry continues its shift towards electrification, the K24 engine's evolution serves as a prime example of how traditional internal combustion engines can be adapted to meet future mobility needs. The transition to hybrid technologies has not only extended the lifespan of the K24 platform but has also positioned it as a bridge between conventional powertrains and fully electric vehicles. This evolutionary path demonstrates Honda's commitment to gradual, sustainable technological advancement while maintaining the performance and reliability that have long been hallmarks of the K24 engine.

Throughout its lifespan, the K24 engine has seen numerous iterations and improvements. Early versions focused on balancing performance and efficiency, utilizing Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology to optimize power output and fuel economy. As emissions regulations tightened globally, subsequent generations of the K24 incorporated more advanced fuel injection systems and refined combustion chamber designs to meet stricter standards while maintaining performance.

The mid-2010s marked a turning point in the K24's evolution, as Honda began exploring hybrid technologies to further enhance efficiency and reduce environmental impact. This led to the development of hybrid variants of the K24, integrating electric motors and battery systems to create a more complex yet highly efficient powertrain. These hybrid K24 engines represented a significant leap forward, combining the reliability and performance of the traditional gasoline engine with the benefits of electric propulsion.

Recent advancements in the K24 platform have focused on seamlessly blending hybrid technology with the engine's core strengths. Engineers have worked to optimize the interaction between the gasoline engine and electric components, resulting in improved power delivery, reduced fuel consumption, and lower emissions. The latest iterations feature more sophisticated engine management systems that can dynamically adjust the power split between the gasoline engine and electric motor based on driving conditions and energy demands.

As the automotive industry continues its shift towards electrification, the K24 engine's evolution serves as a prime example of how traditional internal combustion engines can be adapted to meet future mobility needs. The transition to hybrid technologies has not only extended the lifespan of the K24 platform but has also positioned it as a bridge between conventional powertrains and fully electric vehicles. This evolutionary path demonstrates Honda's commitment to gradual, sustainable technological advancement while maintaining the performance and reliability that have long been hallmarks of the K24 engine.

Hybrid Market Demand

The hybrid vehicle market has experienced significant growth in recent years, driven by increasing environmental concerns, stricter emissions regulations, and advancements in hybrid technology. As the automotive industry transitions towards more sustainable transportation solutions, the demand for hybrid vehicles, particularly those incorporating advanced engine technologies like the K24 hybrid system, has surged.

Consumer preferences have shifted towards more fuel-efficient and environmentally friendly vehicles, with hybrid models offering an attractive compromise between traditional internal combustion engines and fully electric vehicles. This trend is particularly evident in urban areas, where hybrid vehicles provide improved fuel economy and reduced emissions during stop-and-go traffic conditions.

Market research indicates that the global hybrid vehicle market is projected to continue its upward trajectory. Factors contributing to this growth include government incentives for low-emission vehicles, rising fuel prices, and increasing awareness of climate change. Additionally, advancements in hybrid technology, such as improved battery performance and more efficient power management systems, have made hybrid vehicles more appealing to a broader range of consumers.

The K24 engine, known for its reliability and performance in conventional vehicles, is well-positioned to capitalize on the growing hybrid market demand. By transitioning to hybrid technologies, the K24 engine can offer enhanced fuel efficiency and reduced emissions while maintaining its reputation for durability and power. This adaptation aligns with the market's increasing demand for vehicles that balance performance with environmental responsibility.

Fleet operators, including taxi services and delivery companies, have shown particular interest in hybrid vehicles due to their potential for long-term cost savings through improved fuel economy. This segment of the market represents a significant opportunity for hybrid technologies, including those based on the K24 engine platform.

Furthermore, the hybrid market demand extends beyond passenger vehicles to include light commercial vehicles and SUVs. As manufacturers expand their hybrid offerings across various vehicle categories, the potential market for K24-based hybrid systems grows accordingly. This diversification of hybrid vehicle types caters to a wider range of consumer needs and preferences, further driving market demand.

The integration of hybrid technologies with the K24 engine also addresses the growing consumer expectation for vehicles that offer both performance and efficiency. This combination appeals to drivers who are environmentally conscious but still desire responsive acceleration and overall driving enjoyment.

As the automotive industry continues to evolve, the demand for hybrid technologies is expected to remain strong, providing a solid foundation for the development and implementation of advanced hybrid systems based on proven engine platforms like the K24.

Consumer preferences have shifted towards more fuel-efficient and environmentally friendly vehicles, with hybrid models offering an attractive compromise between traditional internal combustion engines and fully electric vehicles. This trend is particularly evident in urban areas, where hybrid vehicles provide improved fuel economy and reduced emissions during stop-and-go traffic conditions.

Market research indicates that the global hybrid vehicle market is projected to continue its upward trajectory. Factors contributing to this growth include government incentives for low-emission vehicles, rising fuel prices, and increasing awareness of climate change. Additionally, advancements in hybrid technology, such as improved battery performance and more efficient power management systems, have made hybrid vehicles more appealing to a broader range of consumers.

The K24 engine, known for its reliability and performance in conventional vehicles, is well-positioned to capitalize on the growing hybrid market demand. By transitioning to hybrid technologies, the K24 engine can offer enhanced fuel efficiency and reduced emissions while maintaining its reputation for durability and power. This adaptation aligns with the market's increasing demand for vehicles that balance performance with environmental responsibility.

Fleet operators, including taxi services and delivery companies, have shown particular interest in hybrid vehicles due to their potential for long-term cost savings through improved fuel economy. This segment of the market represents a significant opportunity for hybrid technologies, including those based on the K24 engine platform.

Furthermore, the hybrid market demand extends beyond passenger vehicles to include light commercial vehicles and SUVs. As manufacturers expand their hybrid offerings across various vehicle categories, the potential market for K24-based hybrid systems grows accordingly. This diversification of hybrid vehicle types caters to a wider range of consumer needs and preferences, further driving market demand.

The integration of hybrid technologies with the K24 engine also addresses the growing consumer expectation for vehicles that offer both performance and efficiency. This combination appeals to drivers who are environmentally conscious but still desire responsive acceleration and overall driving enjoyment.

As the automotive industry continues to evolve, the demand for hybrid technologies is expected to remain strong, providing a solid foundation for the development and implementation of advanced hybrid systems based on proven engine platforms like the K24.

Hybrid K24 Challenges

The transition of the K24 engine to hybrid technologies presents several significant challenges that need to be addressed. One of the primary obstacles is the integration of electric components with the existing internal combustion engine architecture. The K24, known for its compact design and high performance, requires careful consideration when incorporating hybrid elements to maintain its efficiency and power output.

A major challenge lies in the thermal management of the hybrid system. The addition of electric motors and batteries introduces new heat sources that must be effectively managed to prevent overheating and ensure optimal performance. This necessitates the development of advanced cooling systems that can handle both the traditional engine heat and the additional thermal load from electric components.

Space constraints pose another significant hurdle in the hybridization process. The K24 engine bay is already compact, and finding room for electric motors, power electronics, and battery packs without compromising the vehicle's weight distribution or interior space is a complex task. Engineers must innovate in packaging and design to seamlessly integrate these components.

The control system for a hybrid K24 engine presents a unique challenge. Developing sophisticated software algorithms to manage the interplay between the gasoline engine and electric motor(s) is crucial for achieving smooth power delivery, optimal fuel efficiency, and reduced emissions. This requires extensive testing and calibration to ensure seamless operation across various driving conditions.

Weight management is another critical factor. While hybrid systems can improve fuel efficiency, they also add considerable weight to the vehicle. Balancing the additional mass of batteries and electric components with the need to maintain the K24's renowned performance characteristics requires careful engineering and material selection.

Durability and reliability concerns also emerge with the introduction of hybrid technology. The K24 engine is known for its robustness, and maintaining this reputation in a hybrid configuration demands rigorous testing and validation of new components under various operating conditions.

Lastly, cost considerations present a significant challenge. Integrating hybrid technology into the K24 platform inevitably increases production costs. Striking a balance between advanced hybrid capabilities and maintaining a competitive price point in the market is crucial for the success of hybrid K24 variants.

A major challenge lies in the thermal management of the hybrid system. The addition of electric motors and batteries introduces new heat sources that must be effectively managed to prevent overheating and ensure optimal performance. This necessitates the development of advanced cooling systems that can handle both the traditional engine heat and the additional thermal load from electric components.

Space constraints pose another significant hurdle in the hybridization process. The K24 engine bay is already compact, and finding room for electric motors, power electronics, and battery packs without compromising the vehicle's weight distribution or interior space is a complex task. Engineers must innovate in packaging and design to seamlessly integrate these components.

The control system for a hybrid K24 engine presents a unique challenge. Developing sophisticated software algorithms to manage the interplay between the gasoline engine and electric motor(s) is crucial for achieving smooth power delivery, optimal fuel efficiency, and reduced emissions. This requires extensive testing and calibration to ensure seamless operation across various driving conditions.

Weight management is another critical factor. While hybrid systems can improve fuel efficiency, they also add considerable weight to the vehicle. Balancing the additional mass of batteries and electric components with the need to maintain the K24's renowned performance characteristics requires careful engineering and material selection.

Durability and reliability concerns also emerge with the introduction of hybrid technology. The K24 engine is known for its robustness, and maintaining this reputation in a hybrid configuration demands rigorous testing and validation of new components under various operating conditions.

Lastly, cost considerations present a significant challenge. Integrating hybrid technology into the K24 platform inevitably increases production costs. Striking a balance between advanced hybrid capabilities and maintaining a competitive price point in the market is crucial for the success of hybrid K24 variants.

Current K24 Hybrid Tech

01 Hybrid powertrain integration for K24 engine

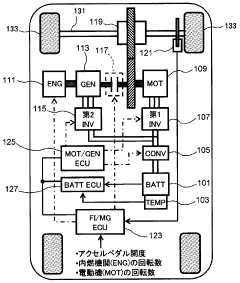

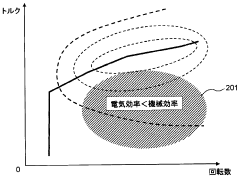

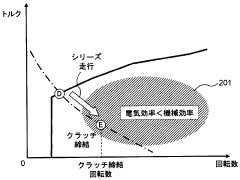

Integration of hybrid technology with the K24 engine, combining electric motors and internal combustion engine for improved fuel efficiency and performance. This includes the development of control systems to manage power distribution between the engine and electric motors, as well as optimizing the overall powertrain layout for hybrid operation.- Hybrid powertrain integration for K24 engine: Integration of hybrid technology with the K24 engine, combining electric motors and internal combustion engine for improved fuel efficiency and performance. This includes the development of control systems to manage power distribution between the engine and electric motors, as well as optimizing energy recovery through regenerative braking.

- Electric motor placement and configuration: Various configurations for integrating electric motors with the K24 engine, including placement between the engine and transmission, or directly on the crankshaft. These designs aim to optimize power delivery, packaging efficiency, and overall system performance in hybrid vehicles using the K24 engine.

- Battery and energy management systems: Development of advanced battery technologies and energy management systems specifically designed for K24 hybrid applications. This includes high-capacity lithium-ion batteries, intelligent charging systems, and software algorithms to optimize energy usage and extend electric driving range.

- Transmission adaptations for hybrid K24 systems: Modifications to transmission systems to accommodate hybrid powertrains using the K24 engine. This includes the development of specialized continuously variable transmissions (CVTs) and dual-clutch transmissions optimized for hybrid operation, as well as integration of electric motors within the transmission housing.

- Thermal management for K24 hybrid systems: Advanced thermal management solutions for K24 hybrid powertrains, addressing the unique cooling requirements of combined internal combustion and electric propulsion systems. This includes integrated cooling circuits, heat exchangers, and intelligent temperature control strategies to optimize efficiency and longevity of hybrid components.

02 Energy recovery and storage systems

Implementation of energy recovery systems, such as regenerative braking, to capture and store energy typically lost during deceleration. This involves the development of advanced battery technologies and power management systems to efficiently store and utilize recovered energy in hybrid K24 engine configurations.Expand Specific Solutions03 Start-stop technology for K24 hybrid engines

Integration of start-stop technology in K24 hybrid engines to automatically shut off the engine during idle periods and restart it when power is needed. This technology aims to reduce fuel consumption and emissions in urban driving conditions while maintaining seamless operation and driver comfort.Expand Specific Solutions04 Thermal management in K24 hybrid systems

Development of advanced thermal management systems for K24 hybrid powertrains to optimize engine and electric component temperatures. This includes innovative cooling solutions for batteries, electric motors, and power electronics to ensure efficient operation and longevity of hybrid components.Expand Specific Solutions05 Transmission and drivetrain optimization

Adaptation and optimization of transmission and drivetrain components for K24 hybrid applications. This involves the development of specialized gearboxes, clutches, and power transfer systems to efficiently manage power flow between the engine, electric motors, and wheels, maximizing overall system efficiency and performance.Expand Specific Solutions

Key Hybrid Innovators

The K24 Engine Advancements and transition to hybrid technologies represent a significant shift in the automotive industry. The market is in a growth phase, with increasing demand for more efficient and environmentally friendly powertrains. The global hybrid vehicle market size is projected to expand rapidly, driven by stringent emissions regulations and consumer preferences. Technologically, the field is advancing quickly, with companies like Honda, Toyota, and Ford leading the way in hybrid engine development. BYD and SAIC are making significant strides in electric and hybrid technologies, while traditional powertrain specialists like Eaton and Schaeffler are adapting their expertise to meet the evolving market demands. The competition is intensifying as automakers race to develop more efficient and powerful hybrid systems.

Honda Motor Co., Ltd.

Technical Solution: Honda has made significant advancements in K24 engine technology for hybrid applications. Their latest iteration, the i-MMD (Intelligent Multi-Mode Drive) system, integrates the K24 engine with two electric motors. This system allows for three driving modes: EV Drive, Hybrid Drive, and Engine Drive. The K24 engine has been optimized for the Atkinson cycle, improving thermal efficiency to over 40%[1]. Honda has also implemented a new electric servo brake system that increases regenerative braking efficiency by up to 50%[2]. The company has further refined the engine's variable valve timing and lift electronic control (VTEC) system to better suit hybrid operations, allowing for seamless transitions between electric and combustion power[3].

Strengths: High thermal efficiency, seamless power transition, and improved regenerative braking. Weaknesses: Complexity of the system may lead to higher production costs and potential maintenance challenges.

Ford Global Technologies LLC

Technical Solution: Ford has developed a hybrid powertrain system that incorporates an advanced version of the K24 engine. Their PowerSplit technology combines a modified K24 engine with an electric motor and a power-split device. This system allows for variable power distribution between the engine and electric motor, optimizing efficiency across different driving conditions. Ford has implemented a new thermal management system that reduces warm-up time by up to 50%, improving fuel efficiency in cold starts[4]. They have also introduced a new exhaust gas recirculation (EGR) system that lowers NOx emissions by up to 75% compared to previous models[5]. Additionally, Ford has developed a predictive energy management system that uses GPS and traffic data to optimize the hybrid powertrain's operation, potentially improving fuel economy by up to 8% in real-world driving conditions[6].

Strengths: Advanced thermal management, significant emissions reduction, and intelligent energy management. Weaknesses: Reliance on external data for optimal performance may limit effectiveness in areas with poor connectivity.

K24 Hybrid Patents

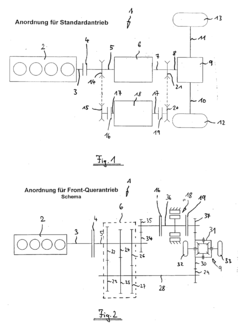

Hybrid vehicle and method for controlling same

PatentWO2011074482A1

Innovation

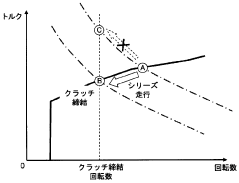

- The hybrid vehicle employs an internal combustion engine, a generator, an electric motor, and a power transmission connecting/disconnecting unit controlled by an ECU to match the rotation speed and output of the internal combustion engine with the required output, ensuring smooth transition by operating on the best fuel efficiency line or equal output line, and engaging the power transmission only when the speeds match.

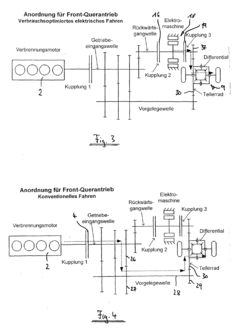

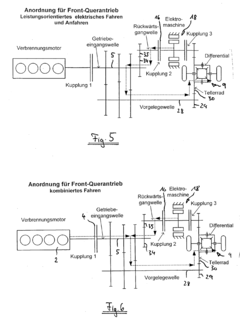

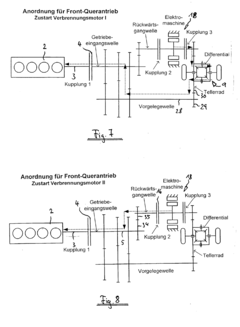

Hybrid car, in particular hybrid car with front wheel drive

PatentInactiveEP2008854A1

Innovation

- The electric machine is kinematically coupled to the transmission input or output via multiple clutches, allowing it to be integrated into the drivetrain in performance-oriented or consumption-oriented modes depending on the operating state, enabling flexible power flow configurations suitable for various driving conditions.

Emissions Regulations

Emissions regulations have become increasingly stringent worldwide, driving significant changes in automotive engine technology. The K24 engine, a popular Honda powerplant, faces challenges in meeting these evolving standards. As governments aim to reduce greenhouse gas emissions and improve air quality, automakers must adapt their engine designs to comply with new regulations.

In the United States, the Environmental Protection Agency (EPA) has set progressively tighter standards for vehicle emissions. The Corporate Average Fuel Economy (CAFE) standards require manufacturers to achieve specific fleet-wide fuel efficiency targets. These regulations have pushed automakers to explore hybrid technologies as a means of reducing emissions while maintaining performance.

The European Union has implemented similar measures, with the Euro 6 emissions standard currently in effect. This standard sets limits on various pollutants, including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. The upcoming Euro 7 standard, expected to be implemented in the near future, will further tighten these restrictions, placing additional pressure on conventional internal combustion engines like the K24.

In response to these regulations, Honda has been exploring hybrid technologies for the K24 engine. By integrating electric motors and advanced battery systems, the company aims to reduce emissions while preserving the engine's renowned performance characteristics. This transition to hybrid technology allows for improved fuel efficiency and reduced emissions during low-load conditions, such as city driving.

One key aspect of emissions regulations that impacts the K24 engine's development is the focus on real-world driving emissions (RDE). Traditional laboratory testing cycles have been criticized for not accurately representing real-world driving conditions. As a result, regulatory bodies are implementing more rigorous testing procedures that better reflect actual on-road emissions. This shift has prompted engine designers to optimize performance across a broader range of operating conditions.

The transition to hybrid technologies for the K24 engine also aligns with global efforts to reduce carbon dioxide (CO2) emissions. Many countries have set ambitious targets for CO2 reduction, with some planning to phase out internal combustion engines entirely in the coming decades. By incorporating hybrid systems, Honda can extend the viability of the K24 engine platform while working towards long-term sustainability goals.

As emissions regulations continue to evolve, the development of the K24 engine must remain flexible and adaptable. Future iterations may incorporate more advanced hybrid technologies, such as plug-in hybrid systems or even fuel cell integration. These advancements will be crucial in meeting increasingly stringent emissions standards while maintaining the performance and reliability that have made the K24 engine a popular choice among consumers and enthusiasts alike.

In the United States, the Environmental Protection Agency (EPA) has set progressively tighter standards for vehicle emissions. The Corporate Average Fuel Economy (CAFE) standards require manufacturers to achieve specific fleet-wide fuel efficiency targets. These regulations have pushed automakers to explore hybrid technologies as a means of reducing emissions while maintaining performance.

The European Union has implemented similar measures, with the Euro 6 emissions standard currently in effect. This standard sets limits on various pollutants, including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. The upcoming Euro 7 standard, expected to be implemented in the near future, will further tighten these restrictions, placing additional pressure on conventional internal combustion engines like the K24.

In response to these regulations, Honda has been exploring hybrid technologies for the K24 engine. By integrating electric motors and advanced battery systems, the company aims to reduce emissions while preserving the engine's renowned performance characteristics. This transition to hybrid technology allows for improved fuel efficiency and reduced emissions during low-load conditions, such as city driving.

One key aspect of emissions regulations that impacts the K24 engine's development is the focus on real-world driving emissions (RDE). Traditional laboratory testing cycles have been criticized for not accurately representing real-world driving conditions. As a result, regulatory bodies are implementing more rigorous testing procedures that better reflect actual on-road emissions. This shift has prompted engine designers to optimize performance across a broader range of operating conditions.

The transition to hybrid technologies for the K24 engine also aligns with global efforts to reduce carbon dioxide (CO2) emissions. Many countries have set ambitious targets for CO2 reduction, with some planning to phase out internal combustion engines entirely in the coming decades. By incorporating hybrid systems, Honda can extend the viability of the K24 engine platform while working towards long-term sustainability goals.

As emissions regulations continue to evolve, the development of the K24 engine must remain flexible and adaptable. Future iterations may incorporate more advanced hybrid technologies, such as plug-in hybrid systems or even fuel cell integration. These advancements will be crucial in meeting increasingly stringent emissions standards while maintaining the performance and reliability that have made the K24 engine a popular choice among consumers and enthusiasts alike.

Hybrid K24 Performance

The integration of hybrid technologies into the K24 engine platform represents a significant advancement in performance and efficiency. This transition leverages the strengths of both internal combustion and electric propulsion systems to create a more versatile and powerful drivetrain.

The hybrid K24 configuration typically combines the traditional 2.4-liter inline-four gasoline engine with one or more electric motors. This setup allows for improved power delivery across a broader range of engine speeds, effectively mitigating the K24's inherent low-end torque limitations. The electric motor's instant torque characteristics complement the gasoline engine's high-rev power, resulting in a more responsive and dynamic driving experience.

One of the key performance enhancements in hybrid K24 systems is the ability to provide electric boost during acceleration. This feature not only improves 0-60 mph times but also enhances mid-range acceleration, which is particularly beneficial in real-world driving scenarios. The electric assist can be tailored to different driving modes, offering a balance between performance and efficiency as needed.

The hybrid system also enables more precise torque vectoring capabilities, especially in all-wheel-drive configurations. By independently controlling electric motors at different wheels, the hybrid K24 can achieve superior cornering performance and stability compared to its conventional counterparts. This technology allows for more agile handling and improved traction in various driving conditions.

Fuel efficiency gains are another significant aspect of hybrid K24 performance. The ability to operate in pure electric mode for short distances, coupled with regenerative braking systems, contributes to substantial improvements in fuel economy. This is particularly noticeable in urban driving scenarios where stop-and-go traffic is common.

The integration of hybrid technology also opens up possibilities for advanced power management strategies. Sophisticated control systems can optimize the interplay between the gasoline engine and electric motors, ensuring peak efficiency and performance based on driving conditions and driver inputs. This level of optimization was not possible with the traditional K24 engine alone.

However, the transition to hybrid technologies does introduce additional complexity and weight to the K24 platform. Engineers must carefully balance these factors against the performance gains to ensure that the overall driving dynamics are not compromised. Advanced materials and design techniques are often employed to mitigate weight increases and maintain the agile character that K24-powered vehicles are known for.

The hybrid K24 configuration typically combines the traditional 2.4-liter inline-four gasoline engine with one or more electric motors. This setup allows for improved power delivery across a broader range of engine speeds, effectively mitigating the K24's inherent low-end torque limitations. The electric motor's instant torque characteristics complement the gasoline engine's high-rev power, resulting in a more responsive and dynamic driving experience.

One of the key performance enhancements in hybrid K24 systems is the ability to provide electric boost during acceleration. This feature not only improves 0-60 mph times but also enhances mid-range acceleration, which is particularly beneficial in real-world driving scenarios. The electric assist can be tailored to different driving modes, offering a balance between performance and efficiency as needed.

The hybrid system also enables more precise torque vectoring capabilities, especially in all-wheel-drive configurations. By independently controlling electric motors at different wheels, the hybrid K24 can achieve superior cornering performance and stability compared to its conventional counterparts. This technology allows for more agile handling and improved traction in various driving conditions.

Fuel efficiency gains are another significant aspect of hybrid K24 performance. The ability to operate in pure electric mode for short distances, coupled with regenerative braking systems, contributes to substantial improvements in fuel economy. This is particularly noticeable in urban driving scenarios where stop-and-go traffic is common.

The integration of hybrid technology also opens up possibilities for advanced power management strategies. Sophisticated control systems can optimize the interplay between the gasoline engine and electric motors, ensuring peak efficiency and performance based on driving conditions and driver inputs. This level of optimization was not possible with the traditional K24 engine alone.

However, the transition to hybrid technologies does introduce additional complexity and weight to the K24 platform. Engineers must carefully balance these factors against the performance gains to ensure that the overall driving dynamics are not compromised. Advanced materials and design techniques are often employed to mitigate weight increases and maintain the agile character that K24-powered vehicles are known for.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!