K24 Engine and Regenerative Systems: Exploring Energy Recuperation

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Background

The K24 engine, developed by Honda, represents a significant milestone in automotive engineering, particularly in the realm of energy efficiency and performance. This 2.4-liter inline-four engine first appeared in the early 2000s and has since undergone several iterations, each improving upon its predecessor's design and capabilities.

Initially introduced in the Honda Accord, the K24 engine quickly gained recognition for its balance of power, fuel efficiency, and reliability. Its design incorporates advanced features such as a high-compression ratio, variable valve timing and lift electronic control (VTEC), and a lightweight aluminum block. These elements contribute to its ability to deliver robust performance while maintaining competitive fuel economy.

Over the years, the K24 engine has been adapted for use in various Honda and Acura models, demonstrating its versatility and adaptability to different vehicle types and performance requirements. Its applications range from family sedans to sporty coupes and even some light truck models, showcasing its broad appeal and engineering flexibility.

The evolution of the K24 engine has been marked by continuous improvements in power output, fuel efficiency, and emissions control. Early versions produced around 160 horsepower, while later iterations have seen power outputs exceeding 200 horsepower in some applications. This progression reflects Honda's commitment to refining and enhancing engine technology to meet changing market demands and regulatory requirements.

In recent years, the focus on energy recuperation and regenerative systems has brought new attention to engines like the K24. The potential for integrating regenerative braking systems and other energy recovery technologies with traditional internal combustion engines presents an exciting frontier for further development. This intersection of conventional engine design and advanced energy recovery systems opens up new possibilities for improving overall vehicle efficiency and reducing environmental impact.

The K24 engine's robust design and widespread adoption make it an ideal candidate for exploring these regenerative technologies. Its presence in a diverse range of vehicles provides a broad platform for testing and implementing energy recuperation systems across different driving conditions and vehicle types. This versatility could accelerate the development and adoption of regenerative technologies in mainstream automotive applications.

Initially introduced in the Honda Accord, the K24 engine quickly gained recognition for its balance of power, fuel efficiency, and reliability. Its design incorporates advanced features such as a high-compression ratio, variable valve timing and lift electronic control (VTEC), and a lightweight aluminum block. These elements contribute to its ability to deliver robust performance while maintaining competitive fuel economy.

Over the years, the K24 engine has been adapted for use in various Honda and Acura models, demonstrating its versatility and adaptability to different vehicle types and performance requirements. Its applications range from family sedans to sporty coupes and even some light truck models, showcasing its broad appeal and engineering flexibility.

The evolution of the K24 engine has been marked by continuous improvements in power output, fuel efficiency, and emissions control. Early versions produced around 160 horsepower, while later iterations have seen power outputs exceeding 200 horsepower in some applications. This progression reflects Honda's commitment to refining and enhancing engine technology to meet changing market demands and regulatory requirements.

In recent years, the focus on energy recuperation and regenerative systems has brought new attention to engines like the K24. The potential for integrating regenerative braking systems and other energy recovery technologies with traditional internal combustion engines presents an exciting frontier for further development. This intersection of conventional engine design and advanced energy recovery systems opens up new possibilities for improving overall vehicle efficiency and reducing environmental impact.

The K24 engine's robust design and widespread adoption make it an ideal candidate for exploring these regenerative technologies. Its presence in a diverse range of vehicles provides a broad platform for testing and implementing energy recuperation systems across different driving conditions and vehicle types. This versatility could accelerate the development and adoption of regenerative technologies in mainstream automotive applications.

Market Demand Analysis

The market demand for K24 Engine and Regenerative Systems in the context of energy recuperation has been steadily growing, driven by increasing environmental concerns and the push for more efficient energy utilization in various industries. This technology, which focuses on capturing and reusing energy that would otherwise be lost, has garnered significant attention in automotive, industrial, and renewable energy sectors.

In the automotive industry, there is a strong demand for energy recuperation systems, particularly in electric and hybrid vehicles. As governments worldwide implement stricter emissions regulations and fuel efficiency standards, automakers are increasingly incorporating regenerative braking systems and other energy recovery technologies into their vehicles. This trend is expected to continue, with the global market for automotive regenerative braking systems projected to expand at a compound annual growth rate of over 10% in the coming years.

The industrial sector also presents a substantial market for K24 Engine and Regenerative Systems. Manufacturing plants, power generation facilities, and large-scale industrial operations are seeking ways to improve energy efficiency and reduce operational costs. Energy recuperation technologies, such as waste heat recovery systems and kinetic energy recovery systems, are becoming increasingly popular in these settings. The industrial waste heat recovery market alone is expected to grow significantly, driven by the need for sustainable energy solutions and cost reduction strategies.

In the renewable energy sector, there is a growing demand for energy storage and efficiency technologies that can complement intermittent power sources like solar and wind. Regenerative systems that can capture and store excess energy during peak production periods for later use are becoming increasingly valuable. This market segment is expected to see robust growth as countries worldwide increase their investments in renewable energy infrastructure.

The transportation sector beyond automotive is also showing increased interest in energy recuperation technologies. Railways, marine vessels, and even aerospace applications are exploring ways to implement regenerative systems to improve overall energy efficiency and reduce fuel consumption. This diversification of applications is expected to further drive market growth in the coming years.

Geographically, developed regions such as North America and Europe are currently leading in the adoption of K24 Engine and Regenerative Systems. However, rapidly industrializing countries in Asia-Pacific, particularly China and India, are expected to become significant markets for these technologies as they seek to balance economic growth with environmental sustainability.

The market demand is further bolstered by government initiatives and regulations promoting energy efficiency and carbon emission reduction. Incentives for adopting green technologies and penalties for excessive emissions are creating a favorable environment for the growth of energy recuperation systems across various industries.

In the automotive industry, there is a strong demand for energy recuperation systems, particularly in electric and hybrid vehicles. As governments worldwide implement stricter emissions regulations and fuel efficiency standards, automakers are increasingly incorporating regenerative braking systems and other energy recovery technologies into their vehicles. This trend is expected to continue, with the global market for automotive regenerative braking systems projected to expand at a compound annual growth rate of over 10% in the coming years.

The industrial sector also presents a substantial market for K24 Engine and Regenerative Systems. Manufacturing plants, power generation facilities, and large-scale industrial operations are seeking ways to improve energy efficiency and reduce operational costs. Energy recuperation technologies, such as waste heat recovery systems and kinetic energy recovery systems, are becoming increasingly popular in these settings. The industrial waste heat recovery market alone is expected to grow significantly, driven by the need for sustainable energy solutions and cost reduction strategies.

In the renewable energy sector, there is a growing demand for energy storage and efficiency technologies that can complement intermittent power sources like solar and wind. Regenerative systems that can capture and store excess energy during peak production periods for later use are becoming increasingly valuable. This market segment is expected to see robust growth as countries worldwide increase their investments in renewable energy infrastructure.

The transportation sector beyond automotive is also showing increased interest in energy recuperation technologies. Railways, marine vessels, and even aerospace applications are exploring ways to implement regenerative systems to improve overall energy efficiency and reduce fuel consumption. This diversification of applications is expected to further drive market growth in the coming years.

Geographically, developed regions such as North America and Europe are currently leading in the adoption of K24 Engine and Regenerative Systems. However, rapidly industrializing countries in Asia-Pacific, particularly China and India, are expected to become significant markets for these technologies as they seek to balance economic growth with environmental sustainability.

The market demand is further bolstered by government initiatives and regulations promoting energy efficiency and carbon emission reduction. Incentives for adopting green technologies and penalties for excessive emissions are creating a favorable environment for the growth of energy recuperation systems across various industries.

Technical Challenges

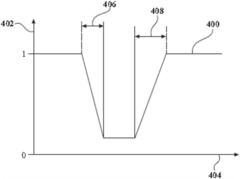

The development of K24 Engine and Regenerative Systems for energy recuperation faces several significant technical challenges. One of the primary obstacles is the integration of regenerative braking systems with traditional internal combustion engines. This requires sophisticated control algorithms to manage the transition between engine braking and regenerative braking, ensuring smooth operation and optimal energy recovery.

Another major challenge lies in the design of efficient energy storage systems. While batteries are commonly used, they often struggle with rapid charge and discharge cycles associated with regenerative braking. Developing high-performance capacitors or advanced battery technologies that can handle these demands without degradation is crucial for system longevity and effectiveness.

The thermal management of regenerative systems presents another hurdle. The conversion of kinetic energy to electrical energy generates heat, which must be effectively dissipated to maintain system efficiency and prevent component damage. This becomes particularly challenging in compact engine compartments where space for cooling systems is limited.

Weight reduction is a critical factor in improving overall vehicle efficiency, but it conflicts with the need for robust regenerative systems. Engineers must strike a delicate balance between adding components for energy recuperation and maintaining a favorable power-to-weight ratio. This often necessitates the use of advanced materials and innovative design solutions.

Durability and reliability of regenerative systems under various driving conditions pose significant challenges. These systems must withstand frequent start-stop cycles, varying temperatures, and diverse road conditions while maintaining consistent performance. Ensuring long-term reliability without frequent maintenance is essential for widespread adoption.

The cost-effectiveness of implementing regenerative systems in K24 engines is another major consideration. While the technology promises fuel savings, the initial investment in research, development, and production must be justified by long-term benefits. This requires careful economic analysis and potentially new manufacturing processes to reduce costs.

Lastly, the integration of regenerative systems with existing vehicle architectures presents compatibility issues. Retrofitting older vehicles or adapting current production lines to incorporate these systems requires extensive redesign and testing. Standardization of components and interfaces across different vehicle models and manufacturers remains a significant challenge in the industry.

Another major challenge lies in the design of efficient energy storage systems. While batteries are commonly used, they often struggle with rapid charge and discharge cycles associated with regenerative braking. Developing high-performance capacitors or advanced battery technologies that can handle these demands without degradation is crucial for system longevity and effectiveness.

The thermal management of regenerative systems presents another hurdle. The conversion of kinetic energy to electrical energy generates heat, which must be effectively dissipated to maintain system efficiency and prevent component damage. This becomes particularly challenging in compact engine compartments where space for cooling systems is limited.

Weight reduction is a critical factor in improving overall vehicle efficiency, but it conflicts with the need for robust regenerative systems. Engineers must strike a delicate balance between adding components for energy recuperation and maintaining a favorable power-to-weight ratio. This often necessitates the use of advanced materials and innovative design solutions.

Durability and reliability of regenerative systems under various driving conditions pose significant challenges. These systems must withstand frequent start-stop cycles, varying temperatures, and diverse road conditions while maintaining consistent performance. Ensuring long-term reliability without frequent maintenance is essential for widespread adoption.

The cost-effectiveness of implementing regenerative systems in K24 engines is another major consideration. While the technology promises fuel savings, the initial investment in research, development, and production must be justified by long-term benefits. This requires careful economic analysis and potentially new manufacturing processes to reduce costs.

Lastly, the integration of regenerative systems with existing vehicle architectures presents compatibility issues. Retrofitting older vehicles or adapting current production lines to incorporate these systems requires extensive redesign and testing. Standardization of components and interfaces across different vehicle models and manufacturers remains a significant challenge in the industry.

Current Regen Solutions

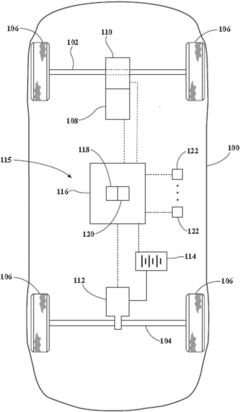

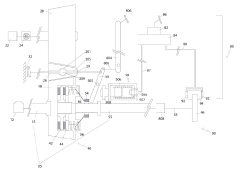

01 K24 Engine with Regenerative Braking System

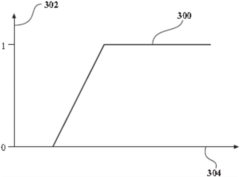

The K24 engine is integrated with a regenerative braking system to recover and store energy during deceleration. This system converts kinetic energy into electrical energy, which can be stored in batteries or used to power auxiliary systems, improving overall vehicle efficiency.- K24 Engine with Regenerative Braking System: The K24 engine, known for its efficiency, can be integrated with a regenerative braking system to recover and store energy during deceleration. This system converts kinetic energy into electrical energy, which can be stored in batteries or used to power auxiliary systems, improving overall vehicle efficiency.

- Energy Recuperation in Hybrid Vehicles: Hybrid vehicles equipped with K24 engines can utilize advanced energy recuperation systems. These systems capture energy during braking and coasting, converting it into electrical power. The recovered energy can be used to assist the engine during acceleration or power onboard electrical systems, reducing fuel consumption and emissions.

- Thermal Energy Recovery in K24 Engines: K24 engines can be equipped with thermal energy recovery systems that capture waste heat from exhaust gases. This recovered heat can be converted into electrical energy or used to warm up the engine more quickly, improving overall efficiency and reducing emissions during cold starts.

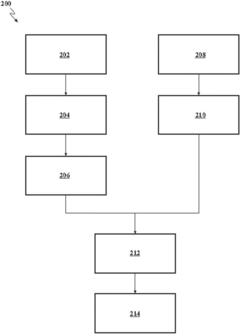

- Intelligent Energy Management Systems: Advanced energy management systems can be integrated with K24 engines to optimize energy recuperation and distribution. These systems use sensors and algorithms to determine the most efficient way to capture, store, and utilize recovered energy based on driving conditions and vehicle demands.

- Regenerative Suspension Systems: Innovative regenerative suspension systems can be combined with K24 engines to recover energy from vehicle vibrations and road irregularities. These systems convert the kinetic energy from suspension movement into electrical energy, further enhancing the vehicle's overall energy efficiency.

02 Energy Recuperation in Hybrid Vehicles

Hybrid vehicles equipped with K24 engines utilize advanced energy recuperation systems. These systems capture energy during braking and coasting, storing it in high-capacity batteries for later use in electric propulsion or to power vehicle systems, thereby reducing fuel consumption and emissions.Expand Specific Solutions03 Thermal Energy Recovery in K24 Engines

K24 engines incorporate thermal energy recovery systems to harness waste heat from exhaust gases and coolant. This recovered thermal energy is converted into usable power, either through thermoelectric generators or by powering auxiliary systems, enhancing overall engine efficiency.Expand Specific Solutions04 Intelligent Energy Management Systems

Advanced energy management systems are implemented in vehicles with K24 engines to optimize energy recuperation and distribution. These systems use sensors and algorithms to determine the most efficient use of recovered energy, balancing between immediate use and storage for later consumption.Expand Specific Solutions05 Mechanical Energy Recovery Mechanisms

K24 engines are equipped with mechanical energy recovery mechanisms such as flywheels or hydraulic accumulators. These systems store kinetic energy during deceleration and release it during acceleration, reducing the load on the engine and improving fuel efficiency.Expand Specific Solutions

Key Industry Players

The K24 Engine and Regenerative Systems market is in a growth phase, driven by increasing demand for energy-efficient technologies in the automotive sector. The market size is expanding rapidly, with major players like GM Global Technology Operations, Robert Bosch GmbH, and Honda Motor Co., Ltd. investing heavily in research and development. The technology's maturity varies across companies, with established automotive manufacturers like Porsche AG and DENSO Corp. leading in implementation, while newer entrants like Echogen Power Systems LLC focus on innovative approaches. Universities such as MIT and the University of Tsukuba are contributing to advancements in the field, indicating a collaborative ecosystem between industry and academia.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced K24 engine regenerative system as part of their commitment to improving vehicle efficiency. Their technology incorporates a belt-driven starter generator (BSG) system, which allows for efficient energy recuperation during vehicle deceleration and coasting[13]. The system utilizes a 48V electrical architecture, enabling higher power regeneration capabilities compared to traditional 12V systems. GM's regenerative technology also features an advanced battery management system that optimizes energy storage and distribution. The company's eAssist technology, which incorporates this regenerative system, can improve fuel economy by up to 15% in city driving conditions[14]. Additionally, GM has integrated start-stop functionality into their system, further enhancing fuel efficiency in urban environments[15].

Strengths: Compatibility with existing vehicle platforms, significant fuel economy improvements, and integration of start-stop technology. Weaknesses: Limited pure electric driving capability compared to full hybrid systems, and potential for increased system complexity.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a cutting-edge K24 engine regenerative system that combines their expertise in powertrain and electrical systems. Their solution features a belt-driven starter generator (BSG) that enables efficient energy recuperation during vehicle deceleration and coasting[4]. The system utilizes a 48V electrical architecture, allowing for higher power recuperation and improved fuel economy. Bosch's regenerative technology also incorporates advanced power electronics and a DC-DC converter to manage energy flow between the 48V and 12V vehicle systems[5]. The company claims their system can reduce fuel consumption by up to 15% in real-world driving conditions, with even greater savings in urban environments[6].

Strengths: High compatibility with existing vehicle architectures, significant fuel economy improvements, and scalable 48V technology. Weaknesses: Limited energy storage capacity compared to full hybrid systems, and potential for increased maintenance complexity.

Core Innovations

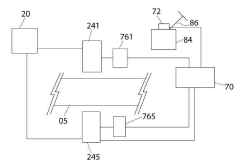

Vehicle, system, and method of calculating an engine torque request value

PatentActiveCN106523167A

Innovation

- A vehicle is designed, including an engine and an energy recovery mechanism coupled to the wheels. The controller calculates the engine torque request value, based on the regenerative torque request value and the expected acceleration value, to ensure that energy recovery can also occur when the vehicle accelerates.

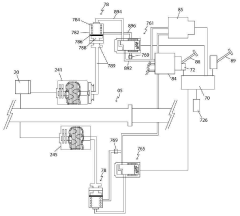

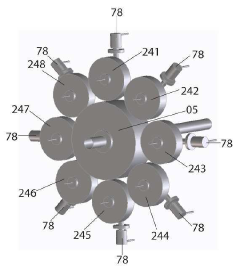

Apparatus and method for energy recovering, vehicle including of the same

PatentActiveKR1020190095232A

Innovation

- A system comprising a rotating body connected to generators, controlled by an electronic control device, which determines the number of generators based on braking force, using sensors to measure pressure and adjust generator connection and disconnection via solenoid valves, storing kinetic energy efficiently.

Environmental Impact

The environmental impact of the K24 Engine and its regenerative systems is a crucial aspect to consider in the context of energy recuperation technologies. These systems have the potential to significantly reduce fuel consumption and emissions, thereby contributing to a more sustainable transportation sector.

The primary environmental benefit of regenerative systems in the K24 Engine lies in their ability to capture and reuse energy that would otherwise be lost as heat during braking or deceleration. This energy recovery process leads to improved fuel efficiency, which directly translates to reduced carbon dioxide emissions. Studies have shown that regenerative braking systems can reduce fuel consumption by up to 25% in urban driving conditions, where frequent stops and starts are common.

Furthermore, the implementation of regenerative systems in the K24 Engine contributes to the reduction of particulate matter and nitrogen oxide emissions. These pollutants are known to have detrimental effects on air quality and human health, particularly in urban areas. By minimizing the reliance on traditional friction braking, regenerative systems help to decrease brake dust emissions, which are a significant source of airborne particulates in urban environments.

The environmental benefits extend beyond the operational phase of the vehicle. The increased efficiency of the K24 Engine with regenerative systems means that less fuel is required over the vehicle's lifetime. This reduction in fuel consumption has far-reaching implications for the entire fuel supply chain, from extraction to refining and distribution, potentially leading to a decrease in overall environmental impact associated with fossil fuel production and transportation.

However, it is important to consider the full lifecycle environmental impact of these technologies. The production of advanced regenerative systems often requires specialized materials and manufacturing processes, which may have their own environmental footprint. For instance, the production of high-capacity batteries or supercapacitors used in some regenerative systems can involve energy-intensive processes and the use of rare earth elements.

Additionally, the end-of-life management of these components presents both challenges and opportunities. Proper recycling and disposal procedures must be developed to ensure that the environmental benefits gained during the operational phase are not offset by improper handling at the end of the vehicle's life. On the positive side, many of the materials used in regenerative systems are valuable and can be recycled, potentially contributing to a more circular economy in the automotive sector.

In conclusion, while the K24 Engine with regenerative systems offers significant environmental benefits through improved energy efficiency and reduced emissions, a holistic approach is necessary to fully understand and optimize its environmental impact across the entire lifecycle of the vehicle.

The primary environmental benefit of regenerative systems in the K24 Engine lies in their ability to capture and reuse energy that would otherwise be lost as heat during braking or deceleration. This energy recovery process leads to improved fuel efficiency, which directly translates to reduced carbon dioxide emissions. Studies have shown that regenerative braking systems can reduce fuel consumption by up to 25% in urban driving conditions, where frequent stops and starts are common.

Furthermore, the implementation of regenerative systems in the K24 Engine contributes to the reduction of particulate matter and nitrogen oxide emissions. These pollutants are known to have detrimental effects on air quality and human health, particularly in urban areas. By minimizing the reliance on traditional friction braking, regenerative systems help to decrease brake dust emissions, which are a significant source of airborne particulates in urban environments.

The environmental benefits extend beyond the operational phase of the vehicle. The increased efficiency of the K24 Engine with regenerative systems means that less fuel is required over the vehicle's lifetime. This reduction in fuel consumption has far-reaching implications for the entire fuel supply chain, from extraction to refining and distribution, potentially leading to a decrease in overall environmental impact associated with fossil fuel production and transportation.

However, it is important to consider the full lifecycle environmental impact of these technologies. The production of advanced regenerative systems often requires specialized materials and manufacturing processes, which may have their own environmental footprint. For instance, the production of high-capacity batteries or supercapacitors used in some regenerative systems can involve energy-intensive processes and the use of rare earth elements.

Additionally, the end-of-life management of these components presents both challenges and opportunities. Proper recycling and disposal procedures must be developed to ensure that the environmental benefits gained during the operational phase are not offset by improper handling at the end of the vehicle's life. On the positive side, many of the materials used in regenerative systems are valuable and can be recycled, potentially contributing to a more circular economy in the automotive sector.

In conclusion, while the K24 Engine with regenerative systems offers significant environmental benefits through improved energy efficiency and reduced emissions, a holistic approach is necessary to fully understand and optimize its environmental impact across the entire lifecycle of the vehicle.

Regulatory Landscape

The regulatory landscape surrounding K24 Engine and Regenerative Systems is complex and evolving, reflecting the growing emphasis on energy efficiency and environmental sustainability in the automotive industry. Governments worldwide are implementing increasingly stringent regulations to reduce carbon emissions and improve fuel economy, directly impacting the development and adoption of energy recuperation technologies.

In the United States, the Corporate Average Fuel Economy (CAFE) standards set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) play a crucial role. These standards mandate progressive improvements in vehicle fuel efficiency, incentivizing manufacturers to invest in advanced technologies like regenerative braking systems. The Biden administration's recent proposal to raise CAFE standards to an industry-wide target of 49 mpg by 2026 further accelerates this trend.

The European Union has established ambitious CO2 emission reduction targets for new vehicles. Regulation (EU) 2019/631 sets EU fleet-wide CO2 emission performance standards, requiring a 37.5% reduction in CO2 emissions from new passenger cars by 2030 compared to 2021 levels. This regulatory framework strongly encourages the integration of energy recuperation systems in vehicle powertrains.

China, the world's largest automotive market, has also implemented rigorous fuel consumption and emission standards. The China VI emission standard, comparable to Euro 6, sets strict limits on pollutant emissions. Additionally, China's dual-credit policy system rewards manufacturers for producing new energy vehicles and vehicles with low fuel consumption, indirectly promoting the adoption of regenerative technologies.

Japan's Top Runner Program sets energy efficiency standards for various products, including vehicles. This program has been instrumental in driving technological innovations in the automotive sector, including advancements in energy recuperation systems.

Globally, the United Nations Economic Commission for Europe (UNECE) has established regulations and guidelines for vehicle energy efficiency and emissions. The World Forum for Harmonization of Vehicle Regulations (WP.29) under UNECE plays a pivotal role in developing international technical regulations, including those related to energy recovery systems.

These regulatory frameworks not only mandate improvements but also provide incentives for manufacturers to invest in research and development of energy recuperation technologies. Tax credits, grants, and other financial incentives are often offered to companies developing or implementing advanced energy-saving technologies, further stimulating innovation in this field.

As environmental concerns continue to grow, it is anticipated that regulatory bodies will further tighten standards and expand their scope to cover a broader range of vehicles and technologies. This evolving regulatory landscape will likely accelerate the development and widespread adoption of K24 Engine and Regenerative Systems, positioning energy recuperation as a key technology in the automotive industry's sustainable future.

In the United States, the Corporate Average Fuel Economy (CAFE) standards set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) play a crucial role. These standards mandate progressive improvements in vehicle fuel efficiency, incentivizing manufacturers to invest in advanced technologies like regenerative braking systems. The Biden administration's recent proposal to raise CAFE standards to an industry-wide target of 49 mpg by 2026 further accelerates this trend.

The European Union has established ambitious CO2 emission reduction targets for new vehicles. Regulation (EU) 2019/631 sets EU fleet-wide CO2 emission performance standards, requiring a 37.5% reduction in CO2 emissions from new passenger cars by 2030 compared to 2021 levels. This regulatory framework strongly encourages the integration of energy recuperation systems in vehicle powertrains.

China, the world's largest automotive market, has also implemented rigorous fuel consumption and emission standards. The China VI emission standard, comparable to Euro 6, sets strict limits on pollutant emissions. Additionally, China's dual-credit policy system rewards manufacturers for producing new energy vehicles and vehicles with low fuel consumption, indirectly promoting the adoption of regenerative technologies.

Japan's Top Runner Program sets energy efficiency standards for various products, including vehicles. This program has been instrumental in driving technological innovations in the automotive sector, including advancements in energy recuperation systems.

Globally, the United Nations Economic Commission for Europe (UNECE) has established regulations and guidelines for vehicle energy efficiency and emissions. The World Forum for Harmonization of Vehicle Regulations (WP.29) under UNECE plays a pivotal role in developing international technical regulations, including those related to energy recovery systems.

These regulatory frameworks not only mandate improvements but also provide incentives for manufacturers to invest in research and development of energy recuperation technologies. Tax credits, grants, and other financial incentives are often offered to companies developing or implementing advanced energy-saving technologies, further stimulating innovation in this field.

As environmental concerns continue to grow, it is anticipated that regulatory bodies will further tighten standards and expand their scope to cover a broader range of vehicles and technologies. This evolving regulatory landscape will likely accelerate the development and widespread adoption of K24 Engine and Regenerative Systems, positioning energy recuperation as a key technology in the automotive industry's sustainable future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!