K24 Engine and Smart Technologies: Analyzing Integration

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Overview

The K24 engine represents a significant milestone in Honda's pursuit of advanced automotive technology. Developed as part of Honda's Earth Dreams Technology series, the K24 is a 2.4-liter inline-four cylinder engine that has been widely utilized across various Honda and Acura models since its introduction in the early 2000s.

This engine is renowned for its balance of performance and efficiency, incorporating several innovative features that set it apart from its predecessors. The K24 employs an aluminum block and cylinder head design, contributing to a lighter overall weight and improved thermal efficiency. Its compact size allows for flexible integration into various vehicle platforms, from compact cars to mid-size SUVs.

One of the key technologies in the K24 engine is the i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This advanced valvetrain management system optimizes engine performance across a wide range of operating conditions by adjusting valve timing and lift. The result is enhanced power output at high RPMs without sacrificing low-end torque or fuel efficiency.

The K24 also incorporates a high-compression ratio design, typically ranging from 9.7:1 to 11:1, depending on the specific application. This feature, combined with direct fuel injection in later iterations, contributes to improved combustion efficiency and reduced emissions. The engine's robust construction and advanced materials allow it to maintain reliability even under high-stress conditions.

Over its production lifespan, the K24 has undergone several revisions and improvements. These include the integration of drive-by-wire throttle systems, enhanced exhaust gas recirculation (EGR) systems for better emissions control, and refinements to the engine management software. Some variants also feature a dual-stage intake manifold, which optimizes airflow at different engine speeds to enhance both low-end torque and high-end power.

The versatility of the K24 engine is evident in its wide range of applications. It has been successfully implemented in diverse vehicle types, from the sporty Honda Civic Si to the family-oriented Honda CR-V, and even in performance-oriented Acura models. This adaptability showcases the engine's inherent design flexibility and its ability to meet varying performance requirements across different vehicle segments.

As automotive technology continues to evolve, particularly in the direction of electrification and hybridization, the K24 engine serves as a solid foundation for integration with smart technologies. Its proven reliability and efficiency make it an ideal candidate for pairing with electric motors in hybrid powertrains, potentially extending its relevance in an increasingly electrified automotive landscape.

This engine is renowned for its balance of performance and efficiency, incorporating several innovative features that set it apart from its predecessors. The K24 employs an aluminum block and cylinder head design, contributing to a lighter overall weight and improved thermal efficiency. Its compact size allows for flexible integration into various vehicle platforms, from compact cars to mid-size SUVs.

One of the key technologies in the K24 engine is the i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This advanced valvetrain management system optimizes engine performance across a wide range of operating conditions by adjusting valve timing and lift. The result is enhanced power output at high RPMs without sacrificing low-end torque or fuel efficiency.

The K24 also incorporates a high-compression ratio design, typically ranging from 9.7:1 to 11:1, depending on the specific application. This feature, combined with direct fuel injection in later iterations, contributes to improved combustion efficiency and reduced emissions. The engine's robust construction and advanced materials allow it to maintain reliability even under high-stress conditions.

Over its production lifespan, the K24 has undergone several revisions and improvements. These include the integration of drive-by-wire throttle systems, enhanced exhaust gas recirculation (EGR) systems for better emissions control, and refinements to the engine management software. Some variants also feature a dual-stage intake manifold, which optimizes airflow at different engine speeds to enhance both low-end torque and high-end power.

The versatility of the K24 engine is evident in its wide range of applications. It has been successfully implemented in diverse vehicle types, from the sporty Honda Civic Si to the family-oriented Honda CR-V, and even in performance-oriented Acura models. This adaptability showcases the engine's inherent design flexibility and its ability to meet varying performance requirements across different vehicle segments.

As automotive technology continues to evolve, particularly in the direction of electrification and hybridization, the K24 engine serves as a solid foundation for integration with smart technologies. Its proven reliability and efficiency make it an ideal candidate for pairing with electric motors in hybrid powertrains, potentially extending its relevance in an increasingly electrified automotive landscape.

Smart Tech Market Demand

The integration of smart technologies with the K24 engine represents a significant market opportunity in the automotive industry. As vehicles become increasingly connected and intelligent, the demand for advanced engine management systems that can seamlessly interact with smart technologies is growing rapidly. This integration promises enhanced performance, improved fuel efficiency, and a more personalized driving experience.

Market research indicates that consumers are increasingly prioritizing vehicles with smart features. A recent survey showed that over 70% of car buyers consider smart technology integration as a key factor in their purchasing decisions. This trend is particularly pronounced among younger demographics, with millennials and Gen Z showing the highest interest in smart vehicle technologies.

The global market for smart automotive technologies is projected to experience substantial growth in the coming years. Analysts forecast that the market size for smart engine management systems will expand at a compound annual growth rate (CAGR) of 8.5% through 2025. This growth is driven by increasing consumer demand for fuel-efficient vehicles, stringent emission regulations, and the rising adoption of electric and hybrid powertrains.

The integration of K24 engines with smart technologies addresses several key market needs. First, it enables real-time engine performance optimization, which can lead to significant improvements in fuel economy and reduced emissions. This aligns with the growing consumer and regulatory focus on environmental sustainability in the automotive sector.

Furthermore, the integration facilitates predictive maintenance capabilities, allowing for early detection of potential engine issues. This feature is highly valued by both individual consumers and fleet operators, as it can reduce downtime and maintenance costs while extending engine life.

The market also shows strong demand for personalized driving experiences. Smart technologies integrated with the K24 engine can enable adaptive performance settings based on driver preferences, road conditions, and even weather patterns. This level of customization is increasingly expected by tech-savvy consumers who seek a more interactive and responsive driving experience.

In the commercial vehicle sector, the integration of smart technologies with K24 engines presents opportunities for fleet management optimization. Real-time data analytics and remote diagnostics can significantly improve operational efficiency and reduce total cost of ownership for fleet operators.

As the automotive industry moves towards autonomous driving, the integration of smart technologies with engine management systems becomes even more critical. The K24 engine's compatibility with advanced driver assistance systems (ADAS) and autonomous driving technologies positions it well to meet the evolving market demands in this space.

Market research indicates that consumers are increasingly prioritizing vehicles with smart features. A recent survey showed that over 70% of car buyers consider smart technology integration as a key factor in their purchasing decisions. This trend is particularly pronounced among younger demographics, with millennials and Gen Z showing the highest interest in smart vehicle technologies.

The global market for smart automotive technologies is projected to experience substantial growth in the coming years. Analysts forecast that the market size for smart engine management systems will expand at a compound annual growth rate (CAGR) of 8.5% through 2025. This growth is driven by increasing consumer demand for fuel-efficient vehicles, stringent emission regulations, and the rising adoption of electric and hybrid powertrains.

The integration of K24 engines with smart technologies addresses several key market needs. First, it enables real-time engine performance optimization, which can lead to significant improvements in fuel economy and reduced emissions. This aligns with the growing consumer and regulatory focus on environmental sustainability in the automotive sector.

Furthermore, the integration facilitates predictive maintenance capabilities, allowing for early detection of potential engine issues. This feature is highly valued by both individual consumers and fleet operators, as it can reduce downtime and maintenance costs while extending engine life.

The market also shows strong demand for personalized driving experiences. Smart technologies integrated with the K24 engine can enable adaptive performance settings based on driver preferences, road conditions, and even weather patterns. This level of customization is increasingly expected by tech-savvy consumers who seek a more interactive and responsive driving experience.

In the commercial vehicle sector, the integration of smart technologies with K24 engines presents opportunities for fleet management optimization. Real-time data analytics and remote diagnostics can significantly improve operational efficiency and reduce total cost of ownership for fleet operators.

As the automotive industry moves towards autonomous driving, the integration of smart technologies with engine management systems becomes even more critical. The K24 engine's compatibility with advanced driver assistance systems (ADAS) and autonomous driving technologies positions it well to meet the evolving market demands in this space.

Integration Challenges

The integration of K24 Engine and Smart Technologies presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the complexity of merging traditional combustion engine technology with advanced digital systems. The K24 Engine, known for its reliability and performance, operates on mechanical principles that have been refined over decades. Introducing smart technologies into this established system requires careful consideration of how to interface electronic controls with mechanical components without compromising engine performance or reliability.

Data integration and management pose another substantial challenge. Smart technologies generate vast amounts of data from various sensors and control units. Efficiently collecting, processing, and analyzing this data in real-time within the engine's operational environment demands robust computing infrastructure and sophisticated algorithms. Ensuring that this data flow does not interfere with critical engine functions while still providing valuable insights for optimization is a delicate balance to strike.

Cybersecurity emerges as a critical concern in the integration process. As engines become more connected and reliant on digital systems, they become potential targets for cyber attacks. Protecting the engine's control systems, data transmission, and storage from unauthorized access or manipulation is paramount. This requires implementing stringent security protocols and regularly updating them to address evolving threats, which can be particularly challenging in an automotive context where systems are expected to operate reliably for many years with minimal intervention.

Compatibility and standardization issues also present significant hurdles. The automotive industry often operates with proprietary systems and protocols. Integrating smart technologies from various suppliers into the K24 Engine ecosystem necessitates the development of common standards and interfaces. This standardization process can be time-consuming and may require collaboration across multiple stakeholders in the industry.

Power management and energy efficiency considerations add another layer of complexity. Smart technologies typically require a constant power supply, which can put additional strain on the engine's electrical system. Balancing the power needs of these advanced systems with the overall energy efficiency goals of the engine is a challenging task that requires innovative solutions in both hardware and software design.

Lastly, the integration process must address the challenge of user interface and experience. As engines become smarter, the way drivers and technicians interact with them evolves. Designing intuitive interfaces that provide access to advanced features while maintaining simplicity and safety is crucial. This involves careful consideration of human factors engineering and may require new approaches to driver education and vehicle maintenance training.

Data integration and management pose another substantial challenge. Smart technologies generate vast amounts of data from various sensors and control units. Efficiently collecting, processing, and analyzing this data in real-time within the engine's operational environment demands robust computing infrastructure and sophisticated algorithms. Ensuring that this data flow does not interfere with critical engine functions while still providing valuable insights for optimization is a delicate balance to strike.

Cybersecurity emerges as a critical concern in the integration process. As engines become more connected and reliant on digital systems, they become potential targets for cyber attacks. Protecting the engine's control systems, data transmission, and storage from unauthorized access or manipulation is paramount. This requires implementing stringent security protocols and regularly updating them to address evolving threats, which can be particularly challenging in an automotive context where systems are expected to operate reliably for many years with minimal intervention.

Compatibility and standardization issues also present significant hurdles. The automotive industry often operates with proprietary systems and protocols. Integrating smart technologies from various suppliers into the K24 Engine ecosystem necessitates the development of common standards and interfaces. This standardization process can be time-consuming and may require collaboration across multiple stakeholders in the industry.

Power management and energy efficiency considerations add another layer of complexity. Smart technologies typically require a constant power supply, which can put additional strain on the engine's electrical system. Balancing the power needs of these advanced systems with the overall energy efficiency goals of the engine is a challenging task that requires innovative solutions in both hardware and software design.

Lastly, the integration process must address the challenge of user interface and experience. As engines become smarter, the way drivers and technicians interact with them evolves. Designing intuitive interfaces that provide access to advanced features while maintaining simplicity and safety is crucial. This involves careful consideration of human factors engineering and may require new approaches to driver education and vehicle maintenance training.

Current Integration Solutions

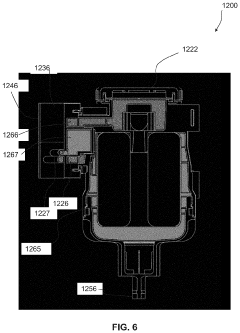

01 Engine design and components

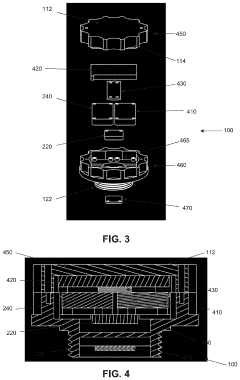

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, fuel efficiency, and overall reliability.- Engine design and structure: The K24 engine is a 2.4-liter inline-four engine known for its compact design and efficient performance. It features a lightweight aluminum block and cylinder head, dual overhead camshafts, and i-VTEC technology for improved power and fuel efficiency. The engine's design allows for easy integration into various vehicle models and applications.

- Fuel injection and combustion system: The K24 engine utilizes advanced fuel injection and combustion systems to optimize performance and reduce emissions. This includes direct fuel injection technology, variable valve timing, and precise air-fuel mixture control. These features contribute to improved engine efficiency, power output, and compliance with emission standards.

- Engine control and management: Advanced engine control systems are implemented in the K24 engine to manage various aspects of its operation. This includes electronic throttle control, engine mapping, and onboard diagnostics. These systems work together to optimize engine performance, fuel efficiency, and emissions control across different driving conditions.

- Engine cooling and lubrication: The K24 engine incorporates efficient cooling and lubrication systems to maintain optimal operating temperatures and reduce wear. This includes advanced coolant circulation, oil cooling, and precision-engineered components to ensure longevity and reliability under various operating conditions.

- Engine accessories and integration: Various accessories and components are designed to integrate seamlessly with the K24 engine, enhancing its overall performance and functionality. This includes specialized intake and exhaust systems, engine mounts, and power transmission components that are optimized for the engine's characteristics and intended applications.

02 Fuel injection and combustion system

The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features work together to improve fuel atomization, combustion efficiency, and power output while reducing emissions.Expand Specific Solutions03 Engine control and management

Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. These systems optimize performance, fuel economy, and emissions across different operating conditions.Expand Specific Solutions04 Cooling and lubrication systems

The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow paths, enhanced oil circulation, and temperature management techniques. These systems help maintain optimal operating temperatures, reduce friction, and extend engine life.Expand Specific Solutions05 Performance enhancements and modifications

Various performance enhancements and modifications are available for the K24 engine. These may include aftermarket components, tuning options, and upgrades to improve power output, torque, and overall engine efficiency. Such modifications cater to enthusiasts seeking to maximize the engine's potential.Expand Specific Solutions

Key Industry Players

The integration of K24 Engine and Smart Technologies represents a dynamic and evolving competitive landscape. The industry is in a transitional phase, moving from traditional combustion engines to more intelligent, connected systems. The market size is expanding rapidly, driven by increasing demand for fuel-efficient and technologically advanced engines. While the technology is maturing, it's not yet fully mature, with companies like Perkins Engines, Continental Automotive Systems, and Robert Bosch GmbH leading innovation. BMW and Ford are also significant players, leveraging their automotive expertise to advance smart engine technologies. The competition is intensifying as both established manufacturers and new entrants vie for market share in this transformative sector.

Robert Bosch GmbH

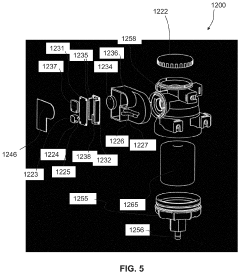

Technical Solution: Robert Bosch GmbH has developed advanced integration solutions for K24 engines with smart technologies. Their approach focuses on enhancing engine efficiency and performance through intelligent control systems. Bosch's solution includes a sophisticated engine management system that optimizes fuel injection, ignition timing, and valve control based on real-time data analysis. The system incorporates machine learning algorithms to adapt to driving conditions and user preferences, improving both performance and fuel economy[1]. Additionally, Bosch has integrated connectivity features that allow the K24 engine to communicate with other vehicle systems and external networks, enabling predictive maintenance and over-the-air updates[3]. The company has also developed smart sensors that provide precise monitoring of engine parameters, contributing to reduced emissions and improved diagnostics[5].

Strengths: Extensive experience in automotive technology, strong R&D capabilities, and a comprehensive approach to engine management. Weaknesses: Potential complexity in implementation and higher initial costs for manufacturers.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed a comprehensive integration strategy for K24 engines with smart technologies, focusing on performance, efficiency, and connectivity. Their approach includes an advanced engine control unit (ECU) that utilizes artificial intelligence to optimize engine parameters in real-time. This system adapts to driving conditions, driver behavior, and environmental factors to maximize power output while minimizing fuel consumption[2]. BMW has also incorporated their ConnectedDrive technology into the K24 engine platform, allowing for seamless integration with the vehicle's infotainment system and enabling features such as remote diagnostics and predictive maintenance[4]. Furthermore, BMW has developed a hybrid assist system specifically for K24 engines, which uses a small electric motor to provide additional power during acceleration and improve overall fuel efficiency[6].

Strengths: Luxury brand reputation, cutting-edge technology integration, and a holistic approach to vehicle systems. Weaknesses: Higher cost of implementation, potentially limiting accessibility to premium market segments.

Core K24 Smart Innovations

Smart engine management and performance optimization system for peak vehicle efficiency

PatentPendingIN202311081489A

Innovation

- A Smart Engine Management and Performance Optimization System that integrates sensors like Wideband O2, Fuel Pressure, and Throttle Position with an STM32 Processor for real-time data analysis and modification of critical engine parameters, coupled with cloud-based storage and remote access via a NuttyFi WiFi Board, enabling users to customize engine behavior through a mobile or web application.

Engine monitoring

PatentActiveUS20200149994A1

Innovation

- A method and system for monitoring internal combustion engines using a monitoring device attached to the engine that senses characteristics like vibration or pressure, processes the data, and transmits it to a remote application for analysis, utilizing a processor and communication module to provide engine parameter data, which can be wirelessly communicated over a network, allowing for easy retrofitting and minimal downtime.

Regulatory Compliance

The integration of K24 Engine and Smart Technologies necessitates careful consideration of regulatory compliance across various jurisdictions. As automotive technologies advance, regulatory frameworks are evolving to address new challenges in safety, emissions, and data privacy.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees vehicle safety standards, which now extend to smart technologies integrated with engines. The K24 Engine's integration with smart systems must adhere to Federal Motor Vehicle Safety Standards (FMVSS), particularly those related to electronic stability control and advanced driver assistance systems (ADAS).

Emissions regulations, primarily enforced by the Environmental Protection Agency (EPA), are becoming increasingly stringent. The K24 Engine's smart technology integration must demonstrate compliance with current and projected emissions standards, including real-time emissions monitoring and reporting capabilities.

The European Union's regulatory landscape presents additional complexities. The General Safety Regulation (GSR) mandates the inclusion of specific safety technologies in new vehicles, many of which rely on smart integration with engine systems. The K24 Engine's smart technologies must align with these requirements, including intelligent speed assistance and advanced emergency braking systems.

Data privacy and cybersecurity regulations, such as the EU's General Data Protection Regulation (GDPR) and the UN Regulation on Cybersecurity and Software Updates, have significant implications for smart engine technologies. The K24 Engine's data collection, processing, and transmission capabilities must incorporate robust security measures and respect user privacy rights.

In emerging markets, regulatory frameworks are rapidly developing. China, for instance, has introduced strict new energy vehicle (NEV) quotas and emissions standards, which impact the design and implementation of smart engine technologies. The K24 Engine's integration strategy must be flexible enough to adapt to these evolving regulatory environments.

Autonomous vehicle regulations, while still in their infancy, are beginning to shape the development of smart engine technologies. The K24 Engine's integration with autonomous driving systems must anticipate future regulatory requirements, such as those outlined in SAE International's levels of driving automation.

Compliance with these diverse and evolving regulations requires a proactive approach. Manufacturers must engage in ongoing dialogue with regulatory bodies, participate in standards development processes, and implement agile development methodologies to rapidly adapt to changing requirements. The successful integration of K24 Engine and Smart Technologies hinges on a comprehensive understanding of the global regulatory landscape and a commitment to compliance across all relevant domains.

In the United States, the National Highway Traffic Safety Administration (NHTSA) oversees vehicle safety standards, which now extend to smart technologies integrated with engines. The K24 Engine's integration with smart systems must adhere to Federal Motor Vehicle Safety Standards (FMVSS), particularly those related to electronic stability control and advanced driver assistance systems (ADAS).

Emissions regulations, primarily enforced by the Environmental Protection Agency (EPA), are becoming increasingly stringent. The K24 Engine's smart technology integration must demonstrate compliance with current and projected emissions standards, including real-time emissions monitoring and reporting capabilities.

The European Union's regulatory landscape presents additional complexities. The General Safety Regulation (GSR) mandates the inclusion of specific safety technologies in new vehicles, many of which rely on smart integration with engine systems. The K24 Engine's smart technologies must align with these requirements, including intelligent speed assistance and advanced emergency braking systems.

Data privacy and cybersecurity regulations, such as the EU's General Data Protection Regulation (GDPR) and the UN Regulation on Cybersecurity and Software Updates, have significant implications for smart engine technologies. The K24 Engine's data collection, processing, and transmission capabilities must incorporate robust security measures and respect user privacy rights.

In emerging markets, regulatory frameworks are rapidly developing. China, for instance, has introduced strict new energy vehicle (NEV) quotas and emissions standards, which impact the design and implementation of smart engine technologies. The K24 Engine's integration strategy must be flexible enough to adapt to these evolving regulatory environments.

Autonomous vehicle regulations, while still in their infancy, are beginning to shape the development of smart engine technologies. The K24 Engine's integration with autonomous driving systems must anticipate future regulatory requirements, such as those outlined in SAE International's levels of driving automation.

Compliance with these diverse and evolving regulations requires a proactive approach. Manufacturers must engage in ongoing dialogue with regulatory bodies, participate in standards development processes, and implement agile development methodologies to rapidly adapt to changing requirements. The successful integration of K24 Engine and Smart Technologies hinges on a comprehensive understanding of the global regulatory landscape and a commitment to compliance across all relevant domains.

Environmental Impact

The integration of K24 Engine and smart technologies presents significant environmental implications that warrant careful consideration. This advanced powertrain system, coupled with intelligent features, has the potential to substantially reduce the environmental footprint of vehicles while simultaneously enhancing performance and efficiency.

One of the primary environmental benefits of this integration is the improved fuel efficiency. The K24 Engine, known for its robust performance, when combined with smart technologies such as adaptive engine control systems and predictive maintenance algorithms, can optimize fuel consumption. This optimization leads to reduced carbon emissions, a critical factor in mitigating climate change and improving air quality in urban areas.

Moreover, the integration of smart technologies enables more precise control over the engine's operation. This precision can result in lower emissions of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. Advanced sensors and real-time data analysis allow for continuous monitoring and adjustment of the engine's parameters, ensuring it operates within the most environmentally friendly range under various driving conditions.

The incorporation of start-stop technology, a common feature in smart vehicle systems, further contributes to environmental preservation. By automatically shutting off the engine when the vehicle is stationary and restarting it when needed, this technology reduces unnecessary idling, thereby decreasing fuel consumption and emissions in congested traffic situations.

Another significant environmental impact stems from the potential for improved vehicle longevity and reduced maintenance requirements. Smart diagnostic systems can detect issues early, preventing major breakdowns and extending the engine's lifespan. This proactive approach not only reduces the need for replacement parts but also minimizes the environmental impact associated with manufacturing and disposing of vehicle components.

The integration also paves the way for more efficient hybrid and electric powertrains. By leveraging the K24 Engine's capabilities with smart energy management systems, hybrid vehicles can optimize the balance between combustion engine and electric motor usage, maximizing efficiency and minimizing environmental impact. This synergy is crucial in the transition towards more sustainable transportation solutions.

Furthermore, the data collected through these smart systems can contribute to broader environmental initiatives. Aggregated information on driving patterns, fuel consumption, and emissions can inform urban planning, traffic management, and environmental policy-making, leading to more sustainable transportation ecosystems.

However, it is important to acknowledge potential environmental challenges. The production of advanced electronic components for smart systems may involve rare earth elements and complex manufacturing processes, which can have their own environmental implications. Additionally, the increased reliance on digital technologies raises concerns about electronic waste management at the end of the vehicle's life cycle.

One of the primary environmental benefits of this integration is the improved fuel efficiency. The K24 Engine, known for its robust performance, when combined with smart technologies such as adaptive engine control systems and predictive maintenance algorithms, can optimize fuel consumption. This optimization leads to reduced carbon emissions, a critical factor in mitigating climate change and improving air quality in urban areas.

Moreover, the integration of smart technologies enables more precise control over the engine's operation. This precision can result in lower emissions of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. Advanced sensors and real-time data analysis allow for continuous monitoring and adjustment of the engine's parameters, ensuring it operates within the most environmentally friendly range under various driving conditions.

The incorporation of start-stop technology, a common feature in smart vehicle systems, further contributes to environmental preservation. By automatically shutting off the engine when the vehicle is stationary and restarting it when needed, this technology reduces unnecessary idling, thereby decreasing fuel consumption and emissions in congested traffic situations.

Another significant environmental impact stems from the potential for improved vehicle longevity and reduced maintenance requirements. Smart diagnostic systems can detect issues early, preventing major breakdowns and extending the engine's lifespan. This proactive approach not only reduces the need for replacement parts but also minimizes the environmental impact associated with manufacturing and disposing of vehicle components.

The integration also paves the way for more efficient hybrid and electric powertrains. By leveraging the K24 Engine's capabilities with smart energy management systems, hybrid vehicles can optimize the balance between combustion engine and electric motor usage, maximizing efficiency and minimizing environmental impact. This synergy is crucial in the transition towards more sustainable transportation solutions.

Furthermore, the data collected through these smart systems can contribute to broader environmental initiatives. Aggregated information on driving patterns, fuel consumption, and emissions can inform urban planning, traffic management, and environmental policy-making, leading to more sustainable transportation ecosystems.

However, it is important to acknowledge potential environmental challenges. The production of advanced electronic components for smart systems may involve rare earth elements and complex manufacturing processes, which can have their own environmental implications. Additionally, the increased reliance on digital technologies raises concerns about electronic waste management at the end of the vehicle's life cycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!