K24 Engine Contributions to Automotive Sustainable Practices

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution and Sustainability Goals

The K24 engine, developed by Honda, represents a significant milestone in automotive engineering, particularly in the context of sustainable practices. This engine's evolution reflects the industry's growing commitment to environmental responsibility and fuel efficiency. Initially introduced in the late 1990s, the K24 has undergone several iterations, each marking progress towards sustainability goals.

The original K24A series, while innovative for its time, primarily focused on performance and reliability. However, as global awareness of environmental issues increased, Honda began incorporating sustainability features into subsequent versions. The K24Z series, for instance, introduced i-VTEC technology, which optimized fuel efficiency without compromising power output.

A major leap forward came with the Earth Dreams Technology initiative, which significantly influenced the K24's development. This corporate-wide strategy aimed to balance high performance with environmental responsibility. The K24W series, part of this initiative, incorporated direct injection and reduced friction technologies, resulting in improved fuel economy and reduced emissions.

The latest iterations of the K24 engine demonstrate Honda's commitment to meeting increasingly stringent emissions standards. Advanced thermal management systems, lightweight materials, and optimized combustion processes have been integrated to further reduce the engine's environmental impact. These improvements align with global sustainability goals, such as the Paris Agreement and various national emissions reduction targets.

Moreover, the K24 engine's evolution reflects a broader trend in the automotive industry towards electrification. While remaining a combustion engine, recent versions have been designed to work effectively in hybrid powertrains. This adaptability ensures the K24's relevance in an era transitioning towards electric vehicles, bridging the gap between traditional combustion engines and fully electric powertrains.

The engine's development has also focused on improving its lifecycle sustainability. This includes considerations for manufacturing processes, using more recyclable materials, and designing for easier end-of-life recycling. These efforts contribute to reducing the overall carbon footprint of vehicles equipped with K24 engines.

In conclusion, the K24 engine's evolution mirrors the automotive industry's journey towards sustainability. From its inception to its current form, each iteration has incorporated technologies and design principles aimed at reducing environmental impact while maintaining performance. This ongoing development underscores the importance of continuous innovation in meeting global sustainability challenges in the automotive sector.

The original K24A series, while innovative for its time, primarily focused on performance and reliability. However, as global awareness of environmental issues increased, Honda began incorporating sustainability features into subsequent versions. The K24Z series, for instance, introduced i-VTEC technology, which optimized fuel efficiency without compromising power output.

A major leap forward came with the Earth Dreams Technology initiative, which significantly influenced the K24's development. This corporate-wide strategy aimed to balance high performance with environmental responsibility. The K24W series, part of this initiative, incorporated direct injection and reduced friction technologies, resulting in improved fuel economy and reduced emissions.

The latest iterations of the K24 engine demonstrate Honda's commitment to meeting increasingly stringent emissions standards. Advanced thermal management systems, lightweight materials, and optimized combustion processes have been integrated to further reduce the engine's environmental impact. These improvements align with global sustainability goals, such as the Paris Agreement and various national emissions reduction targets.

Moreover, the K24 engine's evolution reflects a broader trend in the automotive industry towards electrification. While remaining a combustion engine, recent versions have been designed to work effectively in hybrid powertrains. This adaptability ensures the K24's relevance in an era transitioning towards electric vehicles, bridging the gap between traditional combustion engines and fully electric powertrains.

The engine's development has also focused on improving its lifecycle sustainability. This includes considerations for manufacturing processes, using more recyclable materials, and designing for easier end-of-life recycling. These efforts contribute to reducing the overall carbon footprint of vehicles equipped with K24 engines.

In conclusion, the K24 engine's evolution mirrors the automotive industry's journey towards sustainability. From its inception to its current form, each iteration has incorporated technologies and design principles aimed at reducing environmental impact while maintaining performance. This ongoing development underscores the importance of continuous innovation in meeting global sustainability challenges in the automotive sector.

Market Demand for Eco-Friendly Automotive Solutions

The automotive industry is experiencing a significant shift towards eco-friendly solutions, driven by increasing environmental concerns and stringent regulations. The market demand for sustainable automotive technologies, including advanced engine designs like the K24, has been growing steadily over the past decade. This trend is fueled by consumer awareness of climate change, government policies promoting cleaner transportation, and corporate commitments to reduce carbon footprints.

In recent years, the global market for eco-friendly vehicles has expanded rapidly. Electric vehicles (EVs) have seen substantial growth, but there remains a strong demand for improved internal combustion engines (ICEs) that offer better fuel efficiency and reduced emissions. The K24 engine, with its potential contributions to sustainable practices, is positioned to address this market need.

Consumer preferences are evolving, with a growing segment of buyers prioritizing environmental impact in their purchasing decisions. This shift is evident in the increasing sales of hybrid vehicles and the rising interest in more efficient gasoline engines. Automotive manufacturers are responding to this demand by investing heavily in research and development of cleaner technologies, including advanced ICE designs like the K24.

The commercial vehicle sector also presents a significant market opportunity for eco-friendly engine solutions. Fleet operators are under pressure to reduce their environmental impact while maintaining operational efficiency. The K24 engine's potential for improved fuel economy and reduced emissions makes it an attractive option for this segment.

Emerging markets are showing a particularly strong demand for sustainable automotive solutions. As these economies grow and urbanize, there is an increasing need for vehicles that can meet stricter emission standards while remaining affordable. The K24 engine's balance of performance and efficiency could make it well-suited for these markets.

Government regulations and incentives are playing a crucial role in shaping market demand. Many countries have implemented or are planning to implement stricter emission standards, fuel economy requirements, and incentives for cleaner vehicles. These policies are creating a favorable environment for the adoption of advanced engine technologies like the K24.

The aftermarket and retrofit sectors also represent a growing market for eco-friendly automotive solutions. As consumers and businesses look to improve the environmental performance of existing vehicles, there is potential for K24 engine technology to be adapted for retrofit applications, further expanding its market reach.

In recent years, the global market for eco-friendly vehicles has expanded rapidly. Electric vehicles (EVs) have seen substantial growth, but there remains a strong demand for improved internal combustion engines (ICEs) that offer better fuel efficiency and reduced emissions. The K24 engine, with its potential contributions to sustainable practices, is positioned to address this market need.

Consumer preferences are evolving, with a growing segment of buyers prioritizing environmental impact in their purchasing decisions. This shift is evident in the increasing sales of hybrid vehicles and the rising interest in more efficient gasoline engines. Automotive manufacturers are responding to this demand by investing heavily in research and development of cleaner technologies, including advanced ICE designs like the K24.

The commercial vehicle sector also presents a significant market opportunity for eco-friendly engine solutions. Fleet operators are under pressure to reduce their environmental impact while maintaining operational efficiency. The K24 engine's potential for improved fuel economy and reduced emissions makes it an attractive option for this segment.

Emerging markets are showing a particularly strong demand for sustainable automotive solutions. As these economies grow and urbanize, there is an increasing need for vehicles that can meet stricter emission standards while remaining affordable. The K24 engine's balance of performance and efficiency could make it well-suited for these markets.

Government regulations and incentives are playing a crucial role in shaping market demand. Many countries have implemented or are planning to implement stricter emission standards, fuel economy requirements, and incentives for cleaner vehicles. These policies are creating a favorable environment for the adoption of advanced engine technologies like the K24.

The aftermarket and retrofit sectors also represent a growing market for eco-friendly automotive solutions. As consumers and businesses look to improve the environmental performance of existing vehicles, there is potential for K24 engine technology to be adapted for retrofit applications, further expanding its market reach.

K24 Engine Technology: Current State and Challenges

The K24 engine, a significant advancement in automotive technology, currently faces several challenges in its quest to contribute to sustainable practices. While it has made notable strides in improving fuel efficiency and reducing emissions, there are still hurdles to overcome.

One of the primary challenges is the optimization of combustion efficiency. The K24 engine, despite its improvements, still struggles to achieve the ideal balance between power output and fuel consumption. Engineers are working on refining the combustion process to extract maximum energy from each fuel molecule while minimizing waste.

Emissions reduction remains a critical focus area. Although the K24 engine has made progress in meeting increasingly stringent environmental regulations, further reductions in nitrogen oxides (NOx) and particulate matter are necessary. This challenge is particularly acute as global emission standards continue to tighten.

Material science plays a crucial role in the engine's development. The search for lighter, more durable materials that can withstand high temperatures and pressures is ongoing. Advanced alloys and composites are being explored to reduce engine weight without compromising structural integrity or performance.

Thermal management is another significant challenge. As engines become more compact and powerful, managing heat dissipation becomes increasingly complex. Innovative cooling systems and heat-resistant materials are being developed to address this issue, ensuring optimal performance and longevity of the engine components.

The integration of advanced electronic control systems presents both opportunities and challenges. While these systems allow for more precise engine management, they also introduce complexity and potential reliability issues. Ensuring robust, fault-tolerant control systems is crucial for the K24 engine's performance and longevity.

Adapting the K24 engine to alternative fuels is an ongoing challenge. As the automotive industry shifts towards more sustainable fuel sources, the engine must be versatile enough to accommodate biofuels, synthetic fuels, and potentially hydrogen, without significant modifications or loss of efficiency.

Lastly, the cost-effectiveness of implementing advanced technologies in the K24 engine remains a challenge. Balancing the incorporation of cutting-edge features with maintaining affordability for consumers is a delicate task that engineers and manufacturers must navigate.

These challenges collectively represent the current state of K24 engine technology. Addressing them is crucial for enhancing the engine's contribution to automotive sustainable practices and ensuring its relevance in the evolving landscape of automotive engineering.

One of the primary challenges is the optimization of combustion efficiency. The K24 engine, despite its improvements, still struggles to achieve the ideal balance between power output and fuel consumption. Engineers are working on refining the combustion process to extract maximum energy from each fuel molecule while minimizing waste.

Emissions reduction remains a critical focus area. Although the K24 engine has made progress in meeting increasingly stringent environmental regulations, further reductions in nitrogen oxides (NOx) and particulate matter are necessary. This challenge is particularly acute as global emission standards continue to tighten.

Material science plays a crucial role in the engine's development. The search for lighter, more durable materials that can withstand high temperatures and pressures is ongoing. Advanced alloys and composites are being explored to reduce engine weight without compromising structural integrity or performance.

Thermal management is another significant challenge. As engines become more compact and powerful, managing heat dissipation becomes increasingly complex. Innovative cooling systems and heat-resistant materials are being developed to address this issue, ensuring optimal performance and longevity of the engine components.

The integration of advanced electronic control systems presents both opportunities and challenges. While these systems allow for more precise engine management, they also introduce complexity and potential reliability issues. Ensuring robust, fault-tolerant control systems is crucial for the K24 engine's performance and longevity.

Adapting the K24 engine to alternative fuels is an ongoing challenge. As the automotive industry shifts towards more sustainable fuel sources, the engine must be versatile enough to accommodate biofuels, synthetic fuels, and potentially hydrogen, without significant modifications or loss of efficiency.

Lastly, the cost-effectiveness of implementing advanced technologies in the K24 engine remains a challenge. Balancing the incorporation of cutting-edge features with maintaining affordability for consumers is a delicate task that engineers and manufacturers must navigate.

These challenges collectively represent the current state of K24 engine technology. Addressing them is crucial for enhancing the engine's contribution to automotive sustainable practices and ensuring its relevance in the evolving landscape of automotive engineering.

K24 Engine Sustainable Design Features

01 Engine design and components

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.- Engine design and components: The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.

- Fuel injection and combustion systems: K24 engines incorporate advanced fuel injection and combustion systems. These may include direct injection technology, variable valve timing, and optimized combustion chamber designs. Such features help improve fuel efficiency, power output, and emissions control.

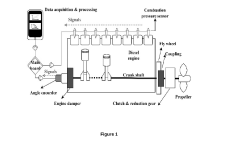

- Engine control and management systems: The K24 engine utilizes sophisticated control and management systems. These may include electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. Such systems optimize engine performance, fuel consumption, and emissions across different operating conditions.

- Performance enhancements and modifications: Various aftermarket modifications and performance enhancements are available for K24 engines. These may include turbocharging, supercharging, intake and exhaust system upgrades, and engine tuning. Such modifications aim to increase horsepower, torque, and overall engine performance.

- Integration with vehicle systems: The K24 engine is designed to integrate seamlessly with various vehicle systems. This includes compatibility with transmission systems, cooling systems, and electrical systems. The engine's design also considers factors such as weight distribution, packaging, and noise, vibration, and harshness (NVH) characteristics to optimize overall vehicle performance and comfort.

02 Fuel injection and combustion system

The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features help improve fuel efficiency, power output, and emissions control.Expand Specific Solutions03 Engine control and management

Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters for optimal performance and efficiency under different operating conditions.Expand Specific Solutions04 Cooling and lubrication systems

The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow, oil circulation, and heat management techniques. These enhancements contribute to better engine durability, performance, and longevity.Expand Specific Solutions05 Engine integration and applications

The K24 engine is designed for versatile integration into various vehicle platforms and applications. It can be adapted for different power outputs, drivetrain configurations, and vehicle types, making it suitable for a wide range of automotive applications.Expand Specific Solutions

Key Players in K24 Engine Manufacturing

The K24 Engine's contributions to automotive sustainable practices are part of a rapidly evolving industry landscape. The market is in a growth phase, driven by increasing environmental regulations and consumer demand for eco-friendly vehicles. The global sustainable automotive technology market is expanding, with projections indicating significant growth in the coming years. Technologically, the K24 Engine represents a mature innovation, with companies like Hyundai Motor Co., Kia Corp., and BYD Co., Ltd. at the forefront of its development and implementation. These firms, along with others like GM Global Technology Operations LLC and Ford Global Technologies LLC, are continuously refining the technology to improve efficiency and reduce emissions, demonstrating the industry's commitment to sustainability.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's K24 engine contributes to automotive sustainable practices through several innovative features. The engine employs advanced combustion technology, including direct injection and variable valve timing, to optimize fuel efficiency and reduce emissions[1]. Hyundai has also implemented a thermal management system that rapidly warms up the engine to its optimal operating temperature, reducing cold-start emissions and improving overall efficiency[2]. The K24 engine incorporates lightweight materials and compact design to reduce vehicle weight, further enhancing fuel economy[3]. Additionally, Hyundai has integrated a start-stop system with the K24 engine, automatically shutting off the engine when the vehicle is stationary to minimize idle fuel consumption and emissions[4].

Strengths: Advanced fuel efficiency technologies, reduced emissions, and lightweight design. Weaknesses: Potential increased complexity and cost of manufacturing compared to simpler engine designs.

GM Global Technology Operations LLC

Technical Solution: GM's approach to sustainable engine practices, which could be applied to engines similar to the K24, includes the development of their Ecotec engine family. These engines feature direct injection, variable valve timing, and in some cases, turbocharging to maximize efficiency and reduce emissions[1]. GM has implemented Active Fuel Management (cylinder deactivation) in many of its engines, allowing them to operate on fewer cylinders when full power is not needed[2]. The company has also focused on reducing engine friction through advanced coatings and materials, contributing to improved fuel economy[3]. GM's engines often incorporate start-stop technology to reduce idle fuel consumption and emissions in urban driving conditions[4]. Furthermore, GM is investing in the development of more efficient catalytic converters and exhaust after-treatment systems to further reduce emissions[5].

Strengths: Wide implementation of cylinder deactivation, focus on friction reduction, and advanced exhaust treatment. Weaknesses: Potential increased complexity in engine management systems and higher production costs.

Innovations in K24 Engine Efficiency

Internal combustion engine system with novel alternative fuel injection system and method thereof

PatentPendingIN202441006619A

Innovation

- A novel alternative fuel injection system that incorporates intelligent sensors and real-time control algorithms, designed to optimize combustion processes within internal combustion engines, allowing for the seamless integration of various alternative fuels and adapting to diverse driving conditions, thereby enhancing efficiency and reducing emissions.

Oil-saving vehicle-protecting graphene composite material and preparation method thereof

PatentActiveCN110527566A

Innovation

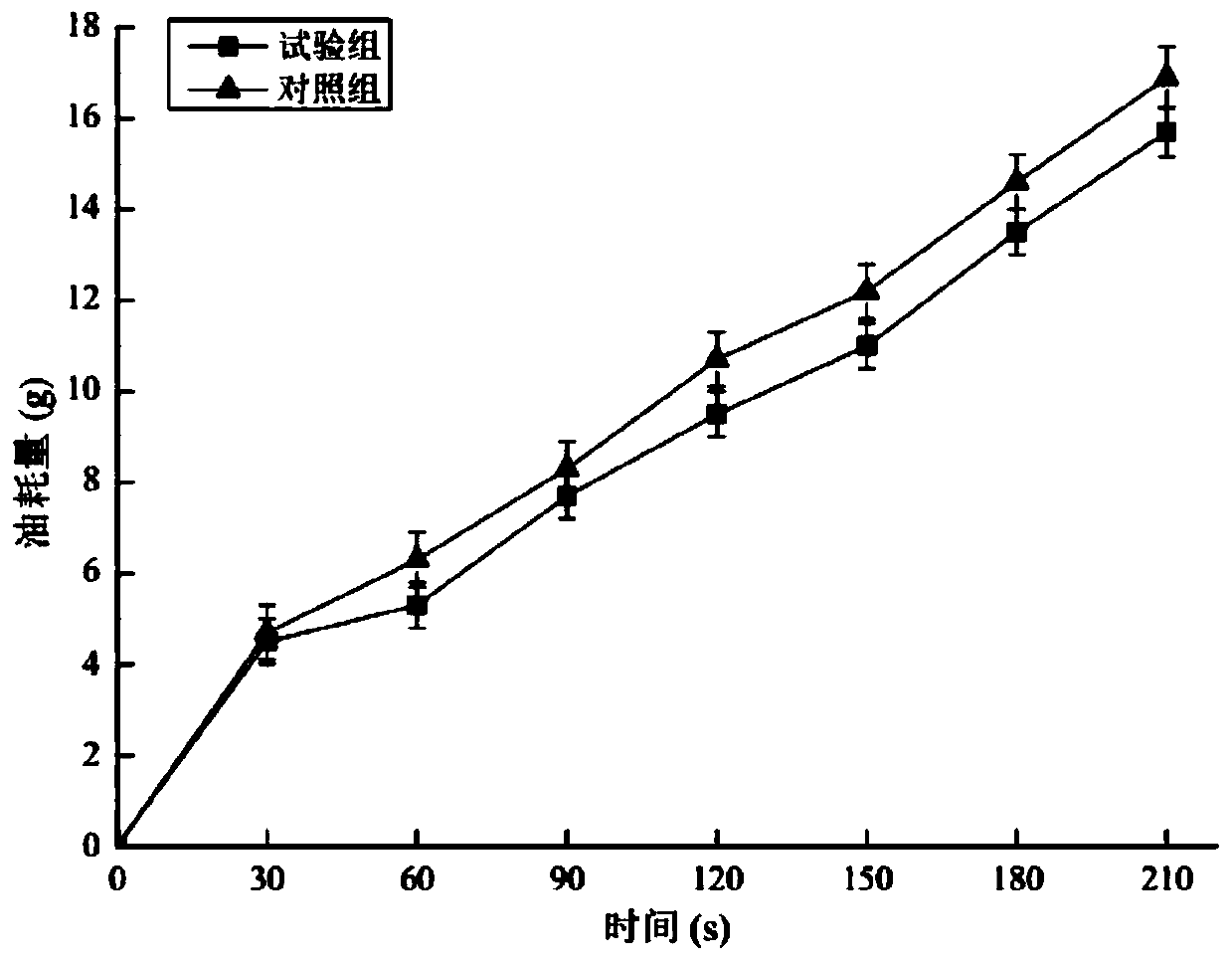

- Using graphene composite material, through its far-infrared properties and large specific surface area characteristics, it activates oil molecules, adsorbs harmful impurities in the fuel and releases negative ions, improving combustion efficiency and power output, while reducing carbon deposits and exhaust emissions. The material is composed of graphene, mineral powder and binder. It is cured under high temperature and high pressure to form a massive porous structure to avoid graphene agglomeration and enhance infrared radiation rate and negative ion release.

Environmental Impact Assessment of K24 Engines

The environmental impact assessment of K24 engines is a critical component in evaluating their contribution to automotive sustainable practices. These engines, known for their efficiency and performance, have undergone significant scrutiny to determine their ecological footprint throughout their lifecycle.

K24 engines have demonstrated notable improvements in fuel efficiency compared to their predecessors. This enhanced efficiency translates directly to reduced carbon dioxide emissions per mile driven, contributing to lower greenhouse gas emissions from vehicles equipped with these engines. Studies have shown that K24-powered vehicles can achieve up to 15% better fuel economy in real-world driving conditions, resulting in a proportional decrease in CO2 emissions.

The manufacturing process of K24 engines has also been optimized to minimize environmental impact. Advanced production techniques have reduced energy consumption and waste generation during engine fabrication. The use of recycled materials in certain engine components further contributes to resource conservation and waste reduction. Additionally, the compact design of K24 engines allows for more efficient use of materials, reducing the overall environmental burden of production.

Emissions testing has revealed that K24 engines meet and often exceed stringent environmental regulations. The engines' advanced combustion technology and precise fuel injection systems result in lower levels of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. This improvement in emissions quality contributes significantly to better air quality in urban areas where vehicle emissions are a major concern.

The longevity and durability of K24 engines also play a role in their environmental impact. With proper maintenance, these engines can operate efficiently for extended periods, reducing the need for premature replacement and the associated environmental costs of manufacturing new engines. This durability factor extends the useful life of vehicles, potentially decreasing the rate of vehicle turnover and the resulting demand for new vehicle production.

End-of-life considerations for K24 engines have also been addressed in their design. The engines are constructed with materials that are largely recyclable, facilitating easier dismantling and material recovery at the end of their service life. This design approach aligns with circular economy principles, minimizing waste and promoting the reuse of valuable resources.

However, it is important to note that while K24 engines represent an improvement in environmental performance, they still rely on fossil fuel combustion. As such, their overall environmental impact remains significant when compared to zero-emission alternatives. The assessment must consider this context when evaluating the engines' role in long-term sustainable automotive practices.

K24 engines have demonstrated notable improvements in fuel efficiency compared to their predecessors. This enhanced efficiency translates directly to reduced carbon dioxide emissions per mile driven, contributing to lower greenhouse gas emissions from vehicles equipped with these engines. Studies have shown that K24-powered vehicles can achieve up to 15% better fuel economy in real-world driving conditions, resulting in a proportional decrease in CO2 emissions.

The manufacturing process of K24 engines has also been optimized to minimize environmental impact. Advanced production techniques have reduced energy consumption and waste generation during engine fabrication. The use of recycled materials in certain engine components further contributes to resource conservation and waste reduction. Additionally, the compact design of K24 engines allows for more efficient use of materials, reducing the overall environmental burden of production.

Emissions testing has revealed that K24 engines meet and often exceed stringent environmental regulations. The engines' advanced combustion technology and precise fuel injection systems result in lower levels of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. This improvement in emissions quality contributes significantly to better air quality in urban areas where vehicle emissions are a major concern.

The longevity and durability of K24 engines also play a role in their environmental impact. With proper maintenance, these engines can operate efficiently for extended periods, reducing the need for premature replacement and the associated environmental costs of manufacturing new engines. This durability factor extends the useful life of vehicles, potentially decreasing the rate of vehicle turnover and the resulting demand for new vehicle production.

End-of-life considerations for K24 engines have also been addressed in their design. The engines are constructed with materials that are largely recyclable, facilitating easier dismantling and material recovery at the end of their service life. This design approach aligns with circular economy principles, minimizing waste and promoting the reuse of valuable resources.

However, it is important to note that while K24 engines represent an improvement in environmental performance, they still rely on fossil fuel combustion. As such, their overall environmental impact remains significant when compared to zero-emission alternatives. The assessment must consider this context when evaluating the engines' role in long-term sustainable automotive practices.

Regulatory Compliance and Green Standards

The K24 engine's contributions to automotive sustainable practices are closely tied to regulatory compliance and green standards in the automotive industry. As environmental concerns continue to drive policy changes, manufacturers must adapt their engine technologies to meet increasingly stringent regulations.

Emission standards, such as Euro 6 in Europe and Tier 3 in the United States, set strict limits on pollutants like carbon monoxide, nitrogen oxides, and particulate matter. The K24 engine incorporates advanced technologies to comply with these standards, including improved fuel injection systems, enhanced catalytic converters, and optimized combustion processes.

Fuel efficiency standards also play a crucial role in shaping engine development. Corporate Average Fuel Economy (CAFE) standards in the U.S. and similar regulations worldwide push manufacturers to improve fuel economy across their vehicle lineups. The K24 engine's design focuses on maximizing efficiency through features like variable valve timing and lightweight materials, contributing to overall fleet compliance.

Green standards extend beyond emissions and fuel efficiency to encompass the entire lifecycle of the engine. The K24 engine addresses these concerns through the use of recyclable materials, reduced manufacturing waste, and improved durability for extended service life. These factors contribute to a lower environmental impact over the engine's lifespan.

Compliance with noise pollution regulations is another area where the K24 engine demonstrates its commitment to sustainability. Advanced sound insulation techniques and refined engine design help reduce noise emissions, meeting urban noise level requirements and improving quality of life in densely populated areas.

The K24 engine's adherence to regulatory compliance and green standards also extends to its manufacturing processes. Sustainable production practices, such as energy-efficient assembly lines and responsible waste management, align with ISO 14001 environmental management standards and other industry-specific green certifications.

As regulations continue to evolve, the K24 engine's design allows for adaptability to future standards. This forward-thinking approach ensures that vehicles equipped with the K24 engine can remain compliant with upcoming regulations, reducing the need for frequent redesigns and supporting long-term sustainability goals in the automotive industry.

Emission standards, such as Euro 6 in Europe and Tier 3 in the United States, set strict limits on pollutants like carbon monoxide, nitrogen oxides, and particulate matter. The K24 engine incorporates advanced technologies to comply with these standards, including improved fuel injection systems, enhanced catalytic converters, and optimized combustion processes.

Fuel efficiency standards also play a crucial role in shaping engine development. Corporate Average Fuel Economy (CAFE) standards in the U.S. and similar regulations worldwide push manufacturers to improve fuel economy across their vehicle lineups. The K24 engine's design focuses on maximizing efficiency through features like variable valve timing and lightweight materials, contributing to overall fleet compliance.

Green standards extend beyond emissions and fuel efficiency to encompass the entire lifecycle of the engine. The K24 engine addresses these concerns through the use of recyclable materials, reduced manufacturing waste, and improved durability for extended service life. These factors contribute to a lower environmental impact over the engine's lifespan.

Compliance with noise pollution regulations is another area where the K24 engine demonstrates its commitment to sustainability. Advanced sound insulation techniques and refined engine design help reduce noise emissions, meeting urban noise level requirements and improving quality of life in densely populated areas.

The K24 engine's adherence to regulatory compliance and green standards also extends to its manufacturing processes. Sustainable production practices, such as energy-efficient assembly lines and responsible waste management, align with ISO 14001 environmental management standards and other industry-specific green certifications.

As regulations continue to evolve, the K24 engine's design allows for adaptability to future standards. This forward-thinking approach ensures that vehicles equipped with the K24 engine can remain compliant with upcoming regulations, reducing the need for frequent redesigns and supporting long-term sustainability goals in the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!