K24 Engine Conversion Kits: What You Need to Know

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in the early 2000s. This 2.4-liter inline-four engine has become a favorite among automotive enthusiasts for its reliability, performance potential, and versatility.

Initially introduced in the 2002 Honda CR-V, the K24A1 variant marked the beginning of the K24 series. This early version produced a modest 160 horsepower and 162 lb-ft of torque. However, Honda quickly recognized the engine's potential and began refining it for various applications across their vehicle lineup.

The evolution of the K24 engine saw several key improvements over time. One significant development was the introduction of the i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This technology allowed for better control over valve timing and lift, resulting in improved performance and fuel efficiency across a broader range of engine speeds.

As the K24 engine matured, Honda introduced higher-performance variants such as the K24A2 found in the Acura TSX. This version boasted increased power output, reaching up to 205 horsepower in some applications. The engine's evolution also included advancements in materials and manufacturing processes, leading to enhanced durability and reduced weight.

The K24's adaptability became evident as it found its way into a diverse array of vehicles, from compact sedans to crossover SUVs. This versatility contributed to its popularity among aftermarket tuners and engine swap enthusiasts. The engine's robust design and high-revving nature made it an ideal candidate for performance modifications.

Later iterations of the K24, such as the K24Z series, incorporated further refinements. These included improved cylinder head designs, more efficient intake and exhaust systems, and enhanced engine management systems. These updates allowed for better thermal efficiency, reduced emissions, and increased power output while maintaining the engine's renowned reliability.

The K24's evolution also saw it adapted for hybrid applications, demonstrating Honda's commitment to environmental consciousness without sacrificing performance. This adaptability ensured the K24's relevance well into the era of increasing fuel economy standards and emissions regulations.

Throughout its lifespan, the K24 engine has maintained a reputation for exceptional balance between performance, efficiency, and reliability. Its evolution from a modest powerplant to a versatile, high-performance engine has cemented its status as one of Honda's most successful and enduring engine designs.

Initially introduced in the 2002 Honda CR-V, the K24A1 variant marked the beginning of the K24 series. This early version produced a modest 160 horsepower and 162 lb-ft of torque. However, Honda quickly recognized the engine's potential and began refining it for various applications across their vehicle lineup.

The evolution of the K24 engine saw several key improvements over time. One significant development was the introduction of the i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This technology allowed for better control over valve timing and lift, resulting in improved performance and fuel efficiency across a broader range of engine speeds.

As the K24 engine matured, Honda introduced higher-performance variants such as the K24A2 found in the Acura TSX. This version boasted increased power output, reaching up to 205 horsepower in some applications. The engine's evolution also included advancements in materials and manufacturing processes, leading to enhanced durability and reduced weight.

The K24's adaptability became evident as it found its way into a diverse array of vehicles, from compact sedans to crossover SUVs. This versatility contributed to its popularity among aftermarket tuners and engine swap enthusiasts. The engine's robust design and high-revving nature made it an ideal candidate for performance modifications.

Later iterations of the K24, such as the K24Z series, incorporated further refinements. These included improved cylinder head designs, more efficient intake and exhaust systems, and enhanced engine management systems. These updates allowed for better thermal efficiency, reduced emissions, and increased power output while maintaining the engine's renowned reliability.

The K24's evolution also saw it adapted for hybrid applications, demonstrating Honda's commitment to environmental consciousness without sacrificing performance. This adaptability ensured the K24's relevance well into the era of increasing fuel economy standards and emissions regulations.

Throughout its lifespan, the K24 engine has maintained a reputation for exceptional balance between performance, efficiency, and reliability. Its evolution from a modest powerplant to a versatile, high-performance engine has cemented its status as one of Honda's most successful and enduring engine designs.

Market Demand Analysis

The market demand for K24 engine conversion kits has been steadily growing in recent years, driven by automotive enthusiasts seeking to upgrade their vehicles' performance and power output. This trend is particularly prominent in the Honda and Acura aftermarket community, where the K24 engine is highly regarded for its reliability, power potential, and versatility.

The primary target market for K24 conversion kits consists of owners of older Honda and Acura models, as well as custom car builders and racing teams. These consumers are typically looking to replace their stock engines with the more powerful and efficient K24 engine. The demand is especially strong among owners of vehicles originally equipped with B-series or F-series engines, as the K24 offers significant performance improvements over these older powerplants.

Market research indicates that the global automotive engine market, which includes aftermarket engine conversions, is expected to grow at a compound annual growth rate (CAGR) of around 6% between 2021 and 2026. While specific data for K24 conversion kits is limited, industry experts estimate that the demand for these kits is growing at a similar or slightly higher rate within the Honda/Acura aftermarket segment.

The increasing popularity of K24 swaps can be attributed to several factors. First, the K24 engine's reputation for reliability and durability makes it an attractive option for those looking to upgrade their vehicles without sacrificing longevity. Second, the wide availability of aftermarket parts and tuning options for the K24 allows enthusiasts to easily customize and enhance their engine builds.

Furthermore, the rising interest in track days and amateur racing events has contributed to the demand for K24 conversion kits. Many enthusiasts are turning to these engine swaps to improve their vehicles' performance on the track while maintaining street drivability.

The market for K24 conversion kits is not limited to Honda and Acura vehicles. There is a growing trend of K24 swaps in other makes and models, including rear-wheel-drive platforms. This expansion into new vehicle applications has further increased the overall market demand for K24 conversion kits and related components.

As environmental regulations become stricter, there is also a potential market for K24 conversions as a more fuel-efficient alternative to older, less efficient engines. This could open up new opportunities for kit manufacturers to target environmentally conscious consumers looking to improve their vehicle's fuel economy without sacrificing performance.

The primary target market for K24 conversion kits consists of owners of older Honda and Acura models, as well as custom car builders and racing teams. These consumers are typically looking to replace their stock engines with the more powerful and efficient K24 engine. The demand is especially strong among owners of vehicles originally equipped with B-series or F-series engines, as the K24 offers significant performance improvements over these older powerplants.

Market research indicates that the global automotive engine market, which includes aftermarket engine conversions, is expected to grow at a compound annual growth rate (CAGR) of around 6% between 2021 and 2026. While specific data for K24 conversion kits is limited, industry experts estimate that the demand for these kits is growing at a similar or slightly higher rate within the Honda/Acura aftermarket segment.

The increasing popularity of K24 swaps can be attributed to several factors. First, the K24 engine's reputation for reliability and durability makes it an attractive option for those looking to upgrade their vehicles without sacrificing longevity. Second, the wide availability of aftermarket parts and tuning options for the K24 allows enthusiasts to easily customize and enhance their engine builds.

Furthermore, the rising interest in track days and amateur racing events has contributed to the demand for K24 conversion kits. Many enthusiasts are turning to these engine swaps to improve their vehicles' performance on the track while maintaining street drivability.

The market for K24 conversion kits is not limited to Honda and Acura vehicles. There is a growing trend of K24 swaps in other makes and models, including rear-wheel-drive platforms. This expansion into new vehicle applications has further increased the overall market demand for K24 conversion kits and related components.

As environmental regulations become stricter, there is also a potential market for K24 conversions as a more fuel-efficient alternative to older, less efficient engines. This could open up new opportunities for kit manufacturers to target environmentally conscious consumers looking to improve their vehicle's fuel economy without sacrificing performance.

Technical Challenges

The K24 engine conversion presents several technical challenges that require careful consideration and engineering expertise to overcome. One of the primary obstacles is the physical fitment of the K24 engine into vehicles not originally designed to accommodate it. This often necessitates custom mounting solutions, modifications to the engine bay, and potential alterations to the vehicle's subframe or chassis.

Another significant challenge lies in the integration of the K24's electronic systems with the host vehicle's existing electrical architecture. Modern engines rely heavily on complex electronic control units (ECUs) and sensor networks, which may not be compatible with older vehicle systems. This incompatibility can lead to issues with engine management, performance optimization, and even basic functionality.

The cooling system presents another area of technical difficulty. The K24 engine may have different cooling requirements compared to the original engine, necessitating redesigns of radiator setups, coolant routing, and potentially the addition of oil coolers to maintain optimal operating temperatures under various conditions.

Transmission compatibility is a crucial aspect that cannot be overlooked. The K24 engine may require a different transmission than what was originally paired with the vehicle's engine. This can lead to challenges in finding appropriate transmission options, designing custom bellhousing adapters, and ensuring proper driveshaft alignment and length.

Exhaust system design and implementation pose additional technical hurdles. The K24's exhaust manifold configuration may not align with the existing exhaust layout of the vehicle, necessitating custom headers and exhaust routing. This can be particularly challenging in tight engine bays or when trying to maintain compliance with emissions regulations.

Fuel system modifications are often necessary to support the K24 engine's fuel delivery requirements. This may involve upgrading fuel pumps, injectors, and fuel lines, as well as recalibrating fuel pressure regulators to ensure optimal fuel delivery across the engine's operating range.

The engine management system presents a complex challenge, as it needs to be tailored to the specific characteristics of the K24 engine while also integrating with any retained vehicle systems. This often requires custom ECU programming, extensive tuning, and potentially the use of aftermarket engine management solutions to achieve optimal performance and drivability.

Lastly, achieving proper weight distribution and maintaining vehicle balance after the engine swap can be technically demanding. The K24 engine may have different weight and center of gravity characteristics compared to the original engine, potentially affecting the vehicle's handling dynamics and requiring suspension modifications to compensate.

Another significant challenge lies in the integration of the K24's electronic systems with the host vehicle's existing electrical architecture. Modern engines rely heavily on complex electronic control units (ECUs) and sensor networks, which may not be compatible with older vehicle systems. This incompatibility can lead to issues with engine management, performance optimization, and even basic functionality.

The cooling system presents another area of technical difficulty. The K24 engine may have different cooling requirements compared to the original engine, necessitating redesigns of radiator setups, coolant routing, and potentially the addition of oil coolers to maintain optimal operating temperatures under various conditions.

Transmission compatibility is a crucial aspect that cannot be overlooked. The K24 engine may require a different transmission than what was originally paired with the vehicle's engine. This can lead to challenges in finding appropriate transmission options, designing custom bellhousing adapters, and ensuring proper driveshaft alignment and length.

Exhaust system design and implementation pose additional technical hurdles. The K24's exhaust manifold configuration may not align with the existing exhaust layout of the vehicle, necessitating custom headers and exhaust routing. This can be particularly challenging in tight engine bays or when trying to maintain compliance with emissions regulations.

Fuel system modifications are often necessary to support the K24 engine's fuel delivery requirements. This may involve upgrading fuel pumps, injectors, and fuel lines, as well as recalibrating fuel pressure regulators to ensure optimal fuel delivery across the engine's operating range.

The engine management system presents a complex challenge, as it needs to be tailored to the specific characteristics of the K24 engine while also integrating with any retained vehicle systems. This often requires custom ECU programming, extensive tuning, and potentially the use of aftermarket engine management solutions to achieve optimal performance and drivability.

Lastly, achieving proper weight distribution and maintaining vehicle balance after the engine swap can be technically demanding. The K24 engine may have different weight and center of gravity characteristics compared to the original engine, potentially affecting the vehicle's handling dynamics and requiring suspension modifications to compensate.

Current Conversion Kits

01 Engine conversion kit components

K24 engine conversion kits typically include various components necessary for installing the K24 engine into a different vehicle. These components may include engine mounts, wiring harnesses, intake and exhaust systems, and other hardware specific to the conversion process. The kit aims to simplify the engine swap by providing all the necessary parts for a successful installation.- Engine conversion kit components: K24 engine conversion kits typically include various components necessary for installing the K24 engine into a different vehicle. These components may include engine mounts, wiring harnesses, intake and exhaust systems, and other hardware specific to the conversion process. The kit aims to simplify the engine swap by providing all the necessary parts and instructions for a successful installation.

- Electronic control unit (ECU) adaptation: Adapting the electronic control unit is crucial for a K24 engine conversion. This involves reprogramming or replacing the ECU to ensure proper communication with the new engine and vehicle systems. The adapted ECU manages fuel injection, ignition timing, and other critical engine functions to optimize performance and efficiency in the new vehicle application.

- Cooling system modifications: K24 engine conversions often require modifications to the cooling system to ensure proper heat management. This may involve installing a new radiator, modifying coolant lines, or adding auxiliary cooling components. The goal is to maintain optimal engine temperature and prevent overheating in the new vehicle configuration.

- Transmission adaptation: Adapting the transmission to work with the K24 engine is a crucial aspect of the conversion process. This may involve using a compatible transmission from the K-series family or modifying the existing transmission to fit the new engine. The kit may include necessary adapters, mounts, and linkages to ensure proper integration of the engine and transmission.

- Performance upgrades and tuning: K24 engine conversion kits may include or accommodate performance upgrades to enhance the engine's output in its new application. This can involve high-flow intake systems, performance exhaust components, and tuning options for the ECU. These upgrades allow users to customize the engine's performance characteristics to suit their specific needs and preferences.

02 Electronic control unit (ECU) adaptation

Adapting the electronic control unit is crucial for a K24 engine conversion. This involves reprogramming or replacing the ECU to ensure proper communication with the new engine and vehicle systems. The adapted ECU manages fuel injection, ignition timing, and other critical engine functions to optimize performance and efficiency in the converted vehicle.Expand Specific Solutions03 Cooling system modifications

K24 engine conversions often require modifications to the cooling system to ensure proper heat management. This may involve installing a new radiator, modifying coolant lines, or adding auxiliary cooling components. The goal is to maintain optimal engine temperature and prevent overheating issues in the converted vehicle.Expand Specific Solutions04 Transmission compatibility and adaptation

Ensuring compatibility between the K24 engine and the vehicle's transmission is essential for a successful conversion. This may involve using adapter plates, modifying the transmission, or installing a new transmission altogether. The aim is to achieve proper fitment and optimal power transfer from the engine to the wheels.Expand Specific Solutions05 Performance tuning and optimization

After the K24 engine conversion, performance tuning and optimization are often necessary to maximize the engine's potential in its new application. This may include adjusting fuel maps, ignition timing, and other parameters to achieve the desired balance of power, efficiency, and reliability. Custom tuning can help address any specific requirements or preferences of the vehicle owner.Expand Specific Solutions

Key Manufacturers

The K24 engine conversion kit market is in a growth phase, driven by increasing demand for performance upgrades in the automotive aftermarket. The market size is expanding as more enthusiasts seek to enhance their vehicles' power and efficiency. Technologically, these kits are becoming more sophisticated, with companies like DENSO Corp., BYD Co., Ltd., and Toyota Motor Corp. leading innovation. While established automotive giants like Ford and GM offer OEM solutions, specialized firms such as Current EV Motors, LLC and BorgWarner, Inc. are developing advanced conversion technologies. The competitive landscape is diverse, with a mix of traditional automakers and emerging tech companies vying for market share in this evolving sector.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive K24 Engine Conversion Kit that allows for seamless integration of their reliable K24 engine into various vehicle models. The kit includes a custom engine mount system, wiring harness adapters, and ECU reprogramming tools. Toyota's approach focuses on maintaining optimal performance while ensuring compatibility with existing vehicle systems. The kit also features advanced thermal management solutions to address heat dissipation concerns in different vehicle configurations[1]. Toyota's engineers have incorporated lessons learned from their hybrid technology to optimize the K24 engine's fuel efficiency and emissions control when used in conversion projects[3].

Strengths: Reliability, comprehensive kit design, and leveraging hybrid technology expertise. Weaknesses: Potentially higher cost compared to aftermarket solutions and limited customization options.

GM Global Technology Operations LLC

Technical Solution: GM's K24 Engine Conversion Kit is designed with a focus on versatility and ease of installation. The kit includes a modular mounting system that can adapt to various GM vehicle platforms, reducing the need for custom fabrication. GM has also developed a proprietary software package that allows for seamless integration of the K24 engine with existing GM vehicle electronics and diagnostics systems. The kit incorporates advanced materials in its components, such as lightweight alloys for brackets and heat-resistant polymers for wiring harnesses, to enhance durability and reduce overall weight[2]. GM's solution also includes a comprehensive emissions control package to ensure compliance with current and future regulations across different markets[5].

Strengths: Wide compatibility with GM vehicles, advanced materials usage, and emissions compliance. Weaknesses: May be less suitable for non-GM vehicles and potentially higher cost due to proprietary technology.

Core Technologies

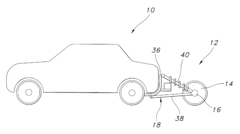

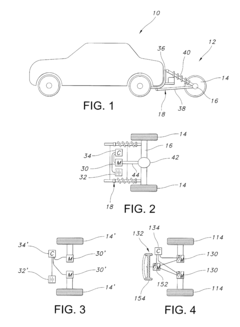

Hybrid Conversion Kits And Methods

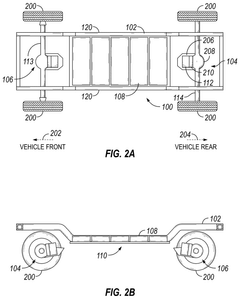

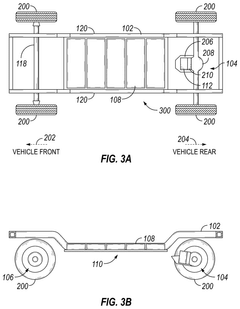

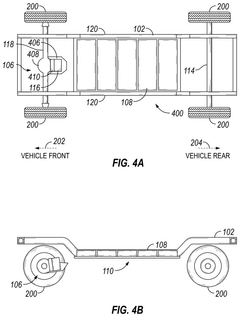

PatentInactiveUS20090127008A1

Innovation

- A hybrid conversion kit comprising a frame assembly, an auxiliary wheel, a generator/motor, and an energy storage device, along with a controller, which allows for the attachment to a pre-existing vehicle to capture kinetic energy during deceleration and store it for later use, enhancing fuel efficiency and reducing environmental impact.

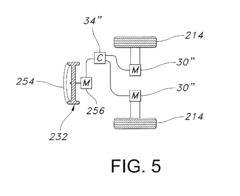

Universal Electric Conversion Process for Internal Combustion Vehicles

PatentPendingUS20240326569A1

Innovation

- The development of a universal electric conversion kit that integrates the electric motor and axle as a single unit, allows for easy mounting under existing vehicle mounting points, and optimizes battery placement between frame rails for improved stability and accessibility, enabling easy upgrades and reducing conversion costs.

Performance Benchmarks

Performance benchmarks are crucial for evaluating the effectiveness of K24 engine conversion kits. These benchmarks provide quantifiable data on the improvements achieved through the conversion process, allowing enthusiasts and mechanics to make informed decisions.

One of the primary performance metrics is horsepower gain. K24 engine conversions typically result in a significant increase in horsepower, with many kits offering gains of 50-100 horsepower or more over the stock engine. This boost in power is often accompanied by a corresponding increase in torque, enhancing overall vehicle performance.

Acceleration times serve as another key benchmark. The 0-60 mph time is a standard measure, with K24 conversions often reducing this time by 1-2 seconds or more, depending on the specific kit and vehicle configuration. Quarter-mile times are also commonly used to assess performance improvements, with converted vehicles frequently shaving off 0.5-1 second from their stock times.

Top speed increases are another notable benchmark, though these are less frequently emphasized due to practical and legal limitations on public roads. Nevertheless, K24 conversions can potentially raise a vehicle's top speed by 10-20 mph or more.

Fuel efficiency is an often-overlooked benchmark, but it's important to consider. While K24 conversions generally focus on performance gains, some kits may offer improved fuel economy due to the engine's more modern design and better power-to-weight ratio. However, this can vary significantly based on driving style and specific modifications.

Throttle response and power delivery characteristics are qualitative benchmarks that are equally important. K24 conversions typically result in more responsive throttle input and smoother power delivery across the RPM range, enhancing the overall driving experience.

Durability and reliability metrics, while harder to quantify, are crucial long-term benchmarks. K24 engines are known for their robustness, and conversion kits often maintain or even improve upon the original engine's longevity, provided proper installation and maintenance procedures are followed.

Lastly, emissions performance is an increasingly important benchmark, especially in regions with strict environmental regulations. Many K24 conversion kits are designed to meet or exceed emissions standards, ensuring that the increased performance doesn't come at the cost of environmental compliance.

One of the primary performance metrics is horsepower gain. K24 engine conversions typically result in a significant increase in horsepower, with many kits offering gains of 50-100 horsepower or more over the stock engine. This boost in power is often accompanied by a corresponding increase in torque, enhancing overall vehicle performance.

Acceleration times serve as another key benchmark. The 0-60 mph time is a standard measure, with K24 conversions often reducing this time by 1-2 seconds or more, depending on the specific kit and vehicle configuration. Quarter-mile times are also commonly used to assess performance improvements, with converted vehicles frequently shaving off 0.5-1 second from their stock times.

Top speed increases are another notable benchmark, though these are less frequently emphasized due to practical and legal limitations on public roads. Nevertheless, K24 conversions can potentially raise a vehicle's top speed by 10-20 mph or more.

Fuel efficiency is an often-overlooked benchmark, but it's important to consider. While K24 conversions generally focus on performance gains, some kits may offer improved fuel economy due to the engine's more modern design and better power-to-weight ratio. However, this can vary significantly based on driving style and specific modifications.

Throttle response and power delivery characteristics are qualitative benchmarks that are equally important. K24 conversions typically result in more responsive throttle input and smoother power delivery across the RPM range, enhancing the overall driving experience.

Durability and reliability metrics, while harder to quantify, are crucial long-term benchmarks. K24 engines are known for their robustness, and conversion kits often maintain or even improve upon the original engine's longevity, provided proper installation and maintenance procedures are followed.

Lastly, emissions performance is an increasingly important benchmark, especially in regions with strict environmental regulations. Many K24 conversion kits are designed to meet or exceed emissions standards, ensuring that the increased performance doesn't come at the cost of environmental compliance.

Emissions Regulations

Emissions regulations play a crucial role in the implementation of K24 engine conversion kits. As environmental concerns continue to grow, governments worldwide have implemented increasingly stringent emissions standards for vehicles. These regulations directly impact the legality and feasibility of engine swaps, including K24 conversions.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) are the primary regulatory bodies overseeing vehicle emissions. The EPA sets federal standards, while CARB enforces more stringent regulations in California, which many other states have adopted. These regulations require that any engine conversion must not increase the vehicle's emissions compared to its original configuration.

For K24 engine conversion kits, compliance with emissions regulations often involves the use of catalytic converters, oxygen sensors, and engine control units (ECUs) that can maintain or improve the vehicle's emissions performance. Installers must ensure that all emissions control devices are properly integrated and functioning as intended. This may require custom programming of the ECU to optimize fuel injection and ignition timing for emissions compliance.

Many jurisdictions require vehicles to undergo periodic emissions testing, which can pose challenges for K24-swapped vehicles. Owners must be prepared to demonstrate that their converted vehicle meets or exceeds the emissions standards of the original engine. This often necessitates careful documentation of the conversion process and may require additional testing and certification.

In some cases, K24 conversion kits may be marketed as "off-road use only" to circumvent emissions regulations. However, this severely limits the vehicle's legal use on public roads. Enthusiasts considering a K24 swap must carefully weigh the potential legal implications and restrictions imposed by local emissions laws.

The complexity of emissions compliance has led to the development of specialized K24 conversion kits designed to meet specific regulatory requirements. These kits often include pre-approved components and detailed installation instructions to ensure emissions compliance. However, the availability and cost of such kits can vary significantly depending on the target vehicle and local regulations.

As emissions standards continue to evolve, particularly with the push towards electrification, the future of engine swaps like the K24 conversion may face additional challenges. Enthusiasts and kit manufacturers must stay informed about changing regulations and adapt their approaches accordingly to ensure the longevity and legality of K24-swapped vehicles.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) are the primary regulatory bodies overseeing vehicle emissions. The EPA sets federal standards, while CARB enforces more stringent regulations in California, which many other states have adopted. These regulations require that any engine conversion must not increase the vehicle's emissions compared to its original configuration.

For K24 engine conversion kits, compliance with emissions regulations often involves the use of catalytic converters, oxygen sensors, and engine control units (ECUs) that can maintain or improve the vehicle's emissions performance. Installers must ensure that all emissions control devices are properly integrated and functioning as intended. This may require custom programming of the ECU to optimize fuel injection and ignition timing for emissions compliance.

Many jurisdictions require vehicles to undergo periodic emissions testing, which can pose challenges for K24-swapped vehicles. Owners must be prepared to demonstrate that their converted vehicle meets or exceeds the emissions standards of the original engine. This often necessitates careful documentation of the conversion process and may require additional testing and certification.

In some cases, K24 conversion kits may be marketed as "off-road use only" to circumvent emissions regulations. However, this severely limits the vehicle's legal use on public roads. Enthusiasts considering a K24 swap must carefully weigh the potential legal implications and restrictions imposed by local emissions laws.

The complexity of emissions compliance has led to the development of specialized K24 conversion kits designed to meet specific regulatory requirements. These kits often include pre-approved components and detailed installation instructions to ensure emissions compliance. However, the availability and cost of such kits can vary significantly depending on the target vehicle and local regulations.

As emissions standards continue to evolve, particularly with the push towards electrification, the future of engine swaps like the K24 conversion may face additional challenges. Enthusiasts and kit manufacturers must stay informed about changing regulations and adapt their approaches accordingly to ensure the longevity and legality of K24-swapped vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!