K24 Engine Evolution: Journey Through Honda Development History

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Background

The K24 engine, a cornerstone of Honda's engineering prowess, has a rich history dating back to the early 2000s. Developed as part of Honda's K-series engine family, the K24 was designed to meet the growing demand for powerful, efficient, and reliable engines in the automotive market. Its inception marked a significant milestone in Honda's commitment to innovation and performance.

The K24 engine was first introduced in 2001, initially appearing in the Honda CR-V and later expanding to various Honda and Acura models. This 2.4-liter inline-four engine was conceived as a larger displacement variant of the K-series, aimed at providing increased power and torque while maintaining the fuel efficiency and reliability that Honda was known for.

Throughout its development history, the K24 engine has undergone several iterations and improvements. The initial versions, such as the K24A1 and K24A4, set the foundation for what would become a highly versatile and adaptable engine platform. These early models demonstrated Honda's ability to balance performance with practicality, offering a compelling mix of power and economy.

As automotive technologies advanced, so did the K24 engine. Honda engineers continuously refined the design, incorporating cutting-edge technologies to enhance performance, efficiency, and emissions compliance. Notable improvements included the integration of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology, which optimized valve timing and lift for better performance across the entire RPM range.

The K24's evolution also saw the introduction of direct injection in later models, further improving fuel efficiency and power output. This adaptation showcased Honda's commitment to staying at the forefront of engine technology, even as the automotive industry began shifting towards electrification.

Over the years, the K24 engine has been utilized in a wide array of vehicles, from compact sedans to SUVs and even performance-oriented models. Its versatility and reliability have made it a favorite among Honda enthusiasts and a benchmark in the automotive industry. The engine's ability to be easily modified and tuned has also contributed to its popularity in aftermarket and racing circles.

The K24 engine's journey through Honda's development history is a testament to the company's engineering philosophy of continuous improvement and innovation. From its initial conception to its various iterations, the K24 has consistently embodied Honda's pursuit of performance, efficiency, and reliability, adapting to changing market demands and technological advancements while maintaining its core strengths.

The K24 engine was first introduced in 2001, initially appearing in the Honda CR-V and later expanding to various Honda and Acura models. This 2.4-liter inline-four engine was conceived as a larger displacement variant of the K-series, aimed at providing increased power and torque while maintaining the fuel efficiency and reliability that Honda was known for.

Throughout its development history, the K24 engine has undergone several iterations and improvements. The initial versions, such as the K24A1 and K24A4, set the foundation for what would become a highly versatile and adaptable engine platform. These early models demonstrated Honda's ability to balance performance with practicality, offering a compelling mix of power and economy.

As automotive technologies advanced, so did the K24 engine. Honda engineers continuously refined the design, incorporating cutting-edge technologies to enhance performance, efficiency, and emissions compliance. Notable improvements included the integration of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology, which optimized valve timing and lift for better performance across the entire RPM range.

The K24's evolution also saw the introduction of direct injection in later models, further improving fuel efficiency and power output. This adaptation showcased Honda's commitment to staying at the forefront of engine technology, even as the automotive industry began shifting towards electrification.

Over the years, the K24 engine has been utilized in a wide array of vehicles, from compact sedans to SUVs and even performance-oriented models. Its versatility and reliability have made it a favorite among Honda enthusiasts and a benchmark in the automotive industry. The engine's ability to be easily modified and tuned has also contributed to its popularity in aftermarket and racing circles.

The K24 engine's journey through Honda's development history is a testament to the company's engineering philosophy of continuous improvement and innovation. From its initial conception to its various iterations, the K24 has consistently embodied Honda's pursuit of performance, efficiency, and reliability, adapting to changing market demands and technological advancements while maintaining its core strengths.

Market Demand Analysis

The K24 engine series has been a cornerstone of Honda's powertrain lineup, with its evolution closely tied to market demands and consumer preferences. Since its introduction in the early 2000s, the K24 has seen consistent growth in demand across various vehicle segments, particularly in mid-size sedans, SUVs, and performance-oriented models.

Initially, the market demand for the K24 engine was driven by the need for a balance between power and fuel efficiency in family-oriented vehicles. As environmental concerns grew, consumers began seeking engines that could deliver improved fuel economy without sacrificing performance. This shift in consumer preferences aligned well with Honda's continuous refinement of the K24, which saw incremental improvements in both power output and fuel efficiency over successive generations.

The versatility of the K24 engine has been a key factor in its market success. Its adaptability to different vehicle platforms has allowed Honda to meet diverse consumer needs, from daily commuters to enthusiast-focused models. This flexibility has contributed to the engine's longevity in the market and its ability to maintain relevance across changing automotive trends.

In recent years, the market demand for K24-powered vehicles has been influenced by the growing popularity of crossovers and SUVs. The engine's robust power delivery and reliability have made it a preferred choice for these larger vehicles, where consumers expect a combination of performance and practicality. This trend has led to increased production and integration of K24 engines in Honda's expanding SUV lineup.

The performance car segment has also played a significant role in sustaining demand for the K24 engine. Enthusiasts have embraced the engine's tuning potential, creating a thriving aftermarket industry. This has not only extended the engine's appeal beyond its original target market but has also contributed to brand loyalty among performance-oriented consumers.

As the automotive industry transitions towards electrification, the market demand for traditional internal combustion engines like the K24 is evolving. While there is a gradual shift towards hybrid and electric powertrains, the K24 continues to find relevance in hybrid applications, where it serves as a reliable and efficient combustion component in Honda's hybrid systems. This adaptation to changing market demands demonstrates the engine's continued importance in Honda's powertrain strategy.

The global nature of Honda's operations has also influenced the market demand for the K24 engine. Regional preferences and regulations have shaped the engine's development and deployment across different markets, with variations in displacement and output tailored to specific geographic needs. This global approach has ensured the K24's widespread adoption and sustained demand across diverse international markets.

Initially, the market demand for the K24 engine was driven by the need for a balance between power and fuel efficiency in family-oriented vehicles. As environmental concerns grew, consumers began seeking engines that could deliver improved fuel economy without sacrificing performance. This shift in consumer preferences aligned well with Honda's continuous refinement of the K24, which saw incremental improvements in both power output and fuel efficiency over successive generations.

The versatility of the K24 engine has been a key factor in its market success. Its adaptability to different vehicle platforms has allowed Honda to meet diverse consumer needs, from daily commuters to enthusiast-focused models. This flexibility has contributed to the engine's longevity in the market and its ability to maintain relevance across changing automotive trends.

In recent years, the market demand for K24-powered vehicles has been influenced by the growing popularity of crossovers and SUVs. The engine's robust power delivery and reliability have made it a preferred choice for these larger vehicles, where consumers expect a combination of performance and practicality. This trend has led to increased production and integration of K24 engines in Honda's expanding SUV lineup.

The performance car segment has also played a significant role in sustaining demand for the K24 engine. Enthusiasts have embraced the engine's tuning potential, creating a thriving aftermarket industry. This has not only extended the engine's appeal beyond its original target market but has also contributed to brand loyalty among performance-oriented consumers.

As the automotive industry transitions towards electrification, the market demand for traditional internal combustion engines like the K24 is evolving. While there is a gradual shift towards hybrid and electric powertrains, the K24 continues to find relevance in hybrid applications, where it serves as a reliable and efficient combustion component in Honda's hybrid systems. This adaptation to changing market demands demonstrates the engine's continued importance in Honda's powertrain strategy.

The global nature of Honda's operations has also influenced the market demand for the K24 engine. Regional preferences and regulations have shaped the engine's development and deployment across different markets, with variations in displacement and output tailored to specific geographic needs. This global approach has ensured the K24's widespread adoption and sustained demand across diverse international markets.

Technical Challenges

The evolution of Honda's K24 engine has been marked by several significant technical challenges that have shaped its development over the years. One of the primary obstacles faced by Honda engineers was the need to balance increased power output with improved fuel efficiency. This challenge required innovative solutions in engine design and materials science to optimize combustion processes and reduce internal friction.

Another major hurdle in the K24's development was meeting increasingly stringent emissions regulations while maintaining performance. This necessitated the implementation of advanced fuel injection systems, variable valve timing technologies, and more efficient catalytic converters. The integration of these systems without compromising the engine's reliability or drivability posed a significant engineering challenge.

Thermal management presented another complex issue for Honda's development team. As power output increased, so did the heat generated by the engine. Developing effective cooling systems that could maintain optimal operating temperatures across a wide range of conditions, from idle to high-speed operation, required extensive research and testing.

The pursuit of a broader torque curve and improved low-end responsiveness was a persistent challenge throughout the K24's evolution. Engineers had to refine intake and exhaust systems, experiment with different camshaft profiles, and optimize valve timing to achieve a more versatile power delivery across the engine's rev range.

Weight reduction was another critical focus area, as Honda sought to improve the engine's power-to-weight ratio and overall vehicle dynamics. This involved exploring lightweight materials for engine components and redesigning parts to reduce mass without sacrificing strength or durability.

Durability and longevity were constant concerns, particularly as the K24 was adapted for use in a variety of vehicles with different duty cycles. Ensuring that the engine could withstand prolonged high-load conditions, frequent start-stop cycles, and varying maintenance schedules required extensive durability testing and refinement of manufacturing processes.

The integration of new technologies, such as direct injection and turbocharging in later iterations, presented its own set of challenges. These advancements required significant redesigns of the engine architecture and careful calibration to maintain the K24's reputation for smoothness and reliability while delivering improved performance and efficiency.

Throughout its development history, the K24 engine faced the ongoing challenge of cost management. Honda had to balance the implementation of advanced technologies and materials with the need to keep production costs competitive, ensuring that vehicles equipped with the K24 remained accessible to a broad range of consumers.

Another major hurdle in the K24's development was meeting increasingly stringent emissions regulations while maintaining performance. This necessitated the implementation of advanced fuel injection systems, variable valve timing technologies, and more efficient catalytic converters. The integration of these systems without compromising the engine's reliability or drivability posed a significant engineering challenge.

Thermal management presented another complex issue for Honda's development team. As power output increased, so did the heat generated by the engine. Developing effective cooling systems that could maintain optimal operating temperatures across a wide range of conditions, from idle to high-speed operation, required extensive research and testing.

The pursuit of a broader torque curve and improved low-end responsiveness was a persistent challenge throughout the K24's evolution. Engineers had to refine intake and exhaust systems, experiment with different camshaft profiles, and optimize valve timing to achieve a more versatile power delivery across the engine's rev range.

Weight reduction was another critical focus area, as Honda sought to improve the engine's power-to-weight ratio and overall vehicle dynamics. This involved exploring lightweight materials for engine components and redesigning parts to reduce mass without sacrificing strength or durability.

Durability and longevity were constant concerns, particularly as the K24 was adapted for use in a variety of vehicles with different duty cycles. Ensuring that the engine could withstand prolonged high-load conditions, frequent start-stop cycles, and varying maintenance schedules required extensive durability testing and refinement of manufacturing processes.

The integration of new technologies, such as direct injection and turbocharging in later iterations, presented its own set of challenges. These advancements required significant redesigns of the engine architecture and careful calibration to maintain the K24's reputation for smoothness and reliability while delivering improved performance and efficiency.

Throughout its development history, the K24 engine faced the ongoing challenge of cost management. Honda had to balance the implementation of advanced technologies and materials with the need to keep production costs competitive, ensuring that vehicles equipped with the K24 remained accessible to a broad range of consumers.

Current K24 Solutions

01 Engine design and components

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.- Engine design and structure: The K24 engine is a 2.4-liter inline-four cylinder engine known for its compact design and efficient performance. It features a lightweight aluminum block and cylinder head, dual overhead camshafts, and i-VTEC technology for improved power and fuel efficiency. The engine's design allows for easy integration into various vehicle models and applications.

- Fuel injection and combustion system: The K24 engine utilizes advanced fuel injection and combustion systems to optimize performance and reduce emissions. This includes direct fuel injection technology, variable valve timing, and precise air-fuel mixture control. The engine's combustion chamber design and piston geometry contribute to improved thermal efficiency and power output.

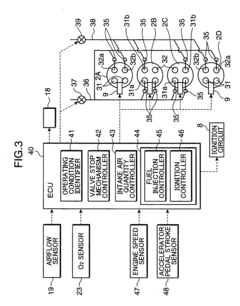

- Engine control and management: Advanced engine control systems are employed in the K24 engine to manage various parameters such as fuel injection timing, ignition timing, and valve timing. These systems utilize sensors and electronic control units to optimize engine performance, fuel efficiency, and emissions control across different operating conditions.

- Engine cooling and lubrication: The K24 engine incorporates efficient cooling and lubrication systems to maintain optimal operating temperatures and reduce friction. This includes advanced coolant circulation designs, oil cooling systems, and precision-engineered components to enhance durability and longevity of the engine.

- Engine accessories and integration: Various accessories and components are designed to integrate seamlessly with the K24 engine, enhancing its overall performance and functionality. These may include specialized intake and exhaust systems, engine mounts, and power transmission components tailored to work efficiently with the K24 engine's characteristics.

02 Fuel injection and combustion systems

Advanced fuel injection and combustion systems are incorporated in the K24 engine. These systems may include direct injection technology, variable valve timing, and optimized combustion chamber designs. Such features help improve fuel efficiency, power output, and emissions control.Expand Specific Solutions03 Engine control and management

The K24 engine utilizes sophisticated engine control and management systems. These may include electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. Such systems contribute to optimal performance, fuel economy, and emissions compliance across different operating conditions.Expand Specific Solutions04 Cooling and lubrication systems

Efficient cooling and lubrication systems are crucial for the K24 engine's performance and longevity. These may include advanced coolant circulation designs, oil pump configurations, and thermal management strategies. Such systems help maintain optimal operating temperatures and reduce wear on engine components.Expand Specific Solutions05 Engine accessories and integration

Various accessories and integration features are designed for the K24 engine to enhance its overall performance and compatibility. These may include specialized mounting systems, power transmission components, and interfaces for integration with vehicle systems. Such features contribute to improved engine installation, operation, and maintenance in different vehicle applications.Expand Specific Solutions

Key Manufacturers

The K24 engine evolution reflects a competitive landscape in the automotive industry, particularly in the realm of high-performance engines. The market is in a mature stage, with established players like Honda Motor Co., Ltd. leading the development. The global automotive engine market size is substantial, estimated to be in the billions of dollars. Technologically, the K24 engine has undergone significant advancements, with Honda at the forefront of innovation. Other major automakers such as Toyota Motor Corp., Ford Global Technologies LLC, and Nissan Motor Co., Ltd. are also actively involved in engine development, contributing to a highly competitive environment focused on improving performance, efficiency, and emissions standards.

Honda Motor Co., Ltd.

Technical Solution: Honda's K24 engine evolution represents a significant journey in automotive engineering. The K24 is part of Honda's K-series engines, known for their high-performance and efficiency. Over the years, Honda has continuously refined the K24, incorporating advanced technologies such as i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) [1]. This system optimizes valve timing and lift for both low-end torque and high-end power. Honda also implemented direct fuel injection in later iterations, improving fuel efficiency and reducing emissions [2]. The K24's aluminum block design with iron cylinder liners contributes to its lightweight yet durable construction. Honda's engineers have consistently worked on enhancing the engine's compression ratio, reaching up to 11.6:1 in some variants, which significantly improves thermal efficiency [3]. The integration of a drive-by-wire throttle system and advanced engine management computers has further optimized the K24's performance and responsiveness.

Strengths: High power-to-weight ratio, excellent fuel efficiency, and proven reliability. The i-VTEC system provides a broad powerband. Weaknesses: Complexity of the VTEC system can lead to higher maintenance costs. Some earlier versions had oil consumption issues.

Toyota Motor Corp.

Technical Solution: While Toyota is not directly involved in the K24 engine development, their approach to engine evolution provides an interesting contrast. Toyota's comparable engine series, such as the 2AZ-FE, has undergone similar evolutionary processes. Toyota has focused on their VVT-i (Variable Valve Timing with intelligence) technology, which is analogous to Honda's VTEC [4]. In recent years, Toyota has pushed towards hybrid powertrains, integrating electric motors with their internal combustion engines to improve efficiency and reduce emissions. Their Dynamic Force Engine technology, introduced in 2016, achieves a thermal efficiency of up to 41% in hybrid vehicles, setting a new benchmark in the industry [5]. Toyota's approach often emphasizes reliability and fuel efficiency over high performance, which contrasts with Honda's more performance-oriented K24 development.

Strengths: High reliability, excellent fuel efficiency, and strong focus on hybrid technology integration. Weaknesses: Sometimes perceived as less exciting or performance-oriented compared to competitors like Honda's K24.

Core K24 Innovations

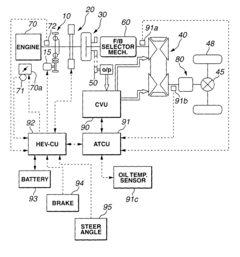

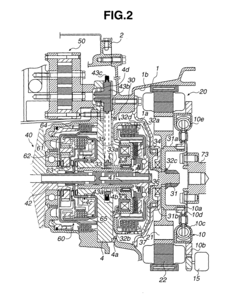

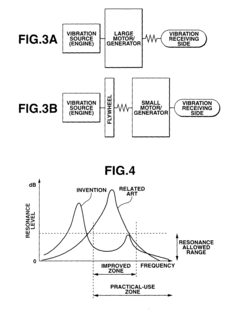

Drive apparatus for hybrid vehicle

PatentInactiveUS20040055800A1

Innovation

- A compact drive apparatus for hybrid vehicles featuring a motor-generator connected to a damper and a starter motor, with a magnetic clutch and control system that allows for engine starting and power transmission, enabling a smaller motor-generator and reduced resonance through a damper, and separate starter motor for normal starting, reducing size and cost.

Spark-ignition engine controller

PatentInactiveUS20040129245A1

Innovation

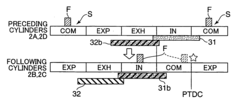

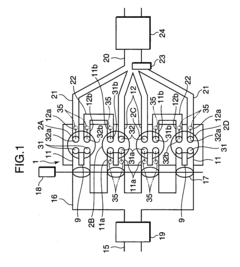

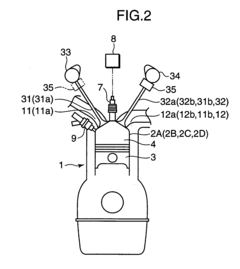

- A spark-ignition engine controller that implements a special operation mode with a two-cylinder connection through an intercylinder gas channel, allowing burned gas from one cylinder to be used for compression ignition in another, while maintaining a lean air-fuel ratio in the first cylinder for forced ignition, and adjusting fuel injection timing to prevent heavy knocking.

Environmental Impact

The environmental impact of Honda's K24 engine evolution has been a significant aspect of its development history. As automotive regulations have become increasingly stringent, Honda has continuously adapted its engine technology to meet and exceed environmental standards.

Throughout the K24 engine's lifespan, Honda has implemented various technologies to reduce emissions and improve fuel efficiency. The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) in the early 2000s marked a significant milestone in this journey. This technology optimized valve timing and lift, resulting in improved fuel economy and reduced emissions without sacrificing performance.

Honda's commitment to environmental responsibility is further evidenced by the integration of advanced catalytic converter systems in the K24 engine. These systems have become increasingly sophisticated over time, effectively reducing harmful exhaust emissions such as carbon monoxide, nitrogen oxides, and hydrocarbons.

The K24 engine's evolution also saw the implementation of direct injection technology in later iterations. This advancement allowed for more precise fuel delivery, leading to improved combustion efficiency and reduced fuel consumption. As a result, vehicles equipped with the K24 engine have consistently met and often exceeded emission standards in various markets worldwide.

Honda's Earth Dreams Technology, introduced in the 2010s, represented another leap forward in the K24 engine's environmental performance. This suite of technological improvements included enhanced thermal efficiency, reduced internal friction, and optimized combustion processes. These advancements collectively contributed to a significant reduction in the engine's carbon footprint.

The company's efforts to improve the K24 engine's environmental impact extended beyond emissions and fuel efficiency. Honda also focused on reducing the environmental impact of the engine's manufacturing process. This included the use of more sustainable materials, implementation of energy-efficient production techniques, and efforts to minimize waste throughout the engine's lifecycle.

As global awareness of climate change has increased, Honda has responded by incorporating hybrid technology into vehicles powered by the K24 engine. This hybridization strategy has further reduced the overall environmental impact of vehicles utilizing this engine, aligning with Honda's long-term sustainability goals.

In conclusion, the environmental impact of the K24 engine's evolution reflects Honda's ongoing commitment to balancing performance with ecological responsibility. Through continuous innovation and adaptation, Honda has ensured that the K24 engine remains relevant and environmentally competitive in an era of increasing environmental consciousness and regulation.

Throughout the K24 engine's lifespan, Honda has implemented various technologies to reduce emissions and improve fuel efficiency. The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) in the early 2000s marked a significant milestone in this journey. This technology optimized valve timing and lift, resulting in improved fuel economy and reduced emissions without sacrificing performance.

Honda's commitment to environmental responsibility is further evidenced by the integration of advanced catalytic converter systems in the K24 engine. These systems have become increasingly sophisticated over time, effectively reducing harmful exhaust emissions such as carbon monoxide, nitrogen oxides, and hydrocarbons.

The K24 engine's evolution also saw the implementation of direct injection technology in later iterations. This advancement allowed for more precise fuel delivery, leading to improved combustion efficiency and reduced fuel consumption. As a result, vehicles equipped with the K24 engine have consistently met and often exceeded emission standards in various markets worldwide.

Honda's Earth Dreams Technology, introduced in the 2010s, represented another leap forward in the K24 engine's environmental performance. This suite of technological improvements included enhanced thermal efficiency, reduced internal friction, and optimized combustion processes. These advancements collectively contributed to a significant reduction in the engine's carbon footprint.

The company's efforts to improve the K24 engine's environmental impact extended beyond emissions and fuel efficiency. Honda also focused on reducing the environmental impact of the engine's manufacturing process. This included the use of more sustainable materials, implementation of energy-efficient production techniques, and efforts to minimize waste throughout the engine's lifecycle.

As global awareness of climate change has increased, Honda has responded by incorporating hybrid technology into vehicles powered by the K24 engine. This hybridization strategy has further reduced the overall environmental impact of vehicles utilizing this engine, aligning with Honda's long-term sustainability goals.

In conclusion, the environmental impact of the K24 engine's evolution reflects Honda's ongoing commitment to balancing performance with ecological responsibility. Through continuous innovation and adaptation, Honda has ensured that the K24 engine remains relevant and environmentally competitive in an era of increasing environmental consciousness and regulation.

Global Regulations

The evolution of Honda's K24 engine has been significantly influenced by global regulations, particularly those focused on emissions and fuel efficiency. These regulations have played a crucial role in shaping the development trajectory of automotive engines worldwide, including Honda's K-series engines.

In the early 2000s, when the K24 engine was first introduced, emission standards were becoming increasingly stringent in major markets such as the United States, Europe, and Japan. The U.S. Environmental Protection Agency (EPA) and California Air Resources Board (CARB) implemented tighter controls on vehicle emissions, pushing automakers to develop cleaner engines.

European regulations, particularly the Euro emission standards, have also been instrumental in driving engine technology forward. The progression from Euro 3 to Euro 6 standards over the years has necessitated continuous improvements in engine design and exhaust after-treatment systems.

Japan's own emission regulations, set by the Ministry of Land, Infrastructure, Transport and Tourism, have similarly influenced Honda's domestic engine development. These standards have been progressively tightened, aligning closely with European norms.

The global push for improved fuel economy has been another significant factor. In the United States, Corporate Average Fuel Economy (CAFE) standards have become increasingly demanding, requiring automakers to achieve higher fleet-wide fuel efficiency. This has driven innovations in engine technology, including the adoption of direct injection and variable valve timing in the K24 engine.

China's rapid growth as an automotive market has introduced another layer of regulatory considerations. The country's emission standards, which have been catching up with European norms, have become a crucial factor for global automakers, including Honda.

These global regulations have not only influenced the technical specifications of the K24 engine but have also driven broader technological trends. The push for electrification, hybrid powertrains, and eventually full electric vehicles can be seen as a response to increasingly stringent global emission standards.

As a result, the K24 engine's evolution has been marked by continuous improvements in combustion efficiency, the integration of advanced fuel injection systems, and the adoption of sophisticated engine management technologies. These advancements have allowed Honda to meet increasingly strict regulatory requirements while maintaining the performance characteristics that have made the K24 engine popular among consumers.

In the early 2000s, when the K24 engine was first introduced, emission standards were becoming increasingly stringent in major markets such as the United States, Europe, and Japan. The U.S. Environmental Protection Agency (EPA) and California Air Resources Board (CARB) implemented tighter controls on vehicle emissions, pushing automakers to develop cleaner engines.

European regulations, particularly the Euro emission standards, have also been instrumental in driving engine technology forward. The progression from Euro 3 to Euro 6 standards over the years has necessitated continuous improvements in engine design and exhaust after-treatment systems.

Japan's own emission regulations, set by the Ministry of Land, Infrastructure, Transport and Tourism, have similarly influenced Honda's domestic engine development. These standards have been progressively tightened, aligning closely with European norms.

The global push for improved fuel economy has been another significant factor. In the United States, Corporate Average Fuel Economy (CAFE) standards have become increasingly demanding, requiring automakers to achieve higher fleet-wide fuel efficiency. This has driven innovations in engine technology, including the adoption of direct injection and variable valve timing in the K24 engine.

China's rapid growth as an automotive market has introduced another layer of regulatory considerations. The country's emission standards, which have been catching up with European norms, have become a crucial factor for global automakers, including Honda.

These global regulations have not only influenced the technical specifications of the K24 engine but have also driven broader technological trends. The push for electrification, hybrid powertrains, and eventually full electric vehicles can be seen as a response to increasingly stringent global emission standards.

As a result, the K24 engine's evolution has been marked by continuous improvements in combustion efficiency, the integration of advanced fuel injection systems, and the adoption of sophisticated engine management technologies. These advancements have allowed Honda to meet increasingly strict regulatory requirements while maintaining the performance characteristics that have made the K24 engine popular among consumers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!