K24 Engine in Electric Conversion: Opportunities and Challenges

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution and EV Conversion Goals

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in the late 1990s. Initially designed for high-performance applications in Honda and Acura vehicles, this 2.4-liter inline-four engine has become renowned for its reliability, efficiency, and potential for modification. Over the years, it has seen numerous improvements in areas such as variable valve timing, direct injection, and materials technology, enhancing its performance and fuel economy.

As the automotive industry shifts towards electrification, the K24 engine faces a new chapter in its evolution: adaptation for electric vehicle (EV) conversion. This transition presents both exciting opportunities and formidable challenges. The primary goal of K24 engine EV conversion is to leverage the robust and well-understood platform of this popular engine while integrating electric powertrain components to create a hybrid or fully electric system.

One key objective is to maintain or improve upon the K24's renowned performance characteristics while significantly reducing emissions and increasing overall efficiency. This involves carefully integrating electric motors, power electronics, and battery systems with the existing engine architecture. Engineers aim to preserve the engine's compact design and lightweight nature, crucial factors in its original success, while incorporating new electric components.

Another important goal is to develop a conversion process that is scalable and adaptable to various vehicle platforms. The K24 engine's widespread use across multiple Honda and Acura models provides a unique opportunity to create a standardized conversion kit that could be applied to a large fleet of vehicles, potentially accelerating the transition to electric mobility.

Preserving the reliability and longevity associated with the K24 engine is paramount in the conversion process. This involves extensive testing and validation to ensure that the integration of electric components does not compromise the engine's structural integrity or long-term durability. Additionally, engineers must address the challenge of balancing power output between the combustion engine and electric motor(s) to optimize performance and efficiency across various driving conditions.

A critical aspect of the EV conversion goals is to minimize the environmental impact of the transition. This includes not only reducing emissions during operation but also considering the lifecycle impact of the conversion process itself. Developing sustainable manufacturing and recycling processes for the new electric components is an integral part of this objective.

Lastly, the conversion aims to future-proof the K24 engine platform, ensuring its relevance in an increasingly electrified automotive landscape. This involves designing the conversion in a modular fashion, allowing for easy upgrades and adaptations as electric vehicle technology continues to advance. By doing so, the K24 engine can continue to evolve, potentially extending its lifecycle well into the era of electric mobility.

As the automotive industry shifts towards electrification, the K24 engine faces a new chapter in its evolution: adaptation for electric vehicle (EV) conversion. This transition presents both exciting opportunities and formidable challenges. The primary goal of K24 engine EV conversion is to leverage the robust and well-understood platform of this popular engine while integrating electric powertrain components to create a hybrid or fully electric system.

One key objective is to maintain or improve upon the K24's renowned performance characteristics while significantly reducing emissions and increasing overall efficiency. This involves carefully integrating electric motors, power electronics, and battery systems with the existing engine architecture. Engineers aim to preserve the engine's compact design and lightweight nature, crucial factors in its original success, while incorporating new electric components.

Another important goal is to develop a conversion process that is scalable and adaptable to various vehicle platforms. The K24 engine's widespread use across multiple Honda and Acura models provides a unique opportunity to create a standardized conversion kit that could be applied to a large fleet of vehicles, potentially accelerating the transition to electric mobility.

Preserving the reliability and longevity associated with the K24 engine is paramount in the conversion process. This involves extensive testing and validation to ensure that the integration of electric components does not compromise the engine's structural integrity or long-term durability. Additionally, engineers must address the challenge of balancing power output between the combustion engine and electric motor(s) to optimize performance and efficiency across various driving conditions.

A critical aspect of the EV conversion goals is to minimize the environmental impact of the transition. This includes not only reducing emissions during operation but also considering the lifecycle impact of the conversion process itself. Developing sustainable manufacturing and recycling processes for the new electric components is an integral part of this objective.

Lastly, the conversion aims to future-proof the K24 engine platform, ensuring its relevance in an increasingly electrified automotive landscape. This involves designing the conversion in a modular fashion, allowing for easy upgrades and adaptations as electric vehicle technology continues to advance. By doing so, the K24 engine can continue to evolve, potentially extending its lifecycle well into the era of electric mobility.

Market Analysis for K24 EV Conversions

The market for K24 engine electric conversions represents a niche but growing segment within the broader electric vehicle (EV) industry. This market is primarily driven by automotive enthusiasts and hobbyists seeking to combine the reliability and performance of the K24 engine with the benefits of electric propulsion. The demand for such conversions is influenced by several factors, including environmental concerns, rising fuel costs, and the desire for unique, customized vehicles.

The target demographic for K24 EV conversions typically consists of Honda and Acura owners, particularly those with vehicles originally equipped with K-series engines. These consumers are often mechanically inclined and value the blend of traditional engineering with modern electric technology. The market also extends to performance enthusiasts looking to enhance their vehicles' power output and torque characteristics through electrification.

Geographically, the market for K24 EV conversions is most prominent in regions with a strong car culture and supportive regulatory environments for modified vehicles. North America, particularly the United States, represents a significant market due to its large base of Honda and Acura vehicles and active aftermarket community. Europe and Japan also show potential for growth, driven by stringent emissions regulations and a culture of automotive innovation.

The market size for K24 EV conversions, while difficult to quantify precisely, is estimated to be in the tens of thousands of units annually. This figure is expected to grow as awareness increases and conversion technologies become more accessible. The average cost of a K24 EV conversion can range from $15,000 to $30,000, depending on the components used and the level of performance desired.

Key market drivers include the increasing availability of EV components, advancements in battery technology, and growing environmental consciousness among car enthusiasts. The market also benefits from the K24 engine's reputation for reliability and its widespread availability, making it an attractive option for conversion projects.

Challenges in the market include regulatory hurdles, as many regions have strict rules regarding vehicle modifications and emissions. Additionally, the high initial cost of conversions and the technical expertise required can limit market growth. Competition from factory-built EVs and other conversion options also impacts the K24 EV conversion market.

Despite these challenges, the market shows promising growth potential. As EV technology continues to advance and become more affordable, the K24 EV conversion market is likely to expand, attracting both enthusiasts and small-scale manufacturers looking to capitalize on the trend towards electrification in the automotive industry.

The target demographic for K24 EV conversions typically consists of Honda and Acura owners, particularly those with vehicles originally equipped with K-series engines. These consumers are often mechanically inclined and value the blend of traditional engineering with modern electric technology. The market also extends to performance enthusiasts looking to enhance their vehicles' power output and torque characteristics through electrification.

Geographically, the market for K24 EV conversions is most prominent in regions with a strong car culture and supportive regulatory environments for modified vehicles. North America, particularly the United States, represents a significant market due to its large base of Honda and Acura vehicles and active aftermarket community. Europe and Japan also show potential for growth, driven by stringent emissions regulations and a culture of automotive innovation.

The market size for K24 EV conversions, while difficult to quantify precisely, is estimated to be in the tens of thousands of units annually. This figure is expected to grow as awareness increases and conversion technologies become more accessible. The average cost of a K24 EV conversion can range from $15,000 to $30,000, depending on the components used and the level of performance desired.

Key market drivers include the increasing availability of EV components, advancements in battery technology, and growing environmental consciousness among car enthusiasts. The market also benefits from the K24 engine's reputation for reliability and its widespread availability, making it an attractive option for conversion projects.

Challenges in the market include regulatory hurdles, as many regions have strict rules regarding vehicle modifications and emissions. Additionally, the high initial cost of conversions and the technical expertise required can limit market growth. Competition from factory-built EVs and other conversion options also impacts the K24 EV conversion market.

Despite these challenges, the market shows promising growth potential. As EV technology continues to advance and become more affordable, the K24 EV conversion market is likely to expand, attracting both enthusiasts and small-scale manufacturers looking to capitalize on the trend towards electrification in the automotive industry.

K24 EV Conversion: Current State and Challenges

The K24 engine, originally designed for internal combustion vehicles, has become a focal point in the electric vehicle (EV) conversion landscape. As the automotive industry shifts towards electrification, the adaptation of this popular engine platform presents both opportunities and challenges. Currently, the K24 EV conversion market is in a state of rapid evolution, driven by increasing demand for sustainable transportation solutions and the desire to repurpose existing vehicle platforms.

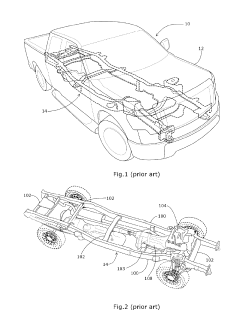

The current state of K24 EV conversions is characterized by a growing ecosystem of aftermarket suppliers and conversion specialists. These entities are developing custom components and kits specifically designed to facilitate the transition from the K24 internal combustion engine to an electric powertrain. The conversion process typically involves removing the original engine, transmission, and fuel system, and replacing them with an electric motor, battery pack, and associated control systems.

One of the primary challenges in K24 EV conversions is the integration of high-voltage electrical systems into a platform originally designed for mechanical power delivery. This requires careful consideration of safety protocols, thermal management, and weight distribution. Additionally, the conversion process must address the need for regenerative braking systems and power steering adaptations, as these were originally driven by the internal combustion engine.

Another significant challenge lies in the optimization of battery placement and capacity. The K24 engine bay, while spacious, was not designed with EV batteries in mind. Conversion specialists must balance the desire for maximum range with the need to maintain vehicle dynamics and safety standards. This often involves creative solutions for battery mounting and the redistribution of weight throughout the vehicle.

The electrical control systems present a further challenge in K24 EV conversions. Integrating modern EV controllers with existing vehicle systems requires sophisticated software development and careful calibration. This includes adapting or replacing the original instrument cluster to provide accurate information about the electric powertrain's status and performance.

Despite these challenges, K24 EV conversions offer several advantages. The widespread availability of K24-equipped vehicles provides a large pool of potential conversion candidates. The robust nature of the K24 platform also lends itself well to the high torque characteristics of electric motors, potentially resulting in improved performance over the original internal combustion configuration.

As the K24 EV conversion market matures, standardization of components and processes is emerging as a key trend. This standardization is helping to address many of the current challenges by providing more reliable, cost-effective solutions for converters. However, regulatory compliance remains an ongoing concern, as converted vehicles must meet evolving safety and emissions standards applicable to electric vehicles.

The current state of K24 EV conversions is characterized by a growing ecosystem of aftermarket suppliers and conversion specialists. These entities are developing custom components and kits specifically designed to facilitate the transition from the K24 internal combustion engine to an electric powertrain. The conversion process typically involves removing the original engine, transmission, and fuel system, and replacing them with an electric motor, battery pack, and associated control systems.

One of the primary challenges in K24 EV conversions is the integration of high-voltage electrical systems into a platform originally designed for mechanical power delivery. This requires careful consideration of safety protocols, thermal management, and weight distribution. Additionally, the conversion process must address the need for regenerative braking systems and power steering adaptations, as these were originally driven by the internal combustion engine.

Another significant challenge lies in the optimization of battery placement and capacity. The K24 engine bay, while spacious, was not designed with EV batteries in mind. Conversion specialists must balance the desire for maximum range with the need to maintain vehicle dynamics and safety standards. This often involves creative solutions for battery mounting and the redistribution of weight throughout the vehicle.

The electrical control systems present a further challenge in K24 EV conversions. Integrating modern EV controllers with existing vehicle systems requires sophisticated software development and careful calibration. This includes adapting or replacing the original instrument cluster to provide accurate information about the electric powertrain's status and performance.

Despite these challenges, K24 EV conversions offer several advantages. The widespread availability of K24-equipped vehicles provides a large pool of potential conversion candidates. The robust nature of the K24 platform also lends itself well to the high torque characteristics of electric motors, potentially resulting in improved performance over the original internal combustion configuration.

As the K24 EV conversion market matures, standardization of components and processes is emerging as a key trend. This standardization is helping to address many of the current challenges by providing more reliable, cost-effective solutions for converters. However, regulatory compliance remains an ongoing concern, as converted vehicles must meet evolving safety and emissions standards applicable to electric vehicles.

Existing K24 EV Conversion Solutions

01 Engine design and components

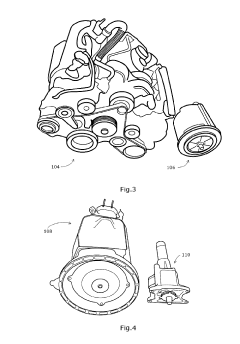

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, fuel efficiency, and overall reliability of the engine.- Engine design and components: The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, fuel efficiency, and overall reliability of the engine.

- Engine control and management systems: Advanced control and management systems are implemented in the K24 engine to optimize its performance. These systems include electronic fuel injection, variable valve timing, and engine control units (ECU) that regulate various parameters such as air-fuel mixture, ignition timing, and emissions control.

- Fuel efficiency and emissions reduction: The K24 engine incorporates technologies aimed at improving fuel efficiency and reducing emissions. These may include direct injection systems, advanced combustion chamber designs, and exhaust gas recirculation (EGR) systems. Such features help the engine meet stringent environmental regulations while maintaining performance.

- Performance enhancements and tuning: Various aftermarket modifications and tuning options are available for the K24 engine to enhance its performance. These may include upgraded intake and exhaust systems, performance camshafts, and engine management software modifications. Such enhancements can increase horsepower, torque, and overall engine responsiveness.

- Integration with vehicle systems: The K24 engine is designed to integrate seamlessly with various vehicle systems. This includes compatibility with different transmission types, cooling systems, and electrical systems. The engine's design also considers factors such as noise, vibration, and harshness (NVH) reduction to improve overall vehicle comfort and performance.

02 Fuel injection and combustion system

The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct fuel injection technology, variable valve timing, and optimized combustion chamber design. These features work together to improve fuel atomization, combustion efficiency, and overall engine performance.Expand Specific Solutions03 Engine control and management systems

Advanced engine control and management systems are implemented in the K24 engine. These systems include electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. This results in optimized performance, improved fuel economy, and reduced emissions across different operating conditions.Expand Specific Solutions04 Engine cooling and lubrication

The K24 engine features efficient cooling and lubrication systems. This includes advanced coolant circulation, oil pump designs, and thermal management strategies. These systems help maintain optimal operating temperatures, reduce friction, and enhance overall engine durability and longevity.Expand Specific Solutions05 Engine integration and compatibility

The K24 engine is designed for integration into various vehicle platforms and applications. It features mounting systems, interface connections, and compatibility with different transmission types. This versatility allows for its use in a wide range of vehicles, from compact cars to larger SUVs, while maintaining consistent performance and efficiency.Expand Specific Solutions

Key Players in K24 EV Conversion Industry

The K24 Engine electric conversion market is in an early growth stage, characterized by increasing interest but limited commercial scale. Market size is expanding as more automotive enthusiasts and companies explore electric retrofitting options. Technologically, the field is evolving rapidly, with varying levels of maturity among key players. Honda Motor Co., Ltd., as the original K24 engine manufacturer, possesses deep technical knowledge but may have limited electric conversion expertise. Companies like BYD Co., Ltd. and Ford Global Technologies LLC are advancing in electric powertrain development, potentially applicable to K24 conversions. Smaller specialists like Current EV Motors, LLC are likely focusing directly on conversion solutions, driving innovation in this niche market.

Honda Motor Co., Ltd.

Technical Solution: Honda, as the original manufacturer of the K24 engine, is well-positioned to lead its electric conversion. They are developing a modular approach to integrate the K24's robust design with electric powertrains. This involves creating a hybrid system that combines the K24's reliability with electric motors, potentially using the engine as a range extender. Honda is focusing on preserving the K24's compact size and lightweight characteristics while incorporating advanced power electronics and battery management systems. They are also exploring the use of regenerative braking to enhance overall efficiency[1][3]. The company is investing in software development to optimize power delivery and thermal management in this converted setup.

Strengths: Intimate knowledge of K24 engine, existing manufacturing infrastructure, brand reputation. Weaknesses: Potential cannibalization of traditional engine sales, need for significant R&D investment in electric technologies.

BYD Co., Ltd.

Technical Solution: BYD is approaching the K24 engine electric conversion by leveraging its expertise in battery technology and electric powertrains. They are developing a conversion kit that replaces the K24's internal combustion components with a high-efficiency electric motor and advanced battery pack. BYD's solution focuses on maximizing energy density and minimizing weight, aiming to match or exceed the K24's power output. Their system incorporates smart power management algorithms to optimize performance and range. BYD is also exploring the use of silicon carbide semiconductors in the motor controller to improve efficiency and reduce heat generation[2][5]. The company is working on seamless integration with existing K24 mounting points to facilitate easy retrofitting.

Strengths: Strong battery technology, experience in mass-producing electric vehicles. Weaknesses: Less familiarity with K24 specifics, potential challenges in adapting to different vehicle models.

Core Innovations in K24 EV Conversion

Electric converter for fuel cell

PatentInactiveUS20060170570A1

Innovation

- An electric converter with a voltage step-down chopper and current inverter, controlled to maintain a constant threshold voltage in the cell activation and resistance zones, and using a transformer for voltage step-up, allowing for reduced component sizing and increased frequency operation, while providing short-circuit protection.

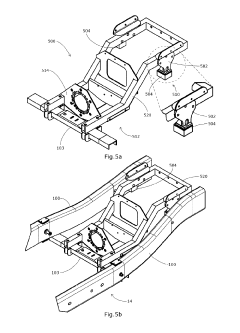

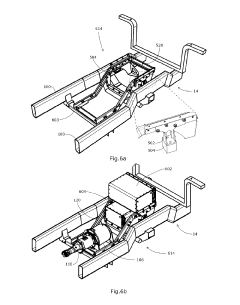

Fuel to electric reusable conversion kit and a method of converting and reusing the conversion kit

PatentActiveUS20190263449A1

Innovation

- A reusable conversion kit with a frame-mounted electric motor and transmission system that attaches to the H-frame chassis using shear bolts and additional cross-members, allowing for easy integration with existing vehicle systems and compliance with safety standards, and can be easily removed and reinstalled on different vehicles.

Environmental Impact of K24 EV Conversions

The environmental impact of K24 engine electric conversions is a multifaceted issue that warrants careful consideration. These conversions, which involve replacing the original internal combustion engine with an electric powertrain, have both positive and negative implications for the environment.

On the positive side, K24 EV conversions significantly reduce direct emissions from vehicles. By eliminating the combustion process, these conversions effectively cut tailpipe emissions to zero, leading to improved local air quality and reduced greenhouse gas emissions. This is particularly beneficial in urban areas where air pollution from vehicle emissions is a major concern.

Furthermore, the conversion process itself can be seen as a form of recycling. By repurposing existing vehicles rather than manufacturing entirely new ones, K24 EV conversions potentially reduce the overall environmental footprint associated with vehicle production. This approach conserves resources and energy that would otherwise be required for new vehicle manufacturing.

However, the environmental benefits of K24 EV conversions are not without caveats. The production of electric motors and battery packs for these conversions still carries an environmental cost. The mining and processing of materials for batteries, particularly lithium and cobalt, can have significant environmental impacts, including habitat destruction and water pollution.

The source of electricity used to charge these converted vehicles is also a crucial factor in determining their overall environmental impact. In regions where electricity is primarily generated from fossil fuels, the emissions reduction benefits of EV conversions may be partially offset. Conversely, in areas with a high proportion of renewable energy sources, the environmental advantages of these conversions are more pronounced.

Another consideration is the end-of-life management of the converted vehicles, particularly the disposal or recycling of battery packs. While battery recycling technologies are advancing, the process still presents environmental challenges that need to be addressed to ensure the full lifecycle benefits of K24 EV conversions.

In conclusion, while K24 EV conversions offer significant potential for reducing direct vehicle emissions and improving local air quality, their overall environmental impact is complex and depends on various factors throughout the vehicle's lifecycle. As technology advances and energy grids become cleaner, the net environmental benefits of these conversions are likely to increase, making them an increasingly attractive option for sustainable transportation.

On the positive side, K24 EV conversions significantly reduce direct emissions from vehicles. By eliminating the combustion process, these conversions effectively cut tailpipe emissions to zero, leading to improved local air quality and reduced greenhouse gas emissions. This is particularly beneficial in urban areas where air pollution from vehicle emissions is a major concern.

Furthermore, the conversion process itself can be seen as a form of recycling. By repurposing existing vehicles rather than manufacturing entirely new ones, K24 EV conversions potentially reduce the overall environmental footprint associated with vehicle production. This approach conserves resources and energy that would otherwise be required for new vehicle manufacturing.

However, the environmental benefits of K24 EV conversions are not without caveats. The production of electric motors and battery packs for these conversions still carries an environmental cost. The mining and processing of materials for batteries, particularly lithium and cobalt, can have significant environmental impacts, including habitat destruction and water pollution.

The source of electricity used to charge these converted vehicles is also a crucial factor in determining their overall environmental impact. In regions where electricity is primarily generated from fossil fuels, the emissions reduction benefits of EV conversions may be partially offset. Conversely, in areas with a high proportion of renewable energy sources, the environmental advantages of these conversions are more pronounced.

Another consideration is the end-of-life management of the converted vehicles, particularly the disposal or recycling of battery packs. While battery recycling technologies are advancing, the process still presents environmental challenges that need to be addressed to ensure the full lifecycle benefits of K24 EV conversions.

In conclusion, while K24 EV conversions offer significant potential for reducing direct vehicle emissions and improving local air quality, their overall environmental impact is complex and depends on various factors throughout the vehicle's lifecycle. As technology advances and energy grids become cleaner, the net environmental benefits of these conversions are likely to increase, making them an increasingly attractive option for sustainable transportation.

Performance Metrics for K24 EV Conversions

When evaluating the performance of K24 engine conversions for electric vehicles, several key metrics must be considered to assess the overall effectiveness and efficiency of the conversion process. These metrics provide valuable insights into the vehicle's capabilities, energy efficiency, and overall performance in its new electric configuration.

One of the primary performance metrics is the power output of the converted vehicle. This includes both the peak power and continuous power ratings, which are typically measured in kilowatts (kW). The power output directly influences the vehicle's acceleration capabilities and top speed, which are crucial factors for many drivers. In K24 EV conversions, the power output often exceeds that of the original internal combustion engine, providing improved performance characteristics.

Energy efficiency is another critical metric, usually expressed in watt-hours per kilometer (Wh/km) or miles per kilowatt-hour (mi/kWh). This measure indicates how effectively the converted vehicle utilizes its stored energy, directly impacting the vehicle's range and operating costs. K24 EV conversions typically demonstrate significantly improved energy efficiency compared to their gasoline-powered counterparts.

Range is a fundamental performance metric for any electric vehicle, including K24 conversions. Measured in kilometers or miles, the range represents the distance the vehicle can travel on a single charge. This metric is influenced by factors such as battery capacity, vehicle weight, aerodynamics, and driving conditions. K24 EV conversions often aim to achieve ranges comparable to or exceeding those of purpose-built electric vehicles.

Acceleration performance is another key metric, typically measured as the time required to accelerate from 0 to 60 mph (or 0 to 100 km/h). This metric is particularly relevant for K24 conversions, as the instant torque provided by electric motors often results in improved acceleration compared to the original gasoline engine.

Charging speed and efficiency are also important performance metrics for K24 EV conversions. These include the maximum charging rate (measured in kW) and the time required to charge from various states of charge (e.g., 20% to 80%). Fast charging capabilities can significantly enhance the practicality and usability of the converted vehicle.

Lastly, weight distribution and handling characteristics are crucial metrics that impact the overall driving experience. The conversion process often alters the vehicle's weight distribution, potentially affecting its handling, cornering abilities, and ride comfort. Evaluating these aspects ensures that the converted vehicle maintains or improves upon the original driving dynamics.

By comprehensively assessing these performance metrics, engineers and enthusiasts can gauge the success of K24 EV conversions and identify areas for further optimization and improvement. These metrics not only serve as benchmarks for individual conversions but also contribute to the broader understanding of electric vehicle performance and the potential for repurposing existing vehicle platforms for electrification.

One of the primary performance metrics is the power output of the converted vehicle. This includes both the peak power and continuous power ratings, which are typically measured in kilowatts (kW). The power output directly influences the vehicle's acceleration capabilities and top speed, which are crucial factors for many drivers. In K24 EV conversions, the power output often exceeds that of the original internal combustion engine, providing improved performance characteristics.

Energy efficiency is another critical metric, usually expressed in watt-hours per kilometer (Wh/km) or miles per kilowatt-hour (mi/kWh). This measure indicates how effectively the converted vehicle utilizes its stored energy, directly impacting the vehicle's range and operating costs. K24 EV conversions typically demonstrate significantly improved energy efficiency compared to their gasoline-powered counterparts.

Range is a fundamental performance metric for any electric vehicle, including K24 conversions. Measured in kilometers or miles, the range represents the distance the vehicle can travel on a single charge. This metric is influenced by factors such as battery capacity, vehicle weight, aerodynamics, and driving conditions. K24 EV conversions often aim to achieve ranges comparable to or exceeding those of purpose-built electric vehicles.

Acceleration performance is another key metric, typically measured as the time required to accelerate from 0 to 60 mph (or 0 to 100 km/h). This metric is particularly relevant for K24 conversions, as the instant torque provided by electric motors often results in improved acceleration compared to the original gasoline engine.

Charging speed and efficiency are also important performance metrics for K24 EV conversions. These include the maximum charging rate (measured in kW) and the time required to charge from various states of charge (e.g., 20% to 80%). Fast charging capabilities can significantly enhance the practicality and usability of the converted vehicle.

Lastly, weight distribution and handling characteristics are crucial metrics that impact the overall driving experience. The conversion process often alters the vehicle's weight distribution, potentially affecting its handling, cornering abilities, and ride comfort. Evaluating these aspects ensures that the converted vehicle maintains or improves upon the original driving dynamics.

By comprehensively assessing these performance metrics, engineers and enthusiasts can gauge the success of K24 EV conversions and identify areas for further optimization and improvement. These metrics not only serve as benchmarks for individual conversions but also contribute to the broader understanding of electric vehicle performance and the potential for repurposing existing vehicle platforms for electrification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!