K24 Engine: Innovations in Cylinder Head Design

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in 2002. This 2.4-liter inline-four engine has been a cornerstone of Honda's powertrain lineup, finding its way into various models across the Honda and Acura brands. The engine's development has been marked by continuous improvements, particularly in cylinder head design, which has played a crucial role in enhancing performance, efficiency, and emissions compliance.

Initially introduced in the Honda Element and Accord, the K24 engine featured a relatively simple DOHC 16-valve design. However, as emissions regulations tightened and consumer demands for performance and fuel efficiency increased, Honda engineers focused on refining the cylinder head design. The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology marked a significant milestone in the K24's evolution, allowing for optimized valve timing and lift across a broader range of engine speeds.

Subsequent iterations saw the implementation of more advanced materials and manufacturing techniques in the cylinder head. The use of high-strength aluminum alloys and precision casting methods allowed for more complex internal geometries, improving coolant flow and reducing overall weight. These advancements contributed to better thermal management and increased durability, critical factors in maintaining performance under varying operating conditions.

The evolution of the K24 engine also saw changes in combustion chamber design. Engineers experimented with different shapes and contours to optimize flame propagation and reduce knock tendencies. This resulted in improved combustion efficiency, allowing for higher compression ratios and better fuel economy without sacrificing performance. The integration of direct injection technology in later versions further enhanced these benefits, providing more precise fuel delivery and improved mixture formation.

Valve train innovations played a significant role in the K24's development. The adoption of roller rocker arms and low-friction coatings reduced parasitic losses, contributing to overall efficiency gains. Additionally, the refinement of variable valve timing systems allowed for more precise control over engine breathing, enhancing both low-end torque and high-rpm power output.

As the K24 engine matured, attention turned to emissions reduction and compliance with increasingly stringent regulations. This led to the incorporation of advanced exhaust gas recirculation (EGR) systems and the optimization of port designs to promote better mixture distribution and more complete combustion. These changes, coupled with improvements in catalytic converter technology, ensured that the K24 remained a viable powerplant even as environmental standards evolved.

Initially introduced in the Honda Element and Accord, the K24 engine featured a relatively simple DOHC 16-valve design. However, as emissions regulations tightened and consumer demands for performance and fuel efficiency increased, Honda engineers focused on refining the cylinder head design. The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology marked a significant milestone in the K24's evolution, allowing for optimized valve timing and lift across a broader range of engine speeds.

Subsequent iterations saw the implementation of more advanced materials and manufacturing techniques in the cylinder head. The use of high-strength aluminum alloys and precision casting methods allowed for more complex internal geometries, improving coolant flow and reducing overall weight. These advancements contributed to better thermal management and increased durability, critical factors in maintaining performance under varying operating conditions.

The evolution of the K24 engine also saw changes in combustion chamber design. Engineers experimented with different shapes and contours to optimize flame propagation and reduce knock tendencies. This resulted in improved combustion efficiency, allowing for higher compression ratios and better fuel economy without sacrificing performance. The integration of direct injection technology in later versions further enhanced these benefits, providing more precise fuel delivery and improved mixture formation.

Valve train innovations played a significant role in the K24's development. The adoption of roller rocker arms and low-friction coatings reduced parasitic losses, contributing to overall efficiency gains. Additionally, the refinement of variable valve timing systems allowed for more precise control over engine breathing, enhancing both low-end torque and high-rpm power output.

As the K24 engine matured, attention turned to emissions reduction and compliance with increasingly stringent regulations. This led to the incorporation of advanced exhaust gas recirculation (EGR) systems and the optimization of port designs to promote better mixture distribution and more complete combustion. These changes, coupled with improvements in catalytic converter technology, ensured that the K24 remained a viable powerplant even as environmental standards evolved.

Market Demand Analysis

The market demand for innovative cylinder head designs in engines, particularly for the K24 engine, has been steadily increasing due to the automotive industry's focus on improving engine efficiency, performance, and emissions. As environmental regulations become more stringent worldwide, manufacturers are seeking advanced cylinder head designs that can optimize combustion processes and enhance overall engine performance.

The K24 engine, known for its reliability and versatility, has been a popular choice in various Honda and Acura models. However, with the evolving market demands, there is a growing need for improvements in its cylinder head design to meet new performance and efficiency standards. This demand is driven by both consumer expectations for better fuel economy and regulatory pressures for reduced emissions.

In the passenger vehicle segment, where the K24 engine is commonly used, there is a significant market for engines that can deliver improved power output without compromising fuel efficiency. This demand is particularly strong in regions with high fuel prices or stringent emissions regulations, such as Europe and parts of Asia. The market also shows a trend towards engines that can support hybrid and mild-hybrid systems, where advanced cylinder head designs can play a crucial role in optimizing the integration of electric and combustion power sources.

The commercial vehicle sector, although a smaller market for the K24 engine, also presents opportunities for cylinder head innovations. Fleet operators are increasingly looking for engines that can reduce operating costs through improved fuel efficiency and lower maintenance requirements. Advanced cylinder head designs that can enhance durability and reduce wear are particularly valued in this segment.

From a geographical perspective, emerging markets in Asia and South America show strong potential for growth in demand for advanced engine technologies. These regions are experiencing rapid motorization and are increasingly adopting stricter emissions standards, creating a market for engines with improved cylinder head designs that can meet these new requirements while maintaining affordability.

The aftermarket and performance tuning sectors also contribute to the demand for innovative cylinder head designs. Enthusiasts and tuning companies are constantly seeking ways to extract more power and efficiency from the K24 engine, creating a niche market for high-performance cylinder head upgrades.

Looking at industry trends, there is a growing interest in cylinder head designs that can support alternative fuels, such as ethanol blends or compressed natural gas. This trend is driven by the global push towards diversifying energy sources and reducing dependency on traditional fossil fuels. Cylinder head innovations that can accommodate these alternative fuels while maintaining or improving engine performance are likely to see increased demand in the coming years.

The K24 engine, known for its reliability and versatility, has been a popular choice in various Honda and Acura models. However, with the evolving market demands, there is a growing need for improvements in its cylinder head design to meet new performance and efficiency standards. This demand is driven by both consumer expectations for better fuel economy and regulatory pressures for reduced emissions.

In the passenger vehicle segment, where the K24 engine is commonly used, there is a significant market for engines that can deliver improved power output without compromising fuel efficiency. This demand is particularly strong in regions with high fuel prices or stringent emissions regulations, such as Europe and parts of Asia. The market also shows a trend towards engines that can support hybrid and mild-hybrid systems, where advanced cylinder head designs can play a crucial role in optimizing the integration of electric and combustion power sources.

The commercial vehicle sector, although a smaller market for the K24 engine, also presents opportunities for cylinder head innovations. Fleet operators are increasingly looking for engines that can reduce operating costs through improved fuel efficiency and lower maintenance requirements. Advanced cylinder head designs that can enhance durability and reduce wear are particularly valued in this segment.

From a geographical perspective, emerging markets in Asia and South America show strong potential for growth in demand for advanced engine technologies. These regions are experiencing rapid motorization and are increasingly adopting stricter emissions standards, creating a market for engines with improved cylinder head designs that can meet these new requirements while maintaining affordability.

The aftermarket and performance tuning sectors also contribute to the demand for innovative cylinder head designs. Enthusiasts and tuning companies are constantly seeking ways to extract more power and efficiency from the K24 engine, creating a niche market for high-performance cylinder head upgrades.

Looking at industry trends, there is a growing interest in cylinder head designs that can support alternative fuels, such as ethanol blends or compressed natural gas. This trend is driven by the global push towards diversifying energy sources and reducing dependency on traditional fossil fuels. Cylinder head innovations that can accommodate these alternative fuels while maintaining or improving engine performance are likely to see increased demand in the coming years.

Cylinder Head Challenges

The cylinder head is a critical component of the K24 engine, playing a vital role in its performance, efficiency, and emissions. However, designing an optimal cylinder head presents several significant challenges that engineers must overcome to achieve the desired engine characteristics.

One of the primary challenges in cylinder head design is optimizing the combustion chamber shape and volume. The combustion chamber geometry directly affects the engine's compression ratio, flame propagation, and overall combustion efficiency. Engineers must carefully balance these factors to maximize power output while minimizing fuel consumption and emissions. Additionally, the design must account for thermal management, as the combustion chamber experiences extreme temperatures during operation.

Another major challenge lies in the intake and exhaust port design. The flow characteristics of these ports significantly impact the engine's breathing ability, which in turn affects power output and fuel efficiency. Designers must optimize port shape, size, and orientation to minimize flow restrictions and maximize volumetric efficiency. This task is further complicated by the need to accommodate varying engine speeds and load conditions, requiring a design that performs well across a wide operating range.

Valve train design presents its own set of challenges. The cylinder head must incorporate robust valve seats and guides while allowing for optimal valve sizing and placement. Engineers must consider factors such as valve lift, duration, and timing to achieve the desired engine performance characteristics. Furthermore, the design must account for the high stresses and temperatures experienced by the valves and their associated components, ensuring long-term reliability and durability.

Material selection and manufacturing processes pose additional challenges in cylinder head design. The chosen material must withstand high temperatures and pressures while providing excellent thermal conductivity and minimal weight. Advanced alloys and manufacturing techniques, such as precision casting and CNC machining, are often required to achieve the complex geometries and tight tolerances necessary for optimal performance.

Cooling system integration is another critical aspect of cylinder head design. Adequate cooling is essential to prevent overheating and maintain consistent performance. Engineers must carefully design coolant passages and ensure proper flow distribution throughout the cylinder head, paying particular attention to high-heat areas such as the combustion chamber and exhaust ports.

Finally, meeting increasingly stringent emissions regulations presents an ongoing challenge in cylinder head design. Engineers must incorporate features that promote complete combustion, reduce unburned hydrocarbons, and minimize NOx formation. This often involves careful tuning of the combustion chamber shape, spark plug placement, and fuel injection strategies.

One of the primary challenges in cylinder head design is optimizing the combustion chamber shape and volume. The combustion chamber geometry directly affects the engine's compression ratio, flame propagation, and overall combustion efficiency. Engineers must carefully balance these factors to maximize power output while minimizing fuel consumption and emissions. Additionally, the design must account for thermal management, as the combustion chamber experiences extreme temperatures during operation.

Another major challenge lies in the intake and exhaust port design. The flow characteristics of these ports significantly impact the engine's breathing ability, which in turn affects power output and fuel efficiency. Designers must optimize port shape, size, and orientation to minimize flow restrictions and maximize volumetric efficiency. This task is further complicated by the need to accommodate varying engine speeds and load conditions, requiring a design that performs well across a wide operating range.

Valve train design presents its own set of challenges. The cylinder head must incorporate robust valve seats and guides while allowing for optimal valve sizing and placement. Engineers must consider factors such as valve lift, duration, and timing to achieve the desired engine performance characteristics. Furthermore, the design must account for the high stresses and temperatures experienced by the valves and their associated components, ensuring long-term reliability and durability.

Material selection and manufacturing processes pose additional challenges in cylinder head design. The chosen material must withstand high temperatures and pressures while providing excellent thermal conductivity and minimal weight. Advanced alloys and manufacturing techniques, such as precision casting and CNC machining, are often required to achieve the complex geometries and tight tolerances necessary for optimal performance.

Cooling system integration is another critical aspect of cylinder head design. Adequate cooling is essential to prevent overheating and maintain consistent performance. Engineers must carefully design coolant passages and ensure proper flow distribution throughout the cylinder head, paying particular attention to high-heat areas such as the combustion chamber and exhaust ports.

Finally, meeting increasingly stringent emissions regulations presents an ongoing challenge in cylinder head design. Engineers must incorporate features that promote complete combustion, reduce unburned hydrocarbons, and minimize NOx formation. This often involves careful tuning of the combustion chamber shape, spark plug placement, and fuel injection strategies.

Current Head Designs

01 Cylinder head design for improved performance

Innovative designs for K24 engine cylinder heads focus on enhancing overall engine performance. These designs may include optimized combustion chamber shapes, improved port configurations, and advanced valve arrangements to increase power output and efficiency.- Cylinder head design for improved performance: Innovative designs for K24 engine cylinder heads focus on enhancing overall engine performance. These designs may include optimized combustion chamber shapes, improved cooling passages, and advanced valve arrangements to increase efficiency and power output.

- Valve train components and arrangements: Specialized valve train components and arrangements are developed for K24 engine cylinder heads. These may include variable valve timing systems, roller rocker arms, and lightweight valves to improve engine breathing and reduce friction losses.

- Cooling system enhancements: Advancements in cooling systems for K24 engine cylinder heads aim to improve heat dissipation and maintain optimal operating temperatures. These may include redesigned coolant passages, improved water jackets, and the use of advanced materials for better thermal management.

- Integration of direct fuel injection: Incorporation of direct fuel injection technology into K24 engine cylinder heads to enhance fuel efficiency and power output. This may involve redesigning the cylinder head to accommodate fuel injectors and optimizing the combustion chamber for direct injection.

- Lightweight materials and manufacturing processes: Use of lightweight materials and advanced manufacturing processes in the production of K24 engine cylinder heads. This may include the use of aluminum alloys, composite materials, or innovative casting techniques to reduce weight while maintaining strength and durability.

02 Cooling system integration in cylinder head

Specialized cooling systems are integrated into the K24 engine cylinder head to manage heat effectively. These may include advanced coolant passages, targeted cooling for high-stress areas, and improved thermal management strategies to enhance engine longevity and performance.Expand Specific Solutions03 Lightweight materials and construction techniques

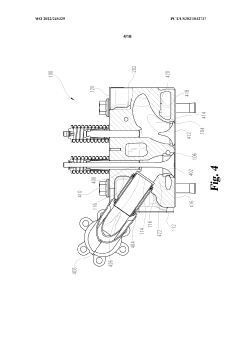

The use of lightweight materials and advanced construction techniques in K24 engine cylinder heads aims to reduce overall engine weight while maintaining strength and durability. This may involve the use of aluminum alloys, composite materials, or innovative casting methods.Expand Specific Solutions04 Valve train optimization

Improvements in the valve train system of K24 engine cylinder heads focus on enhancing valve control and timing. This may include advanced camshaft designs, variable valve timing mechanisms, and optimized valve spring configurations to improve engine breathing and overall efficiency.Expand Specific Solutions05 Integration of direct fuel injection systems

K24 engine cylinder heads are designed to accommodate direct fuel injection systems. This involves integrating fuel injector ports, optimizing spray patterns, and enhancing the combustion chamber design to improve fuel atomization and combustion efficiency.Expand Specific Solutions

Key Engine Manufacturers

The K24 Engine cylinder head design innovation landscape is characterized by intense competition among established automotive manufacturers and specialized engine technology firms. The market is in a mature phase, with ongoing research and development efforts focused on improving efficiency, performance, and emissions. Key players like Mercedes-Benz, Honda, BMW, and Toyota are investing heavily in advanced cylinder head designs to meet stringent regulatory requirements and consumer demands. Smaller specialized firms such as FEV Europe and AVL List are also contributing significant technological advancements. The market size is substantial, driven by the global automotive industry's need for more efficient and environmentally friendly engines. While the technology is well-established, there is still room for innovation, particularly in areas like materials science, combustion optimization, and integration with hybrid and electric powertrains.

Honda Motor Co., Ltd.

Technical Solution: Honda's K24 engine features innovative cylinder head design with i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology. The K24 incorporates a compact combustion chamber design with a high compression ratio of up to 11.1:1 [1]. The cylinder head utilizes a dual overhead camshaft (DOHC) configuration with four valves per cylinder, optimizing airflow and combustion efficiency. Honda has implemented a unique roller rocker arm system in the K24, reducing friction and improving valve control precision [2]. The engine also employs a tuned-length intake manifold and high-flow exhaust ports to enhance breathing and power output across a wide RPM range [3].

Strengths: High power-to-weight ratio, excellent fuel efficiency, and smooth power delivery. Weaknesses: Complexity of the VTEC system may lead to higher maintenance costs, and the high compression ratio requires premium fuel for optimal performance.

Cummins, Inc.

Technical Solution: Cummins has developed advanced cylinder head designs for their engines, including the K24-based platforms. Their approach focuses on optimizing combustion efficiency and reducing emissions. Cummins utilizes computational fluid dynamics (CFD) and finite element analysis (FEA) to refine the cylinder head geometry, improving coolant flow and thermal management [4]. The company has implemented a high-pressure common rail fuel injection system, with centrally mounted injectors in the cylinder head, allowing for precise fuel delivery and multiple injection events per cycle [5]. Cummins' cylinder heads also feature integrated exhaust gas recirculation (EGR) passages, contributing to reduced NOx emissions while maintaining performance [6].

Strengths: Excellent durability and reliability, advanced emissions control, and high thermal efficiency. Weaknesses: Higher initial cost due to advanced technologies, and potential complexity in servicing the integrated systems.

Innovative Head Patents

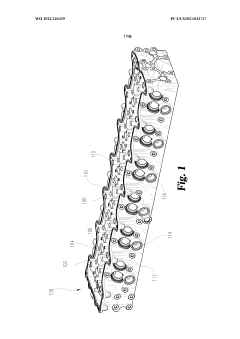

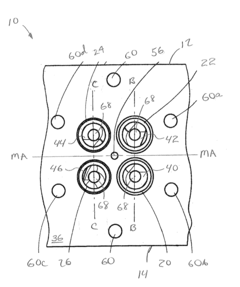

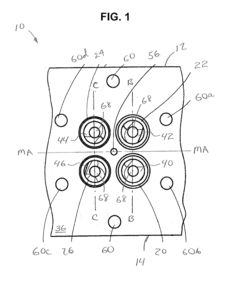

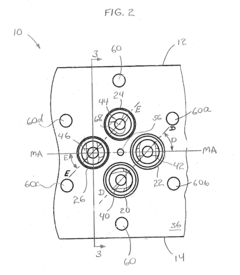

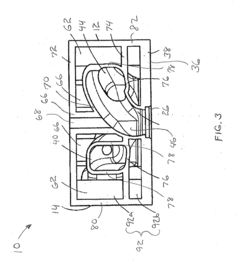

Cylinder head for internal combustion engine

PatentWO2022245329A1

Innovation

- The cylinder head design incorporates novel features such as undercuts, contours of the outer enclosure, coolant jackets, and cavities within the outer enclosure, along with an exhaust jumper tube to enhance heat transfer and temperature control, reducing unwanted heat transfer and weight while maintaining structural integrity.

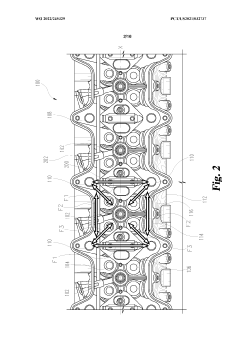

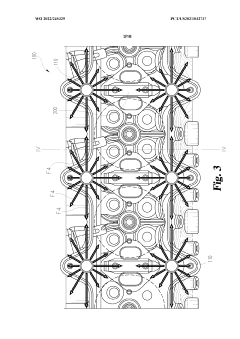

Cylinder Head For An Engine

PatentActiveUS20110083624A1

Innovation

- The cylinder head design is optimized for structural stiffness through a combination of features including angled valve seats, multiple decks with varying thicknesses, cross-flow coolant jackets, and a removable sleeve system that accommodates thermal and mechanical loads, providing enhanced mechanical integrity and pressure capability.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting engine design and performance. The K24 engine, known for its innovative cylinder head design, must adapt to these evolving standards while maintaining its performance characteristics.

Global emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, have set strict limits on pollutants like nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These regulations have driven manufacturers to implement advanced technologies in cylinder head design to optimize combustion efficiency and reduce emissions.

The K24 engine's cylinder head innovations focus on improving airflow and combustion characteristics. One key feature is the implementation of variable valve timing and lift electronic control (VTEC) system, which allows for optimal valve operation across different engine speeds and loads. This technology contributes to reduced emissions by enhancing fuel efficiency and combustion quality.

Another significant innovation in the K24's cylinder head design is the integration of direct fuel injection. This technology enables precise fuel delivery directly into the combustion chamber, resulting in improved fuel atomization and more complete combustion. Consequently, this leads to reduced emissions and increased power output.

The K24 engine also incorporates advanced exhaust gas recirculation (EGR) systems within its cylinder head design. EGR helps reduce NOx emissions by recirculating a portion of the exhaust gases back into the combustion chamber, lowering peak combustion temperatures.

To further address emissions regulations, the K24 engine's cylinder head design includes optimized port shapes and combustion chamber geometry. These refinements contribute to better fuel-air mixing and more efficient combustion, resulting in lower emissions across various operating conditions.

The integration of advanced materials in the K24's cylinder head, such as high-strength aluminum alloys, allows for improved thermal management and reduced weight. This contributes to overall engine efficiency and helps meet emissions targets while maintaining performance.

As emissions regulations continue to evolve, future iterations of the K24 engine may incorporate additional technologies such as water injection or advanced catalytic converters integrated into the cylinder head design. These innovations will be crucial in meeting increasingly stringent emissions standards while preserving the engine's performance characteristics.

Global emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, have set strict limits on pollutants like nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These regulations have driven manufacturers to implement advanced technologies in cylinder head design to optimize combustion efficiency and reduce emissions.

The K24 engine's cylinder head innovations focus on improving airflow and combustion characteristics. One key feature is the implementation of variable valve timing and lift electronic control (VTEC) system, which allows for optimal valve operation across different engine speeds and loads. This technology contributes to reduced emissions by enhancing fuel efficiency and combustion quality.

Another significant innovation in the K24's cylinder head design is the integration of direct fuel injection. This technology enables precise fuel delivery directly into the combustion chamber, resulting in improved fuel atomization and more complete combustion. Consequently, this leads to reduced emissions and increased power output.

The K24 engine also incorporates advanced exhaust gas recirculation (EGR) systems within its cylinder head design. EGR helps reduce NOx emissions by recirculating a portion of the exhaust gases back into the combustion chamber, lowering peak combustion temperatures.

To further address emissions regulations, the K24 engine's cylinder head design includes optimized port shapes and combustion chamber geometry. These refinements contribute to better fuel-air mixing and more efficient combustion, resulting in lower emissions across various operating conditions.

The integration of advanced materials in the K24's cylinder head, such as high-strength aluminum alloys, allows for improved thermal management and reduced weight. This contributes to overall engine efficiency and helps meet emissions targets while maintaining performance.

As emissions regulations continue to evolve, future iterations of the K24 engine may incorporate additional technologies such as water injection or advanced catalytic converters integrated into the cylinder head design. These innovations will be crucial in meeting increasingly stringent emissions standards while preserving the engine's performance characteristics.

Materials Advancements

The advancements in materials for cylinder head design have played a crucial role in enhancing the performance and efficiency of the K24 engine. Over the years, engineers have explored various materials to overcome the challenges associated with high temperatures, pressure, and wear in the combustion chamber.

Traditionally, cast iron was the material of choice for cylinder heads due to its durability and cost-effectiveness. However, the automotive industry's shift towards lightweight and more efficient engines has led to the adoption of aluminum alloys. These alloys offer significant weight reduction while maintaining adequate strength and thermal conductivity.

Recent developments in aluminum alloy compositions have further improved the material's properties. The introduction of silicon and copper in specific ratios has enhanced the alloy's strength and heat resistance. This has allowed for thinner cylinder head walls, reducing overall engine weight without compromising structural integrity.

Composite materials have also emerged as a promising avenue for cylinder head design. Carbon fiber reinforced polymers (CFRP) are being investigated for their potential to provide exceptional strength-to-weight ratios. While still in the experimental stage, CFRP cylinder heads could revolutionize engine design by significantly reducing weight and improving heat dissipation.

Ceramic materials, particularly silicon nitride and aluminum titanate, have gained attention for their excellent thermal properties and wear resistance. These materials can withstand higher combustion temperatures, potentially enabling more efficient engine operation. However, challenges in manufacturing processes and cost have limited their widespread adoption.

Coatings and surface treatments have become integral to cylinder head material advancements. Thermal barrier coatings, such as yttria-stabilized zirconia, are applied to protect the base material from extreme temperatures. Additionally, plasma-sprayed coatings have shown promise in reducing friction and wear within the cylinder head.

The integration of additive manufacturing techniques has opened new possibilities in cylinder head design. 3D printing allows for complex internal cooling channels and optimized material distribution, enhancing heat management and reducing overall weight. This technology enables the creation of cylinder heads with variable material properties, tailoring specific areas for strength or heat dissipation as needed.

Looking ahead, research is focused on developing new alloys and composite materials specifically engineered for cylinder head applications. These materials aim to combine the lightweight properties of aluminum with the heat resistance of more exotic materials, potentially revolutionizing engine design and performance in the coming years.

Traditionally, cast iron was the material of choice for cylinder heads due to its durability and cost-effectiveness. However, the automotive industry's shift towards lightweight and more efficient engines has led to the adoption of aluminum alloys. These alloys offer significant weight reduction while maintaining adequate strength and thermal conductivity.

Recent developments in aluminum alloy compositions have further improved the material's properties. The introduction of silicon and copper in specific ratios has enhanced the alloy's strength and heat resistance. This has allowed for thinner cylinder head walls, reducing overall engine weight without compromising structural integrity.

Composite materials have also emerged as a promising avenue for cylinder head design. Carbon fiber reinforced polymers (CFRP) are being investigated for their potential to provide exceptional strength-to-weight ratios. While still in the experimental stage, CFRP cylinder heads could revolutionize engine design by significantly reducing weight and improving heat dissipation.

Ceramic materials, particularly silicon nitride and aluminum titanate, have gained attention for their excellent thermal properties and wear resistance. These materials can withstand higher combustion temperatures, potentially enabling more efficient engine operation. However, challenges in manufacturing processes and cost have limited their widespread adoption.

Coatings and surface treatments have become integral to cylinder head material advancements. Thermal barrier coatings, such as yttria-stabilized zirconia, are applied to protect the base material from extreme temperatures. Additionally, plasma-sprayed coatings have shown promise in reducing friction and wear within the cylinder head.

The integration of additive manufacturing techniques has opened new possibilities in cylinder head design. 3D printing allows for complex internal cooling channels and optimized material distribution, enhancing heat management and reducing overall weight. This technology enables the creation of cylinder heads with variable material properties, tailoring specific areas for strength or heat dissipation as needed.

Looking ahead, research is focused on developing new alloys and composite materials specifically engineered for cylinder head applications. These materials aim to combine the lightweight properties of aluminum with the heat resistance of more exotic materials, potentially revolutionizing engine design and performance in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!