K24 Engine Parts: From Basic to Advanced Modifications

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Overview

The K24 engine, developed by Honda, is a 2.4-liter inline-four cylinder engine that has become renowned for its reliability, performance potential, and versatility. First introduced in 2001, the K24 has been utilized in various Honda and Acura models, including the Accord, CR-V, and TSX. This engine series represents a significant evolution in Honda's engine technology, building upon the success of its predecessor, the F-series engines.

The K24 engine features an aluminum block and cylinder head, which contributes to its lightweight design and improved thermal efficiency. It employs a dual overhead camshaft (DOHC) configuration, with four valves per cylinder, allowing for optimized airflow and combustion efficiency. The engine's bore and stroke measurements are typically 87mm x 99mm, resulting in a total displacement of 2,354cc.

One of the key innovations in the K24 engine is the implementation of Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This technology allows for variable valve timing and lift, optimizing performance across a wide range of engine speeds. The i-VTEC system contributes to improved low-end torque, enhanced high-rpm power, and better fuel efficiency.

Throughout its production run, the K24 engine has undergone several iterations and improvements. These variations include different compression ratios, power outputs, and specific tuning for various vehicle applications. For instance, the K24A2 variant, used in the Acura TSX, is known for its higher output and sportier character compared to the more economical versions found in some Honda CR-V models.

The K24 engine's robust design and construction have made it a popular choice among enthusiasts for modifications and performance enhancements. Its strong bottom end and forged crankshaft provide a solid foundation for increased power output. The engine's versatility allows for a wide range of modifications, from simple bolt-on upgrades to more extensive internal modifications and forced induction setups.

In terms of basic specifications, most K24 engines produce between 160 to 205 horsepower and 160 to 170 lb-ft of torque in stock form, depending on the specific variant and application. These figures can be significantly increased with aftermarket modifications, making the K24 a favorite among Honda performance enthusiasts.

The longevity and reliability of the K24 engine have contributed to its enduring popularity. Many K24-equipped vehicles have surpassed 200,000 miles with proper maintenance, a testament to Honda's engineering prowess. This durability, combined with its performance potential, has cemented the K24's status as one of Honda's most successful and respected engine designs.

The K24 engine features an aluminum block and cylinder head, which contributes to its lightweight design and improved thermal efficiency. It employs a dual overhead camshaft (DOHC) configuration, with four valves per cylinder, allowing for optimized airflow and combustion efficiency. The engine's bore and stroke measurements are typically 87mm x 99mm, resulting in a total displacement of 2,354cc.

One of the key innovations in the K24 engine is the implementation of Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This technology allows for variable valve timing and lift, optimizing performance across a wide range of engine speeds. The i-VTEC system contributes to improved low-end torque, enhanced high-rpm power, and better fuel efficiency.

Throughout its production run, the K24 engine has undergone several iterations and improvements. These variations include different compression ratios, power outputs, and specific tuning for various vehicle applications. For instance, the K24A2 variant, used in the Acura TSX, is known for its higher output and sportier character compared to the more economical versions found in some Honda CR-V models.

The K24 engine's robust design and construction have made it a popular choice among enthusiasts for modifications and performance enhancements. Its strong bottom end and forged crankshaft provide a solid foundation for increased power output. The engine's versatility allows for a wide range of modifications, from simple bolt-on upgrades to more extensive internal modifications and forced induction setups.

In terms of basic specifications, most K24 engines produce between 160 to 205 horsepower and 160 to 170 lb-ft of torque in stock form, depending on the specific variant and application. These figures can be significantly increased with aftermarket modifications, making the K24 a favorite among Honda performance enthusiasts.

The longevity and reliability of the K24 engine have contributed to its enduring popularity. Many K24-equipped vehicles have surpassed 200,000 miles with proper maintenance, a testament to Honda's engineering prowess. This durability, combined with its performance potential, has cemented the K24's status as one of Honda's most successful and respected engine designs.

Market Demand Analysis

The market demand for K24 engine parts, ranging from basic to advanced modifications, has shown significant growth in recent years. This surge is primarily driven by the increasing popularity of Honda vehicles equipped with K24 engines, particularly among automotive enthusiasts and performance-oriented drivers. The K24 engine, known for its reliability and potential for modification, has become a favorite among tuners and racing enthusiasts.

The aftermarket for K24 engine parts is diverse, catering to various levels of modification needs. Basic modifications, such as air intake systems, exhaust systems, and ECU tuning, represent the largest segment of the market. These entry-level upgrades are popular among everyday drivers looking to enhance their vehicle's performance without significant investment or technical expertise.

As enthusiasts seek more power and performance, the demand for advanced modifications has also seen substantial growth. This includes high-performance camshafts, forged internals, turbocharger kits, and custom engine management systems. The racing and competitive motorsports sectors contribute significantly to this high-end market segment, driving innovation and pushing the boundaries of K24 engine capabilities.

The market for K24 engine parts is not limited to direct replacements and performance upgrades. There is a growing trend in engine swaps, where K24 engines are being installed in various vehicle platforms beyond Honda's lineup. This cross-platform compatibility has expanded the potential market size and diversified the customer base for K24 engine parts.

Geographically, the market for K24 engine parts is global, with strong demand in North America, Europe, and Asia. The United States, in particular, represents a significant market due to the popularity of Honda vehicles and a robust car modification culture. Emerging markets in Southeast Asia and South America are also showing increased interest in K24 engine modifications, driven by growing automotive enthusiast communities.

The COVID-19 pandemic initially caused disruptions in the supply chain and a temporary dip in demand. However, the market has shown resilience, with a notable rebound as automotive enthusiasts invested more time and resources into their projects during lockdowns. This trend has contributed to a renewed interest in DIY modifications and home-based tuning projects.

Looking ahead, the market for K24 engine parts is expected to continue its growth trajectory. Factors such as the increasing average age of vehicles on the road, the rising popularity of track days and amateur racing events, and the continuous innovation in aftermarket technologies are likely to sustain this growth. Additionally, the trend towards electrification in the automotive industry may paradoxically boost interest in modifying internal combustion engines like the K24, as enthusiasts seek to preserve and enhance the performance of these platforms.

The aftermarket for K24 engine parts is diverse, catering to various levels of modification needs. Basic modifications, such as air intake systems, exhaust systems, and ECU tuning, represent the largest segment of the market. These entry-level upgrades are popular among everyday drivers looking to enhance their vehicle's performance without significant investment or technical expertise.

As enthusiasts seek more power and performance, the demand for advanced modifications has also seen substantial growth. This includes high-performance camshafts, forged internals, turbocharger kits, and custom engine management systems. The racing and competitive motorsports sectors contribute significantly to this high-end market segment, driving innovation and pushing the boundaries of K24 engine capabilities.

The market for K24 engine parts is not limited to direct replacements and performance upgrades. There is a growing trend in engine swaps, where K24 engines are being installed in various vehicle platforms beyond Honda's lineup. This cross-platform compatibility has expanded the potential market size and diversified the customer base for K24 engine parts.

Geographically, the market for K24 engine parts is global, with strong demand in North America, Europe, and Asia. The United States, in particular, represents a significant market due to the popularity of Honda vehicles and a robust car modification culture. Emerging markets in Southeast Asia and South America are also showing increased interest in K24 engine modifications, driven by growing automotive enthusiast communities.

The COVID-19 pandemic initially caused disruptions in the supply chain and a temporary dip in demand. However, the market has shown resilience, with a notable rebound as automotive enthusiasts invested more time and resources into their projects during lockdowns. This trend has contributed to a renewed interest in DIY modifications and home-based tuning projects.

Looking ahead, the market for K24 engine parts is expected to continue its growth trajectory. Factors such as the increasing average age of vehicles on the road, the rising popularity of track days and amateur racing events, and the continuous innovation in aftermarket technologies are likely to sustain this growth. Additionally, the trend towards electrification in the automotive industry may paradoxically boost interest in modifying internal combustion engines like the K24, as enthusiasts seek to preserve and enhance the performance of these platforms.

Technical Challenges

The K24 engine, while renowned for its reliability and performance potential, faces several technical challenges when it comes to modifications and enhancements. One of the primary issues is the stock connecting rods, which are prone to failure under high-stress conditions. These rods can bend or break when subjected to increased horsepower and torque, limiting the engine's ability to handle significant power upgrades.

Another challenge lies in the stock valvetrain components, particularly the valve springs. As enthusiasts seek to increase RPM limits and overall engine output, the factory valve springs may struggle to keep up, leading to valve float and potential engine damage. This necessitates upgrading to stronger, aftermarket valve springs to maintain proper valve control at higher engine speeds.

The K24's cylinder head design, while efficient, presents limitations for extreme modifications. The stock ports and combustion chamber shape may restrict airflow and combustion efficiency when pushing for maximum power. Extensive head porting and reshaping are often required to overcome these limitations, which can be both time-consuming and expensive.

Fuel delivery becomes a significant challenge when pursuing advanced modifications. The stock fuel injectors and fuel pump are typically inadequate for supporting high-horsepower builds. Upgrading these components is essential, but it often requires careful calibration and tuning to ensure proper fuel delivery across the entire RPM range.

Heat management is another critical issue, especially in high-performance applications. The stock cooling system may struggle to dissipate the increased heat generated by modified engines, leading to potential overheating and reduced reliability. This necessitates upgrades to the radiator, oil cooler, and sometimes the addition of auxiliary cooling systems.

The K24's stock engine management system poses limitations for advanced tuning. While capable for stock and mild modifications, it often lacks the flexibility and adjustability required for highly modified engines. This leads to the need for aftermarket engine management systems, which adds complexity and cost to the modification process.

Balancing performance gains with engine longevity presents an ongoing challenge. As modifications push the engine beyond its original design parameters, components such as pistons, bearings, and seals may experience accelerated wear. Finding the right balance between performance enhancements and maintaining acceptable engine life requires careful consideration and often involves frequent maintenance and inspections.

Another challenge lies in the stock valvetrain components, particularly the valve springs. As enthusiasts seek to increase RPM limits and overall engine output, the factory valve springs may struggle to keep up, leading to valve float and potential engine damage. This necessitates upgrading to stronger, aftermarket valve springs to maintain proper valve control at higher engine speeds.

The K24's cylinder head design, while efficient, presents limitations for extreme modifications. The stock ports and combustion chamber shape may restrict airflow and combustion efficiency when pushing for maximum power. Extensive head porting and reshaping are often required to overcome these limitations, which can be both time-consuming and expensive.

Fuel delivery becomes a significant challenge when pursuing advanced modifications. The stock fuel injectors and fuel pump are typically inadequate for supporting high-horsepower builds. Upgrading these components is essential, but it often requires careful calibration and tuning to ensure proper fuel delivery across the entire RPM range.

Heat management is another critical issue, especially in high-performance applications. The stock cooling system may struggle to dissipate the increased heat generated by modified engines, leading to potential overheating and reduced reliability. This necessitates upgrades to the radiator, oil cooler, and sometimes the addition of auxiliary cooling systems.

The K24's stock engine management system poses limitations for advanced tuning. While capable for stock and mild modifications, it often lacks the flexibility and adjustability required for highly modified engines. This leads to the need for aftermarket engine management systems, which adds complexity and cost to the modification process.

Balancing performance gains with engine longevity presents an ongoing challenge. As modifications push the engine beyond its original design parameters, components such as pistons, bearings, and seals may experience accelerated wear. Finding the right balance between performance enhancements and maintaining acceptable engine life requires careful consideration and often involves frequent maintenance and inspections.

Current Modification Solutions

01 Engine block and cylinder components

The K24 engine block and cylinder components are crucial parts of the engine's structure. This includes the engine block itself, cylinder liners, and related components that form the foundation of the engine. These parts are designed to withstand high pressures and temperatures while maintaining optimal performance and efficiency.- Engine block and cylinder components: The K24 engine includes various components related to the engine block and cylinders. These may include the cylinder head, pistons, connecting rods, and crankshaft. These parts are crucial for the engine's operation and performance, forming the core of the internal combustion process.

- Valve train and camshaft system: The K24 engine features a valve train system, which includes components such as valves, valve springs, camshafts, and timing chains or belts. These parts are responsible for controlling the intake and exhaust of gases in the engine, contributing to its efficiency and power output.

- Fuel injection and intake system: The fuel injection and intake system of the K24 engine comprises various parts, including fuel injectors, intake manifold, throttle body, and air filter. These components work together to ensure proper fuel delivery and air intake, optimizing the engine's performance and fuel efficiency.

- Cooling and lubrication systems: The K24 engine incorporates cooling and lubrication systems to maintain optimal operating temperatures and reduce friction. Key components may include the water pump, radiator, oil pump, and oil filter. These parts are essential for preventing overheating and ensuring smooth operation of the engine.

- Engine sensors and electronic components: Various sensors and electronic components are integrated into the K24 engine to monitor and control its performance. These may include the oxygen sensor, camshaft position sensor, crankshaft position sensor, and engine control unit (ECU). These parts play a crucial role in optimizing engine performance, fuel efficiency, and emissions control.

02 Valve train and camshaft system

The valve train and camshaft system in the K24 engine are responsible for controlling the intake and exhaust of gases. This includes components such as valves, valve springs, camshafts, and related parts. The design and materials used in these components significantly impact the engine's performance, fuel efficiency, and emissions.Expand Specific Solutions03 Fuel injection and intake system

The fuel injection and intake system of the K24 engine plays a crucial role in delivering the proper air-fuel mixture to the combustion chamber. This includes components such as fuel injectors, intake manifolds, and throttle bodies. These parts are designed to optimize fuel delivery and air intake for improved engine performance and efficiency.Expand Specific Solutions04 Cooling and lubrication systems

The cooling and lubrication systems are essential for maintaining optimal engine temperature and reducing friction between moving parts. This includes components such as water pumps, oil pumps, radiators, and oil filters. These systems work together to prevent overheating and ensure smooth operation of the K24 engine.Expand Specific Solutions05 Engine sensors and electronic components

The K24 engine incorporates various sensors and electronic components to monitor and control engine performance. This includes sensors for temperature, pressure, and position, as well as engine control units (ECUs). These components work together to optimize engine operation, fuel efficiency, and emissions control.Expand Specific Solutions

Key Manufacturers

The K24 engine parts market is in a mature stage, with a well-established global supply chain and diverse players. The market size is substantial, driven by ongoing demand for performance upgrades and replacements in the automotive sector. Technologically, the field is evolving, with companies like GM Global Technology Operations and BorgWarner leading in advanced modifications. Nissan Motor Co. and AUDI AG contribute significant innovations, while specialized firms such as Hangzhou Advance Gearbox Group and Sumitomo Riko focus on specific components. The competitive landscape is characterized by a mix of large automotive manufacturers and specialized parts suppliers, with ongoing research and development efforts aimed at improving engine efficiency and performance.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced modifications for the K24 engine, focusing on improving performance and efficiency. Their approach includes the use of lightweight materials for engine components, such as aluminum alloy pistons and connecting rods, which reduce overall engine weight and improve power-to-weight ratio[1]. GM has also implemented variable valve timing (VVT) technology, allowing for optimized engine performance across different RPM ranges[2]. Additionally, they have developed a direct injection system specifically tailored for the K24 engine, improving fuel efficiency and power output[3]. GM's modifications also extend to the engine's cooling system, with advanced thermal management techniques to maintain optimal operating temperatures under various conditions[4].

Strengths: Comprehensive approach to engine modification, leveraging GM's extensive R&D capabilities. Weaknesses: Modifications may be costly to implement and could potentially affect the engine's long-term reliability if not properly engineered.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has focused on enhancing the K24 engine's performance through a series of advanced modifications. They have developed a high-flow intake manifold design that improves air delivery to the cylinders, resulting in increased horsepower and torque[5]. Nissan's engineers have also implemented a revised camshaft profile with increased lift and duration, optimizing valve timing for better high-RPM performance[6]. To complement these changes, Nissan has designed a performance exhaust system with reduced back pressure, further improving engine efficiency and power output[7]. Additionally, they have developed a custom engine control unit (ECU) tuning package specifically for modified K24 engines, allowing for precise fuel and ignition management to maximize performance gains from other modifications[8].

Strengths: Holistic approach to performance enhancement, focusing on both mechanical and electronic improvements. Weaknesses: Modifications may void warranty and could potentially impact emissions compliance in some regions.

Advanced Tuning Techniques

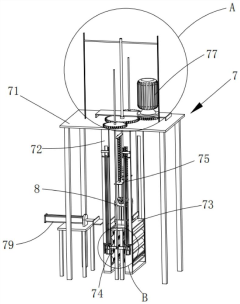

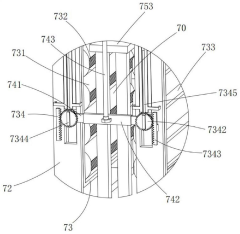

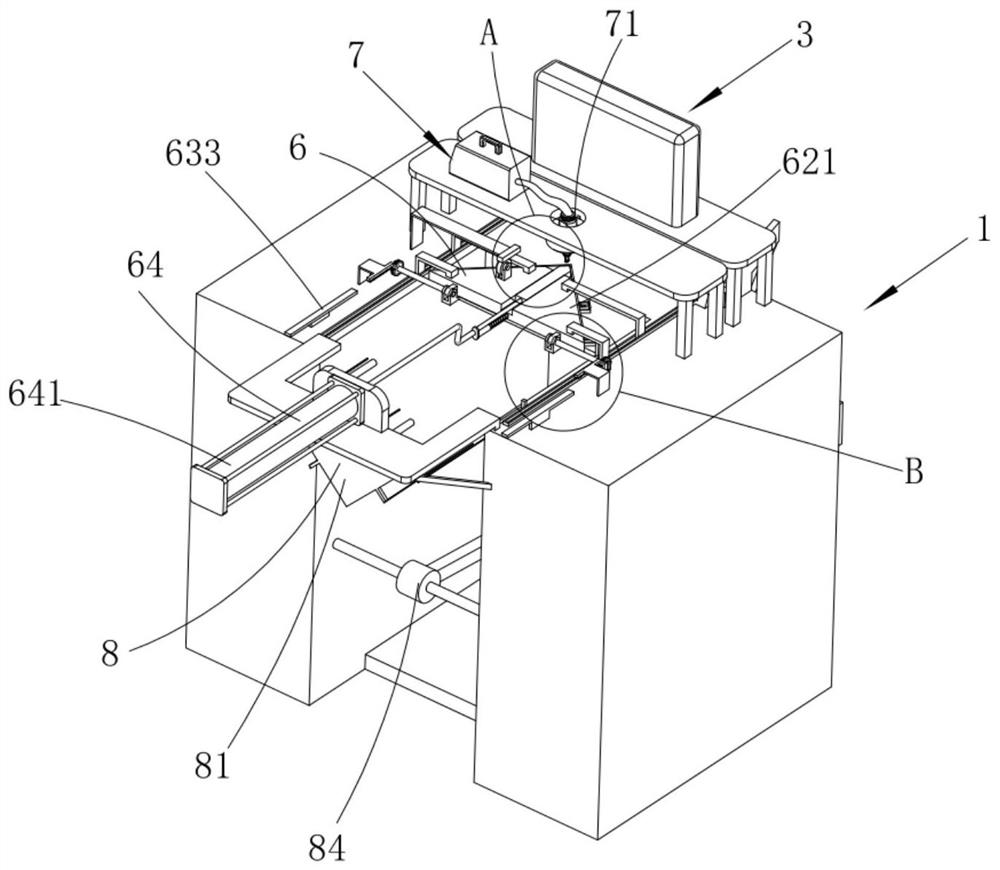

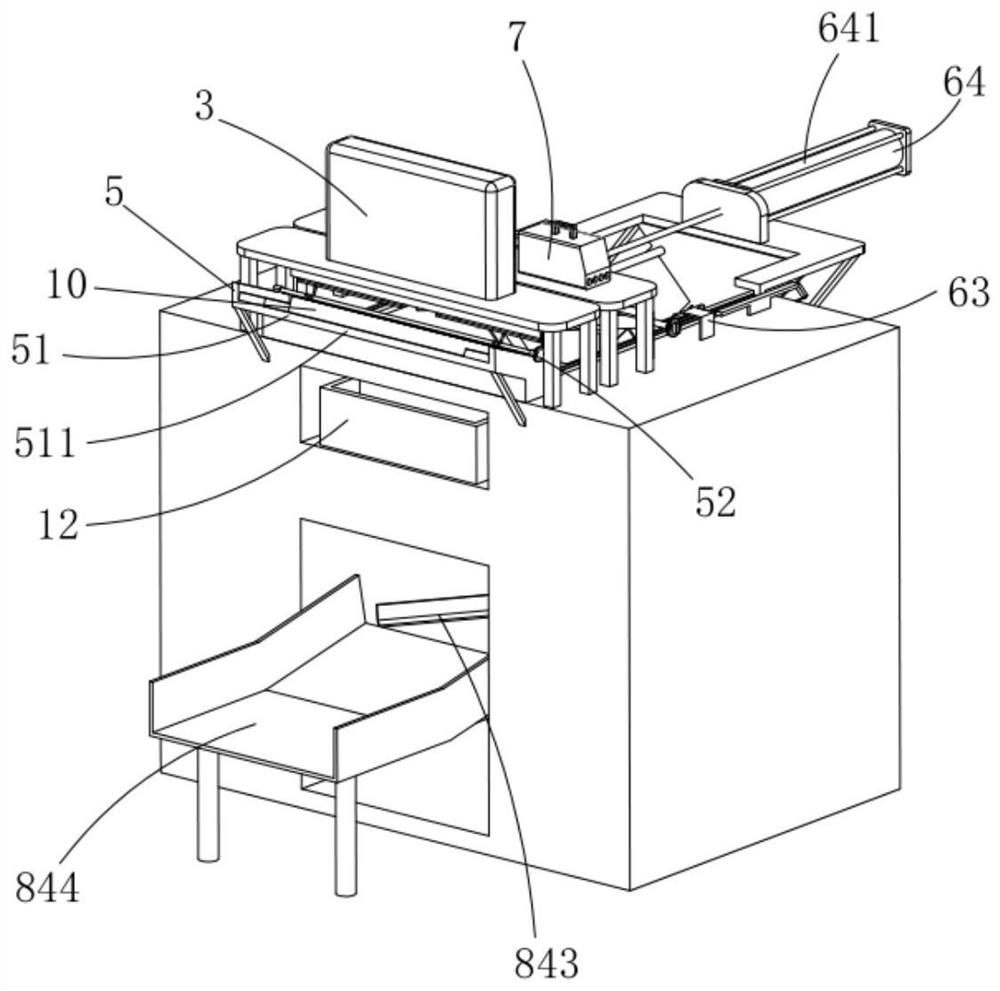

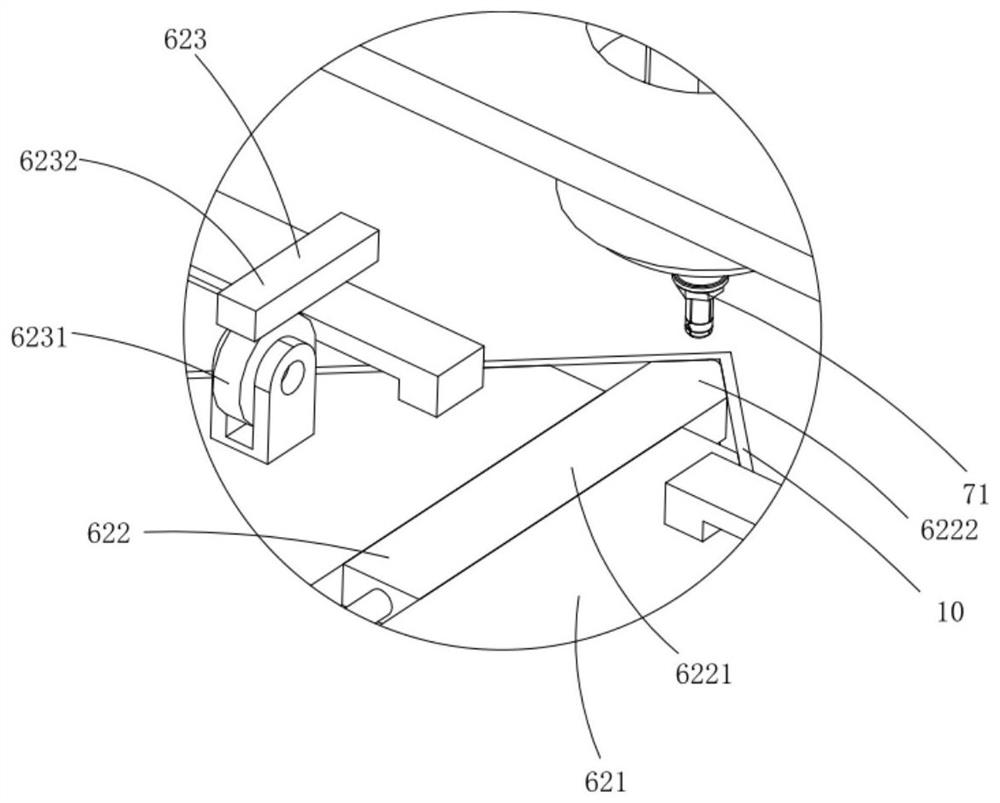

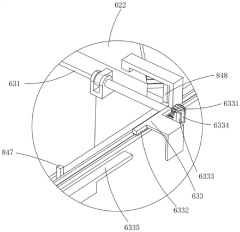

Chemical plastic packaging barrel shredding device

PatentActiveCN112959549A

Innovation

- A device for shredding chemical plastic packaging barrels is designed. The moving frame drives the oil bottle upward, and the ejector pin and pressure plate move downward to push the oil bottle. It combines the heating component to heat the label and the spray component to clean the residual liquid. The cleaning component is moving. When the frame moves down, labels and residual liquid are scraped off to improve processing efficiency.

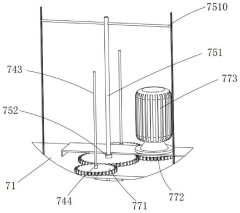

Continuous steel machining device

PatentActiveCN112808813A

Innovation

- A continuous steel processing equipment is designed. The angle steel is bent by the mounting base and the pressing die, and the angle steel is fixed using a welding device. Then the mounting base moves back, the rotating plate rotates, the fastening component loosens the angle steel, and the angle steel is connected. The material component pushes it to the conveying track to achieve rapid demoulding and orderly output of angle steel.

Performance Testing Methods

Performance testing methods for K24 engine parts, from basic to advanced modifications, are crucial for evaluating the effectiveness of upgrades and ensuring optimal engine performance. These methods range from simple dynamometer tests to more complex real-world driving assessments.

Dynamometer testing is a fundamental approach used to measure engine power and torque. This method involves mounting the engine or vehicle on a dynamometer, which simulates various load conditions. For K24 engines, both engine dynamometers and chassis dynamometers are commonly used. Engine dynos provide more accurate measurements of raw engine output, while chassis dynos account for drivetrain losses, offering a more realistic representation of power at the wheels.

In addition to power and torque measurements, dynamometer testing allows for the evaluation of air-fuel ratios, exhaust gas temperatures, and boost pressure in turbocharged applications. These parameters are essential for fine-tuning engine performance and ensuring reliability after modifications.

On-road testing complements dynamometer results by assessing real-world performance. This includes acceleration tests, such as 0-60 mph and quarter-mile times, which provide tangible metrics for comparing stock and modified K24 engines. GPS-based data logging systems are often employed to capture accurate speed and time measurements during these tests.

For more advanced modifications, track testing becomes invaluable. Lap times and sector splits on a closed circuit offer insights into how engine modifications affect overall vehicle performance, including handling and braking characteristics that may be influenced by power increases.

Fuel efficiency testing is another critical aspect, particularly for street-driven K24-powered vehicles. This involves standardized driving cycles or real-world fuel consumption measurements to determine how modifications impact fuel economy.

Emissions testing is increasingly important, especially for modified engines that must meet local regulations. Portable emissions measurement systems (PEMS) allow for real-world emissions data collection, while stationary emissions testing equipment provides more controlled results.

Thermal imaging and temperature monitoring are advanced techniques used to assess heat management in modified K24 engines. These methods help identify potential hot spots or areas of concern, particularly in high-performance applications where thermal management is crucial.

Lastly, long-term durability testing is essential for evaluating the reliability of modified K24 engines. This may involve extended dyno runs, endurance racing, or prolonged daily driving to stress test components and ensure that performance gains are sustainable over time.

Dynamometer testing is a fundamental approach used to measure engine power and torque. This method involves mounting the engine or vehicle on a dynamometer, which simulates various load conditions. For K24 engines, both engine dynamometers and chassis dynamometers are commonly used. Engine dynos provide more accurate measurements of raw engine output, while chassis dynos account for drivetrain losses, offering a more realistic representation of power at the wheels.

In addition to power and torque measurements, dynamometer testing allows for the evaluation of air-fuel ratios, exhaust gas temperatures, and boost pressure in turbocharged applications. These parameters are essential for fine-tuning engine performance and ensuring reliability after modifications.

On-road testing complements dynamometer results by assessing real-world performance. This includes acceleration tests, such as 0-60 mph and quarter-mile times, which provide tangible metrics for comparing stock and modified K24 engines. GPS-based data logging systems are often employed to capture accurate speed and time measurements during these tests.

For more advanced modifications, track testing becomes invaluable. Lap times and sector splits on a closed circuit offer insights into how engine modifications affect overall vehicle performance, including handling and braking characteristics that may be influenced by power increases.

Fuel efficiency testing is another critical aspect, particularly for street-driven K24-powered vehicles. This involves standardized driving cycles or real-world fuel consumption measurements to determine how modifications impact fuel economy.

Emissions testing is increasingly important, especially for modified engines that must meet local regulations. Portable emissions measurement systems (PEMS) allow for real-world emissions data collection, while stationary emissions testing equipment provides more controlled results.

Thermal imaging and temperature monitoring are advanced techniques used to assess heat management in modified K24 engines. These methods help identify potential hot spots or areas of concern, particularly in high-performance applications where thermal management is crucial.

Lastly, long-term durability testing is essential for evaluating the reliability of modified K24 engines. This may involve extended dyno runs, endurance racing, or prolonged daily driving to stress test components and ensure that performance gains are sustainable over time.

Emissions Compliance Strategies

Emissions compliance strategies for K24 engine modifications are crucial in maintaining legal and environmental standards while enhancing performance. As regulations become increasingly stringent, aftermarket parts manufacturers and engine tuners must adapt their approaches to ensure modified K24 engines meet emissions requirements.

One key strategy involves the use of advanced catalytic converters. High-flow catalytic converters designed specifically for modified K24 engines can effectively reduce harmful emissions while minimizing restrictions on exhaust flow. These catalysts often utilize precious metals like platinum and palladium in higher concentrations to improve conversion efficiency, allowing for increased engine output without compromising emissions standards.

Electronic engine management systems play a vital role in emissions compliance. Aftermarket ECU (Engine Control Unit) upgrades can be programmed to optimize fuel injection and ignition timing for both performance and emissions control. These systems can incorporate closed-loop feedback from oxygen sensors to maintain ideal air-fuel ratios across a wide range of operating conditions, ensuring efficient combustion and minimizing pollutants.

Variable valve timing (VVT) modifications can also contribute to emissions compliance. Advanced VVT systems, when properly tuned, can improve engine breathing and combustion efficiency across the RPM range. This results in better fuel economy and reduced emissions, particularly at part-throttle conditions where many emissions tests are conducted.

Exhaust gas recirculation (EGR) systems, often removed in performance modifications, can be redesigned for high-performance applications. Modern EGR solutions can effectively reduce nitrogen oxide (NOx) emissions without significantly impacting engine output. Some aftermarket EGR systems incorporate cooling features to further enhance their effectiveness in emissions reduction.

Fuel system upgrades must also consider emissions compliance. High-flow fuel injectors paired with precise fuel pressure regulators can provide the necessary fuel delivery for increased power while maintaining proper atomization for clean combustion. Additionally, the use of higher-quality fuels or even alternative fuels like E85 can contribute to reduced emissions in modified K24 engines.

Air intake systems, while often modified for increased airflow, must still incorporate effective filtration to prevent particulate emissions. Advanced air filter designs using nano-fiber technology can offer superior filtration without restricting airflow, meeting both performance and emissions goals.

Lastly, regular engine maintenance and proper tuning are essential strategies for emissions compliance. Frequent oil changes, spark plug replacements, and sensor calibrations ensure the engine operates at peak efficiency, minimizing emissions output. Professional dyno tuning services can optimize engine parameters for both performance and emissions, ensuring the modified K24 engine meets local regulations while delivering enhanced performance.

One key strategy involves the use of advanced catalytic converters. High-flow catalytic converters designed specifically for modified K24 engines can effectively reduce harmful emissions while minimizing restrictions on exhaust flow. These catalysts often utilize precious metals like platinum and palladium in higher concentrations to improve conversion efficiency, allowing for increased engine output without compromising emissions standards.

Electronic engine management systems play a vital role in emissions compliance. Aftermarket ECU (Engine Control Unit) upgrades can be programmed to optimize fuel injection and ignition timing for both performance and emissions control. These systems can incorporate closed-loop feedback from oxygen sensors to maintain ideal air-fuel ratios across a wide range of operating conditions, ensuring efficient combustion and minimizing pollutants.

Variable valve timing (VVT) modifications can also contribute to emissions compliance. Advanced VVT systems, when properly tuned, can improve engine breathing and combustion efficiency across the RPM range. This results in better fuel economy and reduced emissions, particularly at part-throttle conditions where many emissions tests are conducted.

Exhaust gas recirculation (EGR) systems, often removed in performance modifications, can be redesigned for high-performance applications. Modern EGR solutions can effectively reduce nitrogen oxide (NOx) emissions without significantly impacting engine output. Some aftermarket EGR systems incorporate cooling features to further enhance their effectiveness in emissions reduction.

Fuel system upgrades must also consider emissions compliance. High-flow fuel injectors paired with precise fuel pressure regulators can provide the necessary fuel delivery for increased power while maintaining proper atomization for clean combustion. Additionally, the use of higher-quality fuels or even alternative fuels like E85 can contribute to reduced emissions in modified K24 engines.

Air intake systems, while often modified for increased airflow, must still incorporate effective filtration to prevent particulate emissions. Advanced air filter designs using nano-fiber technology can offer superior filtration without restricting airflow, meeting both performance and emissions goals.

Lastly, regular engine maintenance and proper tuning are essential strategies for emissions compliance. Frequent oil changes, spark plug replacements, and sensor calibrations ensure the engine operates at peak efficiency, minimizing emissions output. Professional dyno tuning services can optimize engine parameters for both performance and emissions, ensuring the modified K24 engine meets local regulations while delivering enhanced performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!