K24 Engine Replacement: Understanding Compatibility Issues

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a cornerstone of Honda's performance lineup, has undergone significant evolution since its introduction in the early 2000s. Initially designed as a 2.4-liter inline-four engine, the K24 has seen multiple iterations and improvements over the years, each addressing specific performance needs and technological advancements.

The first generation K24A1 engine debuted in 2002, featuring a displacement of 2,354cc and producing around 160 horsepower. This initial version set the foundation for future developments, incorporating Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system, which significantly improved both power output and fuel efficiency.

As the K24 engine evolved, Honda introduced various sub-models to cater to different vehicle applications and performance requirements. The K24A2, for instance, was a higher-output version used in sportier models, producing up to 200 horsepower. This iteration showcased the engine's versatility and potential for increased performance.

In the mid-2000s, Honda further refined the K24 with the introduction of the K24A3 and K24A4 variants. These engines featured improved intake and exhaust systems, revised camshaft profiles, and enhanced engine management systems. These upgrades resulted in smoother power delivery and increased torque across a broader RPM range.

The late 2000s saw the emergence of the K24Z series, marking a significant leap in the engine's evolution. The K24Z7, used in vehicles like the 9th generation Civic Si, incorporated advanced materials and manufacturing techniques to reduce weight and improve thermal efficiency. This version also saw the integration of more sophisticated electronic controls, further optimizing performance and emissions.

As environmental concerns grew, Honda adapted the K24 engine to meet stricter emissions standards without compromising performance. The introduction of direct injection technology in later K24 variants exemplified this approach, allowing for more precise fuel delivery and improved combustion efficiency.

The most recent iterations of the K24 engine have focused on hybridization and electrification. Honda has developed versions of the K24 that work in conjunction with electric motors, creating hybrid powertrains that offer both performance and improved fuel economy. This evolution demonstrates the engine's adaptability to changing market demands and technological trends.

Throughout its lifespan, the K24 engine has maintained its reputation for reliability and tunability, making it a popular choice among enthusiasts for engine swaps and performance modifications. The engine's robust design and wide availability of aftermarket parts have contributed to its enduring popularity in the automotive performance community.

The first generation K24A1 engine debuted in 2002, featuring a displacement of 2,354cc and producing around 160 horsepower. This initial version set the foundation for future developments, incorporating Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system, which significantly improved both power output and fuel efficiency.

As the K24 engine evolved, Honda introduced various sub-models to cater to different vehicle applications and performance requirements. The K24A2, for instance, was a higher-output version used in sportier models, producing up to 200 horsepower. This iteration showcased the engine's versatility and potential for increased performance.

In the mid-2000s, Honda further refined the K24 with the introduction of the K24A3 and K24A4 variants. These engines featured improved intake and exhaust systems, revised camshaft profiles, and enhanced engine management systems. These upgrades resulted in smoother power delivery and increased torque across a broader RPM range.

The late 2000s saw the emergence of the K24Z series, marking a significant leap in the engine's evolution. The K24Z7, used in vehicles like the 9th generation Civic Si, incorporated advanced materials and manufacturing techniques to reduce weight and improve thermal efficiency. This version also saw the integration of more sophisticated electronic controls, further optimizing performance and emissions.

As environmental concerns grew, Honda adapted the K24 engine to meet stricter emissions standards without compromising performance. The introduction of direct injection technology in later K24 variants exemplified this approach, allowing for more precise fuel delivery and improved combustion efficiency.

The most recent iterations of the K24 engine have focused on hybridization and electrification. Honda has developed versions of the K24 that work in conjunction with electric motors, creating hybrid powertrains that offer both performance and improved fuel economy. This evolution demonstrates the engine's adaptability to changing market demands and technological trends.

Throughout its lifespan, the K24 engine has maintained its reputation for reliability and tunability, making it a popular choice among enthusiasts for engine swaps and performance modifications. The engine's robust design and wide availability of aftermarket parts have contributed to its enduring popularity in the automotive performance community.

Market Demand Analysis

The market demand for K24 engine replacements has been steadily growing, driven by several factors in the automotive industry. As vehicles equipped with K24 engines age, owners are increasingly seeking replacement options to extend the life of their vehicles. This trend is particularly evident in regions where K24-powered vehicles, such as certain Honda and Acura models, have been popular.

The compatibility issues surrounding K24 engine replacements have created a niche market for specialized automotive services and aftermarket parts. Many vehicle owners are looking for cost-effective solutions that allow them to maintain their vehicles' performance without the need for a complete vehicle replacement. This has led to an increased demand for both OEM and aftermarket K24 engine components.

In the aftermarket sector, there has been a surge in the development of compatibility kits and adapters designed to address the challenges of fitting K24 engines into various vehicle models. These products cater to enthusiasts and repair shops seeking to overcome compatibility hurdles, thereby expanding the potential market for K24 engine replacements.

The rising interest in engine swaps among automotive enthusiasts has also contributed to the market demand. K24 engines are often sought after for their reliability, power potential, and relative abundance, making them popular choices for engine swap projects across different vehicle platforms.

Environmental regulations and the push for improved fuel efficiency have indirectly impacted the K24 replacement market. As older vehicles face stricter emissions standards, some owners opt for engine replacements or upgrades to comply with regulations while maintaining their existing vehicles. This has created a subset of the market focused on eco-friendly K24 engine replacements and modifications.

The automotive repair and maintenance industry has seen an uptick in requests for K24 engine-related services. Independent mechanics and specialized shops have reported increased inquiries about K24 engine replacements, indicating a growing awareness and demand among vehicle owners.

Online marketplaces and automotive forums have witnessed a rise in discussions and transactions related to K24 engine replacements. This digital trend reflects the broader market interest and highlights the importance of online platforms in connecting buyers with sellers of K24 engines and related components.

As the average age of vehicles on the road continues to increase, the demand for engine replacements, including K24 engines, is expected to remain strong. This trend is likely to persist as long as the benefits of engine replacement outweigh the costs of purchasing new vehicles for many consumers.

The compatibility issues surrounding K24 engine replacements have created a niche market for specialized automotive services and aftermarket parts. Many vehicle owners are looking for cost-effective solutions that allow them to maintain their vehicles' performance without the need for a complete vehicle replacement. This has led to an increased demand for both OEM and aftermarket K24 engine components.

In the aftermarket sector, there has been a surge in the development of compatibility kits and adapters designed to address the challenges of fitting K24 engines into various vehicle models. These products cater to enthusiasts and repair shops seeking to overcome compatibility hurdles, thereby expanding the potential market for K24 engine replacements.

The rising interest in engine swaps among automotive enthusiasts has also contributed to the market demand. K24 engines are often sought after for their reliability, power potential, and relative abundance, making them popular choices for engine swap projects across different vehicle platforms.

Environmental regulations and the push for improved fuel efficiency have indirectly impacted the K24 replacement market. As older vehicles face stricter emissions standards, some owners opt for engine replacements or upgrades to comply with regulations while maintaining their existing vehicles. This has created a subset of the market focused on eco-friendly K24 engine replacements and modifications.

The automotive repair and maintenance industry has seen an uptick in requests for K24 engine-related services. Independent mechanics and specialized shops have reported increased inquiries about K24 engine replacements, indicating a growing awareness and demand among vehicle owners.

Online marketplaces and automotive forums have witnessed a rise in discussions and transactions related to K24 engine replacements. This digital trend reflects the broader market interest and highlights the importance of online platforms in connecting buyers with sellers of K24 engines and related components.

As the average age of vehicles on the road continues to increase, the demand for engine replacements, including K24 engines, is expected to remain strong. This trend is likely to persist as long as the benefits of engine replacement outweigh the costs of purchasing new vehicles for many consumers.

Compatibility Challenges

The K24 engine replacement presents several significant compatibility challenges that must be carefully addressed. One of the primary issues is the physical fitment of the new engine into the existing engine bay. The K24 engine may have different dimensions, mounting points, and overall layout compared to the original engine, requiring modifications to the engine mounts, subframe, and potentially the firewall or transmission tunnel.

Electrical compatibility is another major concern. The K24 engine utilizes a different engine management system and wiring harness compared to older Honda engines. This necessitates either adapting the existing vehicle's electrical system or installing a completely new engine control unit (ECU) and wiring harness. The integration of modern sensors and electronic components with older vehicle systems can be complex and may require specialized knowledge and tools.

Transmission compatibility is a crucial factor to consider. The K24 engine may not directly bolt up to the existing transmission, especially if the vehicle was originally equipped with an older Honda engine series. This might require the use of an adapter plate or even a complete transmission swap to ensure proper fitment and functionality. Additionally, the clutch system and flywheel may need to be upgraded to handle the increased power output of the K24 engine.

Cooling system compatibility is another challenge that needs to be addressed. The K24 engine may have different cooling requirements compared to the original engine, necessitating modifications to the radiator, coolant hoses, and potentially the addition of an oil cooler. Ensuring adequate cooling capacity is essential to maintain engine reliability and performance, especially in high-performance applications.

Fuel system compatibility is also a consideration, as the K24 engine may require higher fuel pressure or flow rates compared to the original engine. This could involve upgrading the fuel pump, fuel lines, and injectors to meet the new engine's requirements. Additionally, the fuel management system may need to be recalibrated to ensure proper air-fuel ratios across the engine's operating range.

Exhaust system compatibility is another challenge to overcome. The K24 engine's exhaust manifold and downpipe configuration may differ from the original engine, requiring custom fabrication or adaptation of the exhaust system. This includes ensuring proper clearance for the new components and maintaining compliance with emissions regulations.

Lastly, compatibility with vehicle accessories and auxiliary systems must be considered. This includes power steering, air conditioning, and alternator mounting. In some cases, custom brackets or relocation of components may be necessary to accommodate the K24 engine's layout while maintaining functionality of these essential systems.

Electrical compatibility is another major concern. The K24 engine utilizes a different engine management system and wiring harness compared to older Honda engines. This necessitates either adapting the existing vehicle's electrical system or installing a completely new engine control unit (ECU) and wiring harness. The integration of modern sensors and electronic components with older vehicle systems can be complex and may require specialized knowledge and tools.

Transmission compatibility is a crucial factor to consider. The K24 engine may not directly bolt up to the existing transmission, especially if the vehicle was originally equipped with an older Honda engine series. This might require the use of an adapter plate or even a complete transmission swap to ensure proper fitment and functionality. Additionally, the clutch system and flywheel may need to be upgraded to handle the increased power output of the K24 engine.

Cooling system compatibility is another challenge that needs to be addressed. The K24 engine may have different cooling requirements compared to the original engine, necessitating modifications to the radiator, coolant hoses, and potentially the addition of an oil cooler. Ensuring adequate cooling capacity is essential to maintain engine reliability and performance, especially in high-performance applications.

Fuel system compatibility is also a consideration, as the K24 engine may require higher fuel pressure or flow rates compared to the original engine. This could involve upgrading the fuel pump, fuel lines, and injectors to meet the new engine's requirements. Additionally, the fuel management system may need to be recalibrated to ensure proper air-fuel ratios across the engine's operating range.

Exhaust system compatibility is another challenge to overcome. The K24 engine's exhaust manifold and downpipe configuration may differ from the original engine, requiring custom fabrication or adaptation of the exhaust system. This includes ensuring proper clearance for the new components and maintaining compliance with emissions regulations.

Lastly, compatibility with vehicle accessories and auxiliary systems must be considered. This includes power steering, air conditioning, and alternator mounting. In some cases, custom brackets or relocation of components may be necessary to accommodate the K24 engine's layout while maintaining functionality of these essential systems.

Current Replacement Solutions

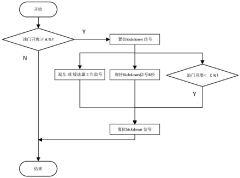

01 Engine control system compatibility

K24 engine compatibility involves developing control systems that can effectively manage and optimize the engine's performance. This includes designing software and hardware components that can interface with the K24 engine's specific requirements, ensuring proper fuel management, ignition timing, and overall engine efficiency.- Engine compatibility assessment systems: Systems and methods for assessing engine compatibility, particularly for the K24 engine. These systems may involve software tools or algorithms that analyze various engine parameters and components to determine compatibility with different vehicle models or aftermarket parts.

- K24 engine performance optimization: Techniques for optimizing the performance of K24 engines, including tuning methods, software adjustments, and hardware modifications. These approaches aim to enhance engine output, efficiency, and reliability while maintaining compatibility with various vehicle systems.

- Compatibility with aftermarket parts: Solutions for ensuring compatibility between K24 engines and aftermarket parts or accessories. This includes adapters, interfaces, or modified components that allow for seamless integration of non-standard parts with the K24 engine architecture.

- K24 engine control unit (ECU) integration: Methods and systems for integrating and optimizing the engine control unit (ECU) for K24 engines. This involves software and hardware solutions to ensure proper communication and functionality between the ECU and various engine components across different vehicle platforms.

- Cross-platform K24 engine adaptation: Techniques for adapting K24 engines to different vehicle platforms or non-standard applications. This includes mechanical, electrical, and software modifications to ensure proper fitment, functionality, and performance across various vehicle makes and models.

02 Transmission and drivetrain integration

Ensuring compatibility between the K24 engine and various transmission systems is crucial. This involves designing appropriate interfaces, adapting drivetrain components, and optimizing power transfer to accommodate the K24 engine's characteristics, such as its power output and torque curve.Expand Specific Solutions03 Fuel system adaptation

Adapting fuel systems for K24 engine compatibility requires modifying fuel delivery, injection systems, and fuel management to match the engine's specifications. This may involve adjusting fuel pressure, injector timing, and fuel mapping to ensure optimal performance and efficiency.Expand Specific Solutions04 Cooling system modifications

K24 engine compatibility often requires adjustments to the cooling system to manage heat effectively. This can include redesigning radiators, modifying coolant flow paths, and implementing advanced thermal management strategies to maintain optimal operating temperatures under various conditions.Expand Specific Solutions05 Electronic integration and diagnostics

Integrating the K24 engine with modern vehicle electronics and diagnostic systems is essential for compatibility. This involves developing appropriate communication protocols, sensor interfaces, and diagnostic tools to monitor engine performance, detect faults, and facilitate maintenance.Expand Specific Solutions

Key Manufacturers

The K24 engine replacement market is in a mature phase, characterized by established players and well-defined compatibility standards. The market size is substantial, driven by the large installed base of K24 engines across various vehicle models. Technologically, the field is relatively stable, with incremental improvements rather than disruptive innovations. Key players like Honda Motor Co., Ltd., the original manufacturer, and aftermarket specialists such as Cummins, Inc. and Robert Bosch GmbH, have developed advanced solutions to address compatibility issues. Other automotive giants like Ford Global Technologies LLC and GM Global Technology Operations LLC also contribute to the ecosystem, ensuring a competitive landscape that fosters ongoing refinement in engine replacement technologies and compatibility solutions.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive approach to K24 engine replacement compatibility. Their solution involves a modular design philosophy, allowing for easier integration of the K24 engine into various vehicle platforms. Ford's engineers have created a universal mounting system that accommodates different vehicle architectures, reducing the need for extensive modifications[1]. Additionally, they've implemented advanced electronic control units (ECUs) that can be easily programmed to optimize the K24 engine's performance in different vehicle applications[3]. Ford has also developed a series of adaptive transmission control modules that ensure seamless integration with existing powertrains[5].

Strengths: Versatile compatibility across multiple vehicle platforms, reduced installation complexity, and optimized performance through adaptive electronics. Weaknesses: Potential increased costs due to modular components and specialized ECUs.

GM Global Technology Operations LLC

Technical Solution: GM's approach to K24 engine replacement compatibility focuses on a standardized interface system. They have developed a universal engine cradle that can accommodate the K24 engine across various GM vehicle models[2]. This system includes standardized mounting points, wiring harnesses, and fluid connections. GM has also created a proprietary software package that allows for quick recalibration of vehicle systems to work with the K24 engine, addressing issues such as throttle response, fuel mapping, and emissions control[4]. Furthermore, GM has invested in developing a range of adaptive components, such as variable-length intake manifolds and adjustable engine mounts, to fine-tune the K24's performance and NVH characteristics in different vehicle applications[6].

Strengths: Standardized installation process across GM's vehicle range, efficient system integration through proprietary software. Weaknesses: Limited compatibility with non-GM vehicles, potential over-reliance on proprietary technology.

Innovative Adaptation Techniques

Control method for providing stable kickdwon signal for gearbox

PatentInactiveCN114439916A

Innovation

- Real-time monitoring of the throttle opening. When the throttle opening reaches or exceeds the first preset value, the kickdown signal is triggered and set. After setting, it is reset with a delay. If the throttle opening is reduced or a brake signal is detected, the kickdown signal is directly reset. The ECU sends a stable kickdown signal to the gearbox.

Method for converting a vehicle, method for providing a drive unit, drive unit and vehicle

PatentWO2024061428A2

Innovation

- A method that involves mechanically separating the internal combustion engine drive unit, replacing it with an electrically operated drive unit that is spatially, mechanically, and functionally compatible, using adapters for thermal and electromechanical adjustments, and maintaining operational compatibility with existing mechanical, thermal, and electromechanical connections, including crankshaft emulation and data interface compatibility.

Regulatory Compliance

Regulatory compliance plays a crucial role in the K24 engine replacement process, as it ensures that the modified vehicle meets all necessary safety and environmental standards. When considering compatibility issues, adherence to regulations becomes even more critical to maintain the vehicle's legal status and performance integrity.

One of the primary regulatory concerns in K24 engine replacements is emissions compliance. Different regions and countries have varying emissions standards, such as the EPA regulations in the United States or Euro standards in Europe. The replacement engine must meet or exceed the original engine's emissions performance to maintain compliance. This often requires careful selection of engine components, including catalytic converters, oxygen sensors, and engine control units (ECUs) that are compatible with the vehicle's existing systems.

Safety regulations also factor heavily into K24 engine replacements. The modified vehicle must continue to meet crash safety standards, which can be affected by changes in engine weight, mounting points, and overall vehicle balance. Additionally, noise regulations must be considered, as the new engine configuration may alter the vehicle's sound profile. Compliance with these safety standards often necessitates modifications to engine mounts, exhaust systems, and potentially even structural components of the vehicle.

Vehicle registration and inspection requirements vary by jurisdiction but generally require that engine replacements be properly documented and approved. This may involve obtaining specific permits or certifications, such as a BAR (Bureau of Automotive Repair) certification in California. Failure to comply with these requirements can result in the vehicle being deemed unroadworthy or illegal to operate on public roads.

Fuel efficiency standards are another regulatory aspect to consider. While the K24 engine is known for its efficiency, ensuring that the replacement maintains or improves upon the original vehicle's fuel economy is important for compliance with corporate average fuel economy (CAFE) standards in some regions. This may influence the choice of engine tuning and auxiliary components.

Lastly, warranty and insurance implications must be addressed. Engine replacements can void manufacturer warranties and may require special insurance considerations. Ensuring that the replacement process and resulting vehicle configuration comply with insurance regulations and disclosure requirements is essential to maintain proper coverage and avoid potential legal issues.

One of the primary regulatory concerns in K24 engine replacements is emissions compliance. Different regions and countries have varying emissions standards, such as the EPA regulations in the United States or Euro standards in Europe. The replacement engine must meet or exceed the original engine's emissions performance to maintain compliance. This often requires careful selection of engine components, including catalytic converters, oxygen sensors, and engine control units (ECUs) that are compatible with the vehicle's existing systems.

Safety regulations also factor heavily into K24 engine replacements. The modified vehicle must continue to meet crash safety standards, which can be affected by changes in engine weight, mounting points, and overall vehicle balance. Additionally, noise regulations must be considered, as the new engine configuration may alter the vehicle's sound profile. Compliance with these safety standards often necessitates modifications to engine mounts, exhaust systems, and potentially even structural components of the vehicle.

Vehicle registration and inspection requirements vary by jurisdiction but generally require that engine replacements be properly documented and approved. This may involve obtaining specific permits or certifications, such as a BAR (Bureau of Automotive Repair) certification in California. Failure to comply with these requirements can result in the vehicle being deemed unroadworthy or illegal to operate on public roads.

Fuel efficiency standards are another regulatory aspect to consider. While the K24 engine is known for its efficiency, ensuring that the replacement maintains or improves upon the original vehicle's fuel economy is important for compliance with corporate average fuel economy (CAFE) standards in some regions. This may influence the choice of engine tuning and auxiliary components.

Lastly, warranty and insurance implications must be addressed. Engine replacements can void manufacturer warranties and may require special insurance considerations. Ensuring that the replacement process and resulting vehicle configuration comply with insurance regulations and disclosure requirements is essential to maintain proper coverage and avoid potential legal issues.

Performance Optimization

Performance optimization is a critical aspect of K24 engine replacement, focusing on enhancing the overall efficiency and power output of the modified vehicle. When addressing compatibility issues, it is essential to consider various factors that can impact the engine's performance.

One key area of optimization is the engine management system. Upgrading to a more advanced ECU (Engine Control Unit) can significantly improve the engine's performance by allowing for precise control over fuel injection, ignition timing, and other critical parameters. This optimization can lead to increased horsepower, improved fuel efficiency, and better overall engine responsiveness.

Another important consideration is the intake and exhaust systems. Upgrading these components to match the characteristics of the replacement K24 engine can result in improved airflow, leading to enhanced power output and throttle response. High-flow air filters, cold air intakes, and performance exhaust systems are common modifications that can contribute to overall performance gains.

Forced induction systems, such as turbochargers or superchargers, can be implemented to dramatically increase the engine's power output. However, careful consideration must be given to ensure compatibility with the K24 engine's internals and supporting systems. Proper tuning and reinforcement of engine components may be necessary to handle the increased power and stress.

Optimizing the engine's internals is another crucial aspect of performance enhancement. This may include upgrading components such as pistons, connecting rods, and camshafts to withstand higher RPMs and increased power output. Balancing these components can also contribute to smoother engine operation and improved reliability.

Cooling system upgrades are often necessary to maintain optimal engine temperatures under increased performance demands. This may involve installing a larger radiator, high-flow water pump, or an oil cooler to ensure proper heat dissipation and prevent overheating issues.

Transmission and drivetrain components should also be considered in the optimization process. Upgrading the clutch, flywheel, and differential can help transfer the increased power to the wheels more effectively, improving overall vehicle performance and drivability.

Finally, proper tuning and calibration are essential to maximize the performance potential of the K24 engine replacement. This involves fine-tuning various parameters such as fuel maps, ignition timing, and boost control (if applicable) to achieve optimal performance while maintaining reliability and drivability.

One key area of optimization is the engine management system. Upgrading to a more advanced ECU (Engine Control Unit) can significantly improve the engine's performance by allowing for precise control over fuel injection, ignition timing, and other critical parameters. This optimization can lead to increased horsepower, improved fuel efficiency, and better overall engine responsiveness.

Another important consideration is the intake and exhaust systems. Upgrading these components to match the characteristics of the replacement K24 engine can result in improved airflow, leading to enhanced power output and throttle response. High-flow air filters, cold air intakes, and performance exhaust systems are common modifications that can contribute to overall performance gains.

Forced induction systems, such as turbochargers or superchargers, can be implemented to dramatically increase the engine's power output. However, careful consideration must be given to ensure compatibility with the K24 engine's internals and supporting systems. Proper tuning and reinforcement of engine components may be necessary to handle the increased power and stress.

Optimizing the engine's internals is another crucial aspect of performance enhancement. This may include upgrading components such as pistons, connecting rods, and camshafts to withstand higher RPMs and increased power output. Balancing these components can also contribute to smoother engine operation and improved reliability.

Cooling system upgrades are often necessary to maintain optimal engine temperatures under increased performance demands. This may involve installing a larger radiator, high-flow water pump, or an oil cooler to ensure proper heat dissipation and prevent overheating issues.

Transmission and drivetrain components should also be considered in the optimization process. Upgrading the clutch, flywheel, and differential can help transfer the increased power to the wheels more effectively, improving overall vehicle performance and drivability.

Finally, proper tuning and calibration are essential to maximize the performance potential of the K24 engine replacement. This involves fine-tuning various parameters such as fuel maps, ignition timing, and boost control (if applicable) to achieve optimal performance while maintaining reliability and drivability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!