K24 Engine Swap Kits: A Breakdown of Popular Choices

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Swap Overview

The K24 engine, originally developed by Honda, has become a popular choice for engine swaps due to its robust design, reliability, and potential for performance upgrades. This overview will explore the key aspects of K24 engine swap kits and their popularity among automotive enthusiasts.

The K24 engine is a 2.4-liter inline-four cylinder engine that was first introduced in 2001. It has been used in various Honda and Acura models, including the Accord, CR-V, and TSX. The engine's popularity for swaps stems from its versatility, power potential, and widespread availability.

K24 engine swap kits typically include essential components necessary to integrate the K24 engine into a different vehicle platform. These kits often contain engine mounts, transmission adapters, wiring harnesses, and other hardware specific to the donor and recipient vehicles. The complexity and comprehensiveness of these kits can vary depending on the manufacturer and the intended application.

One of the primary reasons for the K24's popularity in engine swaps is its power output and tuning potential. In stock form, K24 engines can produce anywhere from 160 to 205 horsepower, depending on the specific variant. However, with aftermarket modifications and proper tuning, these engines can easily surpass 300 horsepower, making them attractive options for performance enthusiasts.

The K24 engine's compatibility with various Honda and Acura platforms also contributes to its widespread use in swaps. Many enthusiasts choose to upgrade their older Honda models, such as Civics or Integras, with the more powerful and modern K24 engine. This compatibility extends to both front-wheel-drive and all-wheel-drive applications, further expanding the range of potential swap candidates.

Another factor driving the popularity of K24 engine swaps is the extensive aftermarket support available. Numerous companies offer specialized parts, tuning solutions, and complete swap kits, making it easier for enthusiasts to undertake these projects. This support ecosystem has led to a wealth of knowledge and resources within the community, further encouraging others to pursue K24 swaps.

When considering popular choices for K24 engine swap kits, several options stand out in the market. These kits often cater to specific vehicle models or generations, ensuring proper fitment and integration. Some well-known manufacturers in this space include Hasport, Innovative Mounts, and K-Tuned, each offering various levels of kit completeness and customization options to suit different budgets and project scopes.

The K24 engine is a 2.4-liter inline-four cylinder engine that was first introduced in 2001. It has been used in various Honda and Acura models, including the Accord, CR-V, and TSX. The engine's popularity for swaps stems from its versatility, power potential, and widespread availability.

K24 engine swap kits typically include essential components necessary to integrate the K24 engine into a different vehicle platform. These kits often contain engine mounts, transmission adapters, wiring harnesses, and other hardware specific to the donor and recipient vehicles. The complexity and comprehensiveness of these kits can vary depending on the manufacturer and the intended application.

One of the primary reasons for the K24's popularity in engine swaps is its power output and tuning potential. In stock form, K24 engines can produce anywhere from 160 to 205 horsepower, depending on the specific variant. However, with aftermarket modifications and proper tuning, these engines can easily surpass 300 horsepower, making them attractive options for performance enthusiasts.

The K24 engine's compatibility with various Honda and Acura platforms also contributes to its widespread use in swaps. Many enthusiasts choose to upgrade their older Honda models, such as Civics or Integras, with the more powerful and modern K24 engine. This compatibility extends to both front-wheel-drive and all-wheel-drive applications, further expanding the range of potential swap candidates.

Another factor driving the popularity of K24 engine swaps is the extensive aftermarket support available. Numerous companies offer specialized parts, tuning solutions, and complete swap kits, making it easier for enthusiasts to undertake these projects. This support ecosystem has led to a wealth of knowledge and resources within the community, further encouraging others to pursue K24 swaps.

When considering popular choices for K24 engine swap kits, several options stand out in the market. These kits often cater to specific vehicle models or generations, ensuring proper fitment and integration. Some well-known manufacturers in this space include Hasport, Innovative Mounts, and K-Tuned, each offering various levels of kit completeness and customization options to suit different budgets and project scopes.

Market Demand Analysis

The market demand for K24 engine swap kits has been steadily growing, driven by the popularity of Honda's K-series engines among automotive enthusiasts. These engines, known for their reliability, performance potential, and versatility, have created a robust aftermarket ecosystem. The K24 variant, in particular, has gained significant traction due to its larger displacement and torque output compared to other K-series engines.

The primary market for K24 swap kits consists of Honda and Acura owners looking to upgrade their vehicles' performance. This includes owners of older Civic, Integra, and RSX models seeking modern engine technology. Additionally, there's a growing trend of K24 swaps in other makes and models, expanding the potential market beyond Honda vehicles.

Performance enthusiasts represent a key demographic, as they seek to extract maximum power from their vehicles. The K24's ability to produce high horsepower figures with relatively simple modifications makes it an attractive option for track day participants and street performance enthusiasts alike. This has led to increased demand for not only basic swap kits but also for supporting performance parts and tuning solutions.

The drift and time attack racing scenes have also contributed to the market growth. K24-swapped vehicles have proven competitive in these motorsport disciplines, further fueling interest and demand for swap kits and related components. This racing pedigree has a trickle-down effect on the street car market, as enthusiasts seek to emulate the performance and style of successful race cars.

From a geographical perspective, the market for K24 swap kits is particularly strong in regions with a robust car culture and less stringent emissions regulations. North America, especially states like California with large automotive enthusiast communities, represents a significant portion of the market. Japan, the home of Honda, also maintains a strong demand for these kits, influencing global trends.

The rise of social media and online automotive communities has played a crucial role in market expansion. Platforms like YouTube, Instagram, and enthusiast forums have facilitated knowledge sharing and showcased successful K24 swaps, inspiring more individuals to undertake similar projects. This has led to a network effect, where increased visibility drives further demand.

Economically, the K24 swap market benefits from the engine's relative affordability and availability. As more vehicles equipped with K24 engines reach salvage yards, the supply of donor engines increases, keeping costs manageable for enthusiasts. This accessibility, combined with the engine's performance potential, contributes to its ongoing popularity and market demand.

The primary market for K24 swap kits consists of Honda and Acura owners looking to upgrade their vehicles' performance. This includes owners of older Civic, Integra, and RSX models seeking modern engine technology. Additionally, there's a growing trend of K24 swaps in other makes and models, expanding the potential market beyond Honda vehicles.

Performance enthusiasts represent a key demographic, as they seek to extract maximum power from their vehicles. The K24's ability to produce high horsepower figures with relatively simple modifications makes it an attractive option for track day participants and street performance enthusiasts alike. This has led to increased demand for not only basic swap kits but also for supporting performance parts and tuning solutions.

The drift and time attack racing scenes have also contributed to the market growth. K24-swapped vehicles have proven competitive in these motorsport disciplines, further fueling interest and demand for swap kits and related components. This racing pedigree has a trickle-down effect on the street car market, as enthusiasts seek to emulate the performance and style of successful race cars.

From a geographical perspective, the market for K24 swap kits is particularly strong in regions with a robust car culture and less stringent emissions regulations. North America, especially states like California with large automotive enthusiast communities, represents a significant portion of the market. Japan, the home of Honda, also maintains a strong demand for these kits, influencing global trends.

The rise of social media and online automotive communities has played a crucial role in market expansion. Platforms like YouTube, Instagram, and enthusiast forums have facilitated knowledge sharing and showcased successful K24 swaps, inspiring more individuals to undertake similar projects. This has led to a network effect, where increased visibility drives further demand.

Economically, the K24 swap market benefits from the engine's relative affordability and availability. As more vehicles equipped with K24 engines reach salvage yards, the supply of donor engines increases, keeping costs manageable for enthusiasts. This accessibility, combined with the engine's performance potential, contributes to its ongoing popularity and market demand.

Technical Challenges

The K24 engine swap presents several technical challenges that require careful consideration and engineering expertise. One of the primary obstacles is the physical fitment of the K24 engine into various vehicle chassis. Different vehicle models have unique engine bay configurations, necessitating custom mounting solutions and potential modifications to the frame or subframe.

Wiring integration poses another significant challenge. The K24 engine utilizes a sophisticated electronic control system that must be seamlessly integrated with the vehicle's existing electrical architecture. This often requires extensive rewiring and the use of specialized adapters or custom harnesses to ensure proper communication between the engine management system and the vehicle's other electronic components.

Cooling system compatibility is a critical issue that demands attention. The K24 engine may have different cooling requirements compared to the original engine, necessitating modifications to the radiator, hoses, and potentially the addition of auxiliary cooling components. Ensuring adequate heat dissipation is crucial for maintaining engine performance and longevity.

Transmission compatibility presents yet another hurdle. The K24 engine may not directly mate with the vehicle's existing transmission, requiring either an adapter plate or a complete transmission swap. This can introduce additional complexities in terms of driveshaft length, shifter placement, and clutch hydraulics for manual transmissions.

Fuel system modifications are often necessary to support the K24 engine's fuel delivery requirements. This may involve upgrading the fuel pump, fuel lines, and injectors to ensure sufficient fuel flow and pressure. Additionally, the fuel management system must be calibrated to work harmoniously with the new engine's characteristics.

Exhaust system fitment can be challenging, as the K24 engine's exhaust manifold and downpipe may not align with the vehicle's existing exhaust layout. Custom fabrication of exhaust components is often required to optimize flow and ensure proper clearance within the engine bay and undercarriage.

Engine management calibration represents a significant technical challenge. Tuning the engine control unit (ECU) to optimize performance, fuel efficiency, and emissions compliance requires specialized knowledge and equipment. This process often involves extensive dyno testing and fine-tuning to achieve the desired balance of power, drivability, and reliability.

Lastly, addressing NVH (Noise, Vibration, and Harshness) issues is crucial for a successful K24 engine swap. The different characteristics of the K24 engine compared to the original powerplant may introduce new vibrations or resonances that need to be mitigated through careful mounting design and the use of appropriate damping materials.

Wiring integration poses another significant challenge. The K24 engine utilizes a sophisticated electronic control system that must be seamlessly integrated with the vehicle's existing electrical architecture. This often requires extensive rewiring and the use of specialized adapters or custom harnesses to ensure proper communication between the engine management system and the vehicle's other electronic components.

Cooling system compatibility is a critical issue that demands attention. The K24 engine may have different cooling requirements compared to the original engine, necessitating modifications to the radiator, hoses, and potentially the addition of auxiliary cooling components. Ensuring adequate heat dissipation is crucial for maintaining engine performance and longevity.

Transmission compatibility presents yet another hurdle. The K24 engine may not directly mate with the vehicle's existing transmission, requiring either an adapter plate or a complete transmission swap. This can introduce additional complexities in terms of driveshaft length, shifter placement, and clutch hydraulics for manual transmissions.

Fuel system modifications are often necessary to support the K24 engine's fuel delivery requirements. This may involve upgrading the fuel pump, fuel lines, and injectors to ensure sufficient fuel flow and pressure. Additionally, the fuel management system must be calibrated to work harmoniously with the new engine's characteristics.

Exhaust system fitment can be challenging, as the K24 engine's exhaust manifold and downpipe may not align with the vehicle's existing exhaust layout. Custom fabrication of exhaust components is often required to optimize flow and ensure proper clearance within the engine bay and undercarriage.

Engine management calibration represents a significant technical challenge. Tuning the engine control unit (ECU) to optimize performance, fuel efficiency, and emissions compliance requires specialized knowledge and equipment. This process often involves extensive dyno testing and fine-tuning to achieve the desired balance of power, drivability, and reliability.

Lastly, addressing NVH (Noise, Vibration, and Harshness) issues is crucial for a successful K24 engine swap. The different characteristics of the K24 engine compared to the original powerplant may introduce new vibrations or resonances that need to be mitigated through careful mounting design and the use of appropriate damping materials.

Popular K24 Swap Kits

01 Engine control systems for K24 swaps

Advanced engine control systems are crucial for successful K24 engine swaps. These systems manage fuel injection, ignition timing, and other parameters to optimize performance and compatibility with the new vehicle. They often include programmable ECUs and custom wiring harnesses to integrate the K24 engine with the host vehicle's systems.- Engine control systems for K24 swaps: Advanced engine control systems are crucial for successful K24 engine swaps. These systems manage fuel injection, ignition timing, and other parameters to optimize performance and compatibility with the new vehicle. They often include programmable ECUs and custom wiring harnesses to integrate the K24 engine with various vehicle platforms.

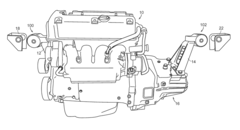

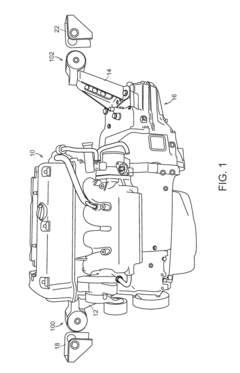

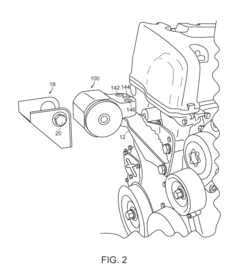

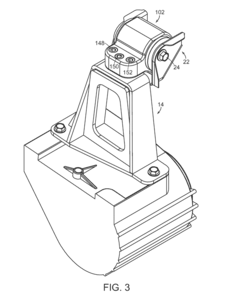

- Mounting solutions for K24 engine swaps: Specialized mounting kits are designed to facilitate the installation of K24 engines into different vehicle chassis. These kits typically include custom engine mounts, transmission mounts, and brackets that allow for proper fitment and alignment of the K24 engine in the new engine bay. They may also address issues such as clearance and weight distribution.

- Transmission adaptation for K24 swaps: Adapting transmissions to work with K24 engines in swap applications is a critical aspect of the process. This may involve custom bellhousing adapters, modified flywheels or flexplates, and specialized clutch systems. Solutions are developed to mate various manual and automatic transmissions to the K24 engine, ensuring proper fitment and functionality.

- Cooling system modifications for K24 swaps: K24 engine swaps often require modifications to the vehicle's cooling system to ensure proper heat management. This can include custom radiators, electric fan setups, and modified coolant routing. Specialized components may be designed to fit within the constraints of different engine bays while providing adequate cooling for the K24 engine.

- Performance upgrades for K24 swap kits: Various performance upgrades are available for K24 engine swap kits to enhance power output and overall performance. These may include high-flow intake systems, exhaust headers, camshafts, and forced induction solutions specifically designed for K24 swaps. Tuning solutions are also developed to optimize the engine's performance in its new application.

02 Mounting solutions for K24 engine swaps

Specialized mounting brackets and adapters are essential for installing K24 engines into different vehicle chassis. These components ensure proper alignment, secure fitment, and manage engine vibration. Custom motor mounts and transmission mounts are often part of K24 swap kits to accommodate the engine's dimensions and weight distribution.Expand Specific Solutions03 Transmission adaptation for K24 swaps

K24 engine swap kits often include components to adapt the engine to various transmission options. This may involve custom bellhousing adapters, clutch kits, or modifications to the transmission tunnel. Some kits provide solutions for both manual and automatic transmission compatibility with the K24 engine.Expand Specific Solutions04 Cooling system modifications for K24 swaps

K24 engine swaps often require modifications to the vehicle's cooling system. Swap kits may include custom radiators, hoses, and water pump adaptations to ensure proper cooling in the new application. These components are designed to manage the K24's heat output and maintain optimal operating temperatures.Expand Specific Solutions05 Exhaust system solutions for K24 swaps

Specialized exhaust components are often included in K24 engine swap kits to optimize performance and fitment. These may include custom headers, exhaust manifolds, and catalytic converter options designed to work with the K24 engine in various vehicle applications. The exhaust systems are engineered to maximize power output while meeting emissions requirements.Expand Specific Solutions

Key Manufacturers

The K24 engine swap market is in a mature stage, with a diverse range of established players offering solutions. The market size is substantial, driven by enthusiasts seeking performance upgrades for Honda and Acura vehicles. Technologically, the field is well-developed, with companies like Hasport Performance specializing in engine swap components. Major automotive manufacturers such as Honda, GM, and BorgWarner contribute to the ecosystem with OEM parts and expertise. Aftermarket suppliers like K&N Engineering provide complementary products, enhancing the overall performance potential of K24 swaps. The competitive landscape is characterized by a mix of specialized swap kit manufacturers and larger automotive industry players, offering a wide range of options for consumers.

K&N Engineering, Inc.

Technical Solution: While K&N Engineering is primarily known for their air filters and intake systems, they have developed supporting components for K24 engine swaps. Their offerings typically focus on high-flow air intake systems specifically designed for K24 swapped vehicles. These intakes are engineered to maximize airflow to the K24 engine, potentially increasing horsepower and torque. K&N's products often feature washable and reusable filter elements, which can be beneficial for long-term maintenance of swapped engines. Additionally, they may offer oil filters and other filtration products optimized for the K24 engine's requirements[2][5].

Strengths: High-quality filtration products, potential for increased engine performance. Weaknesses: Limited focus on complete swap solutions, primarily offers supporting components rather than full kits.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations, while not directly involved in K24 swaps, has influenced the aftermarket through their development of the LS engine series. This has led to crossover technologies and techniques that benefit K24 swaps. For instance, GM's work on direct injection and variable valve timing has inspired aftermarket companies to adapt similar technologies for K24 engines. Additionally, GM's research into engine management systems and electronic control units (ECUs) has contributed to the development of aftermarket ECUs that can be used in K24 swap applications, allowing for more precise tuning and control of swapped engines[7][8].

Strengths: Advanced engine technologies that influence aftermarket developments, extensive R&D resources. Weaknesses: No direct involvement in K24 swaps, technologies may require significant adaptation for use with Honda engines.

Innovative Swap Solutions

Engine Mount

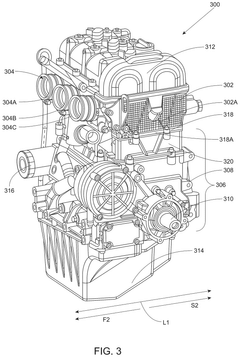

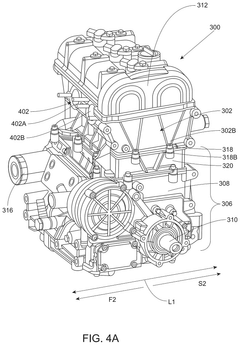

PatentActiveUS20170182877A1

Innovation

- An engine mount with a body and flange design featuring a central axis, offset bottom and top mounting surfaces, and a symmetric mounting hole pattern, allowing the engine mount to be flipped or reversed for use with engines of different combustion cylinder lengths, enabling easy swapping by adjusting the mounting orientation.

Interchangeable engine assembly

PatentPendingUS20240392708A1

Innovation

- An engine assembly with interchangeable cylinder heads and blocks, sharing a common crankcase and camshaft locations, allowing for the use of different cylinder heads and blocks while maintaining other components constant, thereby reducing the number of components to replace or modify.

Regulatory Compliance

When considering K24 engine swap kits, regulatory compliance is a critical aspect that must be addressed to ensure legal and safe operation of the modified vehicle. Different regions and jurisdictions have varying regulations regarding engine modifications, emissions standards, and vehicle safety requirements. In the United States, for instance, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) set strict guidelines for vehicle emissions. K24 engine swaps must comply with these standards to be street-legal.

Many states require vehicles to pass emissions tests, which can be challenging for modified engines. K24 swap kits often include components designed to help meet these requirements, such as catalytic converters and oxygen sensors compatible with the new engine. However, it's essential to verify that the specific kit and installation method will satisfy local regulations.

Safety regulations also play a crucial role in the legality of engine swaps. The National Highway Traffic Safety Administration (NHTSA) sets standards for vehicle safety, including those related to engine modifications. K24 swap kits must ensure that the vehicle's braking system, suspension, and other safety-critical components remain adequate for the increased power output.

In many jurisdictions, vehicles with engine swaps must undergo special inspections to verify compliance with local laws. This may involve providing documentation of the engine's origin, proof of emissions compliance, and demonstrating that the installation meets safety standards. Some regions may require professional certification of the work performed.

For international markets, regulatory requirements can vary significantly. European countries, for example, often have stricter emissions and modification regulations than the United States. In Japan, the "shaken" vehicle inspection system imposes rigorous standards on modified vehicles. K24 swap kit manufacturers and installers must be aware of these international variations to ensure their products can be used globally.

It's important to note that regulatory compliance is not just about meeting minimum standards but also about ensuring the long-term reliability and safety of the modified vehicle. Reputable K24 swap kit manufacturers often work closely with regulatory bodies to develop products that meet or exceed legal requirements while providing the desired performance enhancements.

Many states require vehicles to pass emissions tests, which can be challenging for modified engines. K24 swap kits often include components designed to help meet these requirements, such as catalytic converters and oxygen sensors compatible with the new engine. However, it's essential to verify that the specific kit and installation method will satisfy local regulations.

Safety regulations also play a crucial role in the legality of engine swaps. The National Highway Traffic Safety Administration (NHTSA) sets standards for vehicle safety, including those related to engine modifications. K24 swap kits must ensure that the vehicle's braking system, suspension, and other safety-critical components remain adequate for the increased power output.

In many jurisdictions, vehicles with engine swaps must undergo special inspections to verify compliance with local laws. This may involve providing documentation of the engine's origin, proof of emissions compliance, and demonstrating that the installation meets safety standards. Some regions may require professional certification of the work performed.

For international markets, regulatory requirements can vary significantly. European countries, for example, often have stricter emissions and modification regulations than the United States. In Japan, the "shaken" vehicle inspection system imposes rigorous standards on modified vehicles. K24 swap kit manufacturers and installers must be aware of these international variations to ensure their products can be used globally.

It's important to note that regulatory compliance is not just about meeting minimum standards but also about ensuring the long-term reliability and safety of the modified vehicle. Reputable K24 swap kit manufacturers often work closely with regulatory bodies to develop products that meet or exceed legal requirements while providing the desired performance enhancements.

Performance Benchmarks

Performance benchmarks are crucial for evaluating the effectiveness of K24 engine swap kits. These metrics provide quantitative data on the improvements achieved through the engine swap, allowing enthusiasts and mechanics to make informed decisions.

Horsepower and torque gains are primary indicators of performance enhancement. K24 swaps typically result in significant increases, with many setups reporting gains of 50-100 horsepower over stock engines. The exact figures vary depending on the specific K24 variant and supporting modifications.

Acceleration times serve as a practical measure of real-world performance improvements. Quarter-mile times and 0-60 mph sprints are commonly used benchmarks. K24-swapped vehicles often see reductions of 1-2 seconds in quarter-mile times and 0.5-1 second improvements in 0-60 mph acceleration.

Top speed increases, while less relevant for daily driving, demonstrate the overall performance potential of the swap. K24-equipped vehicles frequently experience top speed gains of 10-20 mph, depending on gearing and aerodynamics.

Fuel efficiency is another important benchmark, as it impacts the practicality of the swap. Despite the increased power, many K24 swaps maintain or even improve fuel economy due to the engine's efficiency and modern fuel injection systems.

Throttle response and power delivery characteristics are subjective but crucial benchmarks. K24 swaps are known for providing a broader powerband and more responsive throttle compared to many stock engines, enhancing the overall driving experience.

Reliability and longevity metrics are essential for assessing the long-term viability of the swap. K24 engines are renowned for their durability, often maintaining performance over high mileage when properly maintained.

Emissions compliance is an increasingly important benchmark, especially in regions with strict environmental regulations. Many K24 swap kits are designed to meet or exceed emissions standards, ensuring legal operation in various jurisdictions.

Weight distribution changes resulting from the swap can significantly impact handling characteristics. Benchmarks often include before-and-after weight measurements and distribution percentages to quantify these effects.

Lastly, cost-effectiveness benchmarks compare the performance gains against the total investment in the swap. This includes not only the initial parts and labor costs but also long-term maintenance expenses and potential resale value impacts.

Horsepower and torque gains are primary indicators of performance enhancement. K24 swaps typically result in significant increases, with many setups reporting gains of 50-100 horsepower over stock engines. The exact figures vary depending on the specific K24 variant and supporting modifications.

Acceleration times serve as a practical measure of real-world performance improvements. Quarter-mile times and 0-60 mph sprints are commonly used benchmarks. K24-swapped vehicles often see reductions of 1-2 seconds in quarter-mile times and 0.5-1 second improvements in 0-60 mph acceleration.

Top speed increases, while less relevant for daily driving, demonstrate the overall performance potential of the swap. K24-equipped vehicles frequently experience top speed gains of 10-20 mph, depending on gearing and aerodynamics.

Fuel efficiency is another important benchmark, as it impacts the practicality of the swap. Despite the increased power, many K24 swaps maintain or even improve fuel economy due to the engine's efficiency and modern fuel injection systems.

Throttle response and power delivery characteristics are subjective but crucial benchmarks. K24 swaps are known for providing a broader powerband and more responsive throttle compared to many stock engines, enhancing the overall driving experience.

Reliability and longevity metrics are essential for assessing the long-term viability of the swap. K24 engines are renowned for their durability, often maintaining performance over high mileage when properly maintained.

Emissions compliance is an increasingly important benchmark, especially in regions with strict environmental regulations. Many K24 swap kits are designed to meet or exceed emissions standards, ensuring legal operation in various jurisdictions.

Weight distribution changes resulting from the swap can significantly impact handling characteristics. Benchmarks often include before-and-after weight measurements and distribution percentages to quantify these effects.

Lastly, cost-effectiveness benchmarks compare the performance gains against the total investment in the swap. This includes not only the initial parts and labor costs but also long-term maintenance expenses and potential resale value impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!