K24 Engine Swap Strategy: Maximizing Vehicle Potential

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in 2001. Initially designed for the Honda Accord, this 2.4-liter inline-four engine has become a popular choice for engine swaps due to its robust design and impressive power output.

The K24's journey began with the K24A1 variant, which produced 160 horsepower and 161 lb-ft of torque. This initial offering set the stage for a series of improvements that would follow. Honda quickly refined the design, introducing the K24A2 in 2003, which boosted power output to 190 horsepower, marking a substantial increase in performance.

As the engine matured, Honda introduced the K24A3 and K24A4 variants, each tailored for specific vehicle applications. These iterations focused on optimizing fuel efficiency and emissions while maintaining respectable power outputs. The K24A8, introduced in 2006, represented a significant leap forward, producing up to 205 horsepower in certain applications.

The evolution of the K24 engine reached new heights with the introduction of the K24Z series. The K24Z7, found in the 2012-2015 Honda Civic Si, showcased Honda's commitment to continuous improvement. This variant incorporated advanced features such as a higher compression ratio, improved valve timing, and enhanced intake and exhaust systems, resulting in a power output of 201 horsepower and 170 lb-ft of torque.

Perhaps the most significant milestone in the K24's evolution came with the K24W, introduced in 2013. This variant incorporated direct injection technology, a first for the K-series engines. The K24W7, found in the 2013-2017 Honda Accord, produced an impressive 185 horsepower and 181 lb-ft of torque, while significantly improving fuel efficiency.

Throughout its evolution, the K24 engine has maintained its reputation for reliability and tunability. The engine's robust construction, including a cast aluminum block and forged steel crankshaft, has made it a favorite among enthusiasts for high-performance builds. The K24's ability to withstand high levels of boost and its compatibility with various aftermarket parts have contributed to its enduring popularity in the engine swap community.

The K24's evolution has not been limited to factory improvements alone. The aftermarket industry has played a crucial role in pushing the boundaries of the engine's capabilities. Turbocharging kits, high-flow cylinder heads, and advanced engine management systems have allowed enthusiasts to extract even more power from these engines, with some builds achieving over 1000 horsepower.

The K24's journey began with the K24A1 variant, which produced 160 horsepower and 161 lb-ft of torque. This initial offering set the stage for a series of improvements that would follow. Honda quickly refined the design, introducing the K24A2 in 2003, which boosted power output to 190 horsepower, marking a substantial increase in performance.

As the engine matured, Honda introduced the K24A3 and K24A4 variants, each tailored for specific vehicle applications. These iterations focused on optimizing fuel efficiency and emissions while maintaining respectable power outputs. The K24A8, introduced in 2006, represented a significant leap forward, producing up to 205 horsepower in certain applications.

The evolution of the K24 engine reached new heights with the introduction of the K24Z series. The K24Z7, found in the 2012-2015 Honda Civic Si, showcased Honda's commitment to continuous improvement. This variant incorporated advanced features such as a higher compression ratio, improved valve timing, and enhanced intake and exhaust systems, resulting in a power output of 201 horsepower and 170 lb-ft of torque.

Perhaps the most significant milestone in the K24's evolution came with the K24W, introduced in 2013. This variant incorporated direct injection technology, a first for the K-series engines. The K24W7, found in the 2013-2017 Honda Accord, produced an impressive 185 horsepower and 181 lb-ft of torque, while significantly improving fuel efficiency.

Throughout its evolution, the K24 engine has maintained its reputation for reliability and tunability. The engine's robust construction, including a cast aluminum block and forged steel crankshaft, has made it a favorite among enthusiasts for high-performance builds. The K24's ability to withstand high levels of boost and its compatibility with various aftermarket parts have contributed to its enduring popularity in the engine swap community.

The K24's evolution has not been limited to factory improvements alone. The aftermarket industry has played a crucial role in pushing the boundaries of the engine's capabilities. Turbocharging kits, high-flow cylinder heads, and advanced engine management systems have allowed enthusiasts to extract even more power from these engines, with some builds achieving over 1000 horsepower.

Market Demand Analysis

The market demand for K24 engine swaps has been steadily growing, driven by automotive enthusiasts seeking to maximize their vehicle's performance potential. This trend is particularly prominent in the aftermarket modification sector, where the K24 engine has gained a reputation for its reliability, power output, and versatility across various vehicle platforms.

The K24 engine, originally developed by Honda, has become a popular choice for engine swaps due to its robust design and impressive power-to-weight ratio. Its compatibility with a wide range of vehicles, from compact cars to larger sedans and even some light trucks, has significantly expanded its market appeal. This versatility has created a substantial demand not only among Honda and Acura owners but also among enthusiasts of other brands looking to upgrade their vehicles' performance.

The aftermarket industry has responded to this demand by developing a range of products specifically designed to facilitate K24 engine swaps. These include engine mounts, wiring harnesses, and custom ECU solutions, which have made the swap process more accessible to a broader range of consumers. As a result, the market for K24 swap-related products and services has experienced significant growth in recent years.

Performance tuning shops and specialized engine swap service providers have reported an increase in customer inquiries and projects related to K24 swaps. This surge in demand has led to the emergence of specialized businesses focusing exclusively on K24 engine swaps and related modifications, indicating a robust and growing market niche.

The rising popularity of motorsports events and track days has further fueled the demand for K24 swaps. Many enthusiasts are turning to this engine as a cost-effective way to boost their vehicle's performance for competitive racing or recreational track use. This trend has expanded the market beyond street-legal modifications to include dedicated track and race vehicles.

Environmental considerations have also played a role in shaping market demand. As older vehicles face increasing scrutiny for emissions, some owners are opting for K24 swaps as a way to modernize their vehicles while potentially improving fuel efficiency and reducing emissions compared to older, less efficient engines.

Looking ahead, market analysts predict continued growth in the K24 engine swap segment. Factors contributing to this outlook include the engine's proven reliability, the expanding ecosystem of aftermarket support, and the ongoing desire among automotive enthusiasts for cost-effective performance upgrades. As the supply of used K24 engines remains steady and aftermarket technology continues to evolve, the market is expected to remain vibrant and potentially expand into new vehicle applications and markets.

The K24 engine, originally developed by Honda, has become a popular choice for engine swaps due to its robust design and impressive power-to-weight ratio. Its compatibility with a wide range of vehicles, from compact cars to larger sedans and even some light trucks, has significantly expanded its market appeal. This versatility has created a substantial demand not only among Honda and Acura owners but also among enthusiasts of other brands looking to upgrade their vehicles' performance.

The aftermarket industry has responded to this demand by developing a range of products specifically designed to facilitate K24 engine swaps. These include engine mounts, wiring harnesses, and custom ECU solutions, which have made the swap process more accessible to a broader range of consumers. As a result, the market for K24 swap-related products and services has experienced significant growth in recent years.

Performance tuning shops and specialized engine swap service providers have reported an increase in customer inquiries and projects related to K24 swaps. This surge in demand has led to the emergence of specialized businesses focusing exclusively on K24 engine swaps and related modifications, indicating a robust and growing market niche.

The rising popularity of motorsports events and track days has further fueled the demand for K24 swaps. Many enthusiasts are turning to this engine as a cost-effective way to boost their vehicle's performance for competitive racing or recreational track use. This trend has expanded the market beyond street-legal modifications to include dedicated track and race vehicles.

Environmental considerations have also played a role in shaping market demand. As older vehicles face increasing scrutiny for emissions, some owners are opting for K24 swaps as a way to modernize their vehicles while potentially improving fuel efficiency and reducing emissions compared to older, less efficient engines.

Looking ahead, market analysts predict continued growth in the K24 engine swap segment. Factors contributing to this outlook include the engine's proven reliability, the expanding ecosystem of aftermarket support, and the ongoing desire among automotive enthusiasts for cost-effective performance upgrades. As the supply of used K24 engines remains steady and aftermarket technology continues to evolve, the market is expected to remain vibrant and potentially expand into new vehicle applications and markets.

Technical Challenges

The K24 engine swap presents several technical challenges that must be addressed to maximize vehicle potential. One of the primary obstacles is ensuring proper fitment within the engine bay of the target vehicle. The K24 engine, while compact, may require modifications to the engine mounts, transmission tunnel, and firewall to accommodate its dimensions and orientation.

Cooling system integration poses another significant challenge. The K24's higher output necessitates an upgraded radiator, oil cooler, and potentially additional cooling components to maintain optimal operating temperatures under increased stress. Designing an efficient cooling system that fits within the confines of the engine bay without compromising other components is crucial.

Electrical integration is a complex aspect of the K24 swap. The engine's electronic control unit (ECU) must be compatible with the vehicle's existing electrical architecture or replaced entirely. This often requires extensive rewiring and the use of aftermarket harnesses to ensure proper communication between the engine and vehicle systems.

Transmission compatibility is another hurdle to overcome. The K24 engine may not directly bolt up to the vehicle's existing transmission, necessitating either an adapter plate or a complete transmission swap. Selecting the appropriate transmission that can handle the K24's power output while maintaining drivability is essential.

Fuel system upgrades are typically required to support the K24's increased fuel demands. This may involve installing a higher-capacity fuel pump, larger fuel injectors, and potentially modifying the fuel lines and tank to ensure adequate fuel delivery under all operating conditions.

Exhaust system modifications present both fitment and performance challenges. Designing a custom exhaust manifold or header that efficiently evacuates exhaust gases while clearing other engine bay components is critical. The entire exhaust system may need to be redesigned to optimize flow and minimize restrictions.

Suspension and chassis reinforcement may be necessary to handle the increased power and weight distribution changes resulting from the K24 swap. This could involve upgrading suspension components, adding chassis bracing, and potentially modifying the subframe to ensure structural integrity and maintain proper handling characteristics.

Software tuning and calibration represent a significant technical challenge in optimizing the K24's performance in its new application. Developing a custom engine map that maximizes power output while ensuring reliability and drivability requires extensive dyno testing and fine-tuning.

Addressing these technical challenges requires a comprehensive approach, combining mechanical engineering, electrical expertise, and software development skills to successfully integrate the K24 engine and unlock its full potential within the target vehicle.

Cooling system integration poses another significant challenge. The K24's higher output necessitates an upgraded radiator, oil cooler, and potentially additional cooling components to maintain optimal operating temperatures under increased stress. Designing an efficient cooling system that fits within the confines of the engine bay without compromising other components is crucial.

Electrical integration is a complex aspect of the K24 swap. The engine's electronic control unit (ECU) must be compatible with the vehicle's existing electrical architecture or replaced entirely. This often requires extensive rewiring and the use of aftermarket harnesses to ensure proper communication between the engine and vehicle systems.

Transmission compatibility is another hurdle to overcome. The K24 engine may not directly bolt up to the vehicle's existing transmission, necessitating either an adapter plate or a complete transmission swap. Selecting the appropriate transmission that can handle the K24's power output while maintaining drivability is essential.

Fuel system upgrades are typically required to support the K24's increased fuel demands. This may involve installing a higher-capacity fuel pump, larger fuel injectors, and potentially modifying the fuel lines and tank to ensure adequate fuel delivery under all operating conditions.

Exhaust system modifications present both fitment and performance challenges. Designing a custom exhaust manifold or header that efficiently evacuates exhaust gases while clearing other engine bay components is critical. The entire exhaust system may need to be redesigned to optimize flow and minimize restrictions.

Suspension and chassis reinforcement may be necessary to handle the increased power and weight distribution changes resulting from the K24 swap. This could involve upgrading suspension components, adding chassis bracing, and potentially modifying the subframe to ensure structural integrity and maintain proper handling characteristics.

Software tuning and calibration represent a significant technical challenge in optimizing the K24's performance in its new application. Developing a custom engine map that maximizes power output while ensuring reliability and drivability requires extensive dyno testing and fine-tuning.

Addressing these technical challenges requires a comprehensive approach, combining mechanical engineering, electrical expertise, and software development skills to successfully integrate the K24 engine and unlock its full potential within the target vehicle.

Current Swap Solutions

01 Engine performance optimization

The K24 engine's potential can be enhanced through various optimization techniques. These may include improving fuel efficiency, increasing power output, and refining combustion processes. Advanced engine management systems and tuning methods can be employed to maximize the engine's capabilities in different vehicle applications.- Engine performance optimization: The K24 engine's potential can be enhanced through various optimization techniques. These may include improving fuel efficiency, increasing power output, and refining combustion processes. Advanced engine management systems and tuning methods can be employed to maximize the engine's capabilities in different vehicle applications.

- Vehicle integration and compatibility: Integrating the K24 engine into various vehicle platforms requires careful consideration of compatibility factors. This includes adapting the engine to different transmission systems, optimizing vehicle weight distribution, and ensuring proper cooling and exhaust configurations. The engine's versatility allows for its use in a range of vehicle types, from compact cars to larger SUVs.

- Emissions control and environmental impact: Developing strategies to reduce emissions and improve the environmental impact of K24 engine-equipped vehicles is crucial. This may involve implementing advanced catalytic converter technologies, optimizing fuel injection systems, and exploring hybrid or alternative fuel configurations to meet stringent emissions standards while maintaining performance.

- Diagnostic and monitoring systems: Implementing advanced diagnostic and monitoring systems can enhance the K24 engine's reliability and performance in vehicles. These systems may include real-time engine health monitoring, predictive maintenance algorithms, and integrated sensor networks to optimize engine operation and alert drivers to potential issues.

- Market potential and consumer trends: Analyzing market trends and consumer preferences is essential for maximizing the K24 engine's potential in various vehicle segments. This includes studying fuel efficiency demands, performance expectations, and emerging technologies that could impact the engine's competitiveness in the automotive market.

02 Vehicle integration and compatibility

Integrating the K24 engine into various vehicle platforms requires consideration of factors such as weight distribution, cooling systems, and transmission compatibility. Adapting the engine to different vehicle types can unlock its potential across a range of applications, from compact cars to larger vehicles.Expand Specific Solutions03 Emissions control and environmental impact

Developing strategies to reduce emissions and improve the environmental performance of K24 engine-equipped vehicles is crucial. This may involve implementing advanced catalytic converters, optimizing exhaust gas recirculation systems, and exploring alternative fuel compatibility to meet stringent emissions standards.Expand Specific Solutions04 Hybrid and electric integration

Exploring the potential of integrating the K24 engine with hybrid or electric powertrains can lead to innovative vehicle designs. This may include developing mild hybrid systems, plug-in hybrid configurations, or using the engine as a range extender in electric vehicles to combine efficiency with performance.Expand Specific Solutions05 Diagnostic and maintenance systems

Implementing advanced diagnostic and maintenance systems can help maximize the longevity and reliability of K24 engine-equipped vehicles. This may include developing predictive maintenance algorithms, real-time performance monitoring, and user-friendly interfaces for vehicle owners and technicians to ensure optimal engine performance throughout its lifecycle.Expand Specific Solutions

Key Industry Players

The K24 engine swap strategy market is in a growth phase, driven by increasing demand for performance upgrades in the automotive aftermarket. The market size is expanding as more enthusiasts seek to enhance their vehicles' potential. Technologically, the K24 swap is relatively mature, with established procedures and aftermarket support. Key players like Honda Motor Co., Ltd., the original manufacturer, and aftermarket specialists such as Ford Global Technologies LLC and GM Global Technology Operations LLC are actively involved in developing compatible parts and solutions. Companies like Robert Bosch GmbH and ZF Friedrichshafen AG contribute advanced components, while performance-oriented brands like Toyota Motor Corp. and Volkswagen AG offer competitive alternatives, shaping a diverse and innovative landscape for engine swap enthusiasts.

Ford Global Technologies LLC

Technical Solution: Ford's K24 engine swap strategy focuses on enhancing vehicle performance and efficiency. They have developed a comprehensive approach that includes custom engine mounts, wiring harness adaptations, and ECU remapping to seamlessly integrate the K24 engine into various Ford models. Ford's strategy also incorporates advanced cooling systems and exhaust modifications to optimize the K24's output. They have implemented a modular design philosophy, allowing for easier installation and maintenance across different vehicle platforms[1]. Additionally, Ford has developed proprietary software to fine-tune the engine's performance characteristics, ensuring optimal power delivery and fuel efficiency in various driving conditions[3].

Strengths: Extensive experience with engine swaps, wide range of compatible vehicles, and advanced ECU tuning capabilities. Weaknesses: Potential warranty issues for modified vehicles and higher initial costs compared to stock engines.

GM Global Technology Operations LLC

Technical Solution: GM's approach to K24 engine swaps involves a comprehensive package designed to maximize vehicle potential across their diverse lineup. They have developed a universal mounting system that allows for easy integration of the K24 engine into various GM platforms, reducing installation time and complexity[2]. GM's strategy also includes custom-designed intake and exhaust systems optimized for the K24's performance characteristics. They have implemented advanced engine management systems that can seamlessly communicate with existing GM vehicle electronics, ensuring proper integration of all systems[4]. Furthermore, GM has developed a series of performance upgrades specifically for K24-swapped vehicles, including turbocharging kits and strengthened internals, to push the engine's capabilities even further[5].

Strengths: Extensive R&D resources, wide range of compatible vehicles, and integrated performance upgrade options. Weaknesses: Potential for increased complexity in some older vehicle models and possible impact on resale value for heavily modified vehicles.

Core K24 Innovations

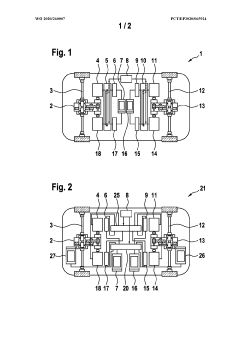

Vehicle and method for operating a vehicle

PatentWO2020260007A1

Innovation

- A vehicle configuration with at least two electrical energy storage devices, two electric motors, and two converters, connected via switching units that allow for variable assignment, enabling automated replacement of faulty components and optimization of energy use, with a control unit to manage component connections for maximum efficiency and availability.

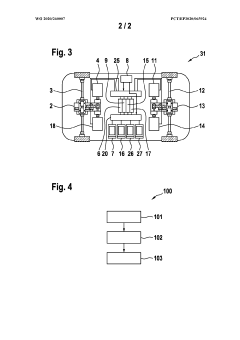

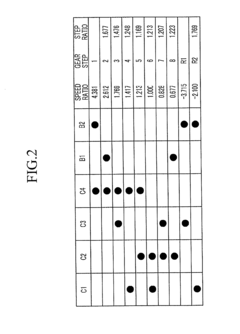

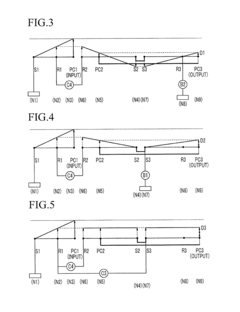

Powertrain of an automatic transmission

PatentActiveUS20130012351A1

Innovation

- A powertrain configuration that combines three simple planetary gear sets and six frictional elements to enable eight forward speeds and two reverse speeds, utilizing specific clutch and brake operations to achieve optimal speed ratios and improve power delivery performance.

Performance Benchmarks

Performance benchmarks are crucial in evaluating the effectiveness of a K24 engine swap strategy. These benchmarks provide quantifiable data to assess the improvements in vehicle performance and potential. When considering a K24 engine swap, several key performance metrics should be measured and compared to the original engine configuration.

Horsepower and torque are primary indicators of engine performance. The K24 engine, known for its robust power output, typically delivers a significant increase in both metrics compared to stock engines in many vehicles. Dyno testing before and after the swap can accurately measure these improvements, with gains often ranging from 30 to 50 horsepower or more, depending on the specific K24 variant and supporting modifications.

Acceleration times are another critical benchmark. The 0-60 mph time and quarter-mile performance are standard measurements that reflect real-world performance gains. A well-executed K24 swap can reduce 0-60 times by 1-2 seconds or more, while quarter-mile times may improve by similar margins. These improvements directly translate to enhanced driving dynamics and overall vehicle responsiveness.

Fuel efficiency, while often overlooked in performance upgrades, is an important consideration. The K24's efficiency can sometimes lead to improved fuel economy, especially when paired with proper tuning and gear ratios. Measuring miles per gallon (MPG) in various driving conditions before and after the swap provides valuable data on the engine's efficiency in real-world scenarios.

Top speed and high-speed stability are relevant benchmarks for vehicles intended for track use or high-performance applications. The K24's power characteristics often allow for higher top speeds and improved high-speed handling, which can be quantified through controlled testing on appropriate facilities.

Throttle response and power delivery smoothness are subjective metrics that can be assessed through driver feedback and data logging. Improvements in these areas contribute significantly to the overall driving experience and can be evaluated using specialized equipment to measure throttle position, manifold pressure, and engine speed over time.

Lastly, durability and reliability benchmarks are crucial for long-term satisfaction with the engine swap. While these metrics require extended testing periods, initial assessments can be made through stress testing and monitoring of key engine parameters such as oil pressure, coolant temperature, and emissions output under various operating conditions.

By establishing and comparing these performance benchmarks, enthusiasts and engineers can objectively evaluate the success of a K24 engine swap strategy and identify areas for further optimization to maximize the vehicle's potential.

Horsepower and torque are primary indicators of engine performance. The K24 engine, known for its robust power output, typically delivers a significant increase in both metrics compared to stock engines in many vehicles. Dyno testing before and after the swap can accurately measure these improvements, with gains often ranging from 30 to 50 horsepower or more, depending on the specific K24 variant and supporting modifications.

Acceleration times are another critical benchmark. The 0-60 mph time and quarter-mile performance are standard measurements that reflect real-world performance gains. A well-executed K24 swap can reduce 0-60 times by 1-2 seconds or more, while quarter-mile times may improve by similar margins. These improvements directly translate to enhanced driving dynamics and overall vehicle responsiveness.

Fuel efficiency, while often overlooked in performance upgrades, is an important consideration. The K24's efficiency can sometimes lead to improved fuel economy, especially when paired with proper tuning and gear ratios. Measuring miles per gallon (MPG) in various driving conditions before and after the swap provides valuable data on the engine's efficiency in real-world scenarios.

Top speed and high-speed stability are relevant benchmarks for vehicles intended for track use or high-performance applications. The K24's power characteristics often allow for higher top speeds and improved high-speed handling, which can be quantified through controlled testing on appropriate facilities.

Throttle response and power delivery smoothness are subjective metrics that can be assessed through driver feedback and data logging. Improvements in these areas contribute significantly to the overall driving experience and can be evaluated using specialized equipment to measure throttle position, manifold pressure, and engine speed over time.

Lastly, durability and reliability benchmarks are crucial for long-term satisfaction with the engine swap. While these metrics require extended testing periods, initial assessments can be made through stress testing and monitoring of key engine parameters such as oil pressure, coolant temperature, and emissions output under various operating conditions.

By establishing and comparing these performance benchmarks, enthusiasts and engineers can objectively evaluate the success of a K24 engine swap strategy and identify areas for further optimization to maximize the vehicle's potential.

Aftermarket Ecosystem

The aftermarket ecosystem surrounding K24 engine swaps has evolved into a robust and diverse network of manufacturers, suppliers, and service providers. This ecosystem plays a crucial role in facilitating and supporting engine swap projects, offering a wide range of components, tools, and expertise to enthusiasts and professionals alike.

At the core of this ecosystem are specialized manufacturers who produce engine swap-specific components. These include custom engine mounts, wiring harnesses, and transmission adapters designed to seamlessly integrate the K24 engine into various vehicle platforms. Companies like Hasport, Innovative Mounts, and K-Tuned have established themselves as leaders in this niche, continuously developing and refining their product offerings to meet the demands of the K24 swap community.

The aftermarket parts supply chain extends beyond swap-specific components to include performance upgrades tailored for K24 engines. This encompasses a vast array of products such as intake systems, exhaust manifolds, turbocharger kits, and engine management systems. Manufacturers like Skunk2, AEM, and Hondata have developed extensive product lines catering to K24-swapped vehicles, allowing enthusiasts to further enhance the performance potential of their swapped engines.

Supporting the hardware side of the ecosystem is a network of specialized software and tuning services. As K24 swaps often involve integrating modern engines into older vehicles, custom engine management solutions are crucial. Companies like Hondata and KTuner provide both hardware interfaces and software solutions that allow for precise tuning of K24 engines in various applications, ensuring optimal performance and drivability.

The installation and service sector of the aftermarket ecosystem has also grown significantly. Specialized shops and mechanics have emerged, offering expertise in K24 swaps across a wide range of vehicle makes and models. These professionals not only perform the swaps but also provide valuable knowledge and troubleshooting services to the community.

Online communities and forums play a vital role in the K24 swap ecosystem, serving as platforms for knowledge sharing, problem-solving, and product reviews. Websites like K20A.org and Honda-Tech.com have become hubs for enthusiasts and professionals to exchange information, discuss challenges, and showcase their projects.

The aftermarket ecosystem's growth has been further fueled by motorsports and competitive events. K24-swapped vehicles have found success in various racing disciplines, from time attack to endurance racing, driving demand for specialized components and tuning solutions.

As the K24 swap trend continues to gain popularity, the aftermarket ecosystem is likely to expand further, with new players entering the market and existing companies diversifying their offerings. This dynamic environment ensures that enthusiasts have access to an ever-growing range of options to maximize the potential of their K24-swapped vehicles.

At the core of this ecosystem are specialized manufacturers who produce engine swap-specific components. These include custom engine mounts, wiring harnesses, and transmission adapters designed to seamlessly integrate the K24 engine into various vehicle platforms. Companies like Hasport, Innovative Mounts, and K-Tuned have established themselves as leaders in this niche, continuously developing and refining their product offerings to meet the demands of the K24 swap community.

The aftermarket parts supply chain extends beyond swap-specific components to include performance upgrades tailored for K24 engines. This encompasses a vast array of products such as intake systems, exhaust manifolds, turbocharger kits, and engine management systems. Manufacturers like Skunk2, AEM, and Hondata have developed extensive product lines catering to K24-swapped vehicles, allowing enthusiasts to further enhance the performance potential of their swapped engines.

Supporting the hardware side of the ecosystem is a network of specialized software and tuning services. As K24 swaps often involve integrating modern engines into older vehicles, custom engine management solutions are crucial. Companies like Hondata and KTuner provide both hardware interfaces and software solutions that allow for precise tuning of K24 engines in various applications, ensuring optimal performance and drivability.

The installation and service sector of the aftermarket ecosystem has also grown significantly. Specialized shops and mechanics have emerged, offering expertise in K24 swaps across a wide range of vehicle makes and models. These professionals not only perform the swaps but also provide valuable knowledge and troubleshooting services to the community.

Online communities and forums play a vital role in the K24 swap ecosystem, serving as platforms for knowledge sharing, problem-solving, and product reviews. Websites like K20A.org and Honda-Tech.com have become hubs for enthusiasts and professionals to exchange information, discuss challenges, and showcase their projects.

The aftermarket ecosystem's growth has been further fueled by motorsports and competitive events. K24-swapped vehicles have found success in various racing disciplines, from time attack to endurance racing, driving demand for specialized components and tuning solutions.

As the K24 swap trend continues to gain popularity, the aftermarket ecosystem is likely to expand further, with new players entering the market and existing companies diversifying their offerings. This dynamic environment ensures that enthusiasts have access to an ever-growing range of options to maximize the potential of their K24-swapped vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!