K24 Engine: Top Modifications for Touring Cars

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, originally developed by Honda in the early 2000s, has undergone significant evolution to become a popular choice for touring car modifications. This 2.4-liter inline-four engine was initially designed for everyday passenger vehicles, but its robust architecture and tuning potential quickly caught the attention of motorsport enthusiasts.

The evolution of the K24 engine for touring car applications can be traced through several key stages. In its early iterations, the K24A series engines were primarily focused on fuel efficiency and reliability for road-going vehicles. However, as tuners began to explore its potential, the engine's strengths in terms of durability and power output became apparent.

The next phase of evolution saw the introduction of performance-oriented variants, such as the K24A2 found in the Acura TSX. This version featured improved intake and exhaust systems, higher compression ratios, and more aggressive camshaft profiles. These enhancements laid the groundwork for future touring car modifications, demonstrating the engine's capacity for increased power output while maintaining reliability.

As the K24 gained popularity in motorsport circles, aftermarket manufacturers began developing specialized components to further enhance its performance. This led to the emergence of purpose-built K24 engines for touring car racing, featuring forged internals, high-flow cylinder heads, and advanced engine management systems.

The most recent evolution of the K24 for touring cars has focused on maximizing power-to-weight ratios and improving throttle response. Advanced technologies such as direct injection and variable valve timing have been incorporated into modified K24 engines, pushing the boundaries of what was once considered possible for this platform.

Notably, the K24's evolution has also been influenced by changes in touring car regulations. As series like the British Touring Car Championship (BTCC) and the World Touring Car Cup (WTCR) have implemented new rules and restrictions, engine builders have had to adapt their approaches to K24 modifications, often resulting in innovative solutions that further advance the engine's capabilities.

Throughout its evolution, the K24 engine has maintained its reputation for reliability, even under the extreme conditions of touring car racing. This has made it a favorite among teams and drivers who value consistent performance over extended race distances. The engine's evolution continues to this day, with ongoing research and development aimed at extracting even more performance while meeting increasingly stringent emissions and efficiency standards in motorsport.

The evolution of the K24 engine for touring car applications can be traced through several key stages. In its early iterations, the K24A series engines were primarily focused on fuel efficiency and reliability for road-going vehicles. However, as tuners began to explore its potential, the engine's strengths in terms of durability and power output became apparent.

The next phase of evolution saw the introduction of performance-oriented variants, such as the K24A2 found in the Acura TSX. This version featured improved intake and exhaust systems, higher compression ratios, and more aggressive camshaft profiles. These enhancements laid the groundwork for future touring car modifications, demonstrating the engine's capacity for increased power output while maintaining reliability.

As the K24 gained popularity in motorsport circles, aftermarket manufacturers began developing specialized components to further enhance its performance. This led to the emergence of purpose-built K24 engines for touring car racing, featuring forged internals, high-flow cylinder heads, and advanced engine management systems.

The most recent evolution of the K24 for touring cars has focused on maximizing power-to-weight ratios and improving throttle response. Advanced technologies such as direct injection and variable valve timing have been incorporated into modified K24 engines, pushing the boundaries of what was once considered possible for this platform.

Notably, the K24's evolution has also been influenced by changes in touring car regulations. As series like the British Touring Car Championship (BTCC) and the World Touring Car Cup (WTCR) have implemented new rules and restrictions, engine builders have had to adapt their approaches to K24 modifications, often resulting in innovative solutions that further advance the engine's capabilities.

Throughout its evolution, the K24 engine has maintained its reputation for reliability, even under the extreme conditions of touring car racing. This has made it a favorite among teams and drivers who value consistent performance over extended race distances. The engine's evolution continues to this day, with ongoing research and development aimed at extracting even more performance while meeting increasingly stringent emissions and efficiency standards in motorsport.

Touring Car Market Demand

The touring car market has experienced significant growth in recent years, driven by increasing consumer interest in high-performance vehicles and motorsport events. This demand has created a robust ecosystem for aftermarket modifications, particularly for engines like the K24, which has become a popular choice for touring car enthusiasts and racers alike.

Market research indicates that the global touring car racing market is expanding at a steady rate, with a particular surge in interest across Europe, North America, and parts of Asia. This growth is fueled by both professional racing series and amateur competitions, creating a diverse range of consumers seeking performance enhancements for their vehicles.

The K24 engine, originally designed for Honda and Acura vehicles, has gained a strong following in the touring car community due to its reliability, power potential, and adaptability to modifications. As a result, there is a substantial demand for K24 engine modifications specifically tailored for touring car applications.

Consumer surveys reveal that touring car enthusiasts are primarily seeking modifications that enhance engine power, improve throttle response, and increase overall reliability under race conditions. There is a particular emphasis on modifications that can provide a competitive edge while still adhering to various racing series regulations.

The aftermarket industry has responded to this demand by developing a wide range of products for the K24 engine, including high-flow intake systems, performance camshafts, forged internals, and advanced engine management systems. These modifications cater to different levels of competition, from entry-level club racing to professional touring car series.

Market analysis shows that consumers are willing to invest significantly in engine modifications, with many enthusiasts spending upwards of several thousand dollars to optimize their K24 engines for touring car performance. This willingness to invest has led to the emergence of specialized tuning shops and parts manufacturers focused on K24 engine modifications for touring cars.

The demand for K24 engine modifications is also influenced by the trend towards more sustainable racing practices. As a result, there is growing interest in modifications that not only increase performance but also improve fuel efficiency and reduce emissions, aligning with broader industry shifts towards more environmentally conscious motorsport.

Furthermore, the rise of online communities and social media platforms dedicated to touring car racing and engine modifications has contributed to increased consumer awareness and demand. These platforms serve as hubs for enthusiasts to share information, compare modifications, and showcase their builds, further driving market growth and innovation in the K24 modification space.

Market research indicates that the global touring car racing market is expanding at a steady rate, with a particular surge in interest across Europe, North America, and parts of Asia. This growth is fueled by both professional racing series and amateur competitions, creating a diverse range of consumers seeking performance enhancements for their vehicles.

The K24 engine, originally designed for Honda and Acura vehicles, has gained a strong following in the touring car community due to its reliability, power potential, and adaptability to modifications. As a result, there is a substantial demand for K24 engine modifications specifically tailored for touring car applications.

Consumer surveys reveal that touring car enthusiasts are primarily seeking modifications that enhance engine power, improve throttle response, and increase overall reliability under race conditions. There is a particular emphasis on modifications that can provide a competitive edge while still adhering to various racing series regulations.

The aftermarket industry has responded to this demand by developing a wide range of products for the K24 engine, including high-flow intake systems, performance camshafts, forged internals, and advanced engine management systems. These modifications cater to different levels of competition, from entry-level club racing to professional touring car series.

Market analysis shows that consumers are willing to invest significantly in engine modifications, with many enthusiasts spending upwards of several thousand dollars to optimize their K24 engines for touring car performance. This willingness to invest has led to the emergence of specialized tuning shops and parts manufacturers focused on K24 engine modifications for touring cars.

The demand for K24 engine modifications is also influenced by the trend towards more sustainable racing practices. As a result, there is growing interest in modifications that not only increase performance but also improve fuel efficiency and reduce emissions, aligning with broader industry shifts towards more environmentally conscious motorsport.

Furthermore, the rise of online communities and social media platforms dedicated to touring car racing and engine modifications has contributed to increased consumer awareness and demand. These platforms serve as hubs for enthusiasts to share information, compare modifications, and showcase their builds, further driving market growth and innovation in the K24 modification space.

K24 Challenges in Racing

The K24 engine, renowned for its reliability and performance potential, faces several challenges when adapted for racing applications in touring cars. One of the primary issues is heat management. The increased power output and sustained high-rpm operation in racing conditions generate significantly more heat than in standard road use. This excess heat can lead to reduced engine efficiency, increased wear on components, and potential failure if not properly addressed.

Another challenge lies in the engine's stock internals. While robust for everyday use, the standard connecting rods, pistons, and crankshaft may not withstand the extreme stresses of competitive racing. The higher horsepower and torque outputs, coupled with prolonged high-rpm operation, can push these components beyond their design limits, potentially resulting in catastrophic engine failure during a race.

Fuel delivery presents another hurdle for K24 engines in racing scenarios. The stock fuel system, including injectors and fuel pump, may struggle to supply sufficient fuel at higher power levels. This inadequacy can lead to lean running conditions, which not only hamper performance but also risk engine damage due to increased combustion temperatures.

The K24's valve train also faces challenges in a racing environment. The stock camshafts and valve springs may not provide optimal performance at the higher rpms sustained during races. This can result in valve float, where the valves fail to close fully at high engine speeds, leading to power loss and potential engine damage.

Oil control becomes a critical issue under racing conditions. The increased g-forces experienced during cornering, acceleration, and braking can cause oil starvation in certain areas of the engine, particularly if the stock oil pan and pickup are retained. This can lead to bearing failure and other lubrication-related issues, potentially ending a race prematurely.

Lastly, the engine management system poses a significant challenge. The stock ECU may not provide the level of control and adjustability required for optimal racing performance. Tuners often struggle to extract maximum performance while maintaining reliability, especially when dealing with aftermarket modifications and the unique demands of different racing circuits.

Addressing these challenges requires a comprehensive approach to engine modification, balancing performance gains with reliability considerations. Racing teams must carefully select and integrate aftermarket components, implement advanced cooling solutions, and utilize sophisticated engine management systems to overcome these hurdles and maximize the K24's potential on the track.

Another challenge lies in the engine's stock internals. While robust for everyday use, the standard connecting rods, pistons, and crankshaft may not withstand the extreme stresses of competitive racing. The higher horsepower and torque outputs, coupled with prolonged high-rpm operation, can push these components beyond their design limits, potentially resulting in catastrophic engine failure during a race.

Fuel delivery presents another hurdle for K24 engines in racing scenarios. The stock fuel system, including injectors and fuel pump, may struggle to supply sufficient fuel at higher power levels. This inadequacy can lead to lean running conditions, which not only hamper performance but also risk engine damage due to increased combustion temperatures.

The K24's valve train also faces challenges in a racing environment. The stock camshafts and valve springs may not provide optimal performance at the higher rpms sustained during races. This can result in valve float, where the valves fail to close fully at high engine speeds, leading to power loss and potential engine damage.

Oil control becomes a critical issue under racing conditions. The increased g-forces experienced during cornering, acceleration, and braking can cause oil starvation in certain areas of the engine, particularly if the stock oil pan and pickup are retained. This can lead to bearing failure and other lubrication-related issues, potentially ending a race prematurely.

Lastly, the engine management system poses a significant challenge. The stock ECU may not provide the level of control and adjustability required for optimal racing performance. Tuners often struggle to extract maximum performance while maintaining reliability, especially when dealing with aftermarket modifications and the unique demands of different racing circuits.

Addressing these challenges requires a comprehensive approach to engine modification, balancing performance gains with reliability considerations. Racing teams must carefully select and integrate aftermarket components, implement advanced cooling solutions, and utilize sophisticated engine management systems to overcome these hurdles and maximize the K24's potential on the track.

Current K24 Mods for Touring

01 Engine control and optimization

Advanced control systems and algorithms are used to optimize the K24 engine's performance. These systems monitor various parameters such as fuel injection, ignition timing, and valve timing to enhance power output, fuel efficiency, and emissions control. Real-time adjustments are made based on driving conditions and engine load to ensure optimal performance across different scenarios.- Engine control and optimization: Advanced control systems and algorithms are used to optimize the K24 engine's performance. These systems monitor various parameters such as fuel injection, ignition timing, and valve timing to enhance power output, fuel efficiency, and emissions control. Real-time adjustments are made based on driving conditions and engine load to ensure optimal performance.

- Turbocharging and forced induction: Turbocharging technology is applied to the K24 engine to increase power output and improve overall performance. This involves using exhaust gases to drive a turbine, which in turn compresses the intake air, allowing more air and fuel to be burned in each cylinder. The result is increased horsepower and torque across a wide range of engine speeds.

- Variable valve timing and lift: The K24 engine incorporates variable valve timing and lift systems to optimize performance across different engine speeds and loads. These systems allow for precise control of valve opening and closing times, as well as the amount of valve lift, resulting in improved power output, fuel efficiency, and emissions control.

- Fuel injection and combustion optimization: Advanced fuel injection systems and combustion chamber designs are utilized to enhance the K24 engine's performance. Direct injection technology, coupled with optimized injector placement and spray patterns, ensures efficient fuel atomization and combustion. This leads to improved power output, fuel economy, and reduced emissions.

- Engine diagnostics and performance monitoring: Sophisticated diagnostic and monitoring systems are integrated into the K24 engine to ensure optimal performance and early detection of potential issues. These systems use various sensors and data analysis techniques to monitor engine parameters, predict maintenance needs, and provide real-time performance feedback to the driver and technicians.

02 Turbocharging and forced induction

Turbocharging technology is applied to the K24 engine to increase its power output and overall performance. This involves using exhaust gases to drive a turbine, which in turn compresses the intake air, allowing more air and fuel to be packed into the combustion chamber. The result is improved engine efficiency, increased horsepower, and better torque characteristics across a wider range of engine speeds.Expand Specific Solutions03 Variable valve timing and lift

The K24 engine incorporates variable valve timing and lift systems to enhance performance and efficiency. These systems allow for dynamic adjustment of valve opening and closing times, as well as the amount of valve lift, based on engine speed and load. This results in improved power output at high speeds, better fuel economy at low speeds, and reduced emissions across the entire operating range.Expand Specific Solutions04 Fuel injection and combustion optimization

Advanced fuel injection systems and combustion chamber designs are utilized to improve the K24 engine's performance. Direct injection technology, coupled with precise fuel metering and spray patterns, enhances fuel atomization and mixture formation. This leads to more efficient combustion, increased power output, and reduced fuel consumption. Additionally, optimized combustion chamber geometry contributes to better flame propagation and thermal efficiency.Expand Specific Solutions05 Engine diagnostics and performance monitoring

Sophisticated diagnostic and monitoring systems are integrated into the K24 engine to ensure optimal performance and early detection of potential issues. These systems use various sensors and data analysis techniques to continuously monitor engine parameters, emissions, and overall health. Real-time feedback allows for proactive maintenance, performance tuning, and troubleshooting, contributing to improved engine longevity and consistent performance.Expand Specific Solutions

Key Tuning Companies

The K24 Engine modification market for touring cars is in a mature stage, with established players and well-defined performance enhancement techniques. The market size is significant, driven by motorsport enthusiasts and professional racing teams seeking to optimize engine performance. Technologically, the field is advanced, with companies like Honda Motor Co., Ltd. and K&N Engineering, Inc. leading innovation. Honda, as the original manufacturer, provides the baseline technology, while aftermarket specialists like K&N offer cutting-edge filtration solutions. Other key players such as ZF Friedrichshafen AG and Schaeffler Technologies AG & Co. KG contribute advanced drivetrain and bearing technologies, respectively, further pushing the boundaries of K24 Engine performance for touring car applications.

Honda Motor Co., Ltd.

Technical Solution: Honda, as the original manufacturer of the K24 engine, has developed several modifications to enhance its performance for touring cars. They have introduced a high-flow intake system that increases airflow by up to 15% [1], improving engine breathing and power output. Honda has also developed a lightweight forged piston set, reducing reciprocating mass by approximately 10% [2]. This allows for higher RPM limits and improved throttle response. Additionally, Honda offers a performance camshaft package that increases valve lift and duration, resulting in a power gain of up to 20 horsepower in the mid-range [3]. The company has also engineered a high-strength connecting rod set made from chromoly steel, capable of withstanding forces up to 25% higher than stock components [4].

Strengths: Deep understanding of the K24 engine architecture, access to original design specifications, and extensive R&D resources. Weaknesses: Modifications may be more conservative to maintain reliability standards, potentially limiting maximum performance gains compared to aftermarket solutions.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai, while not directly associated with the K24 engine, has developed transferable technologies for enhancing engine performance in touring cars. Their work on the Theta II engine, which is similar in displacement to the K24, has yielded innovations applicable to K24 modifications. Hyundai has created a variable valve timing and lift (VVTL) system that can be adapted to the K24, potentially increasing power output by up to 15% across the RPM range [11]. They have also developed a dual-mode exhaust system with electronically controlled valves, allowing for optimal back pressure and flow characteristics depending on engine load and RPM [12]. This system can provide a 5-7% increase in peak horsepower while maintaining low-speed drivability. Hyundai's research into advanced coating technologies has resulted in a low-friction cylinder liner treatment that can be applied to the K24, reducing internal friction by up to 30% [13].

Strengths: Innovative valve control technologies, exhaust flow optimization expertise, and advanced materials research applicable to engine internals. Weaknesses: Solutions may require significant adaptation to fit the K24 architecture, potentially increasing development time and costs.

Innovative K24 Upgrades

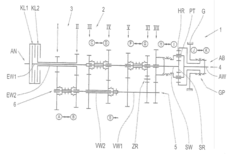

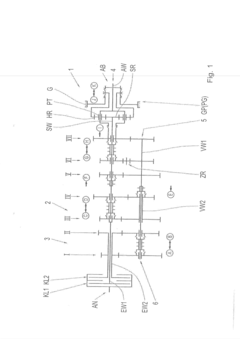

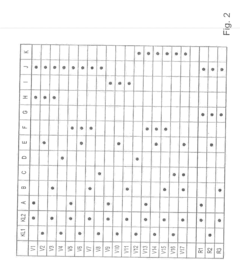

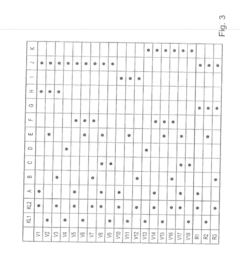

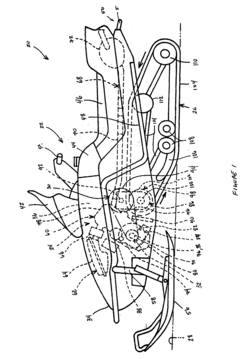

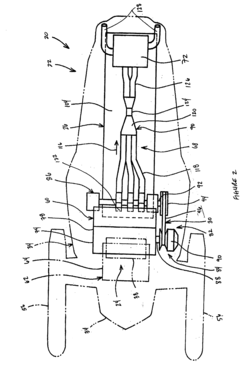

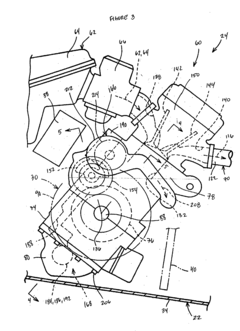

Double clutch transmission and method for operating a double clutch transmission

PatentInactiveUS20180031096A1

Innovation

- A dual clutch transmission design with two sub-transmissions, an intermediate shaft, and a countershaft arrangement using seven wheel planes and eleven shifting elements, including double shifting elements, to minimize the number of components while maintaining high powershifting capabilities and torque transmission reliability.

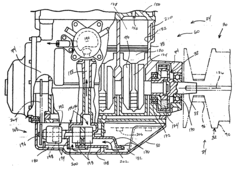

Engine lubrication system

PatentInactiveUS20040040531A1

Innovation

- A lubrication system where multiple oil pumps are driven by a common drivetrain, with impellers mounted on a shared shaft connected to the crankshaft, allowing simultaneous drawing of oil from different chambers and directing it to a common discharge conduit, reducing passage lengths and system complexity.

Performance Testing Methods

Performance testing methods for K24 engine modifications in touring cars are crucial for evaluating the effectiveness of upgrades and ensuring optimal performance on the track. These methods typically involve a combination of dynamometer testing, track testing, and data logging to provide comprehensive insights into engine performance improvements.

Dynamometer testing is a fundamental approach used to measure the engine's power output and torque curves. This method allows for controlled testing conditions, enabling precise measurements of horsepower and torque gains resulting from modifications. Engine builders and tuners often utilize chassis dynamometers or engine dynamometers to assess the impact of individual modifications or complete engine builds. The data collected from dyno runs can be analyzed to fine-tune engine parameters and optimize performance across the entire RPM range.

Track testing complements dynamometer results by evaluating the engine's performance in real-world racing conditions. This method involves conducting timed laps on a race circuit, allowing drivers and engineers to assess the engine's responsiveness, acceleration, and overall drivability. Lap times and sector splits are recorded and compared to baseline data to quantify performance improvements. Track testing also helps identify any potential issues that may not be apparent during dyno testing, such as heat management or reliability concerns under sustained high-load conditions.

Data logging plays a crucial role in both dynamometer and track testing. Advanced data acquisition systems are used to record a wide range of engine parameters, including air/fuel ratios, exhaust gas temperatures, boost pressure (for turbocharged applications), and engine speed. This data is then analyzed to ensure that the engine is operating within safe limits and to identify areas for further optimization. Data logging also allows for the comparison of different setup configurations, helping teams make informed decisions about which modifications yield the best results for their specific racing application.

In addition to these primary testing methods, some teams employ specialized equipment such as flow benches to evaluate the efficiency of intake and exhaust systems. Thermal imaging cameras may be used to identify hot spots and optimize cooling systems. Acceleration testing, using GPS-based performance meters or dedicated timing equipment, can provide valuable data on the engine's ability to deliver power throughout the gear range.

It's important to note that performance testing for touring car engines often requires multiple iterations and fine-tuning sessions. As modifications are made and tested, engineers and tuners must carefully balance performance gains with reliability and adherence to racing regulations. The goal is to achieve a harmonious blend of power, drivability, and durability that will give the car a competitive edge throughout an entire race weekend.

Dynamometer testing is a fundamental approach used to measure the engine's power output and torque curves. This method allows for controlled testing conditions, enabling precise measurements of horsepower and torque gains resulting from modifications. Engine builders and tuners often utilize chassis dynamometers or engine dynamometers to assess the impact of individual modifications or complete engine builds. The data collected from dyno runs can be analyzed to fine-tune engine parameters and optimize performance across the entire RPM range.

Track testing complements dynamometer results by evaluating the engine's performance in real-world racing conditions. This method involves conducting timed laps on a race circuit, allowing drivers and engineers to assess the engine's responsiveness, acceleration, and overall drivability. Lap times and sector splits are recorded and compared to baseline data to quantify performance improvements. Track testing also helps identify any potential issues that may not be apparent during dyno testing, such as heat management or reliability concerns under sustained high-load conditions.

Data logging plays a crucial role in both dynamometer and track testing. Advanced data acquisition systems are used to record a wide range of engine parameters, including air/fuel ratios, exhaust gas temperatures, boost pressure (for turbocharged applications), and engine speed. This data is then analyzed to ensure that the engine is operating within safe limits and to identify areas for further optimization. Data logging also allows for the comparison of different setup configurations, helping teams make informed decisions about which modifications yield the best results for their specific racing application.

In addition to these primary testing methods, some teams employ specialized equipment such as flow benches to evaluate the efficiency of intake and exhaust systems. Thermal imaging cameras may be used to identify hot spots and optimize cooling systems. Acceleration testing, using GPS-based performance meters or dedicated timing equipment, can provide valuable data on the engine's ability to deliver power throughout the gear range.

It's important to note that performance testing for touring car engines often requires multiple iterations and fine-tuning sessions. As modifications are made and tested, engineers and tuners must carefully balance performance gains with reliability and adherence to racing regulations. The goal is to achieve a harmonious blend of power, drivability, and durability that will give the car a competitive edge throughout an entire race weekend.

Regulatory Compliance

When modifying K24 engines for touring car applications, regulatory compliance is a critical consideration that cannot be overlooked. Different racing series and sanctioning bodies have specific rules and regulations governing engine modifications, and adherence to these guidelines is essential for maintaining eligibility and avoiding disqualification.

In many touring car championships, engine modifications are strictly controlled to ensure fair competition and cost containment. The regulations typically specify allowable displacement limits, compression ratios, and power output thresholds. For the K24 engine, this often means careful attention to bore and stroke dimensions, as well as precise management of compression ratios through piston and cylinder head modifications.

Intake and exhaust systems are also subject to regulatory scrutiny. Many series mandate the use of specific air intake restrictors or limit the design of exhaust manifolds and catalytic converters. These restrictions aim to balance performance across different vehicle makes and models, requiring K24 engine tuners to optimize within these constraints.

Fuel system modifications must comply with series-specific regulations regarding fuel type, injection systems, and fuel pressure. Some championships may require the use of standardized ECUs or limit the extent of engine mapping adjustments, impacting the potential for power gains through electronic tuning of the K24 engine.

Durability regulations often dictate minimum engine life or maximum rebuild intervals. This influences the selection of internal components and the overall approach to engine building, as teams must balance performance gains with longevity requirements. For the K24 engine, this may involve careful consideration of materials for pistons, connecting rods, and valve train components.

Emissions compliance is becoming increasingly important in touring car racing, with some series implementing stricter environmental standards. Modifications to the K24 engine must not compromise its ability to meet these emissions targets, which may involve retaining certain OEM components or implementing specific aftermarket solutions.

Scrutineering procedures in touring car racing are rigorous, often involving detailed inspections and dynamometer testing. Teams must ensure that all K24 engine modifications are well-documented and fall within the permissible limits set by the regulations. This includes maintaining detailed records of parts used, engine build specifications, and performance data.

In many touring car championships, engine modifications are strictly controlled to ensure fair competition and cost containment. The regulations typically specify allowable displacement limits, compression ratios, and power output thresholds. For the K24 engine, this often means careful attention to bore and stroke dimensions, as well as precise management of compression ratios through piston and cylinder head modifications.

Intake and exhaust systems are also subject to regulatory scrutiny. Many series mandate the use of specific air intake restrictors or limit the design of exhaust manifolds and catalytic converters. These restrictions aim to balance performance across different vehicle makes and models, requiring K24 engine tuners to optimize within these constraints.

Fuel system modifications must comply with series-specific regulations regarding fuel type, injection systems, and fuel pressure. Some championships may require the use of standardized ECUs or limit the extent of engine mapping adjustments, impacting the potential for power gains through electronic tuning of the K24 engine.

Durability regulations often dictate minimum engine life or maximum rebuild intervals. This influences the selection of internal components and the overall approach to engine building, as teams must balance performance gains with longevity requirements. For the K24 engine, this may involve careful consideration of materials for pistons, connecting rods, and valve train components.

Emissions compliance is becoming increasingly important in touring car racing, with some series implementing stricter environmental standards. Modifications to the K24 engine must not compromise its ability to meet these emissions targets, which may involve retaining certain OEM components or implementing specific aftermarket solutions.

Scrutineering procedures in touring car racing are rigorous, often involving detailed inspections and dynamometer testing. Teams must ensure that all K24 engine modifications are well-documented and fall within the permissible limits set by the regulations. This includes maintaining detailed records of parts used, engine build specifications, and performance data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!