K24 Engine Tuning Software: A Guide to Calibration Tools

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Overview

The K24 engine, developed by Honda, is a 2.4-liter inline-four cylinder engine that has become renowned for its reliability, performance, and tuning potential. First introduced in 2002, the K24 has been utilized in various Honda and Acura models, including the Accord, CR-V, and TSX. This engine is part of Honda's K-series family, which represents a significant leap forward in engine technology compared to its predecessors.

The K24 engine features an aluminum block and cylinder head, dual overhead camshafts (DOHC), and Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This advanced valvetrain technology allows for optimized performance across a wide range of engine speeds, contributing to the engine's versatility and efficiency. The K24's displacement of 2.4 liters is achieved through a bore of 87mm and a stroke of 99mm, resulting in a slightly undersquare design that balances low-end torque with high-rpm power.

One of the key strengths of the K24 engine is its robust construction. The engine block features a deep-skirt design and integrated oil passages, providing excellent structural rigidity and efficient lubrication. The cylinder head is designed with a pent-roof combustion chamber and centrally located spark plugs, promoting efficient combustion and allowing for high compression ratios.

Throughout its production run, the K24 engine has undergone several iterations and improvements. Early versions produced around 160 horsepower, while later models saw power outputs increase to over 200 horsepower in stock form. This progression demonstrates Honda's commitment to continuous improvement and the engine's inherent potential for performance enhancement.

The K24's popularity among enthusiasts stems from its excellent balance of performance, reliability, and tuning potential. Its strong bottom end and capable cylinder head design provide a solid foundation for modifications, allowing for significant power gains with proper tuning and upgrades. This has led to a thriving aftermarket industry offering a wide range of performance parts and tuning solutions specifically tailored to the K24 platform.

In the context of engine tuning software and calibration tools, the K24 engine presents an ideal candidate for optimization. Its electronic engine management system, which controls fuel injection, ignition timing, and variable valve timing, offers numerous parameters that can be adjusted to enhance performance, fuel efficiency, or emissions compliance. Understanding the K24's architecture and operating principles is crucial for effective use of tuning software, as it allows calibrators to make informed decisions when modifying engine parameters.

The K24 engine features an aluminum block and cylinder head, dual overhead camshafts (DOHC), and Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This advanced valvetrain technology allows for optimized performance across a wide range of engine speeds, contributing to the engine's versatility and efficiency. The K24's displacement of 2.4 liters is achieved through a bore of 87mm and a stroke of 99mm, resulting in a slightly undersquare design that balances low-end torque with high-rpm power.

One of the key strengths of the K24 engine is its robust construction. The engine block features a deep-skirt design and integrated oil passages, providing excellent structural rigidity and efficient lubrication. The cylinder head is designed with a pent-roof combustion chamber and centrally located spark plugs, promoting efficient combustion and allowing for high compression ratios.

Throughout its production run, the K24 engine has undergone several iterations and improvements. Early versions produced around 160 horsepower, while later models saw power outputs increase to over 200 horsepower in stock form. This progression demonstrates Honda's commitment to continuous improvement and the engine's inherent potential for performance enhancement.

The K24's popularity among enthusiasts stems from its excellent balance of performance, reliability, and tuning potential. Its strong bottom end and capable cylinder head design provide a solid foundation for modifications, allowing for significant power gains with proper tuning and upgrades. This has led to a thriving aftermarket industry offering a wide range of performance parts and tuning solutions specifically tailored to the K24 platform.

In the context of engine tuning software and calibration tools, the K24 engine presents an ideal candidate for optimization. Its electronic engine management system, which controls fuel injection, ignition timing, and variable valve timing, offers numerous parameters that can be adjusted to enhance performance, fuel efficiency, or emissions compliance. Understanding the K24's architecture and operating principles is crucial for effective use of tuning software, as it allows calibrators to make informed decisions when modifying engine parameters.

Market Analysis

The market for K24 engine tuning software and calibration tools has experienced significant growth in recent years, driven by the increasing demand for performance optimization in Honda and Acura vehicles. This market segment caters to automotive enthusiasts, racing teams, and professional tuners seeking to enhance the power output, fuel efficiency, and overall performance of K24-equipped vehicles.

The global automotive engine management system market, which includes engine tuning software, is projected to reach substantial value in the coming years. This growth is attributed to the rising popularity of aftermarket modifications and the continuous advancements in engine technology. The K24 engine, known for its versatility and tuning potential, has contributed to the expansion of this niche market.

Within the K24 tuning software market, there is a diverse range of products catering to different user needs. Entry-level software solutions target DIY enthusiasts looking for basic tuning capabilities, while advanced calibration tools are designed for professional tuners and racing teams requiring precise control over engine parameters. This segmentation has led to a competitive landscape with various price points and feature sets.

The market demand for K24 engine tuning software is closely tied to the popularity of Honda and Acura models equipped with this engine. As these vehicles age, owners often seek performance upgrades, creating a steady demand for tuning solutions. Additionally, the growing trend of engine swaps, where K24 engines are installed in other vehicle platforms, has expanded the potential customer base for these calibration tools.

Geographically, the market for K24 engine tuning software is particularly strong in regions with a robust car modification culture, such as North America, Japan, and parts of Europe. These areas have well-established automotive aftermarket industries and a high concentration of Honda and Acura enthusiasts.

The increasing focus on emissions regulations and fuel efficiency has also influenced the K24 tuning software market. Many modern calibration tools now incorporate features that allow users to optimize engine performance while maintaining compliance with environmental standards. This trend has opened up new opportunities for software developers to create more sophisticated and eco-friendly tuning solutions.

As the automotive industry shifts towards electrification, there is speculation about the long-term prospects of the internal combustion engine tuning market. However, experts predict that the K24 engine tuning software segment will remain resilient in the medium term, supported by a dedicated enthusiast base and the ongoing popularity of Honda's naturally aspirated engines in motorsports.

The global automotive engine management system market, which includes engine tuning software, is projected to reach substantial value in the coming years. This growth is attributed to the rising popularity of aftermarket modifications and the continuous advancements in engine technology. The K24 engine, known for its versatility and tuning potential, has contributed to the expansion of this niche market.

Within the K24 tuning software market, there is a diverse range of products catering to different user needs. Entry-level software solutions target DIY enthusiasts looking for basic tuning capabilities, while advanced calibration tools are designed for professional tuners and racing teams requiring precise control over engine parameters. This segmentation has led to a competitive landscape with various price points and feature sets.

The market demand for K24 engine tuning software is closely tied to the popularity of Honda and Acura models equipped with this engine. As these vehicles age, owners often seek performance upgrades, creating a steady demand for tuning solutions. Additionally, the growing trend of engine swaps, where K24 engines are installed in other vehicle platforms, has expanded the potential customer base for these calibration tools.

Geographically, the market for K24 engine tuning software is particularly strong in regions with a robust car modification culture, such as North America, Japan, and parts of Europe. These areas have well-established automotive aftermarket industries and a high concentration of Honda and Acura enthusiasts.

The increasing focus on emissions regulations and fuel efficiency has also influenced the K24 tuning software market. Many modern calibration tools now incorporate features that allow users to optimize engine performance while maintaining compliance with environmental standards. This trend has opened up new opportunities for software developers to create more sophisticated and eco-friendly tuning solutions.

As the automotive industry shifts towards electrification, there is speculation about the long-term prospects of the internal combustion engine tuning market. However, experts predict that the K24 engine tuning software segment will remain resilient in the medium term, supported by a dedicated enthusiast base and the ongoing popularity of Honda's naturally aspirated engines in motorsports.

Tuning Software Landscape

The K24 engine tuning software landscape has evolved significantly over the years, offering a diverse array of calibration tools for automotive enthusiasts and professionals alike. These software solutions cater to various aspects of engine performance optimization, from basic adjustments to advanced fine-tuning capabilities.

At the forefront of this landscape are comprehensive platforms like HP Tuners and EcuTek, which provide extensive support for a wide range of vehicle makes and models. These tools offer robust features such as real-time data logging, custom map creation, and advanced diagnostics, making them popular choices among professional tuners and performance shops.

For Honda-specific applications, including the K24 engine, Hondata stands out as a specialized solution. Their FlashPro and KPro systems are tailored for Honda and Acura vehicles, offering precise control over engine parameters and compatibility with factory ECUs.

Open-source alternatives like TunerStudio and MegaSquirt have gained traction in the DIY tuning community. These platforms provide flexibility and customization options for enthusiasts who prefer a more hands-on approach to engine management and are willing to invest time in learning the intricacies of engine tuning.

Mobile-based tuning solutions have also emerged, with apps like OBD Fusion and Torque Pro offering basic monitoring and adjustment capabilities. While not as comprehensive as dedicated tuning software, these apps provide accessibility and convenience for quick checks and minor tweaks.

Cloud-based tuning services, such as VirtualDyno and DynoSim, have introduced remote tuning capabilities, allowing experts to fine-tune engines from anywhere in the world. This has opened up new possibilities for collaboration and expertise sharing in the tuning community.

The landscape also includes manufacturer-specific tools like Cobb Tuning's AccessPort, which, while not directly applicable to the K24 engine, demonstrates the trend towards integrated hardware-software solutions in the tuning market.

As environmental regulations tighten, we're seeing an increase in eco-focused tuning software that aims to balance performance gains with emissions compliance. These tools incorporate features for optimizing fuel efficiency and reducing emissions while still enhancing engine output.

The future of K24 engine tuning software is likely to see further integration of artificial intelligence and machine learning algorithms. These advancements promise to automate certain aspects of the tuning process, potentially making high-level engine optimization more accessible to a broader range of users.

At the forefront of this landscape are comprehensive platforms like HP Tuners and EcuTek, which provide extensive support for a wide range of vehicle makes and models. These tools offer robust features such as real-time data logging, custom map creation, and advanced diagnostics, making them popular choices among professional tuners and performance shops.

For Honda-specific applications, including the K24 engine, Hondata stands out as a specialized solution. Their FlashPro and KPro systems are tailored for Honda and Acura vehicles, offering precise control over engine parameters and compatibility with factory ECUs.

Open-source alternatives like TunerStudio and MegaSquirt have gained traction in the DIY tuning community. These platforms provide flexibility and customization options for enthusiasts who prefer a more hands-on approach to engine management and are willing to invest time in learning the intricacies of engine tuning.

Mobile-based tuning solutions have also emerged, with apps like OBD Fusion and Torque Pro offering basic monitoring and adjustment capabilities. While not as comprehensive as dedicated tuning software, these apps provide accessibility and convenience for quick checks and minor tweaks.

Cloud-based tuning services, such as VirtualDyno and DynoSim, have introduced remote tuning capabilities, allowing experts to fine-tune engines from anywhere in the world. This has opened up new possibilities for collaboration and expertise sharing in the tuning community.

The landscape also includes manufacturer-specific tools like Cobb Tuning's AccessPort, which, while not directly applicable to the K24 engine, demonstrates the trend towards integrated hardware-software solutions in the tuning market.

As environmental regulations tighten, we're seeing an increase in eco-focused tuning software that aims to balance performance gains with emissions compliance. These tools incorporate features for optimizing fuel efficiency and reducing emissions while still enhancing engine output.

The future of K24 engine tuning software is likely to see further integration of artificial intelligence and machine learning algorithms. These advancements promise to automate certain aspects of the tuning process, potentially making high-level engine optimization more accessible to a broader range of users.

Current Tuning Solutions

01 Engine Control Unit (ECU) Software Calibration

Software calibration for the K24 engine's ECU involves adjusting parameters to optimize performance, fuel efficiency, and emissions. This process includes fine-tuning fuel injection timing, ignition timing, and air-fuel ratios based on various sensor inputs and operating conditions.- Engine Control Unit (ECU) Software Calibration: Software calibration for the K24 engine's ECU involves adjusting parameters to optimize performance, fuel efficiency, and emissions. This process includes fine-tuning fuel injection timing, ignition timing, and air-fuel ratios based on various sensor inputs and operating conditions.

- Real-time Engine Performance Monitoring: Implementing real-time monitoring systems for the K24 engine allows for continuous data collection and analysis of engine performance metrics. This enables dynamic adjustments to engine parameters and facilitates diagnostics and predictive maintenance.

- Machine Learning Algorithms for Engine Tuning: Incorporating machine learning algorithms into K24 engine tuning software enhances the calibration process by analyzing large datasets of engine performance data. These algorithms can identify optimal settings for various driving conditions and adapt to individual driving styles.

- Wireless Connectivity for Remote Tuning: Integrating wireless connectivity features in K24 engine tuning software allows for remote calibration and updates. This enables tuners to make adjustments without physical access to the vehicle, improving convenience and enabling real-time optimization based on driving conditions.

- User Interface for Tuning Software: Developing intuitive user interfaces for K24 engine tuning software improves accessibility for both professional tuners and enthusiasts. These interfaces provide visual representations of engine parameters, real-time data graphs, and user-friendly controls for making calibration adjustments.

02 Real-time Engine Performance Monitoring

Implementing real-time monitoring systems for the K24 engine allows for continuous data collection and analysis of engine performance metrics. This enables dynamic adjustments to engine parameters and facilitates predictive maintenance strategies.Expand Specific Solutions03 Machine Learning Algorithms for Engine Tuning

Utilizing machine learning algorithms to analyze engine performance data and automatically adjust tuning parameters. These algorithms can learn from historical data and driver behavior to optimize engine performance and efficiency over time.Expand Specific Solutions04 Wireless Tuning and Diagnostics

Implementing wireless connectivity for remote tuning and diagnostics of the K24 engine. This allows for over-the-air updates to engine software, remote troubleshooting, and real-time performance adjustments without physical access to the vehicle.Expand Specific Solutions05 Adaptive Tuning Based on Driving Conditions

Developing adaptive tuning systems that automatically adjust engine parameters based on current driving conditions, such as altitude, temperature, and road type. This ensures optimal performance and efficiency across various environments and driving scenarios.Expand Specific Solutions

Key Software Providers

The K24 Engine Tuning Software market is in a growth phase, driven by increasing demand for performance optimization in automotive applications. The market size is expanding as more vehicle owners seek customization options. Technologically, the field is advancing rapidly, with companies like Robert Bosch GmbH and Honda Motor Co., Ltd. leading innovation. These firms, along with others like DENSO Corp. and General Electric Company, are developing sophisticated calibration tools that offer precise engine management. The competitive landscape is characterized by a mix of established automotive giants and specialized software developers, each striving to enhance tuning capabilities and user-friendly interfaces for both professional mechanics and enthusiasts.

Robert Bosch GmbH

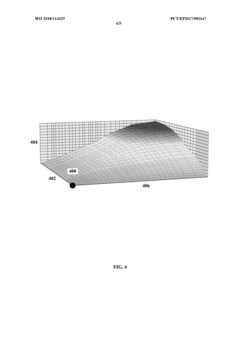

Technical Solution: Bosch's K24 Engine Tuning Software utilizes advanced calibration tools to optimize engine performance. The software employs model-based calibration techniques, allowing for precise adjustment of fuel injection, ignition timing, and valve control. It incorporates machine learning algorithms to analyze vast amounts of sensor data, enabling real-time adaptations to varying driving conditions[1]. The software also features a user-friendly interface with 3D mapping capabilities, allowing technicians to visualize and fine-tune engine parameters efficiently[3]. Bosch's solution integrates seamlessly with their wide range of engine control units (ECUs), providing a comprehensive ecosystem for K24 engine tuning[5].

Strengths: Comprehensive ecosystem integration, advanced machine learning capabilities, and user-friendly interface. Weaknesses: May require specialized training for full utilization, potentially higher cost compared to simpler solutions.

Honda Motor Co., Ltd.

Technical Solution: Honda's proprietary K24 Engine Tuning Software focuses on maximizing the potential of their K-series engines. The software utilizes Honda's extensive knowledge of the K24 engine architecture to provide precise calibration tools. It features adaptive learning algorithms that continuously optimize engine performance based on driving patterns and environmental conditions[2]. The software includes a comprehensive database of pre-set tunes for various K24 engine configurations, allowing for quick baseline setups[4]. Honda's solution also incorporates advanced knock detection and prevention algorithms, ensuring engine longevity while pushing performance boundaries[6]. The software integrates with Honda's diagnostic systems, providing seamless troubleshooting and maintenance capabilities.

Strengths: Tailored specifically for K24 engines, extensive pre-set tune database, and integrated diagnostic capabilities. Weaknesses: Limited compatibility with non-Honda ECUs, potentially less flexible for extreme modifications.

Advanced Calibration Tech

calibration of engine controls in real time

PatentPendingDE102020200208A1

Innovation

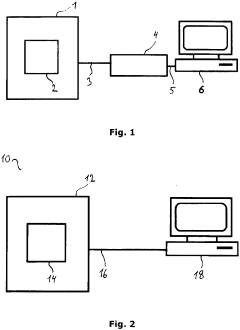

- A vehicle engine controller capable of generating and transmitting control and calibration data in parallel and real-time, utilizing an interface to connect with a host computer, without requiring additional hardware, by overclocking processor cores and memory to ensure uninterrupted control functionality.

A system and method to calibrate an engine control unit (ECU) of a vehicle

PatentWO2018114329A1

Innovation

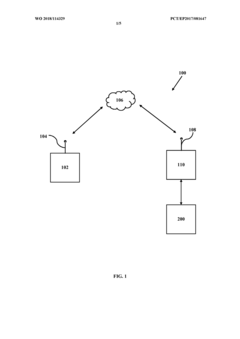

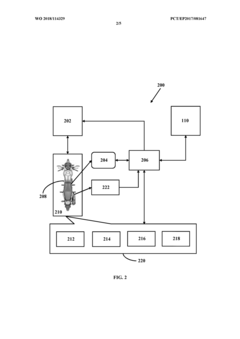

- A system and method for remote ECU calibration using cloud services, which automates the calibration process by interfacing a remote computer with a central server, local computer, and dynamometer, utilizing actuators and sensors to control engine operating points, allowing for automated and reproducible calibration through scripted instructions and actuator control.

Emissions Regulations

Emissions regulations play a crucial role in the development and implementation of K24 engine tuning software and calibration tools. These regulations, established by governmental agencies worldwide, aim to reduce harmful emissions from vehicles and improve air quality. As engine tuning software becomes more sophisticated, it must adapt to increasingly stringent emissions standards.

The United States Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) are two of the most influential regulatory bodies in this field. Their standards often serve as benchmarks for other countries and regions. In recent years, these agencies have implemented more stringent regulations, such as the Tier 3 and LEV III standards, which require significant reductions in emissions of nitrogen oxides (NOx), particulate matter (PM), and non-methane organic gases (NMOG).

Engine tuning software developers must ensure that their calibration tools comply with these regulations while still optimizing engine performance. This challenge has led to the development of advanced algorithms and modeling techniques that balance emissions control with power output and fuel efficiency. For instance, many modern calibration tools incorporate real-time emissions monitoring capabilities, allowing tuners to make adjustments that maintain compliance with regulatory limits.

The European Union has also implemented strict emissions standards through its Euro 6 regulations, which have been in effect since 2015. These standards have pushed engine tuning software developers to create more sophisticated calibration tools that can handle complex aftertreatment systems, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF).

As emissions regulations continue to evolve, K24 engine tuning software must adapt to new testing procedures and measurement methods. For example, the introduction of Real Driving Emissions (RDE) tests in Europe has necessitated the development of calibration tools that can optimize engine performance across a wider range of driving conditions, not just in laboratory settings.

The global nature of the automotive industry means that engine tuning software must be capable of meeting diverse regulatory requirements across different markets. This has led to the creation of modular calibration tools that can be easily adapted to various regional standards, allowing manufacturers and tuners to efficiently develop compliant engine maps for multiple markets.

In conclusion, emissions regulations have become a driving force in the evolution of K24 engine tuning software and calibration tools. As these regulations become more stringent and complex, software developers must continue to innovate, creating more advanced tools that can optimize engine performance while ensuring compliance with environmental standards across diverse global markets.

The United States Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) are two of the most influential regulatory bodies in this field. Their standards often serve as benchmarks for other countries and regions. In recent years, these agencies have implemented more stringent regulations, such as the Tier 3 and LEV III standards, which require significant reductions in emissions of nitrogen oxides (NOx), particulate matter (PM), and non-methane organic gases (NMOG).

Engine tuning software developers must ensure that their calibration tools comply with these regulations while still optimizing engine performance. This challenge has led to the development of advanced algorithms and modeling techniques that balance emissions control with power output and fuel efficiency. For instance, many modern calibration tools incorporate real-time emissions monitoring capabilities, allowing tuners to make adjustments that maintain compliance with regulatory limits.

The European Union has also implemented strict emissions standards through its Euro 6 regulations, which have been in effect since 2015. These standards have pushed engine tuning software developers to create more sophisticated calibration tools that can handle complex aftertreatment systems, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF).

As emissions regulations continue to evolve, K24 engine tuning software must adapt to new testing procedures and measurement methods. For example, the introduction of Real Driving Emissions (RDE) tests in Europe has necessitated the development of calibration tools that can optimize engine performance across a wider range of driving conditions, not just in laboratory settings.

The global nature of the automotive industry means that engine tuning software must be capable of meeting diverse regulatory requirements across different markets. This has led to the creation of modular calibration tools that can be easily adapted to various regional standards, allowing manufacturers and tuners to efficiently develop compliant engine maps for multiple markets.

In conclusion, emissions regulations have become a driving force in the evolution of K24 engine tuning software and calibration tools. As these regulations become more stringent and complex, software developers must continue to innovate, creating more advanced tools that can optimize engine performance while ensuring compliance with environmental standards across diverse global markets.

Performance Benchmarking

Performance benchmarking is a critical aspect of K24 engine tuning software and calibration tools. To effectively evaluate the performance of these tools, a comprehensive approach is necessary, encompassing various metrics and testing scenarios.

One key area of focus is the software's ability to optimize engine performance parameters. This includes measuring improvements in horsepower, torque, and fuel efficiency across different engine load conditions and RPM ranges. Benchmarking should involve before-and-after comparisons using standardized dynamometer testing procedures to quantify gains accurately.

Another important benchmark is the software's real-time data processing capabilities. This involves assessing the speed and accuracy of sensor data interpretation, as well as the responsiveness of adjustments made to engine parameters. Latency measurements and data throughput rates are crucial metrics in this regard.

The user interface and overall user experience also play a significant role in performance benchmarking. Metrics such as time required to complete common tuning tasks, ease of navigation, and the intuitiveness of data visualization tools should be evaluated. This can be done through user testing sessions with experienced tuners, measuring task completion times and gathering qualitative feedback.

Compatibility and integration with various engine control units (ECUs) and aftermarket components is another critical benchmark. The software's ability to communicate effectively with different ECU models and seamlessly integrate with popular performance modifications should be thoroughly tested and documented.

Stability and reliability under various operating conditions are essential benchmarks. This includes stress testing the software under extreme engine conditions, evaluating its performance during extended tuning sessions, and assessing its ability to handle unexpected interruptions or system errors without data loss.

Finally, the benchmarking process should include a comparison with industry-leading competitors. This involves side-by-side testing of key features, performance gains, and overall user satisfaction across multiple K24 engine tuning software options. Such comparative analysis provides valuable insights into the strengths and weaknesses of each tool, helping users make informed decisions based on their specific needs and preferences.

One key area of focus is the software's ability to optimize engine performance parameters. This includes measuring improvements in horsepower, torque, and fuel efficiency across different engine load conditions and RPM ranges. Benchmarking should involve before-and-after comparisons using standardized dynamometer testing procedures to quantify gains accurately.

Another important benchmark is the software's real-time data processing capabilities. This involves assessing the speed and accuracy of sensor data interpretation, as well as the responsiveness of adjustments made to engine parameters. Latency measurements and data throughput rates are crucial metrics in this regard.

The user interface and overall user experience also play a significant role in performance benchmarking. Metrics such as time required to complete common tuning tasks, ease of navigation, and the intuitiveness of data visualization tools should be evaluated. This can be done through user testing sessions with experienced tuners, measuring task completion times and gathering qualitative feedback.

Compatibility and integration with various engine control units (ECUs) and aftermarket components is another critical benchmark. The software's ability to communicate effectively with different ECU models and seamlessly integrate with popular performance modifications should be thoroughly tested and documented.

Stability and reliability under various operating conditions are essential benchmarks. This includes stress testing the software under extreme engine conditions, evaluating its performance during extended tuning sessions, and assessing its ability to handle unexpected interruptions or system errors without data loss.

Finally, the benchmarking process should include a comparison with industry-leading competitors. This involves side-by-side testing of key features, performance gains, and overall user satisfaction across multiple K24 engine tuning software options. Such comparative analysis provides valuable insights into the strengths and weaknesses of each tool, helping users make informed decisions based on their specific needs and preferences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!