K24 Engine Upgrades: Boosting Horsepower for Enthusiasts

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in 2001. Initially designed for the Honda Accord, this 2.4-liter inline-four engine quickly gained popularity among enthusiasts for its robust design and tuning potential. The engine's journey began with the K24A1 variant, which set the foundation for future improvements.

Throughout its lifespan, the K24 engine saw several iterations, each bringing incremental enhancements to performance and efficiency. The K24A2 and K24A3 variants introduced in subsequent years featured refined cylinder heads and improved intake systems, resulting in modest power gains. However, it was the introduction of the K24A4 in 2004 that marked a significant leap forward, incorporating Honda's advanced i-VTEC technology for enhanced valve control and power delivery across a broader RPM range.

The evolution continued with the K24Z series, which saw further refinements in combustion efficiency and emissions control. The K24Z7, introduced in 2008, represented a pinnacle in the naturally aspirated K24 lineup, boasting higher compression ratios and more aggressive cam profiles. This variant became a favorite among tuners for its balance of reliability and performance potential.

In response to growing demand for fuel efficiency, later iterations of the K24 incorporated direct injection technology. The Earth Dreams K24W series, launched in 2013, showcased Honda's commitment to blending performance with environmental consciousness. These engines featured reduced friction internals, lighter components, and advanced fuel management systems, resulting in improved fuel economy without sacrificing the K24's renowned power characteristics.

Throughout its evolution, the K24 engine maintained its core strengths of durability and tunability. The engine's robust bottom end, capable of handling significant power increases, remained a constant. This attribute, combined with the continuous refinement of the cylinder head design and valvetrain, ensured that the K24 remained a prime candidate for performance upgrades.

The engine's evolution also saw advancements in materials and manufacturing processes. Later models incorporated more aluminum and magnesium components to reduce weight, while improved casting techniques enhanced structural integrity. These developments not only contributed to better performance but also improved the engine's longevity and reliability, further cementing its status among enthusiasts.

As the automotive industry shifted towards turbocharging and electrification, the naturally aspirated K24 began to phase out of production. However, its legacy lives on in the aftermarket community, where it continues to be a popular choice for engine swaps and high-performance builds. The K24's evolution from a reliable daily driver engine to a versatile performance powerplant stands as a testament to Honda's engineering philosophy and the engine's inherent potential for modification and improvement.

Throughout its lifespan, the K24 engine saw several iterations, each bringing incremental enhancements to performance and efficiency. The K24A2 and K24A3 variants introduced in subsequent years featured refined cylinder heads and improved intake systems, resulting in modest power gains. However, it was the introduction of the K24A4 in 2004 that marked a significant leap forward, incorporating Honda's advanced i-VTEC technology for enhanced valve control and power delivery across a broader RPM range.

The evolution continued with the K24Z series, which saw further refinements in combustion efficiency and emissions control. The K24Z7, introduced in 2008, represented a pinnacle in the naturally aspirated K24 lineup, boasting higher compression ratios and more aggressive cam profiles. This variant became a favorite among tuners for its balance of reliability and performance potential.

In response to growing demand for fuel efficiency, later iterations of the K24 incorporated direct injection technology. The Earth Dreams K24W series, launched in 2013, showcased Honda's commitment to blending performance with environmental consciousness. These engines featured reduced friction internals, lighter components, and advanced fuel management systems, resulting in improved fuel economy without sacrificing the K24's renowned power characteristics.

Throughout its evolution, the K24 engine maintained its core strengths of durability and tunability. The engine's robust bottom end, capable of handling significant power increases, remained a constant. This attribute, combined with the continuous refinement of the cylinder head design and valvetrain, ensured that the K24 remained a prime candidate for performance upgrades.

The engine's evolution also saw advancements in materials and manufacturing processes. Later models incorporated more aluminum and magnesium components to reduce weight, while improved casting techniques enhanced structural integrity. These developments not only contributed to better performance but also improved the engine's longevity and reliability, further cementing its status among enthusiasts.

As the automotive industry shifted towards turbocharging and electrification, the naturally aspirated K24 began to phase out of production. However, its legacy lives on in the aftermarket community, where it continues to be a popular choice for engine swaps and high-performance builds. The K24's evolution from a reliable daily driver engine to a versatile performance powerplant stands as a testament to Honda's engineering philosophy and the engine's inherent potential for modification and improvement.

Performance Market Analysis

The performance aftermarket for the Honda K24 engine has experienced significant growth in recent years, driven by enthusiasts seeking to unlock the full potential of this versatile powerplant. The K24, originally designed for efficiency and reliability in Honda's mainstream vehicles, has become a popular choice for performance upgrades due to its robust construction and inherent tuning potential.

Market demand for K24 engine upgrades is primarily fueled by two distinct segments: street performance enthusiasts and amateur racers. Street performance enthusiasts typically seek moderate power gains while maintaining daily drivability, focusing on bolt-on modifications such as intake systems, exhaust upgrades, and ECU tuning. Amateur racers, on the other hand, often pursue more extensive modifications, including forced induction systems, high-compression pistons, and camshaft upgrades to achieve maximum horsepower output.

The global market for K24 engine upgrades has shown steady growth, with a notable increase in demand observed in North America, Europe, and parts of Asia. This growth is attributed to the widespread availability of K24-equipped vehicles in these regions and the engine's reputation for reliability and tunability. Online marketplaces and specialized performance shops have reported consistent year-over-year increases in sales of K24-specific performance parts.

Key market drivers include the rising popularity of grassroots motorsports events, such as time attack and autocross competitions, where K24-powered vehicles have proven competitive. Additionally, the growing trend of engine swaps, particularly in older Honda chassis, has created a new market segment for K24 performance products. This trend is supported by the engine's compatibility with a wide range of Honda and Acura models, making it a versatile choice for enthusiasts looking to modernize their older vehicles.

The aftermarket industry has responded to this demand with a diverse range of products catering to various performance goals and budgets. Entry-level upgrades, such as cold air intakes and cat-back exhaust systems, represent the largest volume of sales. However, high-end components like turbocharger kits and fully built engine packages, while lower in volume, contribute significantly to overall market value due to their higher price points.

Market analysis indicates that consumer preferences are shifting towards integrated upgrade packages that offer balanced performance gains across multiple engine systems. This trend has led to the development of comprehensive stage kits that combine compatible components, simplifying the upgrade process for consumers and potentially increasing average transaction values for retailers and manufacturers.

Looking ahead, the K24 performance market is expected to continue its growth trajectory, supported by ongoing technological advancements in engine management systems and materials science. The increasing availability of 3D-printed prototypes and custom parts is likely to accelerate product development cycles and enable more specialized, niche offerings in the market.

Market demand for K24 engine upgrades is primarily fueled by two distinct segments: street performance enthusiasts and amateur racers. Street performance enthusiasts typically seek moderate power gains while maintaining daily drivability, focusing on bolt-on modifications such as intake systems, exhaust upgrades, and ECU tuning. Amateur racers, on the other hand, often pursue more extensive modifications, including forced induction systems, high-compression pistons, and camshaft upgrades to achieve maximum horsepower output.

The global market for K24 engine upgrades has shown steady growth, with a notable increase in demand observed in North America, Europe, and parts of Asia. This growth is attributed to the widespread availability of K24-equipped vehicles in these regions and the engine's reputation for reliability and tunability. Online marketplaces and specialized performance shops have reported consistent year-over-year increases in sales of K24-specific performance parts.

Key market drivers include the rising popularity of grassroots motorsports events, such as time attack and autocross competitions, where K24-powered vehicles have proven competitive. Additionally, the growing trend of engine swaps, particularly in older Honda chassis, has created a new market segment for K24 performance products. This trend is supported by the engine's compatibility with a wide range of Honda and Acura models, making it a versatile choice for enthusiasts looking to modernize their older vehicles.

The aftermarket industry has responded to this demand with a diverse range of products catering to various performance goals and budgets. Entry-level upgrades, such as cold air intakes and cat-back exhaust systems, represent the largest volume of sales. However, high-end components like turbocharger kits and fully built engine packages, while lower in volume, contribute significantly to overall market value due to their higher price points.

Market analysis indicates that consumer preferences are shifting towards integrated upgrade packages that offer balanced performance gains across multiple engine systems. This trend has led to the development of comprehensive stage kits that combine compatible components, simplifying the upgrade process for consumers and potentially increasing average transaction values for retailers and manufacturers.

Looking ahead, the K24 performance market is expected to continue its growth trajectory, supported by ongoing technological advancements in engine management systems and materials science. The increasing availability of 3D-printed prototypes and custom parts is likely to accelerate product development cycles and enable more specialized, niche offerings in the market.

K24 Upgrade Challenges

The K24 engine, renowned for its reliability and potential, presents several challenges when it comes to boosting horsepower for enthusiasts. One of the primary obstacles is the stock engine's compression ratio, which limits the amount of boost that can be safely applied without risking detonation. This high compression ratio, while beneficial for naturally aspirated performance, becomes a hindrance when attempting to add forced induction.

Another significant challenge lies in the K24's stock fuel system. As horsepower increases, the factory fuel injectors and fuel pump often struggle to keep up with the increased fuel demand. This can lead to lean conditions, potentially causing severe engine damage. Upgrading these components becomes necessary but adds complexity and cost to the modification process.

The K24's stock connecting rods are another weak point when pushing for higher horsepower. While adequate for moderate power increases, they become a liability as boost levels rise, risking failure under high-stress conditions. This necessitates internal engine modifications, significantly increasing the complexity and expense of the upgrade process.

Heat management presents another hurdle for K24 enthusiasts. As power output increases, so does the heat generated by the engine. The stock cooling system may struggle to dissipate this additional heat effectively, potentially leading to overheating issues and reduced performance. Addressing this often requires upgrades to the radiator, oil cooler, and sometimes even the addition of an intercooler for forced induction setups.

The K24's valve train also poses challenges when aiming for high-rpm power. The stock valve springs may not be able to control valve movement adequately at higher engine speeds, leading to potential valve float. This limits the engine's ability to rev freely and produce power at the top end, necessitating upgrades to the valve train components.

Tuning presents its own set of challenges. The stock ECU has limitations in terms of adjustability and often requires replacement or piggyback systems to properly manage increased airflow and fuel requirements. This adds another layer of complexity and cost to the upgrade process, requiring specialized knowledge or professional tuning services.

Lastly, maintaining drivability and reliability while significantly increasing horsepower is a constant challenge. Balancing performance gains with everyday usability often requires careful component selection and tuning expertise to ensure the upgraded K24 remains a practical daily driver while delivering the desired performance increases.

Another significant challenge lies in the K24's stock fuel system. As horsepower increases, the factory fuel injectors and fuel pump often struggle to keep up with the increased fuel demand. This can lead to lean conditions, potentially causing severe engine damage. Upgrading these components becomes necessary but adds complexity and cost to the modification process.

The K24's stock connecting rods are another weak point when pushing for higher horsepower. While adequate for moderate power increases, they become a liability as boost levels rise, risking failure under high-stress conditions. This necessitates internal engine modifications, significantly increasing the complexity and expense of the upgrade process.

Heat management presents another hurdle for K24 enthusiasts. As power output increases, so does the heat generated by the engine. The stock cooling system may struggle to dissipate this additional heat effectively, potentially leading to overheating issues and reduced performance. Addressing this often requires upgrades to the radiator, oil cooler, and sometimes even the addition of an intercooler for forced induction setups.

The K24's valve train also poses challenges when aiming for high-rpm power. The stock valve springs may not be able to control valve movement adequately at higher engine speeds, leading to potential valve float. This limits the engine's ability to rev freely and produce power at the top end, necessitating upgrades to the valve train components.

Tuning presents its own set of challenges. The stock ECU has limitations in terms of adjustability and often requires replacement or piggyback systems to properly manage increased airflow and fuel requirements. This adds another layer of complexity and cost to the upgrade process, requiring specialized knowledge or professional tuning services.

Lastly, maintaining drivability and reliability while significantly increasing horsepower is a constant challenge. Balancing performance gains with everyday usability often requires careful component selection and tuning expertise to ensure the upgraded K24 remains a practical daily driver while delivering the desired performance increases.

Popular K24 Upgrade Methods

01 Engine performance measurement

Various methods and systems are used to measure and analyze engine performance, including horsepower. These may involve dynamometers, sensors, and data acquisition systems to accurately determine the power output of engines, including the K24 engine.- Engine performance measurement: Various methods and systems are used to measure and analyze engine performance, including horsepower. These may involve dynamometers, sensors, and data acquisition systems to accurately determine the power output of engines, including the K24 engine.

- Engine control and optimization: Advanced control systems and algorithms are employed to optimize engine performance and horsepower. These may include electronic control units (ECUs) and software that adjust various parameters to maximize power output while maintaining efficiency and reliability.

- Fuel injection and combustion improvements: Enhancements in fuel injection systems and combustion processes can significantly impact engine horsepower. This may involve precise fuel delivery, improved atomization, and optimized combustion chamber design to increase power output in engines like the K24.

- Turbocharging and forced induction: Forced induction systems, such as turbochargers or superchargers, can be used to increase the horsepower of engines. These systems compress the intake air, allowing for more fuel to be burned and resulting in higher power output.

- Engine component design and materials: Advancements in engine component design and materials can contribute to increased horsepower. This may include lightweight pistons, high-strength connecting rods, and advanced cylinder head designs that improve airflow and combustion efficiency.

02 Engine control and optimization

Advanced control systems and algorithms are employed to optimize engine performance and horsepower. These may include electronic control units (ECUs) and software that manage fuel injection, ignition timing, and other parameters to maximize power output in the K24 engine.Expand Specific Solutions03 Combustion efficiency improvements

Techniques for enhancing combustion efficiency are crucial for increasing horsepower. This may involve optimizing fuel mixture, improving air intake systems, and refining combustion chamber design to extract more power from the K24 engine.Expand Specific Solutions04 Turbocharging and supercharging

Forced induction methods such as turbocharging and supercharging can significantly boost the horsepower of engines. These technologies can be applied to the K24 engine to increase its power output beyond naturally aspirated levels.Expand Specific Solutions05 Materials and manufacturing improvements

Advancements in materials science and manufacturing processes can lead to stronger, lighter engine components. These improvements can reduce friction, increase durability, and ultimately contribute to higher horsepower output in engines like the K24.Expand Specific Solutions

Key Aftermarket Players

The K24 engine upgrade market is in a mature growth phase, characterized by steady demand from automotive enthusiasts seeking increased horsepower. The global market size for aftermarket engine upgrades is substantial, driven by a growing performance car culture. Technologically, K24 upgrades are well-established, with companies like Toyota Motor Corp., Ford Global Technologies LLC, and Infineum International Ltd. offering advanced solutions. These firms leverage their extensive R&D capabilities to develop innovative performance-enhancing products, while smaller specialized companies like Achates Power, Inc. focus on niche, cutting-edge technologies to compete in this competitive landscape.

Toyota Motor Corp.

Technical Solution: Toyota's K24 engine upgrade strategy focuses on a balance of performance and efficiency. They have developed a variable valve timing and lift system (VVTL-i) specifically tailored for the K24, allowing for optimized performance at both low and high RPMs[4]. Toyota has also implemented a dual-stage intake manifold design, which improves airflow characteristics across the engine's operating range[5]. To boost horsepower, they've incorporated a high-compression ratio design coupled with advanced materials for pistons and connecting rods to withstand increased stress[6]. Toyota's upgrades also include a revised exhaust system with larger diameter piping and a high-flow catalytic converter to reduce back pressure.

Strengths: Emphasis on balancing performance gains with reliability and efficiency. Weaknesses: May not provide as dramatic horsepower increases as more aggressive aftermarket solutions.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced upgrades for the K24 engine, focusing on increasing horsepower while maintaining reliability. Their approach includes implementing a high-flow intake system with a larger throttle body and redesigned intake manifold, optimizing camshaft profiles for improved valve timing, and utilizing lightweight forged pistons to reduce reciprocating mass[1]. Ford has also integrated direct fuel injection technology, allowing for more precise fuel delivery and improved combustion efficiency[2]. Additionally, they have developed a custom engine control unit (ECU) tuning strategy that maximizes power output across the RPM range while ensuring engine longevity[3].

Strengths: Comprehensive approach addressing multiple aspects of engine performance, backed by extensive R&D resources. Weaknesses: Potential increased complexity and cost compared to simpler upgrade methods.

Innovative K24 Mods

System and method for increasing output horsepower and efficiency in a motor

PatentInactiveUS20050189904A1

Innovation

- Operating an induction motor at a voltage and frequency greater than its rated values using a variable speed drive that provides enhanced output voltage and frequency, allowing the motor to operate in constant flux or constant volts/Hz mode, thereby increasing output horsepower and efficiency.

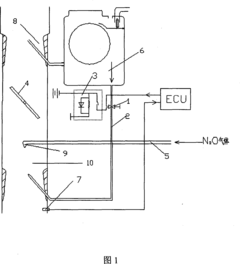

One-way thickening device for improving engine power performance

PatentInactiveCN201103495Y

Innovation

- Design a one-way enrichment device based on the nitrogen-oxygen supercharging system. By setting up an enrichment pipe under the throttle in the carburetor, the nitrous oxide gas is combined with the gasoline nozzle, and connected to the car through a sensor and an electric regulating valve. The driving computer ECU is connected to realize the enhancement of power output and fine control of gasoline injection amount.

Emissions Compliance

Emissions compliance is a critical consideration in the pursuit of increased horsepower for K24 engine enthusiasts. As performance modifications are implemented to boost power output, careful attention must be paid to ensure that the engine continues to meet regulatory standards for emissions. This challenge requires a delicate balance between performance enhancement and environmental responsibility.

The K24 engine, originally designed to meet specific emissions standards, may face increased scrutiny when modified for higher horsepower. Enthusiasts and aftermarket manufacturers must navigate a complex landscape of federal, state, and local regulations that govern vehicle emissions. These regulations typically set limits on various pollutants, including carbon monoxide, hydrocarbons, nitrogen oxides, and particulate matter.

One of the primary challenges in maintaining emissions compliance while increasing horsepower is the potential for increased fuel consumption. As more fuel is burned to achieve higher power outputs, there is a corresponding increase in emissions. This necessitates the implementation of advanced fuel management systems and engine control units (ECUs) that can optimize fuel delivery and combustion efficiency across a wider range of operating conditions.

Catalytic converters play a crucial role in emissions control, and upgrading these components is often necessary when boosting horsepower. High-flow catalytic converters can help maintain emissions compliance while minimizing restrictions on exhaust flow. However, care must be taken to ensure that these aftermarket components meet or exceed the original equipment manufacturer (OEM) specifications for emissions reduction.

Advanced engine management systems are essential for balancing performance gains with emissions compliance. Programmable ECUs allow for precise tuning of fuel injection, ignition timing, and other parameters to maximize power while minimizing emissions. Some aftermarket ECUs incorporate features specifically designed to help maintain compliance, such as closed-loop feedback systems that continuously monitor and adjust engine performance based on real-time emissions data.

Exhaust gas recirculation (EGR) systems, which help reduce nitrogen oxide emissions, may require modification or upgrading when increasing horsepower. Properly designed EGR systems can help maintain emissions compliance without significantly impacting performance gains. Similarly, positive crankcase ventilation (PCV) systems may need to be upgraded to handle increased blow-by gases associated with higher power outputs.

For enthusiasts seeking substantial horsepower increases, forced induction systems such as turbochargers or superchargers may be employed. These systems can significantly boost power output while potentially improving fuel efficiency and emissions performance when properly implemented. However, they also introduce additional complexities in terms of emissions compliance, requiring careful integration with other engine systems and potentially necessitating upgrades to fuel delivery and exhaust components.

Ultimately, achieving emissions compliance while boosting horsepower in K24 engines requires a holistic approach that considers the interplay between various engine systems and components. Enthusiasts and aftermarket manufacturers must stay informed about evolving emissions regulations and invest in research and development to create solutions that deliver both performance and environmental responsibility. By embracing innovative technologies and engineering practices, it is possible to achieve significant horsepower gains while maintaining compliance with emissions standards, ensuring that K24-powered vehicles can continue to be enjoyed on public roads for years to come.

The K24 engine, originally designed to meet specific emissions standards, may face increased scrutiny when modified for higher horsepower. Enthusiasts and aftermarket manufacturers must navigate a complex landscape of federal, state, and local regulations that govern vehicle emissions. These regulations typically set limits on various pollutants, including carbon monoxide, hydrocarbons, nitrogen oxides, and particulate matter.

One of the primary challenges in maintaining emissions compliance while increasing horsepower is the potential for increased fuel consumption. As more fuel is burned to achieve higher power outputs, there is a corresponding increase in emissions. This necessitates the implementation of advanced fuel management systems and engine control units (ECUs) that can optimize fuel delivery and combustion efficiency across a wider range of operating conditions.

Catalytic converters play a crucial role in emissions control, and upgrading these components is often necessary when boosting horsepower. High-flow catalytic converters can help maintain emissions compliance while minimizing restrictions on exhaust flow. However, care must be taken to ensure that these aftermarket components meet or exceed the original equipment manufacturer (OEM) specifications for emissions reduction.

Advanced engine management systems are essential for balancing performance gains with emissions compliance. Programmable ECUs allow for precise tuning of fuel injection, ignition timing, and other parameters to maximize power while minimizing emissions. Some aftermarket ECUs incorporate features specifically designed to help maintain compliance, such as closed-loop feedback systems that continuously monitor and adjust engine performance based on real-time emissions data.

Exhaust gas recirculation (EGR) systems, which help reduce nitrogen oxide emissions, may require modification or upgrading when increasing horsepower. Properly designed EGR systems can help maintain emissions compliance without significantly impacting performance gains. Similarly, positive crankcase ventilation (PCV) systems may need to be upgraded to handle increased blow-by gases associated with higher power outputs.

For enthusiasts seeking substantial horsepower increases, forced induction systems such as turbochargers or superchargers may be employed. These systems can significantly boost power output while potentially improving fuel efficiency and emissions performance when properly implemented. However, they also introduce additional complexities in terms of emissions compliance, requiring careful integration with other engine systems and potentially necessitating upgrades to fuel delivery and exhaust components.

Ultimately, achieving emissions compliance while boosting horsepower in K24 engines requires a holistic approach that considers the interplay between various engine systems and components. Enthusiasts and aftermarket manufacturers must stay informed about evolving emissions regulations and invest in research and development to create solutions that deliver both performance and environmental responsibility. By embracing innovative technologies and engineering practices, it is possible to achieve significant horsepower gains while maintaining compliance with emissions standards, ensuring that K24-powered vehicles can continue to be enjoyed on public roads for years to come.

Reliability Considerations

When considering K24 engine upgrades for boosting horsepower, reliability becomes a critical factor that enthusiasts must carefully evaluate. The K24 engine, known for its robustness in stock form, can handle moderate power increases without significant reliability concerns. However, as horsepower levels climb, the stress on various engine components increases exponentially, potentially compromising long-term durability.

One of the primary reliability considerations is the engine's internals. While the K24's stock bottom end is relatively strong, pushing beyond certain power thresholds may necessitate upgrades to components such as pistons, connecting rods, and crankshafts. These reinforced parts can better withstand the increased cylinder pressures and rotational forces associated with higher horsepower outputs.

The valvetrain is another area of concern when boosting power. Stock valve springs may struggle to control valve movement at higher RPMs, leading to potential valve float or even catastrophic valve-to-piston contact. Upgrading to stronger valve springs, along with lightweight titanium retainers, can help maintain proper valve control and timing under more demanding conditions.

Cooling system efficiency becomes increasingly important as power levels rise. The stock radiator and oil cooler may struggle to dissipate the additional heat generated by a high-output K24. Upgrading to a larger capacity radiator, installing an oil cooler, or even considering a water-methanol injection system can help maintain optimal operating temperatures and prevent heat-related engine damage.

Fuel system modifications are crucial for both performance and reliability. As horsepower increases, so does the engine's fuel demand. Upgrading fuel injectors, installing a higher-flow fuel pump, and ensuring proper fuel pressure regulation are essential steps to prevent lean conditions that could lead to engine failure.

The engine management system plays a vital role in maintaining reliability while extracting maximum performance. A properly tuned ECU can optimize fuel and ignition timing for increased power while still protecting the engine from harmful conditions such as detonation or over-revving.

Lastly, regular maintenance becomes even more critical with a modified K24 engine. More frequent oil changes, using high-quality synthetic oils, and closely monitoring engine parameters can help identify potential issues before they lead to catastrophic failure. Enthusiasts should also consider the impact of their driving habits and usage patterns on long-term reliability, as track use or aggressive street driving can accelerate wear on even well-built engines.

One of the primary reliability considerations is the engine's internals. While the K24's stock bottom end is relatively strong, pushing beyond certain power thresholds may necessitate upgrades to components such as pistons, connecting rods, and crankshafts. These reinforced parts can better withstand the increased cylinder pressures and rotational forces associated with higher horsepower outputs.

The valvetrain is another area of concern when boosting power. Stock valve springs may struggle to control valve movement at higher RPMs, leading to potential valve float or even catastrophic valve-to-piston contact. Upgrading to stronger valve springs, along with lightweight titanium retainers, can help maintain proper valve control and timing under more demanding conditions.

Cooling system efficiency becomes increasingly important as power levels rise. The stock radiator and oil cooler may struggle to dissipate the additional heat generated by a high-output K24. Upgrading to a larger capacity radiator, installing an oil cooler, or even considering a water-methanol injection system can help maintain optimal operating temperatures and prevent heat-related engine damage.

Fuel system modifications are crucial for both performance and reliability. As horsepower increases, so does the engine's fuel demand. Upgrading fuel injectors, installing a higher-flow fuel pump, and ensuring proper fuel pressure regulation are essential steps to prevent lean conditions that could lead to engine failure.

The engine management system plays a vital role in maintaining reliability while extracting maximum performance. A properly tuned ECU can optimize fuel and ignition timing for increased power while still protecting the engine from harmful conditions such as detonation or over-revving.

Lastly, regular maintenance becomes even more critical with a modified K24 engine. More frequent oil changes, using high-quality synthetic oils, and closely monitoring engine parameters can help identify potential issues before they lead to catastrophic failure. Enthusiasts should also consider the impact of their driving habits and usage patterns on long-term reliability, as track use or aggressive street driving can accelerate wear on even well-built engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!