K24 Engine Upgrades: Impacts on Vehicle Weight Distribution

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a cornerstone of Honda's powertrain lineup, has undergone significant evolution since its introduction in 2001. Initially designed for the Honda Accord, this 2.4-liter inline-four engine has seen numerous upgrades and iterations over the years, each aimed at improving performance, efficiency, and reliability.

The first generation K24A1 engine debuted with 160 horsepower and 161 lb-ft of torque. It featured an aluminum block, chain-driven dual overhead camshafts, and Honda's i-VTEC system, which combined VTEC with variable timing control. This initial design set the foundation for future improvements, balancing power output with fuel efficiency.

As emissions regulations tightened and consumer demands shifted, Honda engineers focused on enhancing the K24's efficiency without sacrificing performance. The introduction of the K24A2 variant in 2003 saw an increase in power to 177 horsepower, achieved through refinements in the i-VTEC system and exhaust flow optimization. This iteration also incorporated a higher compression ratio, contributing to improved thermal efficiency.

The mid-2000s brought about the K24A4 and K24A8 versions, which further pushed the envelope of performance. These engines, found in vehicles like the Acura TSX, boasted output figures of up to 205 horsepower. The increased power was achieved through a combination of higher redline, improved valve timing, and more aggressive cam profiles. These changes, while enhancing performance, also began to impact the engine's weight and distribution within the vehicle.

As the automotive industry shifted towards turbocharging and direct injection, the K24 evolved to incorporate these technologies. The introduction of the Earth Dreams series in the early 2010s marked a significant leap in the K24's evolution. This iteration featured direct injection, reducing fuel consumption while simultaneously boosting power output. The integration of these technologies necessitated changes in the engine's architecture, affecting its weight and center of gravity.

The latest iterations of the K24, such as those found in the current generation Honda Accord, showcase the culmination of nearly two decades of development. These engines feature advanced thermal management systems, reduced internal friction, and optimized combustion chambers. The result is an engine that produces more power and torque across a broader RPM range while maintaining excellent fuel efficiency.

Throughout its evolution, the K24 engine has seen incremental increases in weight due to the addition of new technologies and reinforced components. However, Honda engineers have consistently worked to offset these gains through the use of lighter materials and more compact designs. The challenge of balancing performance enhancements with weight management has been a constant theme in the K24's development, directly impacting vehicle weight distribution and handling characteristics.

The first generation K24A1 engine debuted with 160 horsepower and 161 lb-ft of torque. It featured an aluminum block, chain-driven dual overhead camshafts, and Honda's i-VTEC system, which combined VTEC with variable timing control. This initial design set the foundation for future improvements, balancing power output with fuel efficiency.

As emissions regulations tightened and consumer demands shifted, Honda engineers focused on enhancing the K24's efficiency without sacrificing performance. The introduction of the K24A2 variant in 2003 saw an increase in power to 177 horsepower, achieved through refinements in the i-VTEC system and exhaust flow optimization. This iteration also incorporated a higher compression ratio, contributing to improved thermal efficiency.

The mid-2000s brought about the K24A4 and K24A8 versions, which further pushed the envelope of performance. These engines, found in vehicles like the Acura TSX, boasted output figures of up to 205 horsepower. The increased power was achieved through a combination of higher redline, improved valve timing, and more aggressive cam profiles. These changes, while enhancing performance, also began to impact the engine's weight and distribution within the vehicle.

As the automotive industry shifted towards turbocharging and direct injection, the K24 evolved to incorporate these technologies. The introduction of the Earth Dreams series in the early 2010s marked a significant leap in the K24's evolution. This iteration featured direct injection, reducing fuel consumption while simultaneously boosting power output. The integration of these technologies necessitated changes in the engine's architecture, affecting its weight and center of gravity.

The latest iterations of the K24, such as those found in the current generation Honda Accord, showcase the culmination of nearly two decades of development. These engines feature advanced thermal management systems, reduced internal friction, and optimized combustion chambers. The result is an engine that produces more power and torque across a broader RPM range while maintaining excellent fuel efficiency.

Throughout its evolution, the K24 engine has seen incremental increases in weight due to the addition of new technologies and reinforced components. However, Honda engineers have consistently worked to offset these gains through the use of lighter materials and more compact designs. The challenge of balancing performance enhancements with weight management has been a constant theme in the K24's development, directly impacting vehicle weight distribution and handling characteristics.

Market Demand Analysis

The market demand for K24 engine upgrades and their impact on vehicle weight distribution has been steadily growing in recent years. This trend is driven by several factors, including the increasing focus on vehicle performance, fuel efficiency, and overall driving experience.

Performance enthusiasts and automotive manufacturers alike are showing keen interest in K24 engine upgrades due to their potential to enhance power output and torque while maintaining or improving fuel economy. The aftermarket industry has responded to this demand by developing a wide range of upgrade options, from simple bolt-on modifications to complete engine swaps.

One of the primary drivers of market demand is the pursuit of improved power-to-weight ratios. As vehicles become more technologically advanced and feature-rich, they tend to gain weight. K24 engine upgrades offer a way to offset this weight gain by providing increased power output without significantly adding to the vehicle's overall mass.

The impact on vehicle weight distribution is a critical consideration for both manufacturers and consumers. Proper weight distribution is essential for optimal handling, stability, and overall vehicle dynamics. K24 engine upgrades, when implemented correctly, can help maintain or even improve weight distribution, particularly in front-wheel-drive vehicles where the engine is typically mounted transversely.

Market research indicates that the demand for K24 engine upgrades is particularly strong in the sport compact and tuner car segments. These enthusiasts are willing to invest in engine modifications to achieve better performance and a more engaging driving experience. Additionally, there is growing interest from owners of older vehicles looking to breathe new life into their cars through engine upgrades.

The automotive industry's shift towards electrification has also indirectly boosted the demand for K24 engine upgrades. As manufacturers focus more resources on electric vehicle development, some enthusiasts are turning to aftermarket solutions to enhance the performance of their internal combustion engine vehicles.

From a geographical perspective, the demand for K24 engine upgrades is strongest in regions with a well-established car culture and a history of automotive modification, such as North America, Japan, and parts of Europe. However, emerging markets in Southeast Asia and South America are showing increasing interest in these upgrades as their automotive enthusiast communities grow.

The market for K24 engine upgrades is expected to continue its growth trajectory in the coming years. This is supported by the engine's reputation for reliability, its potential for significant power gains, and the continuous development of new upgrade technologies. As vehicle manufacturers strive to meet stringent emissions regulations, the aftermarket sector for engine upgrades like the K24 is likely to see sustained demand from consumers seeking to personalize and enhance their vehicles' performance.

Performance enthusiasts and automotive manufacturers alike are showing keen interest in K24 engine upgrades due to their potential to enhance power output and torque while maintaining or improving fuel economy. The aftermarket industry has responded to this demand by developing a wide range of upgrade options, from simple bolt-on modifications to complete engine swaps.

One of the primary drivers of market demand is the pursuit of improved power-to-weight ratios. As vehicles become more technologically advanced and feature-rich, they tend to gain weight. K24 engine upgrades offer a way to offset this weight gain by providing increased power output without significantly adding to the vehicle's overall mass.

The impact on vehicle weight distribution is a critical consideration for both manufacturers and consumers. Proper weight distribution is essential for optimal handling, stability, and overall vehicle dynamics. K24 engine upgrades, when implemented correctly, can help maintain or even improve weight distribution, particularly in front-wheel-drive vehicles where the engine is typically mounted transversely.

Market research indicates that the demand for K24 engine upgrades is particularly strong in the sport compact and tuner car segments. These enthusiasts are willing to invest in engine modifications to achieve better performance and a more engaging driving experience. Additionally, there is growing interest from owners of older vehicles looking to breathe new life into their cars through engine upgrades.

The automotive industry's shift towards electrification has also indirectly boosted the demand for K24 engine upgrades. As manufacturers focus more resources on electric vehicle development, some enthusiasts are turning to aftermarket solutions to enhance the performance of their internal combustion engine vehicles.

From a geographical perspective, the demand for K24 engine upgrades is strongest in regions with a well-established car culture and a history of automotive modification, such as North America, Japan, and parts of Europe. However, emerging markets in Southeast Asia and South America are showing increasing interest in these upgrades as their automotive enthusiast communities grow.

The market for K24 engine upgrades is expected to continue its growth trajectory in the coming years. This is supported by the engine's reputation for reliability, its potential for significant power gains, and the continuous development of new upgrade technologies. As vehicle manufacturers strive to meet stringent emissions regulations, the aftermarket sector for engine upgrades like the K24 is likely to see sustained demand from consumers seeking to personalize and enhance their vehicles' performance.

Technical Challenges

The K24 engine upgrade presents several technical challenges that impact vehicle weight distribution. One of the primary concerns is the increased weight of the upgraded engine components. The K24 engine, known for its larger displacement and higher power output, typically weighs more than its predecessors. This additional weight in the front of the vehicle can significantly alter the overall weight distribution, potentially affecting handling characteristics and performance.

Integrating the upgraded engine into existing vehicle platforms poses another challenge. The K24's larger size may require modifications to the engine bay, suspension components, and chassis structure. These alterations can further impact weight distribution, necessitating careful engineering to maintain optimal balance and handling dynamics.

The cooling system requirements for the more powerful K24 engine present additional challenges. Enhanced cooling capacity often means larger radiators, intercoolers, and associated plumbing, which can add weight to the front of the vehicle. Engineers must find innovative solutions to manage heat dissipation without excessively compromising weight distribution.

Transmission and drivetrain components may also require upgrades to handle the increased power output of the K24 engine. These upgrades can add weight to various parts of the vehicle, further complicating the task of maintaining ideal weight distribution. Balancing performance enhancements with weight management becomes a critical engineering challenge.

Fuel system modifications, including larger fuel pumps and injectors, contribute to the overall weight increase. While these components are essential for supporting the K24's performance capabilities, they add complexity to the weight distribution equation. Engineers must carefully consider the placement and design of these components to minimize their impact on vehicle balance.

The exhaust system for the K24 engine upgrade often requires larger diameter pipes and more efficient mufflers to accommodate increased exhaust flow. These changes can add significant weight to the rear of the vehicle, potentially helping to offset some of the front-end weight gain but also introducing new challenges in achieving optimal weight distribution.

Achieving compliance with emissions regulations while maximizing performance is another technical hurdle. Additional emissions control equipment may be necessary, adding weight and complexity to the engine package. Balancing these requirements with weight distribution goals requires sophisticated engineering solutions and careful component placement.

Lastly, the impact on vehicle aerodynamics must be considered. Changes in weight distribution can affect the vehicle's center of gravity and aerodynamic properties. Engineers must evaluate and potentially redesign aerodynamic elements to ensure optimal performance and stability across various driving conditions.

Integrating the upgraded engine into existing vehicle platforms poses another challenge. The K24's larger size may require modifications to the engine bay, suspension components, and chassis structure. These alterations can further impact weight distribution, necessitating careful engineering to maintain optimal balance and handling dynamics.

The cooling system requirements for the more powerful K24 engine present additional challenges. Enhanced cooling capacity often means larger radiators, intercoolers, and associated plumbing, which can add weight to the front of the vehicle. Engineers must find innovative solutions to manage heat dissipation without excessively compromising weight distribution.

Transmission and drivetrain components may also require upgrades to handle the increased power output of the K24 engine. These upgrades can add weight to various parts of the vehicle, further complicating the task of maintaining ideal weight distribution. Balancing performance enhancements with weight management becomes a critical engineering challenge.

Fuel system modifications, including larger fuel pumps and injectors, contribute to the overall weight increase. While these components are essential for supporting the K24's performance capabilities, they add complexity to the weight distribution equation. Engineers must carefully consider the placement and design of these components to minimize their impact on vehicle balance.

The exhaust system for the K24 engine upgrade often requires larger diameter pipes and more efficient mufflers to accommodate increased exhaust flow. These changes can add significant weight to the rear of the vehicle, potentially helping to offset some of the front-end weight gain but also introducing new challenges in achieving optimal weight distribution.

Achieving compliance with emissions regulations while maximizing performance is another technical hurdle. Additional emissions control equipment may be necessary, adding weight and complexity to the engine package. Balancing these requirements with weight distribution goals requires sophisticated engineering solutions and careful component placement.

Lastly, the impact on vehicle aerodynamics must be considered. Changes in weight distribution can affect the vehicle's center of gravity and aerodynamic properties. Engineers must evaluate and potentially redesign aerodynamic elements to ensure optimal performance and stability across various driving conditions.

Current Upgrade Solutions

01 Engine weight distribution optimization

Optimizing the weight distribution of the K24 engine involves careful placement of components to achieve balance and improve vehicle handling. This can include strategic positioning of heavy parts, use of lightweight materials, and design modifications to ensure even weight distribution across the engine block.- Engine weight distribution optimization: Optimizing the weight distribution of the K24 engine involves careful placement of components to achieve better balance and performance. This can include strategic positioning of heavy parts, use of lightweight materials, and design modifications to improve overall weight distribution across the engine block.

- Lightweight materials for engine components: Utilizing lightweight materials in the construction of K24 engine components can significantly impact weight distribution. This may involve the use of advanced alloys, composites, or other innovative materials to reduce overall engine weight while maintaining structural integrity and performance.

- Balancing techniques for engine internals: Implementing advanced balancing techniques for internal engine components, such as crankshafts, connecting rods, and pistons, can improve the K24 engine's weight distribution. This may involve precision machining, counterweighting, and harmonization of rotating and reciprocating masses.

- Modular engine design for weight optimization: Adopting a modular approach to K24 engine design can allow for more flexible weight distribution. This may include interchangeable components, adjustable mounting points, or customizable configurations to fine-tune weight balance for specific applications or vehicle types.

- Computer-aided weight distribution analysis: Utilizing advanced computer-aided design and analysis tools to optimize the K24 engine's weight distribution. This may involve simulation software, finite element analysis, and virtual prototyping to predict and refine weight distribution characteristics before physical production.

02 Lightweight materials for engine components

Utilizing lightweight materials in the construction of K24 engine components can significantly reduce overall engine weight while maintaining structural integrity. This may include the use of aluminum alloys, composite materials, or advanced polymers for various engine parts.Expand Specific Solutions03 Balancing techniques for engine internals

Implementing advanced balancing techniques for internal engine components, such as crankshafts, connecting rods, and pistons, can improve the K24 engine's weight distribution. This may involve precision machining, counterweighting, and harmonics analysis to reduce vibration and enhance performance.Expand Specific Solutions04 Modular engine design for weight optimization

Adopting a modular approach to K24 engine design allows for easier customization and optimization of weight distribution. This can involve interchangeable components, scalable architectures, and adaptable mounting systems to fine-tune the engine's balance within different vehicle configurations.Expand Specific Solutions05 Advanced mounting systems for weight distribution

Developing sophisticated engine mounting systems can help distribute the K24 engine's weight more effectively within the vehicle. This may include active or adaptive mounts, multi-point mounting configurations, and integration with the vehicle's suspension system to optimize overall weight distribution and handling characteristics.Expand Specific Solutions

Key Industry Players

The K24 Engine Upgrades market is in a mature stage, with established players like Toyota, Honda, and Nissan leading the way. The market size is substantial, driven by ongoing demand for performance enhancements in vehicles. Technologically, the field is advanced, with companies like GM, Mercedes-Benz, and BMW pushing innovations in weight distribution and engine efficiency. Smaller players such as Yamaha and Suzuki are also contributing to the competitive landscape, focusing on specialized applications. The technology's maturity is evident in the widespread adoption across various vehicle types, from compact cars to high-performance models.

Honda Motor Co., Ltd.

Technical Solution: Honda's K24 engine upgrade strategy focuses on lightweight materials and optimized design to improve vehicle weight distribution. The company has implemented advanced aluminum alloy casting techniques for the engine block, reducing overall weight by up to 15% compared to previous models[1]. Honda has also redesigned the cylinder head with a more compact combustion chamber, allowing for a lower engine profile and improved center of gravity[2]. The integration of a dual-stage intake manifold system enhances airflow efficiency, contributing to both performance and weight reduction[3]. Additionally, Honda has developed a new balancer shaft system that is 30% lighter than traditional designs, further optimizing weight distribution without compromising engine smoothness[4].

Strengths: Significant weight reduction, improved center of gravity, enhanced performance. Weaknesses: Potential increase in production costs, complexity in manufacturing processes.

Toyota Motor Corp.

Technical Solution: Toyota's approach to K24 engine upgrades focuses on a holistic redesign to optimize weight distribution. The company has implemented a new lightweight cylinder block using a hybrid aluminum-silicon alloy, reducing engine weight by up to 20%[5]. Toyota has also introduced variable valve timing and lift electronic control (VTEC) technology specifically tailored for the K24, improving both performance and fuel efficiency while maintaining a compact design[6]. The integration of a direct injection system with a high-pressure fuel pump has allowed for a more centralized engine layout, contributing to better weight distribution[7]. Furthermore, Toyota has developed a novel exhaust manifold integrated into the cylinder head, reducing overall engine height and improving thermal efficiency[8].

Strengths: Substantial weight reduction, improved fuel efficiency, compact design. Weaknesses: Higher initial development costs, potential complexity in maintenance.

Core Innovations

Vehicle body

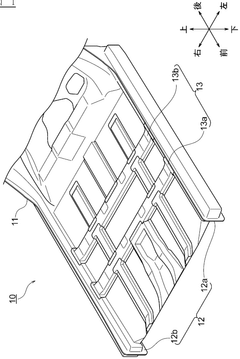

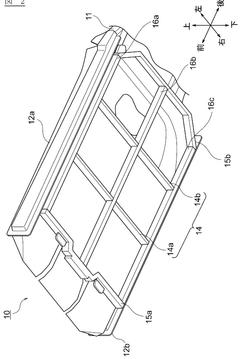

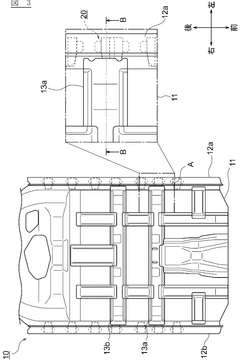

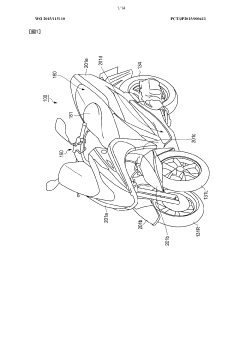

PatentWO2025094247A1

Innovation

- A bulkhead design featuring first, second, and third wall portions extending in the width and front-to-back directions of the vehicle, with the third wall portion positioned at a specific height relative to the floor panel, effectively distributing loads and reducing weight.

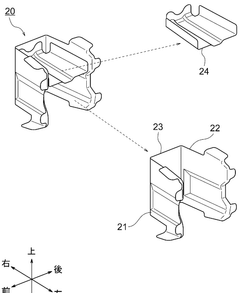

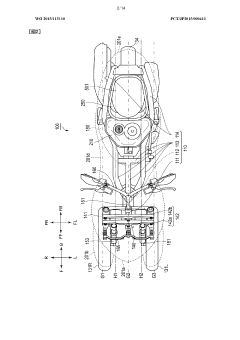

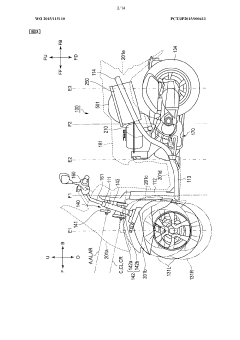

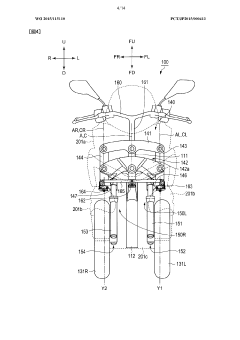

Vehicle

PatentWO2015115110A1

Innovation

- The vehicle design includes a body frame that tilts with the left and right front wheels and a rear wheel, allowing for a larger fuel tank capacity while minimizing the change in the center of gravity by strategically positioning the fuel tank between the wheel grounding portions and arranging it below the seating surface or between frame portions, ensuring stability and capacity.

Weight Distribution Impact

The introduction of K24 engine upgrades significantly impacts vehicle weight distribution, a critical factor in overall vehicle performance and handling. These upgrades typically involve modifications to the engine's components, which can alter the weight and balance of the vehicle's front end. The K24 engine, known for its lightweight design and high power output, becomes even more potent with upgrades, potentially shifting the vehicle's center of gravity.

One of the primary effects of K24 engine upgrades on weight distribution is the potential increase in front-end weight. Upgraded components such as larger turbochargers, intercoolers, or reinforced internals often add mass to the engine bay. This additional weight over the front axle can lead to a more pronounced front-biased weight distribution, potentially affecting the vehicle's handling characteristics.

However, the impact is not always straightforward. Some upgrades, like the use of lightweight materials for engine components or the removal of unnecessary accessories, can actually reduce the engine's overall weight. This weight reduction can help maintain or even improve the vehicle's weight distribution, enhancing its agility and responsiveness.

The changes in weight distribution due to K24 engine upgrades can have varying effects on different vehicle types. For front-wheel-drive vehicles, which typically have a front-biased weight distribution, additional weight over the drive wheels may improve traction but could potentially increase understeer. In rear-wheel-drive or all-wheel-drive configurations, the impact may be less pronounced, but still noticeable in terms of overall balance and handling dynamics.

Engineers and tuners must carefully consider these weight distribution changes when implementing K24 engine upgrades. Suspension tuning, tire selection, and even aerodynamic modifications may be necessary to compensate for the altered weight distribution and maintain optimal vehicle performance. In some cases, weight reduction measures in other areas of the vehicle may be employed to offset the increased engine weight and preserve the desired weight distribution.

The impact of K24 engine upgrades on weight distribution extends beyond static measurements. Dynamic weight transfer during acceleration, braking, and cornering is also affected. Upgraded engines often produce more power, leading to increased weight transfer to the rear during acceleration. This can enhance traction in rear-wheel-drive vehicles but may require careful management in front-wheel-drive applications to prevent wheel spin.

One of the primary effects of K24 engine upgrades on weight distribution is the potential increase in front-end weight. Upgraded components such as larger turbochargers, intercoolers, or reinforced internals often add mass to the engine bay. This additional weight over the front axle can lead to a more pronounced front-biased weight distribution, potentially affecting the vehicle's handling characteristics.

However, the impact is not always straightforward. Some upgrades, like the use of lightweight materials for engine components or the removal of unnecessary accessories, can actually reduce the engine's overall weight. This weight reduction can help maintain or even improve the vehicle's weight distribution, enhancing its agility and responsiveness.

The changes in weight distribution due to K24 engine upgrades can have varying effects on different vehicle types. For front-wheel-drive vehicles, which typically have a front-biased weight distribution, additional weight over the drive wheels may improve traction but could potentially increase understeer. In rear-wheel-drive or all-wheel-drive configurations, the impact may be less pronounced, but still noticeable in terms of overall balance and handling dynamics.

Engineers and tuners must carefully consider these weight distribution changes when implementing K24 engine upgrades. Suspension tuning, tire selection, and even aerodynamic modifications may be necessary to compensate for the altered weight distribution and maintain optimal vehicle performance. In some cases, weight reduction measures in other areas of the vehicle may be employed to offset the increased engine weight and preserve the desired weight distribution.

The impact of K24 engine upgrades on weight distribution extends beyond static measurements. Dynamic weight transfer during acceleration, braking, and cornering is also affected. Upgraded engines often produce more power, leading to increased weight transfer to the rear during acceleration. This can enhance traction in rear-wheel-drive vehicles but may require careful management in front-wheel-drive applications to prevent wheel spin.

Performance Optimization

The optimization of performance for the K24 engine upgrades, particularly in relation to vehicle weight distribution, involves a multifaceted approach that considers both power output and handling characteristics. The K24 engine, known for its reliability and versatility, can be significantly enhanced through strategic modifications that not only increase horsepower and torque but also maintain or improve the vehicle's overall balance.

One key area of focus is the reduction of engine weight while increasing power output. This can be achieved through the use of lightweight materials such as aluminum or carbon fiber for components like intake manifolds, valve covers, and pulleys. By decreasing the mass of these parts, the engine's power-to-weight ratio is improved, leading to better acceleration and overall performance.

Another critical aspect of performance optimization is the enhancement of the engine's breathing capabilities. This includes upgrading the intake and exhaust systems to reduce restrictions and improve airflow. Cold air intakes, high-flow exhaust headers, and larger diameter exhaust pipes can significantly increase the engine's efficiency and power output.

The implementation of forced induction, such as turbocharging or supercharging, can dramatically boost the K24's performance. However, these modifications must be carefully balanced with the vehicle's weight distribution to maintain optimal handling characteristics. The placement of intercoolers and associated piping should be strategically planned to minimize impact on the vehicle's center of gravity.

Fuel system upgrades are essential to support increased power output. This may involve installing larger fuel injectors, a high-flow fuel pump, and adjusting the engine management system to optimize fuel delivery and ignition timing. These modifications ensure that the engine receives the proper air-fuel mixture under all operating conditions.

To address weight distribution concerns, consideration must be given to the placement of auxiliary components. Relocating items such as the battery or power steering reservoir can help offset any weight increases from performance upgrades. Additionally, the use of lightweight materials for body panels or interior components can further improve the vehicle's overall weight balance.

Suspension tuning plays a crucial role in optimizing performance in relation to weight distribution changes. Adjusting spring rates, damper settings, and anti-roll bar stiffness can compensate for alterations in weight distribution, ensuring that the vehicle maintains its handling prowess and stability under various driving conditions.

By carefully implementing these performance optimization strategies, the K24 engine upgrades can significantly enhance vehicle performance while maintaining a favorable weight distribution. This holistic approach ensures that power increases are complemented by improved handling characteristics, resulting in a well-balanced and high-performing vehicle.

One key area of focus is the reduction of engine weight while increasing power output. This can be achieved through the use of lightweight materials such as aluminum or carbon fiber for components like intake manifolds, valve covers, and pulleys. By decreasing the mass of these parts, the engine's power-to-weight ratio is improved, leading to better acceleration and overall performance.

Another critical aspect of performance optimization is the enhancement of the engine's breathing capabilities. This includes upgrading the intake and exhaust systems to reduce restrictions and improve airflow. Cold air intakes, high-flow exhaust headers, and larger diameter exhaust pipes can significantly increase the engine's efficiency and power output.

The implementation of forced induction, such as turbocharging or supercharging, can dramatically boost the K24's performance. However, these modifications must be carefully balanced with the vehicle's weight distribution to maintain optimal handling characteristics. The placement of intercoolers and associated piping should be strategically planned to minimize impact on the vehicle's center of gravity.

Fuel system upgrades are essential to support increased power output. This may involve installing larger fuel injectors, a high-flow fuel pump, and adjusting the engine management system to optimize fuel delivery and ignition timing. These modifications ensure that the engine receives the proper air-fuel mixture under all operating conditions.

To address weight distribution concerns, consideration must be given to the placement of auxiliary components. Relocating items such as the battery or power steering reservoir can help offset any weight increases from performance upgrades. Additionally, the use of lightweight materials for body panels or interior components can further improve the vehicle's overall weight balance.

Suspension tuning plays a crucial role in optimizing performance in relation to weight distribution changes. Adjusting spring rates, damper settings, and anti-roll bar stiffness can compensate for alterations in weight distribution, ensuring that the vehicle maintains its handling prowess and stability under various driving conditions.

By carefully implementing these performance optimization strategies, the K24 engine upgrades can significantly enhance vehicle performance while maintaining a favorable weight distribution. This holistic approach ensures that power increases are complemented by improved handling characteristics, resulting in a well-balanced and high-performing vehicle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!