LDPE in Agriculture: Solutions for Crop Protection

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE in Agriculture: Evolution and Objectives

Low-density polyethylene (LDPE) has played a significant role in agricultural practices since its introduction in the 1930s. Initially developed as an insulation material, LDPE quickly found applications in agriculture due to its versatility, durability, and cost-effectiveness. The evolution of LDPE in agriculture has been marked by continuous improvements in material properties and manufacturing techniques, leading to its widespread adoption in crop protection solutions.

In the early stages, LDPE was primarily used for simple applications such as greenhouse coverings and mulch films. These basic implementations demonstrated the material's potential to create controlled environments for plant growth and protect crops from adverse weather conditions. As research progressed, agricultural scientists and polymer engineers collaborated to enhance LDPE's properties, focusing on UV stability, light transmission, and thermal retention capabilities.

The 1960s and 1970s saw a significant expansion in LDPE applications for agriculture. Innovations in film extrusion technology allowed for the production of thinner, more specialized films tailored for specific crop protection needs. This period marked the introduction of LDPE-based drip irrigation systems, which revolutionized water management in agriculture, especially in arid regions.

By the 1980s and 1990s, environmental concerns began to shape the development of LDPE in agriculture. Researchers focused on creating biodegradable variants and improving recycling processes to address the growing issue of plastic waste in farmlands. This shift in focus led to the development of more eco-friendly LDPE formulations and the exploration of bio-based alternatives.

The turn of the millennium brought about a new era of precision agriculture, where LDPE films were engineered to deliver specific agrochemicals or to create tailored microclimates for crops. Advanced manufacturing techniques enabled the production of multi-layer films with enhanced barrier properties and controlled permeability, further expanding the range of crop protection solutions.

Today, the objectives for LDPE in agriculture are multifaceted. Researchers and industry leaders are striving to develop LDPE products that not only provide superior crop protection but also address sustainability concerns. Key goals include improving the material's biodegradability without compromising performance, enhancing its ability to mitigate climate change effects on crops, and integrating smart technologies for real-time monitoring and response to environmental conditions.

Looking ahead, the future of LDPE in agriculture aims to achieve a balance between crop protection efficiency and environmental stewardship. Objectives include developing fully recyclable or compostable LDPE products, creating films with adaptive properties that respond to changing environmental conditions, and integrating nanotechnology to enhance the material's functionality in pest control and nutrient delivery.

In the early stages, LDPE was primarily used for simple applications such as greenhouse coverings and mulch films. These basic implementations demonstrated the material's potential to create controlled environments for plant growth and protect crops from adverse weather conditions. As research progressed, agricultural scientists and polymer engineers collaborated to enhance LDPE's properties, focusing on UV stability, light transmission, and thermal retention capabilities.

The 1960s and 1970s saw a significant expansion in LDPE applications for agriculture. Innovations in film extrusion technology allowed for the production of thinner, more specialized films tailored for specific crop protection needs. This period marked the introduction of LDPE-based drip irrigation systems, which revolutionized water management in agriculture, especially in arid regions.

By the 1980s and 1990s, environmental concerns began to shape the development of LDPE in agriculture. Researchers focused on creating biodegradable variants and improving recycling processes to address the growing issue of plastic waste in farmlands. This shift in focus led to the development of more eco-friendly LDPE formulations and the exploration of bio-based alternatives.

The turn of the millennium brought about a new era of precision agriculture, where LDPE films were engineered to deliver specific agrochemicals or to create tailored microclimates for crops. Advanced manufacturing techniques enabled the production of multi-layer films with enhanced barrier properties and controlled permeability, further expanding the range of crop protection solutions.

Today, the objectives for LDPE in agriculture are multifaceted. Researchers and industry leaders are striving to develop LDPE products that not only provide superior crop protection but also address sustainability concerns. Key goals include improving the material's biodegradability without compromising performance, enhancing its ability to mitigate climate change effects on crops, and integrating smart technologies for real-time monitoring and response to environmental conditions.

Looking ahead, the future of LDPE in agriculture aims to achieve a balance between crop protection efficiency and environmental stewardship. Objectives include developing fully recyclable or compostable LDPE products, creating films with adaptive properties that respond to changing environmental conditions, and integrating nanotechnology to enhance the material's functionality in pest control and nutrient delivery.

Market Analysis for LDPE Crop Protection Solutions

The global market for LDPE crop protection solutions has experienced significant growth in recent years, driven by the increasing demand for sustainable and efficient agricultural practices. As farmers seek to maximize crop yields while minimizing environmental impact, LDPE-based products have emerged as a versatile and cost-effective solution for various crop protection applications.

The market for LDPE crop protection solutions can be segmented into several key categories, including mulch films, greenhouse covers, and protective packaging for agricultural products. Mulch films represent the largest segment, with a growing adoption rate among farmers worldwide. These films help conserve soil moisture, suppress weed growth, and regulate soil temperature, leading to improved crop yields and reduced pesticide use.

Geographically, Asia-Pacific dominates the LDPE crop protection market, with China and India being the major contributors. The region's large agricultural sector, coupled with increasing government support for modern farming techniques, has fueled the demand for LDPE-based solutions. North America and Europe follow as significant markets, driven by the adoption of precision agriculture and sustainable farming practices.

The market is characterized by a mix of established players and new entrants, creating a competitive landscape. Major companies in the LDPE crop protection sector include Dow Chemical Company, BASF SE, and Berry Global Group, among others. These companies are investing heavily in research and development to improve product performance and sustainability, addressing growing environmental concerns related to plastic use in agriculture.

One of the key trends shaping the market is the development of biodegradable LDPE alternatives. As environmental regulations become stricter, manufacturers are focusing on creating products that offer the benefits of traditional LDPE while reducing long-term environmental impact. This shift is expected to open new opportunities in the market, particularly in regions with stringent environmental policies.

The COVID-19 pandemic has had a mixed impact on the LDPE crop protection market. While disruptions in supply chains initially caused some setbacks, the increased focus on food security and self-sufficiency has led to a renewed interest in agricultural technologies, including LDPE-based solutions.

Looking ahead, the market for LDPE crop protection solutions is projected to continue its growth trajectory. Factors such as population growth, climate change, and the need for sustainable farming practices are expected to drive demand. However, challenges such as plastic waste management and the push for organic farming methods may influence market dynamics in the coming years.

The market for LDPE crop protection solutions can be segmented into several key categories, including mulch films, greenhouse covers, and protective packaging for agricultural products. Mulch films represent the largest segment, with a growing adoption rate among farmers worldwide. These films help conserve soil moisture, suppress weed growth, and regulate soil temperature, leading to improved crop yields and reduced pesticide use.

Geographically, Asia-Pacific dominates the LDPE crop protection market, with China and India being the major contributors. The region's large agricultural sector, coupled with increasing government support for modern farming techniques, has fueled the demand for LDPE-based solutions. North America and Europe follow as significant markets, driven by the adoption of precision agriculture and sustainable farming practices.

The market is characterized by a mix of established players and new entrants, creating a competitive landscape. Major companies in the LDPE crop protection sector include Dow Chemical Company, BASF SE, and Berry Global Group, among others. These companies are investing heavily in research and development to improve product performance and sustainability, addressing growing environmental concerns related to plastic use in agriculture.

One of the key trends shaping the market is the development of biodegradable LDPE alternatives. As environmental regulations become stricter, manufacturers are focusing on creating products that offer the benefits of traditional LDPE while reducing long-term environmental impact. This shift is expected to open new opportunities in the market, particularly in regions with stringent environmental policies.

The COVID-19 pandemic has had a mixed impact on the LDPE crop protection market. While disruptions in supply chains initially caused some setbacks, the increased focus on food security and self-sufficiency has led to a renewed interest in agricultural technologies, including LDPE-based solutions.

Looking ahead, the market for LDPE crop protection solutions is projected to continue its growth trajectory. Factors such as population growth, climate change, and the need for sustainable farming practices are expected to drive demand. However, challenges such as plastic waste management and the push for organic farming methods may influence market dynamics in the coming years.

Current LDPE Technologies and Challenges in Agriculture

Low-density polyethylene (LDPE) has become an integral part of modern agricultural practices, particularly in crop protection. The current LDPE technologies in agriculture primarily focus on creating protective barriers, enhancing crop yield, and improving resource efficiency. One of the most prevalent applications is in the form of plastic mulch films, which are used to cover soil around plants. These films help in moisture retention, weed suppression, and temperature regulation, creating a more favorable microclimate for crop growth.

Another significant use of LDPE in agriculture is in greenhouse coverings. These structures provide a controlled environment for plant growth, extending growing seasons and protecting crops from adverse weather conditions. LDPE films used in greenhouses are engineered to allow optimal light transmission while maintaining thermal insulation properties.

Drip irrigation systems, which utilize LDPE tubing, represent another crucial application. These systems enable precise water and nutrient delivery directly to plant roots, significantly reducing water consumption and improving nutrient uptake efficiency. The flexibility and durability of LDPE make it an ideal material for these irrigation components.

Despite its widespread use, the application of LDPE in agriculture faces several challenges. One of the primary concerns is environmental sustainability. The accumulation of plastic waste in agricultural soils poses a significant threat to soil health and ecosystem balance. Microplastic pollution resulting from the degradation of LDPE films is an emerging issue that requires immediate attention.

Durability and longevity of LDPE products in agricultural settings present another challenge. Exposure to UV radiation, temperature fluctuations, and mechanical stress can lead to premature degradation of LDPE films, reducing their effectiveness and increasing replacement frequency. This not only adds to operational costs but also exacerbates the plastic waste problem.

The development of biodegradable alternatives to traditional LDPE is an ongoing challenge. While some biodegradable plastics have been introduced, they often fall short in terms of performance, durability, or cost-effectiveness compared to conventional LDPE. Striking a balance between biodegradability and functional performance remains a significant hurdle for researchers and manufacturers.

Recycling of agricultural LDPE waste presents its own set of challenges. Contamination with soil, pesticides, and other agricultural chemicals makes the recycling process complex and often economically unfeasible. Developing efficient cleaning and recycling technologies for agricultural plastics is crucial for improving the sustainability of LDPE use in agriculture.

As the agricultural sector faces increasing pressure to adopt more sustainable practices, the LDPE industry must innovate to address these challenges. This includes developing more durable and UV-resistant films, improving the performance of biodegradable alternatives, and creating effective recycling systems for agricultural plastics. The future of LDPE in agriculture will likely involve a combination of material innovations, improved waste management strategies, and the integration of smart technologies to optimize the use and lifecycle of agricultural plastics.

Another significant use of LDPE in agriculture is in greenhouse coverings. These structures provide a controlled environment for plant growth, extending growing seasons and protecting crops from adverse weather conditions. LDPE films used in greenhouses are engineered to allow optimal light transmission while maintaining thermal insulation properties.

Drip irrigation systems, which utilize LDPE tubing, represent another crucial application. These systems enable precise water and nutrient delivery directly to plant roots, significantly reducing water consumption and improving nutrient uptake efficiency. The flexibility and durability of LDPE make it an ideal material for these irrigation components.

Despite its widespread use, the application of LDPE in agriculture faces several challenges. One of the primary concerns is environmental sustainability. The accumulation of plastic waste in agricultural soils poses a significant threat to soil health and ecosystem balance. Microplastic pollution resulting from the degradation of LDPE films is an emerging issue that requires immediate attention.

Durability and longevity of LDPE products in agricultural settings present another challenge. Exposure to UV radiation, temperature fluctuations, and mechanical stress can lead to premature degradation of LDPE films, reducing their effectiveness and increasing replacement frequency. This not only adds to operational costs but also exacerbates the plastic waste problem.

The development of biodegradable alternatives to traditional LDPE is an ongoing challenge. While some biodegradable plastics have been introduced, they often fall short in terms of performance, durability, or cost-effectiveness compared to conventional LDPE. Striking a balance between biodegradability and functional performance remains a significant hurdle for researchers and manufacturers.

Recycling of agricultural LDPE waste presents its own set of challenges. Contamination with soil, pesticides, and other agricultural chemicals makes the recycling process complex and often economically unfeasible. Developing efficient cleaning and recycling technologies for agricultural plastics is crucial for improving the sustainability of LDPE use in agriculture.

As the agricultural sector faces increasing pressure to adopt more sustainable practices, the LDPE industry must innovate to address these challenges. This includes developing more durable and UV-resistant films, improving the performance of biodegradable alternatives, and creating effective recycling systems for agricultural plastics. The future of LDPE in agriculture will likely involve a combination of material innovations, improved waste management strategies, and the integration of smart technologies to optimize the use and lifecycle of agricultural plastics.

Existing LDPE-based Crop Protection Methods

01 LDPE composition and manufacturing process

Low-Density Polyethylene (LDPE) is a versatile thermoplastic polymer with various applications. The manufacturing process and composition of LDPE can be optimized to enhance its properties. This includes controlling the polymerization conditions, incorporating additives, and modifying the molecular structure to achieve desired characteristics such as improved strength, flexibility, or thermal stability.- Composition and properties of LDPE: Low-Density Polyethylene (LDPE) is a thermoplastic polymer with a low density and high flexibility. It is characterized by its branched structure, which results in lower crystallinity and density compared to other polyethylene types. LDPE exhibits good chemical resistance, low water absorption, and excellent electrical insulation properties.

- Manufacturing processes for LDPE: LDPE is typically produced through high-pressure polymerization of ethylene using free-radical initiators. Various manufacturing techniques have been developed to improve the production efficiency and control the properties of LDPE, including the use of different catalysts, reactor designs, and process conditions.

- Applications of LDPE: LDPE finds widespread use in various industries due to its unique properties. Common applications include packaging materials, such as plastic bags and films, agricultural films, wire and cable insulation, and molded products. Its flexibility and chemical resistance make it suitable for a wide range of consumer and industrial products.

- Modifications and blends of LDPE: To enhance its properties and expand its applications, LDPE is often modified or blended with other materials. This can include the addition of additives, crosslinking agents, or blending with other polymers to improve strength, heat resistance, or other specific characteristics. These modifications allow for tailored properties to meet specific application requirements.

- Recycling and sustainability of LDPE: As environmental concerns grow, there is increasing focus on the recycling and sustainability of LDPE products. Research and development efforts are directed towards improving recycling processes, developing biodegradable alternatives, and finding new ways to reduce the environmental impact of LDPE production and disposal.

02 LDPE blends and composites

LDPE can be blended with other polymers or materials to create composites with enhanced properties. These blends can improve the mechanical strength, barrier properties, or processability of the resulting material. Researchers are exploring various combinations of LDPE with other polymers, natural fibers, or nanoparticles to develop new materials with tailored characteristics for specific applications.Expand Specific Solutions03 LDPE recycling and sustainability

As environmental concerns grow, there is an increasing focus on recycling and improving the sustainability of LDPE. This includes developing more efficient recycling processes, creating products from recycled LDPE, and exploring biodegradable or bio-based alternatives. Researchers are also working on methods to reduce the environmental impact of LDPE production and use.Expand Specific Solutions04 LDPE film and packaging applications

LDPE is widely used in film and packaging applications due to its flexibility, transparency, and moisture resistance. Ongoing research focuses on improving the performance of LDPE films, such as enhancing their barrier properties, increasing their strength, or developing new packaging solutions. This includes modifications to the LDPE structure or the incorporation of additives to meet specific packaging requirements.Expand Specific Solutions05 LDPE in medical and healthcare applications

LDPE is being explored for various medical and healthcare applications due to its biocompatibility and versatility. This includes the development of LDPE-based materials for medical devices, drug delivery systems, and protective equipment. Researchers are working on modifying LDPE to enhance its antimicrobial properties, improve its compatibility with biological tissues, or create smart materials for healthcare applications.Expand Specific Solutions

Key Players in Agricultural LDPE Industry

The LDPE in agriculture market is in a growth phase, driven by increasing demand for crop protection solutions. The global market size is expanding, with projections indicating continued growth due to rising food security concerns and sustainable farming practices. Technologically, LDPE solutions are relatively mature but still evolving, with companies like BASF, Bayer CropScience, and Sumitomo Chemical leading innovation. These industry giants, along with emerging players like Apeel Technology and Alpha BioPesticides, are focusing on developing more environmentally friendly and efficient LDPE-based products for agricultural applications, indicating a competitive and dynamic market landscape.

BASF Corp.

Technical Solution: BASF has developed innovative LDPE-based solutions for crop protection in agriculture. Their ecovio® biodegradable plastic mulch films offer an environmentally friendly alternative to traditional polyethylene films. These films are designed to fully biodegrade in soil after use, reducing plastic waste and soil contamination[1]. BASF's LDPE mulch films incorporate advanced UV stabilizers and anti-fog additives, enhancing durability and light transmission for improved crop yields[2]. The company has also introduced LDPE-based controlled-release fertilizer coatings, which optimize nutrient delivery and reduce environmental impact[3].

Strengths: Biodegradable solutions reduce environmental impact; advanced additives improve film performance and crop yields. Weaknesses: Higher initial cost compared to traditional LDPE films; biodegradation rate may vary depending on soil conditions.

Bayer AG

Technical Solution: Bayer AG has developed a range of LDPE-based crop protection solutions. Their Bayeco™ line of LDPE films incorporates proprietary additives that enhance UV resistance and mechanical strength, extending the lifespan of agricultural films[4]. Bayer has also introduced LDPE-based seed coatings that combine crop protection agents with nutrients, promoting seedling establishment and early growth[5]. Additionally, their LDPE-based controlled-release formulations for pesticides and herbicides improve efficacy while reducing environmental impact. Bayer's research focuses on optimizing LDPE blends to create multifunctional agricultural films that can adapt to various climatic conditions[6].

Strengths: Comprehensive range of LDPE-based solutions; strong focus on integrating crop protection agents with LDPE materials. Weaknesses: Potential concerns about long-term accumulation of LDPE residues in soil; reliance on chemical-based crop protection may face increasing regulatory scrutiny.

Innovations in LDPE for Enhanced Crop Protection

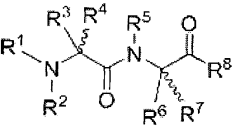

Agricultural crop protector containing dipeptide derivative as active ingredient

PatentWO2013157871A1

Innovation

- A dipeptide derivative is used as an active ingredient in an agricultural crop protection agent, inducing the expression of plant disease resistance genes such as PR-1, glucanase, chitinase, PR4, and peroxidase, thereby enhancing plant immunity and promoting growth by suppressing pathogen proliferation and cold damage.

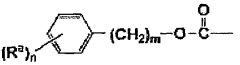

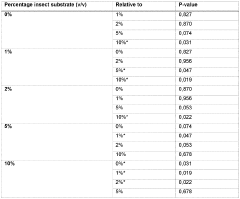

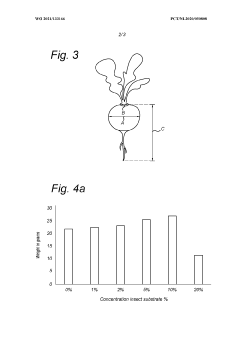

Thrips control

PatentWO2021133166A1

Innovation

- A biological crop protection agent derived from industrial insect farming by-products, specifically from Hermetia illucens larvae, is used, which includes chitin-rich insect remains and excrements processed into a meal or powder, enhancing plant defense mechanisms and reducing Thrips populations.

Environmental Impact of LDPE in Agriculture

The widespread use of Low-Density Polyethylene (LDPE) in agriculture, particularly for crop protection, has raised significant environmental concerns. While LDPE films and covers offer numerous benefits in terms of crop yield and quality, their environmental impact cannot be overlooked. The primary issue stems from the non-biodegradable nature of LDPE, which leads to long-term accumulation in soil and water bodies.

When LDPE films are left in fields after use, they fragment into smaller pieces, contributing to microplastic pollution. These microplastics can persist in the environment for hundreds of years, affecting soil structure, water retention capacity, and nutrient cycling. Studies have shown that microplastics can be taken up by plants, potentially entering the food chain and posing risks to human health.

The production of LDPE also contributes to greenhouse gas emissions and energy consumption. The manufacturing process relies heavily on fossil fuels, both as raw materials and energy sources, leading to a significant carbon footprint. Additionally, the disposal of used LDPE films often involves incineration or landfilling, further exacerbating environmental issues through air pollution and land use.

Water pollution is another critical concern associated with LDPE use in agriculture. Runoff from fields can carry LDPE fragments into rivers, lakes, and oceans, where they harm aquatic ecosystems. Marine life can mistake these plastic particles for food, leading to malnutrition, starvation, and the bioaccumulation of toxins in the food web.

The impact on soil health is particularly noteworthy. LDPE residues in soil can alter its physical and chemical properties, affecting microbial communities and reducing overall soil fertility. This can lead to decreased crop productivity in the long term, ironically counteracting the initial benefits of using LDPE for crop protection.

Efforts to mitigate these environmental impacts have led to the development of biodegradable alternatives and improved recycling technologies. However, the adoption of these solutions faces challenges such as higher costs and the need for specialized infrastructure. Balancing the agricultural benefits of LDPE with its environmental costs remains a complex issue that requires ongoing research and policy interventions.

When LDPE films are left in fields after use, they fragment into smaller pieces, contributing to microplastic pollution. These microplastics can persist in the environment for hundreds of years, affecting soil structure, water retention capacity, and nutrient cycling. Studies have shown that microplastics can be taken up by plants, potentially entering the food chain and posing risks to human health.

The production of LDPE also contributes to greenhouse gas emissions and energy consumption. The manufacturing process relies heavily on fossil fuels, both as raw materials and energy sources, leading to a significant carbon footprint. Additionally, the disposal of used LDPE films often involves incineration or landfilling, further exacerbating environmental issues through air pollution and land use.

Water pollution is another critical concern associated with LDPE use in agriculture. Runoff from fields can carry LDPE fragments into rivers, lakes, and oceans, where they harm aquatic ecosystems. Marine life can mistake these plastic particles for food, leading to malnutrition, starvation, and the bioaccumulation of toxins in the food web.

The impact on soil health is particularly noteworthy. LDPE residues in soil can alter its physical and chemical properties, affecting microbial communities and reducing overall soil fertility. This can lead to decreased crop productivity in the long term, ironically counteracting the initial benefits of using LDPE for crop protection.

Efforts to mitigate these environmental impacts have led to the development of biodegradable alternatives and improved recycling technologies. However, the adoption of these solutions faces challenges such as higher costs and the need for specialized infrastructure. Balancing the agricultural benefits of LDPE with its environmental costs remains a complex issue that requires ongoing research and policy interventions.

Regulatory Framework for Agricultural Plastics

The regulatory framework for agricultural plastics, particularly LDPE used in crop protection, is evolving to address environmental concerns while balancing the needs of the agricultural sector. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the Food and Agriculture Organization (FAO) have developed guidelines for sustainable plastic use in agriculture. These guidelines emphasize the importance of proper management, recycling, and disposal of agricultural plastics to minimize environmental impact.

In the European Union, the Directive on Single-Use Plastics (SUP) has implications for agricultural plastics, including LDPE films used for crop protection. While the directive primarily targets consumer products, it has prompted discussions on extending similar regulations to the agricultural sector. The EU's Circular Economy Action Plan also addresses agricultural plastics, promoting the development of biodegradable alternatives and improved recycling infrastructure.

At the national level, countries have implemented varying degrees of regulation. France, for instance, has introduced legislation requiring the use of biodegradable mulch films in agriculture, with a phased approach to implementation. Spain has established a national agricultural plastic waste management system, mandating the collection and recycling of used plastics.

In the United States, regulations are primarily managed at the state level. California has implemented stringent recycling requirements for agricultural plastics, while other states are in the process of developing similar programs. The Environmental Protection Agency (EPA) provides guidelines for the proper disposal of agricultural plastics but has not yet introduced comprehensive federal regulations.

Developing countries are also recognizing the need for regulatory frameworks. China, a major producer and consumer of agricultural plastics, has introduced policies to promote the recycling of agricultural films and encourage the use of biodegradable alternatives. India has implemented the Plastic Waste Management Rules, which include provisions for agricultural plastic waste management.

Industry self-regulation plays a significant role in shaping practices. Organizations such as the Crop Protection Association and the European Plastics Converters have developed voluntary codes of practice for the responsible use and disposal of agricultural plastics. These initiatives often complement governmental regulations and can serve as precursors to formal legislation.

As research continues to reveal the long-term environmental impacts of agricultural plastics, regulatory frameworks are likely to become more comprehensive and stringent. Future regulations may focus on mandating the use of biodegradable materials, implementing extended producer responsibility schemes, and establishing more robust recycling and recovery systems for agricultural plastics.

In the European Union, the Directive on Single-Use Plastics (SUP) has implications for agricultural plastics, including LDPE films used for crop protection. While the directive primarily targets consumer products, it has prompted discussions on extending similar regulations to the agricultural sector. The EU's Circular Economy Action Plan also addresses agricultural plastics, promoting the development of biodegradable alternatives and improved recycling infrastructure.

At the national level, countries have implemented varying degrees of regulation. France, for instance, has introduced legislation requiring the use of biodegradable mulch films in agriculture, with a phased approach to implementation. Spain has established a national agricultural plastic waste management system, mandating the collection and recycling of used plastics.

In the United States, regulations are primarily managed at the state level. California has implemented stringent recycling requirements for agricultural plastics, while other states are in the process of developing similar programs. The Environmental Protection Agency (EPA) provides guidelines for the proper disposal of agricultural plastics but has not yet introduced comprehensive federal regulations.

Developing countries are also recognizing the need for regulatory frameworks. China, a major producer and consumer of agricultural plastics, has introduced policies to promote the recycling of agricultural films and encourage the use of biodegradable alternatives. India has implemented the Plastic Waste Management Rules, which include provisions for agricultural plastic waste management.

Industry self-regulation plays a significant role in shaping practices. Organizations such as the Crop Protection Association and the European Plastics Converters have developed voluntary codes of practice for the responsible use and disposal of agricultural plastics. These initiatives often complement governmental regulations and can serve as precursors to formal legislation.

As research continues to reveal the long-term environmental impacts of agricultural plastics, regulatory frameworks are likely to become more comprehensive and stringent. Future regulations may focus on mandating the use of biodegradable materials, implementing extended producer responsibility schemes, and establishing more robust recycling and recovery systems for agricultural plastics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!