LDPE in Construction: Durable and Cost-Effective Solutions

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE in Construction: Background and Objectives

Low-density polyethylene (LDPE) has emerged as a versatile and innovative material in the construction industry, offering durable and cost-effective solutions for various applications. The evolution of LDPE in construction can be traced back to the mid-20th century when its unique properties were first recognized and harnessed for building purposes.

Initially, LDPE found its way into construction as a moisture barrier and insulation material. Its excellent water resistance and flexibility made it an ideal choice for vapor barriers in walls and foundations. As technology advanced, the potential applications of LDPE in construction expanded significantly, leading to its incorporation in a wide range of building components and systems.

The development of LDPE in construction has been driven by several key factors. Firstly, the increasing demand for energy-efficient buildings has led to the adoption of LDPE-based materials in insulation and weatherproofing. Secondly, the need for lightweight yet durable materials in modern construction practices has positioned LDPE as a viable alternative to traditional building materials.

One of the primary objectives in utilizing LDPE in construction is to enhance the overall performance and longevity of buildings. LDPE-based products offer excellent resistance to weathering, UV radiation, and chemical degradation, making them ideal for both interior and exterior applications. This durability translates into reduced maintenance costs and extended building lifespans, aligning with sustainable construction practices.

Cost-effectiveness is another crucial objective driving the adoption of LDPE in construction. The material's relatively low production costs, coupled with its ease of installation and minimal maintenance requirements, make it an attractive option for builders and developers seeking to optimize project budgets without compromising on quality.

The versatility of LDPE has led to its integration into various construction elements, including roofing membranes, geomembranes for foundation waterproofing, piping systems, and even as a component in composite building materials. This adaptability has opened up new possibilities for innovative design solutions and construction techniques.

As the construction industry continues to evolve, the objectives for LDPE usage are expanding to include enhanced sustainability and recyclability. Research efforts are focused on developing LDPE formulations with improved environmental profiles, exploring bio-based alternatives, and implementing efficient recycling processes for LDPE construction waste.

Looking ahead, the future of LDPE in construction is poised for further innovation. Emerging technologies such as 3D printing and advanced polymer engineering are expected to unlock new potential for LDPE applications, potentially revolutionizing construction methodologies and expanding the material's role in creating durable, cost-effective, and sustainable built environments.

Initially, LDPE found its way into construction as a moisture barrier and insulation material. Its excellent water resistance and flexibility made it an ideal choice for vapor barriers in walls and foundations. As technology advanced, the potential applications of LDPE in construction expanded significantly, leading to its incorporation in a wide range of building components and systems.

The development of LDPE in construction has been driven by several key factors. Firstly, the increasing demand for energy-efficient buildings has led to the adoption of LDPE-based materials in insulation and weatherproofing. Secondly, the need for lightweight yet durable materials in modern construction practices has positioned LDPE as a viable alternative to traditional building materials.

One of the primary objectives in utilizing LDPE in construction is to enhance the overall performance and longevity of buildings. LDPE-based products offer excellent resistance to weathering, UV radiation, and chemical degradation, making them ideal for both interior and exterior applications. This durability translates into reduced maintenance costs and extended building lifespans, aligning with sustainable construction practices.

Cost-effectiveness is another crucial objective driving the adoption of LDPE in construction. The material's relatively low production costs, coupled with its ease of installation and minimal maintenance requirements, make it an attractive option for builders and developers seeking to optimize project budgets without compromising on quality.

The versatility of LDPE has led to its integration into various construction elements, including roofing membranes, geomembranes for foundation waterproofing, piping systems, and even as a component in composite building materials. This adaptability has opened up new possibilities for innovative design solutions and construction techniques.

As the construction industry continues to evolve, the objectives for LDPE usage are expanding to include enhanced sustainability and recyclability. Research efforts are focused on developing LDPE formulations with improved environmental profiles, exploring bio-based alternatives, and implementing efficient recycling processes for LDPE construction waste.

Looking ahead, the future of LDPE in construction is poised for further innovation. Emerging technologies such as 3D printing and advanced polymer engineering are expected to unlock new potential for LDPE applications, potentially revolutionizing construction methodologies and expanding the material's role in creating durable, cost-effective, and sustainable built environments.

Market Analysis for LDPE Construction Materials

The global market for LDPE construction materials has been experiencing steady growth, driven by the increasing demand for durable, lightweight, and cost-effective building solutions. As the construction industry continues to evolve, LDPE products have gained significant traction due to their versatility and performance characteristics.

In recent years, the market size for LDPE construction materials has reached substantial figures, with projections indicating continued expansion. This growth is attributed to several factors, including the rising urbanization rates, infrastructure development in emerging economies, and the shift towards sustainable building practices. The construction sector's recovery post-pandemic has also contributed to the increased adoption of LDPE materials.

Geographically, the Asia-Pacific region leads the market, with China and India being the primary growth drivers. The rapid industrialization and urban development in these countries have fueled the demand for LDPE construction materials. North America and Europe follow closely, with mature markets showing a steady uptake of innovative LDPE solutions in both residential and commercial construction projects.

The market segmentation for LDPE construction materials spans various applications, including insulation, vapor barriers, waterproofing membranes, and packaging for construction materials. Among these, insulation applications hold a significant market share due to the growing emphasis on energy-efficient buildings and stringent building codes.

Key market trends shaping the LDPE construction materials landscape include the increasing focus on recyclability and sustainability. Manufacturers are investing in research and development to create LDPE products with higher recycled content and improved end-of-life recyclability. This aligns with the construction industry's shift towards circular economy principles and reduced environmental impact.

Another notable trend is the integration of advanced technologies in LDPE production, resulting in enhanced material properties such as improved UV resistance, fire retardancy, and durability. These advancements are expanding the potential applications of LDPE in construction, particularly in challenging environmental conditions.

The competitive landscape of the LDPE construction materials market is characterized by the presence of both global players and regional manufacturers. Major companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position. The market also sees the entry of new players, particularly those offering specialized or eco-friendly LDPE solutions.

Looking ahead, the market for LDPE construction materials is expected to maintain its growth trajectory. Factors such as the increasing adoption of prefabricated construction methods, the growing renovation and remodeling activities, and the rising awareness of energy-efficient building materials are likely to drive market expansion in the coming years.

In recent years, the market size for LDPE construction materials has reached substantial figures, with projections indicating continued expansion. This growth is attributed to several factors, including the rising urbanization rates, infrastructure development in emerging economies, and the shift towards sustainable building practices. The construction sector's recovery post-pandemic has also contributed to the increased adoption of LDPE materials.

Geographically, the Asia-Pacific region leads the market, with China and India being the primary growth drivers. The rapid industrialization and urban development in these countries have fueled the demand for LDPE construction materials. North America and Europe follow closely, with mature markets showing a steady uptake of innovative LDPE solutions in both residential and commercial construction projects.

The market segmentation for LDPE construction materials spans various applications, including insulation, vapor barriers, waterproofing membranes, and packaging for construction materials. Among these, insulation applications hold a significant market share due to the growing emphasis on energy-efficient buildings and stringent building codes.

Key market trends shaping the LDPE construction materials landscape include the increasing focus on recyclability and sustainability. Manufacturers are investing in research and development to create LDPE products with higher recycled content and improved end-of-life recyclability. This aligns with the construction industry's shift towards circular economy principles and reduced environmental impact.

Another notable trend is the integration of advanced technologies in LDPE production, resulting in enhanced material properties such as improved UV resistance, fire retardancy, and durability. These advancements are expanding the potential applications of LDPE in construction, particularly in challenging environmental conditions.

The competitive landscape of the LDPE construction materials market is characterized by the presence of both global players and regional manufacturers. Major companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position. The market also sees the entry of new players, particularly those offering specialized or eco-friendly LDPE solutions.

Looking ahead, the market for LDPE construction materials is expected to maintain its growth trajectory. Factors such as the increasing adoption of prefabricated construction methods, the growing renovation and remodeling activities, and the rising awareness of energy-efficient building materials are likely to drive market expansion in the coming years.

Current Challenges in LDPE Construction Applications

Despite the widespread use of Low-Density Polyethylene (LDPE) in construction, several challenges persist in its application. One of the primary concerns is the material's long-term durability under various environmental conditions. While LDPE exhibits excellent resistance to moisture and chemicals, prolonged exposure to UV radiation can lead to degradation, affecting its structural integrity and aesthetic appearance. This issue is particularly pronounced in outdoor applications, where LDPE components are constantly subjected to sunlight and weathering.

Another significant challenge lies in the fire safety aspects of LDPE in construction. The material's inherent flammability poses risks in building applications, especially in regions with stringent fire safety regulations. Although fire-retardant additives can be incorporated, they often come at the cost of compromising other desirable properties of LDPE, such as flexibility or cost-effectiveness. Balancing fire resistance with maintaining the material's beneficial characteristics remains a complex task for manufacturers and builders alike.

The environmental impact of LDPE usage in construction also presents ongoing challenges. While the material is recyclable, the process of separating and recycling LDPE from construction waste streams is often complicated and economically challenging. This difficulty is compounded by the fact that LDPE used in construction is frequently mixed with other materials or contaminated, making recycling more complex and less efficient. The industry faces pressure to improve the end-of-life management of LDPE products to align with growing sustainability demands.

Mechanical performance under load is another area of concern, particularly in structural applications. LDPE's relatively low tensile strength and tendency to creep under sustained loads limit its use in load-bearing components. Engineers and designers must carefully consider these limitations when incorporating LDPE into construction projects, often necessitating the use of reinforcements or alternative materials for critical structural elements.

Lastly, the variability in LDPE quality and performance across different manufacturers and grades poses challenges in standardization and quality control. Construction professionals often struggle with inconsistencies in material properties, which can affect the reliability and predictability of LDPE-based solutions. This variability necessitates rigorous testing and quality assurance processes, adding complexity and cost to construction projects utilizing LDPE materials.

Addressing these challenges requires ongoing research and development efforts, focusing on enhancing LDPE's durability, fire resistance, recyclability, and mechanical properties while maintaining its cost-effectiveness. Innovations in material science, such as the development of advanced LDPE composites or novel additives, may hold the key to overcoming these limitations and expanding the material's applications in the construction industry.

Another significant challenge lies in the fire safety aspects of LDPE in construction. The material's inherent flammability poses risks in building applications, especially in regions with stringent fire safety regulations. Although fire-retardant additives can be incorporated, they often come at the cost of compromising other desirable properties of LDPE, such as flexibility or cost-effectiveness. Balancing fire resistance with maintaining the material's beneficial characteristics remains a complex task for manufacturers and builders alike.

The environmental impact of LDPE usage in construction also presents ongoing challenges. While the material is recyclable, the process of separating and recycling LDPE from construction waste streams is often complicated and economically challenging. This difficulty is compounded by the fact that LDPE used in construction is frequently mixed with other materials or contaminated, making recycling more complex and less efficient. The industry faces pressure to improve the end-of-life management of LDPE products to align with growing sustainability demands.

Mechanical performance under load is another area of concern, particularly in structural applications. LDPE's relatively low tensile strength and tendency to creep under sustained loads limit its use in load-bearing components. Engineers and designers must carefully consider these limitations when incorporating LDPE into construction projects, often necessitating the use of reinforcements or alternative materials for critical structural elements.

Lastly, the variability in LDPE quality and performance across different manufacturers and grades poses challenges in standardization and quality control. Construction professionals often struggle with inconsistencies in material properties, which can affect the reliability and predictability of LDPE-based solutions. This variability necessitates rigorous testing and quality assurance processes, adding complexity and cost to construction projects utilizing LDPE materials.

Addressing these challenges requires ongoing research and development efforts, focusing on enhancing LDPE's durability, fire resistance, recyclability, and mechanical properties while maintaining its cost-effectiveness. Innovations in material science, such as the development of advanced LDPE composites or novel additives, may hold the key to overcoming these limitations and expanding the material's applications in the construction industry.

Existing LDPE Solutions for Construction

01 Enhanced durability through additives and blending

LDPE durability can be improved by incorporating additives or blending with other polymers. This approach enhances resistance to environmental factors, UV radiation, and mechanical stress, extending the material's lifespan and improving its overall performance in various applications.- Enhanced durability through additives and blending: LDPE durability can be improved by incorporating additives or blending with other polymers. This approach enhances resistance to environmental factors, UV radiation, and mechanical stress, extending the material's lifespan and improving its overall performance in various applications.

- Cost-effective production methods: Innovative production techniques for LDPE aim to reduce manufacturing costs while maintaining or improving quality. These methods may include optimized polymerization processes, energy-efficient equipment, or the use of alternative catalysts, resulting in more economical LDPE production.

- Recycling and sustainability improvements: Efforts to enhance LDPE recycling and sustainability focus on developing more efficient recycling processes, improving the quality of recycled LDPE, and incorporating recycled content into new products. These advancements contribute to cost-effectiveness and environmental sustainability.

- Application-specific LDPE formulations: Tailored LDPE formulations are developed for specific applications, optimizing durability and cost-effectiveness for particular use cases. These formulations may involve modifying the polymer structure, incorporating specific additives, or creating specialized blends to meet the requirements of different industries.

- Advanced testing and quality control methods: Improved testing and quality control techniques are employed to assess and ensure LDPE durability and performance. These methods help identify potential weaknesses, optimize formulations, and maintain consistent product quality, ultimately contributing to enhanced durability and cost-effectiveness.

02 Cost-effective production methods

Innovative production techniques for LDPE aim to reduce manufacturing costs while maintaining or improving quality. These methods may include optimized polymerization processes, energy-efficient production lines, or the use of alternative catalysts, resulting in more economical LDPE products.Expand Specific Solutions03 Recycling and sustainability improvements

Efforts to enhance LDPE's recyclability and overall sustainability focus on developing new recycling technologies, improving the material's biodegradability, or incorporating recycled content. These advancements aim to reduce environmental impact and improve cost-effectiveness through circular economy principles.Expand Specific Solutions04 Application-specific LDPE formulations

Tailored LDPE formulations are developed for specific applications, optimizing durability and cost-effectiveness for particular use cases. This may involve adjusting molecular weight, density, or incorporating specific additives to meet the performance requirements of diverse industries such as packaging, agriculture, or construction.Expand Specific Solutions05 Advanced testing and quality control methods

Improved testing and quality control techniques are developed to accurately assess LDPE durability and performance. These methods help manufacturers optimize production processes, ensure consistent quality, and potentially reduce costs by minimizing waste and improving product reliability.Expand Specific Solutions

Key Players in LDPE Construction Materials Industry

The LDPE construction market is in a mature growth phase, with a global market size estimated to reach $39.12 billion by 2027. The technology for LDPE production and application in construction is well-established, with major players like ExxonMobil, Dow Chemical, and SABIC dominating the market. These companies have advanced R&D capabilities and extensive product portfolios. Emerging players such as DL Chemical and Wanhua Chemical are also making significant strides in LDPE technology development. The competitive landscape is characterized by ongoing innovation in product formulations and manufacturing processes to improve LDPE performance and sustainability in construction applications.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced LDPE resins specifically for construction applications. Their technology focuses on enhancing the durability and cost-effectiveness of LDPE in construction materials. They have introduced LDPE formulations with improved UV resistance and weatherability, extending the lifespan of construction products[1]. Dow's ELITE™ Enhanced Polyethylene resins offer superior strength and toughness, allowing for thinner and lighter construction materials without compromising performance[2]. Their AGILITY™ LDPE resins provide excellent processability and consistency, enabling efficient manufacturing of construction products like geomembranes and vapor barriers[3].

Strengths: Industry-leading research capabilities, wide range of specialized LDPE formulations, global presence and distribution network. Weaknesses: Higher costs compared to generic LDPE, potential over-reliance on petroleum-based feedstocks.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed proprietary catalysts and process technologies for LDPE production, focusing on improving the material's properties for construction applications. Their Exceed™ XP performance polymers offer exceptional toughness and tear resistance, making them ideal for geomembranes and protective films in construction[4]. ExxonMobil's Enable™ performance polyethylene provides enhanced strength and processability, allowing for the production of thinner, yet durable construction materials[5]. They have also introduced metallocene LDPE grades that offer improved optical properties and seal strength for packaging applications in the construction industry[6].

Strengths: Advanced catalyst technology, broad portfolio of specialized LDPE grades, strong R&D capabilities. Weaknesses: Potentially higher production costs, environmental concerns related to fossil fuel-based production.

Innovations in LDPE Construction Materials

Raw mixture for producing a building material

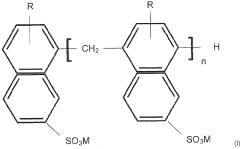

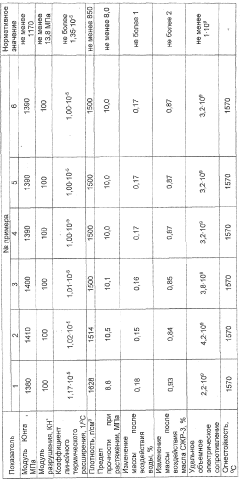

PatentWO2023101577A1

Innovation

- A sand-polymer mixture comprising sand, a blend of linear low-density polyethylene (LLDPE) and high-density polyethylene (LDPE), fibers, and a liquid phase containing sulfonated polycondensate, sodium sulfate, glycerin, and water, with specific ratios, is used, along with dyes, to enhance mechanical and physical properties. The mixture is processed at elevated temperatures and pressures to create a durable building material.

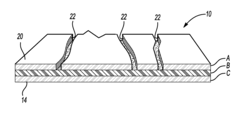

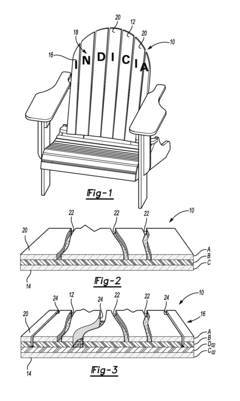

Method of furniture construction

PatentInactiveUS20140077570A1

Innovation

- A method involving a three-layer construction of HDPE (High Density Polyethylene) where the outer layers are the same color and the inner layer is different, with a router used to expose the inner layer to create a multi-color, three-dimensional design that lasts the life of the furniture.

Environmental Impact of LDPE in Construction

The environmental impact of LDPE (Low-Density Polyethylene) in construction is a complex issue that requires careful consideration. While LDPE offers numerous benefits in terms of durability and cost-effectiveness, its environmental footprint cannot be overlooked.

One of the primary environmental concerns associated with LDPE in construction is its non-biodegradable nature. LDPE can persist in the environment for hundreds of years, contributing to long-term pollution if not properly managed. This longevity, while advantageous for construction purposes, poses significant challenges for waste management and ecosystem health.

The production of LDPE also raises environmental issues. The manufacturing process relies heavily on fossil fuels, both as raw materials and energy sources. This dependence contributes to greenhouse gas emissions and the depletion of non-renewable resources. However, advancements in production technologies have led to more energy-efficient processes, somewhat mitigating these impacts.

On a positive note, LDPE's durability in construction applications can lead to reduced material replacement rates, potentially lowering the overall environmental impact over the lifecycle of a building or structure. Additionally, LDPE's lightweight nature can contribute to reduced transportation emissions during the construction phase.

Recycling presents both an opportunity and a challenge for LDPE in construction. While LDPE is technically recyclable, the process can be complicated by contamination and the presence of additives used to enhance its performance in construction applications. Improving recycling technologies and implementing effective collection systems are crucial steps in minimizing the environmental impact of LDPE waste.

The use of LDPE in construction can also have indirect environmental benefits. For instance, when used in insulation, it can significantly improve energy efficiency in buildings, leading to reduced energy consumption and lower carbon emissions over the structure's lifetime.

Water conservation is another area where LDPE in construction can have a positive environmental impact. LDPE membranes and liners are effective in preventing water loss in reservoirs and irrigation systems, contributing to more efficient water management in drought-prone areas.

However, the potential for microplastic pollution remains a significant concern. As LDPE products in construction weather and degrade over time, they can release microplastics into the environment, potentially affecting soil and water ecosystems.

In conclusion, while LDPE offers valuable properties for construction, its environmental impact is multifaceted. Balancing its benefits against its environmental costs requires ongoing research, innovation in recycling and production methods, and careful consideration of lifecycle assessments in construction projects.

One of the primary environmental concerns associated with LDPE in construction is its non-biodegradable nature. LDPE can persist in the environment for hundreds of years, contributing to long-term pollution if not properly managed. This longevity, while advantageous for construction purposes, poses significant challenges for waste management and ecosystem health.

The production of LDPE also raises environmental issues. The manufacturing process relies heavily on fossil fuels, both as raw materials and energy sources. This dependence contributes to greenhouse gas emissions and the depletion of non-renewable resources. However, advancements in production technologies have led to more energy-efficient processes, somewhat mitigating these impacts.

On a positive note, LDPE's durability in construction applications can lead to reduced material replacement rates, potentially lowering the overall environmental impact over the lifecycle of a building or structure. Additionally, LDPE's lightweight nature can contribute to reduced transportation emissions during the construction phase.

Recycling presents both an opportunity and a challenge for LDPE in construction. While LDPE is technically recyclable, the process can be complicated by contamination and the presence of additives used to enhance its performance in construction applications. Improving recycling technologies and implementing effective collection systems are crucial steps in minimizing the environmental impact of LDPE waste.

The use of LDPE in construction can also have indirect environmental benefits. For instance, when used in insulation, it can significantly improve energy efficiency in buildings, leading to reduced energy consumption and lower carbon emissions over the structure's lifetime.

Water conservation is another area where LDPE in construction can have a positive environmental impact. LDPE membranes and liners are effective in preventing water loss in reservoirs and irrigation systems, contributing to more efficient water management in drought-prone areas.

However, the potential for microplastic pollution remains a significant concern. As LDPE products in construction weather and degrade over time, they can release microplastics into the environment, potentially affecting soil and water ecosystems.

In conclusion, while LDPE offers valuable properties for construction, its environmental impact is multifaceted. Balancing its benefits against its environmental costs requires ongoing research, innovation in recycling and production methods, and careful consideration of lifecycle assessments in construction projects.

Cost-Benefit Analysis of LDPE Construction Solutions

The cost-benefit analysis of LDPE construction solutions reveals significant advantages in terms of durability, cost-effectiveness, and versatility. LDPE (Low-Density Polyethylene) offers a range of benefits that make it an attractive option for various construction applications.

From a durability perspective, LDPE demonstrates excellent resistance to weathering, chemicals, and UV radiation. This translates to longer-lasting structures and reduced maintenance costs over time. The material's flexibility and impact resistance contribute to its ability to withstand environmental stresses, potentially extending the lifespan of construction projects.

Cost-wise, LDPE presents a compelling case. The initial material costs are generally lower compared to traditional construction materials like concrete or metal. Additionally, the lightweight nature of LDPE reduces transportation and installation costs, further enhancing its economic appeal. The ease of installation also leads to reduced labor costs and shorter project timelines.

Energy efficiency is another area where LDPE shines. Its insulating properties can contribute to improved thermal performance in buildings, potentially leading to reduced heating and cooling costs. This aspect not only provides economic benefits but also aligns with sustainability goals.

In terms of versatility, LDPE can be molded into various shapes and forms, allowing for innovative design solutions. This flexibility opens up new possibilities in architectural design and can lead to more efficient use of space and resources.

However, it's important to consider potential drawbacks. While LDPE is durable, it may not match the structural strength of materials like steel or concrete for certain applications. There may also be concerns about long-term environmental impact, although advancements in recycling technologies are addressing this issue.

When evaluating the overall cost-benefit ratio, it's crucial to consider the entire lifecycle of the construction project. While upfront costs may be lower, the long-term savings in maintenance, energy efficiency, and potential for extended lifespan often tip the scales in favor of LDPE solutions.

In conclusion, the cost-benefit analysis suggests that LDPE construction solutions offer significant advantages in terms of cost-effectiveness and durability. The material's versatility and potential for innovation further enhance its value proposition in the construction industry. As technology advances and sustainability concerns grow, LDPE is likely to play an increasingly important role in modern construction practices.

From a durability perspective, LDPE demonstrates excellent resistance to weathering, chemicals, and UV radiation. This translates to longer-lasting structures and reduced maintenance costs over time. The material's flexibility and impact resistance contribute to its ability to withstand environmental stresses, potentially extending the lifespan of construction projects.

Cost-wise, LDPE presents a compelling case. The initial material costs are generally lower compared to traditional construction materials like concrete or metal. Additionally, the lightweight nature of LDPE reduces transportation and installation costs, further enhancing its economic appeal. The ease of installation also leads to reduced labor costs and shorter project timelines.

Energy efficiency is another area where LDPE shines. Its insulating properties can contribute to improved thermal performance in buildings, potentially leading to reduced heating and cooling costs. This aspect not only provides economic benefits but also aligns with sustainability goals.

In terms of versatility, LDPE can be molded into various shapes and forms, allowing for innovative design solutions. This flexibility opens up new possibilities in architectural design and can lead to more efficient use of space and resources.

However, it's important to consider potential drawbacks. While LDPE is durable, it may not match the structural strength of materials like steel or concrete for certain applications. There may also be concerns about long-term environmental impact, although advancements in recycling technologies are addressing this issue.

When evaluating the overall cost-benefit ratio, it's crucial to consider the entire lifecycle of the construction project. While upfront costs may be lower, the long-term savings in maintenance, energy efficiency, and potential for extended lifespan often tip the scales in favor of LDPE solutions.

In conclusion, the cost-benefit analysis suggests that LDPE construction solutions offer significant advantages in terms of cost-effectiveness and durability. The material's versatility and potential for innovation further enhance its value proposition in the construction industry. As technology advances and sustainability concerns grow, LDPE is likely to play an increasingly important role in modern construction practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!