Mild hybrid powertrain strategies for optimizing towing vehicle efficiency

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Towing Evolution

The evolution of mild hybrid towing technology has been driven by the increasing demand for fuel efficiency and reduced emissions in heavy-duty vehicles. This progression can be traced through several key stages, each marked by significant technological advancements and innovative solutions.

In the early 2000s, the first generation of mild hybrid systems for towing vehicles focused primarily on start-stop functionality and limited regenerative braking. These initial systems provided modest fuel savings but laid the groundwork for future developments. The primary goal was to reduce idle time and recover some energy during deceleration, which was particularly beneficial in urban environments.

As the technology matured, the second generation of mild hybrid towing systems emerged in the mid-2000s. These systems incorporated more powerful electric motors and higher capacity batteries, allowing for electric assist during acceleration and low-speed operation. This advancement significantly improved fuel efficiency, especially during stop-and-go traffic conditions often encountered by towing vehicles in urban areas.

The third generation, introduced in the early 2010s, saw the integration of more sophisticated power management systems and the use of 48-volt electrical architectures. This higher voltage allowed for the implementation of more powerful electric motors, capable of providing substantial torque assistance during towing operations. Additionally, these systems enabled the electrification of auxiliary components, further reducing the load on the internal combustion engine.

In recent years, the fourth generation of mild hybrid towing technology has focused on intelligent power distribution and predictive energy management. Advanced algorithms and connectivity features allow these systems to optimize power delivery based on road conditions, traffic patterns, and even topographical data. This predictive approach ensures that the hybrid system is always operating at peak efficiency, particularly crucial during demanding towing scenarios.

Looking towards the future, the next evolution in mild hybrid towing technology is likely to involve even greater integration with vehicle systems and external data sources. This may include real-time route optimization for maximum efficiency, dynamic load balancing between the electric motor and internal combustion engine based on towing weight, and advanced thermal management systems to maintain optimal battery and motor performance under heavy loads.

In the early 2000s, the first generation of mild hybrid systems for towing vehicles focused primarily on start-stop functionality and limited regenerative braking. These initial systems provided modest fuel savings but laid the groundwork for future developments. The primary goal was to reduce idle time and recover some energy during deceleration, which was particularly beneficial in urban environments.

As the technology matured, the second generation of mild hybrid towing systems emerged in the mid-2000s. These systems incorporated more powerful electric motors and higher capacity batteries, allowing for electric assist during acceleration and low-speed operation. This advancement significantly improved fuel efficiency, especially during stop-and-go traffic conditions often encountered by towing vehicles in urban areas.

The third generation, introduced in the early 2010s, saw the integration of more sophisticated power management systems and the use of 48-volt electrical architectures. This higher voltage allowed for the implementation of more powerful electric motors, capable of providing substantial torque assistance during towing operations. Additionally, these systems enabled the electrification of auxiliary components, further reducing the load on the internal combustion engine.

In recent years, the fourth generation of mild hybrid towing technology has focused on intelligent power distribution and predictive energy management. Advanced algorithms and connectivity features allow these systems to optimize power delivery based on road conditions, traffic patterns, and even topographical data. This predictive approach ensures that the hybrid system is always operating at peak efficiency, particularly crucial during demanding towing scenarios.

Looking towards the future, the next evolution in mild hybrid towing technology is likely to involve even greater integration with vehicle systems and external data sources. This may include real-time route optimization for maximum efficiency, dynamic load balancing between the electric motor and internal combustion engine based on towing weight, and advanced thermal management systems to maintain optimal battery and motor performance under heavy loads.

Towing Market Demand Analysis

The towing market has experienced significant growth in recent years, driven by increasing demand for recreational vehicles, boats, and trailers. This trend is particularly evident in North America and Europe, where outdoor activities and road trips have gained popularity. The global towing vehicle market is expected to continue its upward trajectory, with a compound annual growth rate projected to exceed 5% over the next five years.

Consumer preferences are shifting towards more fuel-efficient and environmentally friendly towing vehicles, creating a strong demand for innovative powertrain solutions. This shift is partly due to rising fuel costs and growing environmental consciousness among consumers. As a result, there is a growing market for mild hybrid powertrains that can optimize towing vehicle efficiency without compromising performance.

The recreational vehicle (RV) industry, a major driver of towing vehicle demand, has seen substantial growth. In the United States alone, RV shipments have increased by over 30% in the past five years, indicating a robust market for towing vehicles. This trend is mirrored in other developed countries, with Australia and several European nations experiencing similar growth patterns in their RV and towing markets.

Commercial applications of towing vehicles, such as in construction, agriculture, and logistics, also contribute significantly to market demand. These sectors require vehicles capable of towing heavy loads while maintaining fuel efficiency, creating a substantial market for advanced powertrain technologies.

The automotive industry's push towards electrification has begun to influence the towing vehicle market. Consumers are increasingly interested in hybrid and electric options for towing, driving demand for innovative powertrain solutions that can deliver both power and efficiency. This trend is expected to accelerate as battery technology improves and charging infrastructure expands.

Government regulations and environmental policies play a crucial role in shaping market demand. Stricter emissions standards and fuel economy requirements are pushing manufacturers to develop more efficient towing vehicles, further driving the need for advanced powertrain strategies like mild hybrid systems.

The COVID-19 pandemic has had a mixed impact on the towing market. While it initially caused disruptions in supply chains and manufacturing, it has also led to increased interest in outdoor activities and domestic travel, potentially boosting demand for recreational towing vehicles in the long term.

As urbanization continues and parking spaces become scarcer, there is a growing demand for towing vehicles that are more compact and maneuverable without sacrificing towing capacity. This trend is particularly evident in densely populated regions and is influencing the development of new powertrain technologies.

Consumer preferences are shifting towards more fuel-efficient and environmentally friendly towing vehicles, creating a strong demand for innovative powertrain solutions. This shift is partly due to rising fuel costs and growing environmental consciousness among consumers. As a result, there is a growing market for mild hybrid powertrains that can optimize towing vehicle efficiency without compromising performance.

The recreational vehicle (RV) industry, a major driver of towing vehicle demand, has seen substantial growth. In the United States alone, RV shipments have increased by over 30% in the past five years, indicating a robust market for towing vehicles. This trend is mirrored in other developed countries, with Australia and several European nations experiencing similar growth patterns in their RV and towing markets.

Commercial applications of towing vehicles, such as in construction, agriculture, and logistics, also contribute significantly to market demand. These sectors require vehicles capable of towing heavy loads while maintaining fuel efficiency, creating a substantial market for advanced powertrain technologies.

The automotive industry's push towards electrification has begun to influence the towing vehicle market. Consumers are increasingly interested in hybrid and electric options for towing, driving demand for innovative powertrain solutions that can deliver both power and efficiency. This trend is expected to accelerate as battery technology improves and charging infrastructure expands.

Government regulations and environmental policies play a crucial role in shaping market demand. Stricter emissions standards and fuel economy requirements are pushing manufacturers to develop more efficient towing vehicles, further driving the need for advanced powertrain strategies like mild hybrid systems.

The COVID-19 pandemic has had a mixed impact on the towing market. While it initially caused disruptions in supply chains and manufacturing, it has also led to increased interest in outdoor activities and domestic travel, potentially boosting demand for recreational towing vehicles in the long term.

As urbanization continues and parking spaces become scarcer, there is a growing demand for towing vehicles that are more compact and maneuverable without sacrificing towing capacity. This trend is particularly evident in densely populated regions and is influencing the development of new powertrain technologies.

Mild Hybrid Towing Challenges

Mild hybrid powertrains present unique challenges when applied to towing vehicles, primarily due to the increased power demands and complex load dynamics involved in hauling heavy trailers. One of the main hurdles is the need for significantly higher torque output, especially during initial acceleration and uphill climbs. Traditional mild hybrid systems, designed for passenger vehicles, often lack the necessary power boost to effectively assist in these high-load scenarios.

The integration of regenerative braking systems in towing applications poses another significant challenge. While regenerative braking is a key feature of mild hybrid technology, its effectiveness can be compromised when towing heavy loads. The increased vehicle mass and momentum require more robust braking systems, potentially limiting the energy recovery potential of regenerative systems.

Battery management becomes increasingly complex in towing scenarios. The frequent high-power demands can lead to rapid battery depletion, necessitating more advanced energy management strategies. This is further complicated by the need to balance power distribution between the engine and electric motor to optimize efficiency without compromising towing performance.

Thermal management is another critical issue in mild hybrid towing vehicles. The combination of increased engine load, electric motor operation, and battery usage generates substantial heat, requiring more sophisticated cooling systems. This challenge is particularly acute in prolonged towing situations or in hot climates, where overheating can lead to reduced performance or system failures.

The added weight of the mild hybrid system itself presents a paradox in towing applications. While the system aims to improve efficiency, its additional mass can partially offset these gains, especially in vehicles already operating near their maximum gross vehicle weight rating. This necessitates careful consideration of component selection and placement to minimize weight impact while maximizing efficiency benefits.

Lastly, the control strategies for mild hybrid systems in towing vehicles need significant refinement. The algorithms must account for varying trailer weights, road conditions, and driving scenarios to optimally balance power output between the internal combustion engine and the electric motor. This requires more sophisticated sensors and predictive algorithms to anticipate power needs and manage energy flow effectively.

The integration of regenerative braking systems in towing applications poses another significant challenge. While regenerative braking is a key feature of mild hybrid technology, its effectiveness can be compromised when towing heavy loads. The increased vehicle mass and momentum require more robust braking systems, potentially limiting the energy recovery potential of regenerative systems.

Battery management becomes increasingly complex in towing scenarios. The frequent high-power demands can lead to rapid battery depletion, necessitating more advanced energy management strategies. This is further complicated by the need to balance power distribution between the engine and electric motor to optimize efficiency without compromising towing performance.

Thermal management is another critical issue in mild hybrid towing vehicles. The combination of increased engine load, electric motor operation, and battery usage generates substantial heat, requiring more sophisticated cooling systems. This challenge is particularly acute in prolonged towing situations or in hot climates, where overheating can lead to reduced performance or system failures.

The added weight of the mild hybrid system itself presents a paradox in towing applications. While the system aims to improve efficiency, its additional mass can partially offset these gains, especially in vehicles already operating near their maximum gross vehicle weight rating. This necessitates careful consideration of component selection and placement to minimize weight impact while maximizing efficiency benefits.

Lastly, the control strategies for mild hybrid systems in towing vehicles need significant refinement. The algorithms must account for varying trailer weights, road conditions, and driving scenarios to optimally balance power output between the internal combustion engine and the electric motor. This requires more sophisticated sensors and predictive algorithms to anticipate power needs and manage energy flow effectively.

Current Mild Hybrid Solutions

01 Energy management strategies

Mild hybrid powertrains employ sophisticated energy management strategies to optimize efficiency. These strategies involve intelligent control of the electric motor and internal combustion engine, balancing power distribution and regenerative braking to maximize fuel economy and reduce emissions. Advanced algorithms and predictive systems are used to determine the most efficient operating mode based on driving conditions and energy demands.- Regenerative braking systems: Mild hybrid powertrains often incorporate regenerative braking systems to recover energy during deceleration. This energy is stored in batteries and can be used to assist the engine during acceleration, improving overall efficiency. The system helps reduce fuel consumption and emissions by capturing energy that would otherwise be lost as heat during braking.

- Start-stop technology: Mild hybrid systems frequently utilize start-stop technology, which automatically shuts off the engine when the vehicle is stationary and restarts it when the driver releases the brake pedal. This feature reduces idle fuel consumption and emissions, particularly in urban driving conditions. The electric motor assists in quick and smooth engine restarts, enhancing the efficiency of the powertrain.

- Electric motor assist: Mild hybrid powertrains use an electric motor to assist the internal combustion engine during acceleration and high-load conditions. This allows for the use of a smaller, more efficient engine without compromising performance. The electric motor provides additional torque when needed, reducing the load on the engine and improving fuel efficiency.

- Advanced power management systems: Sophisticated power management systems are employed in mild hybrid powertrains to optimize the use of electric and combustion power sources. These systems continuously monitor driving conditions, energy levels, and power demands to determine the most efficient way to distribute power between the engine and electric motor. This intelligent management contributes significantly to overall powertrain efficiency.

- Lightweight materials and aerodynamic design: To further enhance efficiency, mild hybrid vehicles often incorporate lightweight materials in their construction and feature aerodynamic designs. These elements reduce the overall weight of the vehicle and minimize air resistance, decreasing the power required to move the vehicle. This approach complements the hybrid powertrain, resulting in improved fuel economy and reduced emissions.

02 Electric motor integration

The integration of electric motors in mild hybrid powertrains plays a crucial role in improving efficiency. These motors assist the internal combustion engine during acceleration, enable engine start-stop functionality, and recover energy during deceleration. The placement and sizing of the electric motor are optimized to provide the best balance between performance and efficiency gains.Expand Specific Solutions03 Transmission system optimization

Mild hybrid powertrains often feature optimized transmission systems to enhance overall efficiency. This includes the use of advanced continuously variable transmissions (CVTs), dual-clutch transmissions, or specially designed hybrid transmissions that can seamlessly integrate power from both the electric motor and the internal combustion engine. These systems are designed to maintain optimal engine speeds and reduce energy losses during power transfer.Expand Specific Solutions04 Thermal management and waste heat recovery

Efficient thermal management systems are implemented in mild hybrid powertrains to optimize operating temperatures and reduce energy losses. This includes advanced cooling systems for both the electric components and the internal combustion engine. Additionally, waste heat recovery systems are employed to capture and utilize thermal energy that would otherwise be lost, further improving overall powertrain efficiency.Expand Specific Solutions05 Lightweight materials and aerodynamic design

To enhance the efficiency of mild hybrid powertrains, manufacturers focus on reducing vehicle weight through the use of lightweight materials and optimizing aerodynamic design. This includes the use of advanced composites, high-strength steels, and aluminum alloys in powertrain components. Improved aerodynamics reduce drag, which in turn decreases the power required to propel the vehicle, leading to better overall efficiency of the mild hybrid system.Expand Specific Solutions

Key Mild Hybrid Towing Players

The mild hybrid powertrain market for towing vehicles is in a growth phase, driven by increasing demand for fuel-efficient and environmentally friendly solutions. The market size is expanding as automakers integrate mild hybrid systems into their towing vehicle lineups. Technologically, the field is advancing rapidly, with companies like Ford, GM, and Hyundai leading innovation. These firms are developing sophisticated powertrain strategies that optimize efficiency while maintaining towing capabilities. Other players such as Bosch, Schaeffler, and Eaton are contributing with specialized components and systems. The technology's maturity is progressing, with various approaches being explored and refined by major automotive manufacturers and suppliers to meet evolving emissions regulations and consumer expectations.

Ford Global Technologies LLC

Technical Solution: Ford's mild hybrid powertrain strategy for towing vehicles focuses on a 48V belt-driven integrated starter generator (BISG) system. This system allows for engine-off coasting, regenerative braking, and torque assist during acceleration and towing[1]. The BISG is coupled with a 48V lithium-ion battery pack, providing additional power to support the engine during high-load conditions. Ford has also implemented advanced engine management software that optimizes the combustion process and fuel injection timing based on towing conditions[2]. The system includes a smart alternator control strategy that reduces parasitic losses when the vehicle is not under heavy load[3].

Strengths: Improved fuel efficiency, enhanced low-end torque for towing, and seamless integration with existing powertrains. Weaknesses: Limited electric-only operation and additional system complexity.

GM Global Technology Operations LLC

Technical Solution: GM's approach to mild hybrid powertrains for towing vehicles incorporates their eAssist technology. This system utilizes a 24V lithium-ion battery pack and a belt-driven motor generator unit (MGU) that provides up to 15 kW of power assist[4]. The eAssist system enables start-stop functionality, regenerative braking, and electric power assist during acceleration and towing. GM has also developed an advanced thermal management system that helps maintain optimal battery and MGU temperatures during high-load towing conditions[5]. Additionally, GM's strategy includes a predictive energy management system that uses GPS and route data to optimize the use of electric assist and regenerative braking based on upcoming terrain and traffic conditions[6].

Strengths: Seamless integration with existing powertrains, improved fuel economy, and intelligent energy management. Weaknesses: Limited pure electric capability and additional weight from the hybrid system.

Core Mild Hybrid Technologies

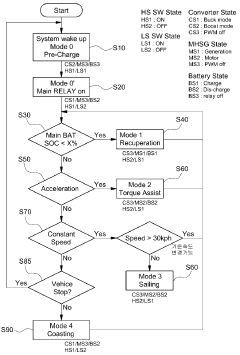

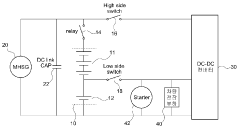

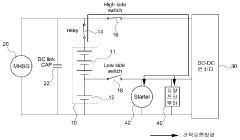

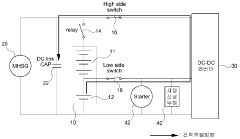

Mild hybrid system of vehicle

PatentActiveKR1020170135039A

Innovation

- Integration of a first and second battery unit in series, with a DC-DC converter, relay switch, and control switches to manage power flow efficiently, reducing the overall system size and improving power conversion efficiency.

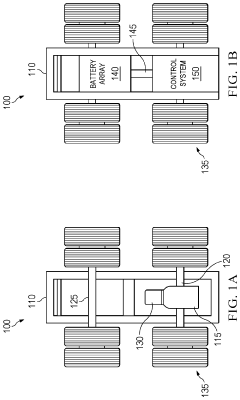

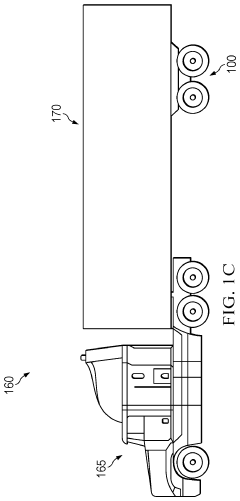

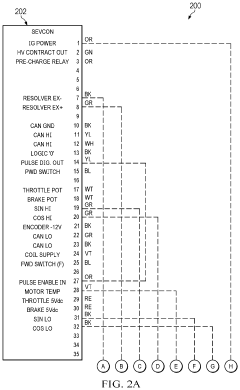

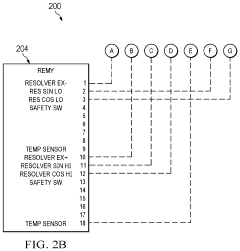

Trailer-based energy capture and management

PatentActiveUS20230271508A1

Innovation

- Implementing a through-the-road hybridization strategy with an electrically powered drive axle that supplements motive forces and uses regenerative braking to recharge energy stores, operating independently of the fuel-fed engine and primary drivetrain, and utilizing control strategies like ECMS to optimize energy management and fuel efficiency.

Emissions Regulations Impact

Emissions regulations have become increasingly stringent worldwide, significantly impacting the development of mild hybrid powertrain strategies for towing vehicles. These regulations aim to reduce greenhouse gas emissions and improve air quality, pushing manufacturers to innovate and optimize their vehicle efficiency.

In the European Union, the implementation of Euro 6d and the upcoming Euro 7 standards has set challenging targets for reducing nitrogen oxides (NOx) and particulate matter emissions. These standards have prompted automakers to invest heavily in mild hybrid technologies for towing vehicles, as they offer a cost-effective solution to meet emission requirements while maintaining performance.

The United States has also tightened its emissions regulations, with the Corporate Average Fuel Economy (CAFE) standards and the Environmental Protection Agency's (EPA) greenhouse gas emissions standards driving the adoption of mild hybrid systems in towing vehicles. These regulations have led to the development of more efficient powertrains that can handle the additional load of towing while still meeting stringent emissions targets.

China, the world's largest automotive market, has implemented its China 6 emissions standards, which are comparable to Euro 6 standards. This has created a significant demand for mild hybrid technologies in towing vehicles, as manufacturers seek to comply with these regulations while catering to the growing market for SUVs and light trucks capable of towing.

The impact of these regulations on mild hybrid powertrain strategies for towing vehicles has been multifaceted. Firstly, it has accelerated the development of more efficient internal combustion engines, often downsized and turbocharged, which work in conjunction with electric motors to optimize fuel consumption and reduce emissions during towing operations.

Secondly, emissions regulations have driven improvements in energy recovery systems, such as regenerative braking, which are particularly beneficial for towing vehicles due to their higher mass and frequent deceleration events. These systems help to capture and store energy that would otherwise be lost, improving overall efficiency and reducing emissions.

Furthermore, the regulations have spurred advancements in powertrain control strategies, with sophisticated engine management systems and hybrid control units working together to optimize power delivery and emissions reduction. These systems can adapt to various towing conditions, ensuring that the vehicle operates within regulatory limits while maintaining performance.

The impact of emissions regulations has also extended to the development of new materials and manufacturing processes. Lightweight materials are being increasingly used in towing vehicle construction to offset the additional weight of hybrid components, helping to maintain efficiency and meet emissions targets.

In the European Union, the implementation of Euro 6d and the upcoming Euro 7 standards has set challenging targets for reducing nitrogen oxides (NOx) and particulate matter emissions. These standards have prompted automakers to invest heavily in mild hybrid technologies for towing vehicles, as they offer a cost-effective solution to meet emission requirements while maintaining performance.

The United States has also tightened its emissions regulations, with the Corporate Average Fuel Economy (CAFE) standards and the Environmental Protection Agency's (EPA) greenhouse gas emissions standards driving the adoption of mild hybrid systems in towing vehicles. These regulations have led to the development of more efficient powertrains that can handle the additional load of towing while still meeting stringent emissions targets.

China, the world's largest automotive market, has implemented its China 6 emissions standards, which are comparable to Euro 6 standards. This has created a significant demand for mild hybrid technologies in towing vehicles, as manufacturers seek to comply with these regulations while catering to the growing market for SUVs and light trucks capable of towing.

The impact of these regulations on mild hybrid powertrain strategies for towing vehicles has been multifaceted. Firstly, it has accelerated the development of more efficient internal combustion engines, often downsized and turbocharged, which work in conjunction with electric motors to optimize fuel consumption and reduce emissions during towing operations.

Secondly, emissions regulations have driven improvements in energy recovery systems, such as regenerative braking, which are particularly beneficial for towing vehicles due to their higher mass and frequent deceleration events. These systems help to capture and store energy that would otherwise be lost, improving overall efficiency and reducing emissions.

Furthermore, the regulations have spurred advancements in powertrain control strategies, with sophisticated engine management systems and hybrid control units working together to optimize power delivery and emissions reduction. These systems can adapt to various towing conditions, ensuring that the vehicle operates within regulatory limits while maintaining performance.

The impact of emissions regulations has also extended to the development of new materials and manufacturing processes. Lightweight materials are being increasingly used in towing vehicle construction to offset the additional weight of hybrid components, helping to maintain efficiency and meet emissions targets.

Total Cost of Ownership Analysis

The Total Cost of Ownership (TCO) analysis for mild hybrid powertrain strategies in towing vehicles reveals significant economic implications for both manufacturers and end-users. This comprehensive evaluation encompasses initial purchase costs, operational expenses, maintenance requirements, and potential resale value over the vehicle's lifecycle.

Upfront costs for mild hybrid towing vehicles typically exceed those of conventional counterparts due to the additional components such as electric motors, batteries, and power electronics. However, this price premium is often offset by long-term savings in fuel consumption and reduced maintenance needs. The extent of these savings varies depending on factors such as driving patterns, towing frequency, and local fuel prices.

Operational costs represent a substantial portion of the TCO for towing vehicles. Mild hybrid systems can significantly reduce fuel consumption, especially in urban environments and during frequent start-stop scenarios. For towing applications, the regenerative braking feature proves particularly beneficial, capturing energy typically lost during deceleration and downhill driving. This energy recovery translates to tangible fuel savings, especially when towing heavy loads.

Maintenance costs for mild hybrid towing vehicles generally trend lower than traditional powertrains. The electric assist reduces strain on the internal combustion engine, potentially extending its lifespan and decreasing wear on components like brake pads due to regenerative braking. However, the complexity of the hybrid system may necessitate specialized maintenance, potentially increasing service costs in some instances.

Insurance costs can vary, with some providers offering discounts for hybrid vehicles due to their advanced safety features and lower accident rates. Conversely, the higher initial value and potential repair costs of hybrid components may lead to increased premiums in certain markets.

Depreciation rates for mild hybrid towing vehicles are generally favorable compared to conventional models. The growing emphasis on fuel efficiency and environmental consciousness in the automotive market tends to support stronger resale values for hybrid vehicles. This trend is particularly pronounced in regions with stringent emissions regulations or high fuel prices.

Government incentives can significantly impact the TCO equation. Many jurisdictions offer tax credits, rebates, or other financial incentives for purchasing hybrid vehicles, effectively reducing the initial cost barrier. Additionally, some areas provide ongoing benefits such as reduced road taxes or preferential parking rates, further enhancing the long-term economic proposition of mild hybrid towing vehicles.

In conclusion, while the initial investment in mild hybrid technology for towing vehicles is higher, the TCO analysis often reveals favorable long-term economics. The combination of reduced fuel consumption, lower maintenance costs, potential incentives, and strong resale values typically results in a compelling financial case for adoption, particularly for high-mileage users or those frequently engaged in towing activities.

Upfront costs for mild hybrid towing vehicles typically exceed those of conventional counterparts due to the additional components such as electric motors, batteries, and power electronics. However, this price premium is often offset by long-term savings in fuel consumption and reduced maintenance needs. The extent of these savings varies depending on factors such as driving patterns, towing frequency, and local fuel prices.

Operational costs represent a substantial portion of the TCO for towing vehicles. Mild hybrid systems can significantly reduce fuel consumption, especially in urban environments and during frequent start-stop scenarios. For towing applications, the regenerative braking feature proves particularly beneficial, capturing energy typically lost during deceleration and downhill driving. This energy recovery translates to tangible fuel savings, especially when towing heavy loads.

Maintenance costs for mild hybrid towing vehicles generally trend lower than traditional powertrains. The electric assist reduces strain on the internal combustion engine, potentially extending its lifespan and decreasing wear on components like brake pads due to regenerative braking. However, the complexity of the hybrid system may necessitate specialized maintenance, potentially increasing service costs in some instances.

Insurance costs can vary, with some providers offering discounts for hybrid vehicles due to their advanced safety features and lower accident rates. Conversely, the higher initial value and potential repair costs of hybrid components may lead to increased premiums in certain markets.

Depreciation rates for mild hybrid towing vehicles are generally favorable compared to conventional models. The growing emphasis on fuel efficiency and environmental consciousness in the automotive market tends to support stronger resale values for hybrid vehicles. This trend is particularly pronounced in regions with stringent emissions regulations or high fuel prices.

Government incentives can significantly impact the TCO equation. Many jurisdictions offer tax credits, rebates, or other financial incentives for purchasing hybrid vehicles, effectively reducing the initial cost barrier. Additionally, some areas provide ongoing benefits such as reduced road taxes or preferential parking rates, further enhancing the long-term economic proposition of mild hybrid towing vehicles.

In conclusion, while the initial investment in mild hybrid technology for towing vehicles is higher, the TCO analysis often reveals favorable long-term economics. The combination of reduced fuel consumption, lower maintenance costs, potential incentives, and strong resale values typically results in a compelling financial case for adoption, particularly for high-mileage users or those frequently engaged in towing activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!