Mild hybrid systems as enablers of future mobility solutions

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Evolution

Mild hybrid systems have undergone significant evolution since their inception, marking key milestones in the automotive industry's journey towards more sustainable and efficient mobility solutions. The evolution of mild hybrid technology can be traced through several distinct phases, each characterized by advancements in system integration, energy management, and overall vehicle performance.

In the early 2000s, the first generation of mild hybrid systems emerged, primarily focusing on basic start-stop functionality and limited regenerative braking. These systems utilized small electric motors and batteries to provide minimal assistance to the internal combustion engine (ICE), offering modest improvements in fuel efficiency and emissions reduction.

The second generation, introduced in the mid-2000s, saw the integration of more powerful electric motors and improved energy storage systems. This allowed for enhanced regenerative braking capabilities and the ability to provide limited electric assist during acceleration. The integration of these systems became more seamless, with manufacturers developing sophisticated control strategies to optimize the interaction between the electric components and the ICE.

As the technology matured in the early 2010s, the third generation of mild hybrid systems introduced more advanced energy management techniques. This phase saw the widespread adoption of 48-volt electrical systems, which enabled the integration of larger electric motors and more powerful batteries. These systems could provide significant torque assistance, allowing for engine downsizing without compromising performance.

The current generation of mild hybrid systems, emerging in the late 2010s and early 2020s, represents a significant leap forward in terms of integration and functionality. These systems now incorporate advanced power electronics, intelligent energy management algorithms, and sophisticated control units. They can provide extended electric-only operation at low speeds, more substantial power boost during acceleration, and improved fuel efficiency across a wider range of driving conditions.

Looking towards the future, the evolution of mild hybrid systems is expected to continue, with a focus on further integration with other vehicle systems, enhanced connectivity, and predictive energy management strategies. The next generation of mild hybrids may incorporate artificial intelligence to optimize energy usage based on driving patterns, traffic conditions, and even topography. Additionally, the integration of mild hybrid systems with advanced driver assistance systems (ADAS) and autonomous driving technologies is likely to play a crucial role in shaping the future of mobility solutions.

In the early 2000s, the first generation of mild hybrid systems emerged, primarily focusing on basic start-stop functionality and limited regenerative braking. These systems utilized small electric motors and batteries to provide minimal assistance to the internal combustion engine (ICE), offering modest improvements in fuel efficiency and emissions reduction.

The second generation, introduced in the mid-2000s, saw the integration of more powerful electric motors and improved energy storage systems. This allowed for enhanced regenerative braking capabilities and the ability to provide limited electric assist during acceleration. The integration of these systems became more seamless, with manufacturers developing sophisticated control strategies to optimize the interaction between the electric components and the ICE.

As the technology matured in the early 2010s, the third generation of mild hybrid systems introduced more advanced energy management techniques. This phase saw the widespread adoption of 48-volt electrical systems, which enabled the integration of larger electric motors and more powerful batteries. These systems could provide significant torque assistance, allowing for engine downsizing without compromising performance.

The current generation of mild hybrid systems, emerging in the late 2010s and early 2020s, represents a significant leap forward in terms of integration and functionality. These systems now incorporate advanced power electronics, intelligent energy management algorithms, and sophisticated control units. They can provide extended electric-only operation at low speeds, more substantial power boost during acceleration, and improved fuel efficiency across a wider range of driving conditions.

Looking towards the future, the evolution of mild hybrid systems is expected to continue, with a focus on further integration with other vehicle systems, enhanced connectivity, and predictive energy management strategies. The next generation of mild hybrids may incorporate artificial intelligence to optimize energy usage based on driving patterns, traffic conditions, and even topography. Additionally, the integration of mild hybrid systems with advanced driver assistance systems (ADAS) and autonomous driving technologies is likely to play a crucial role in shaping the future of mobility solutions.

Market Demand Analysis

The market demand for mild hybrid systems as enablers of future mobility solutions has been steadily increasing in recent years. This growth is primarily driven by stringent emissions regulations, rising fuel costs, and increasing consumer awareness of environmental issues. Automotive manufacturers are increasingly turning to mild hybrid technology as a cost-effective solution to meet these challenges while improving vehicle performance and fuel efficiency.

In the passenger vehicle segment, mild hybrid systems have gained significant traction. Major automakers have introduced mild hybrid variants across their product lines, from compact cars to luxury SUVs. This widespread adoption indicates a strong market pull for the technology. The commercial vehicle sector is also showing interest in mild hybrid systems, particularly for urban delivery vehicles and light-duty trucks, where frequent start-stop operations can benefit from the energy recovery capabilities of mild hybrids.

The global mild hybrid market is expected to grow substantially over the next decade. This growth is attributed to the technology's ability to provide a balance between improved fuel economy and performance without the complexity and cost associated with full hybrid or electric vehicles. Mild hybrid systems offer a pragmatic stepping stone towards electrification for many consumers and fleet operators who are not yet ready to transition to fully electric vehicles.

Geographically, Europe has been at the forefront of mild hybrid adoption, driven by strict CO2 emissions targets. The Asian market, particularly China and India, is also showing rapid growth in demand for mild hybrid vehicles. These markets are characterized by dense urban environments where the benefits of mild hybrid technology are most pronounced. North America, while initially slower to adopt, is now seeing increased interest in mild hybrid systems as automakers seek to improve their fleet-wide fuel economy.

The market demand is further bolstered by advancements in mild hybrid technology. The integration of more powerful electric motors, improved battery technology, and sophisticated power management systems is enhancing the capabilities of mild hybrid vehicles. This evolution is expanding the potential applications of mild hybrid systems, making them attractive for a wider range of vehicle types and use cases.

However, the market demand for mild hybrid systems is not without challenges. The technology faces competition from full hybrid and battery electric vehicles, which offer more significant emissions reductions. Additionally, the cost-benefit ratio of mild hybrid systems must continually improve to maintain their appeal in the face of rapidly advancing electric vehicle technology. Despite these challenges, the market for mild hybrid systems remains robust, with many industry analysts predicting continued growth in the medium term as a key enabler of future mobility solutions.

In the passenger vehicle segment, mild hybrid systems have gained significant traction. Major automakers have introduced mild hybrid variants across their product lines, from compact cars to luxury SUVs. This widespread adoption indicates a strong market pull for the technology. The commercial vehicle sector is also showing interest in mild hybrid systems, particularly for urban delivery vehicles and light-duty trucks, where frequent start-stop operations can benefit from the energy recovery capabilities of mild hybrids.

The global mild hybrid market is expected to grow substantially over the next decade. This growth is attributed to the technology's ability to provide a balance between improved fuel economy and performance without the complexity and cost associated with full hybrid or electric vehicles. Mild hybrid systems offer a pragmatic stepping stone towards electrification for many consumers and fleet operators who are not yet ready to transition to fully electric vehicles.

Geographically, Europe has been at the forefront of mild hybrid adoption, driven by strict CO2 emissions targets. The Asian market, particularly China and India, is also showing rapid growth in demand for mild hybrid vehicles. These markets are characterized by dense urban environments where the benefits of mild hybrid technology are most pronounced. North America, while initially slower to adopt, is now seeing increased interest in mild hybrid systems as automakers seek to improve their fleet-wide fuel economy.

The market demand is further bolstered by advancements in mild hybrid technology. The integration of more powerful electric motors, improved battery technology, and sophisticated power management systems is enhancing the capabilities of mild hybrid vehicles. This evolution is expanding the potential applications of mild hybrid systems, making them attractive for a wider range of vehicle types and use cases.

However, the market demand for mild hybrid systems is not without challenges. The technology faces competition from full hybrid and battery electric vehicles, which offer more significant emissions reductions. Additionally, the cost-benefit ratio of mild hybrid systems must continually improve to maintain their appeal in the face of rapidly advancing electric vehicle technology. Despite these challenges, the market for mild hybrid systems remains robust, with many industry analysts predicting continued growth in the medium term as a key enabler of future mobility solutions.

Technical Challenges

Mild hybrid systems face several technical challenges that need to be addressed to fully realize their potential as enablers of future mobility solutions. One of the primary challenges is the integration of the electric motor with the conventional internal combustion engine (ICE). This integration requires sophisticated control systems to manage the seamless transition between electric and ICE power, ensuring optimal performance and efficiency.

The energy storage system presents another significant challenge. Current battery technologies used in mild hybrid systems have limited capacity and power density. Improving these aspects without significantly increasing cost or weight is crucial for enhancing the overall performance of mild hybrid vehicles. Additionally, the durability and lifespan of these batteries under frequent charge-discharge cycles in real-world driving conditions remain areas of concern.

Thermal management is a critical issue in mild hybrid systems. The electric components, particularly the battery and power electronics, generate heat during operation. Efficient cooling systems are necessary to maintain optimal operating temperatures, which directly impacts system performance and longevity. Developing compact and effective thermal management solutions without adding substantial weight or complexity to the vehicle is a ongoing challenge.

Weight reduction is another key area of focus. While mild hybrid systems offer improved fuel efficiency, they also add weight to the vehicle due to the additional electric components. Engineers must find innovative ways to offset this weight gain through the use of lightweight materials and optimized designs, without compromising safety or performance.

The cost-effectiveness of mild hybrid systems remains a significant hurdle. While these systems offer improved fuel economy and reduced emissions, the additional components increase the overall cost of the vehicle. Striking a balance between performance benefits and cost is crucial for widespread adoption. This challenge extends to the manufacturing process, where integrating mild hybrid components into existing production lines requires substantial investment and retooling.

Lastly, the development of standardized architectures for mild hybrid systems is an ongoing challenge. The lack of industry-wide standards can lead to increased complexity in design, manufacturing, and maintenance. Establishing common platforms and interfaces could significantly reduce costs and improve interoperability across different vehicle models and manufacturers.

Addressing these technical challenges is crucial for the continued evolution of mild hybrid systems. As these issues are resolved, mild hybrids will play an increasingly important role in bridging the gap between conventional ICE vehicles and fully electric vehicles, paving the way for more sustainable and efficient mobility solutions in the future.

The energy storage system presents another significant challenge. Current battery technologies used in mild hybrid systems have limited capacity and power density. Improving these aspects without significantly increasing cost or weight is crucial for enhancing the overall performance of mild hybrid vehicles. Additionally, the durability and lifespan of these batteries under frequent charge-discharge cycles in real-world driving conditions remain areas of concern.

Thermal management is a critical issue in mild hybrid systems. The electric components, particularly the battery and power electronics, generate heat during operation. Efficient cooling systems are necessary to maintain optimal operating temperatures, which directly impacts system performance and longevity. Developing compact and effective thermal management solutions without adding substantial weight or complexity to the vehicle is a ongoing challenge.

Weight reduction is another key area of focus. While mild hybrid systems offer improved fuel efficiency, they also add weight to the vehicle due to the additional electric components. Engineers must find innovative ways to offset this weight gain through the use of lightweight materials and optimized designs, without compromising safety or performance.

The cost-effectiveness of mild hybrid systems remains a significant hurdle. While these systems offer improved fuel economy and reduced emissions, the additional components increase the overall cost of the vehicle. Striking a balance between performance benefits and cost is crucial for widespread adoption. This challenge extends to the manufacturing process, where integrating mild hybrid components into existing production lines requires substantial investment and retooling.

Lastly, the development of standardized architectures for mild hybrid systems is an ongoing challenge. The lack of industry-wide standards can lead to increased complexity in design, manufacturing, and maintenance. Establishing common platforms and interfaces could significantly reduce costs and improve interoperability across different vehicle models and manufacturers.

Addressing these technical challenges is crucial for the continued evolution of mild hybrid systems. As these issues are resolved, mild hybrids will play an increasingly important role in bridging the gap between conventional ICE vehicles and fully electric vehicles, paving the way for more sustainable and efficient mobility solutions in the future.

Current Mild Hybrid

01 Electric motor integration in mild hybrid systems

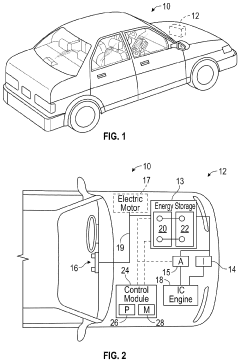

Mild hybrid systems incorporate electric motors to assist the internal combustion engine, improving fuel efficiency and performance. These motors can be integrated in various configurations, such as belt-driven starter generators or integrated starter generators, to provide additional power during acceleration and enable start-stop functionality.- Mild hybrid system architecture: Mild hybrid systems typically consist of a conventional internal combustion engine combined with an electric motor-generator. This setup allows for improved fuel efficiency and reduced emissions through features like engine start-stop, regenerative braking, and electric assist during acceleration. The electric components are generally smaller and less powerful than those in full hybrid systems, making mild hybrids a cost-effective option for improving vehicle efficiency.

- Energy management and control strategies: Efficient energy management is crucial in mild hybrid systems. Advanced control strategies are employed to optimize the interaction between the internal combustion engine and the electric motor-generator. These strategies may include predictive energy management, adaptive control algorithms, and real-time optimization techniques to maximize fuel efficiency and performance based on driving conditions and driver behavior.

- Integration with transmission systems: Mild hybrid systems can be integrated with various transmission types, including manual, automatic, and continuously variable transmissions (CVT). The integration often involves placing the electric motor-generator between the engine and transmission or directly coupling it to the transmission. This arrangement allows for seamless power blending and enables features like electric creep and smoother gear shifts.

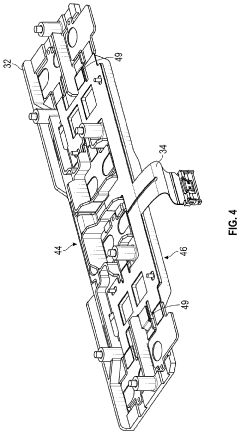

- Battery and power electronics: Mild hybrid systems typically use smaller battery packs compared to full hybrids, often with voltages ranging from 48V to 160V. Advanced power electronics are employed to manage the flow of electrical energy between the battery, motor-generator, and vehicle electrical systems. These components are designed for high efficiency, compact size, and cost-effectiveness to suit the mild hybrid application.

- Regenerative braking and energy recovery: Regenerative braking is a key feature of mild hybrid systems, allowing for the recovery of kinetic energy during deceleration and braking. The electric motor-generator acts as a generator during these events, converting kinetic energy into electrical energy to charge the battery. This recovered energy can then be used to power vehicle electrical systems or assist the engine during acceleration, further improving overall efficiency.

02 Energy management and power distribution

Mild hybrid systems employ sophisticated energy management strategies to optimize power distribution between the electric motor and internal combustion engine. This includes controlling battery charging, regenerative braking, and power assist modes to maximize efficiency and reduce emissions.Expand Specific Solutions03 Battery and electrical system design

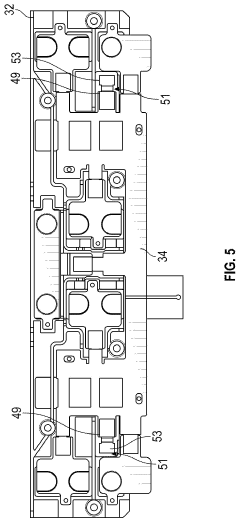

The design of the battery and electrical system is crucial in mild hybrid systems. This includes the selection of appropriate battery chemistry, capacity, and voltage levels to support the electric motor's operation while minimizing weight and space requirements. Advanced power electronics and control systems are also essential for managing the flow of electrical energy.Expand Specific Solutions04 Transmission and drivetrain integration

Mild hybrid systems often require modifications to the transmission and drivetrain to accommodate the electric motor's integration. This may involve redesigning the transmission to incorporate the electric motor or developing new hybrid-specific transmissions that optimize the interaction between the electric motor and internal combustion engine.Expand Specific Solutions05 Control strategies and software algorithms

Advanced control strategies and software algorithms are essential for the efficient operation of mild hybrid systems. These include predictive energy management, adaptive control systems, and intelligent power distribution algorithms that optimize the use of electric and combustion power based on driving conditions and user preferences.Expand Specific Solutions

Key Industry Players

The mild hybrid systems market is in a growth phase, driven by increasing demand for fuel-efficient vehicles and stricter emissions regulations. The global market size is projected to expand significantly in the coming years. Technologically, mild hybrid systems are relatively mature, with major automotive players like Hyundai, General Motors, and Volkswagen actively developing and implementing these solutions. Companies such as BYD, NIO, and Beijing Electric Vehicle are pushing innovation in this space, particularly in the Chinese market. Established suppliers like ZF Friedrichshafen, Schaeffler, and DENSO are also key players, providing components and systems to automakers. The technology's adoption is accelerating across various vehicle segments, indicating its growing importance in future mobility solutions.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative 48V mild hybrid system that integrates seamlessly with existing powertrains. This system includes a 48V lithium-ion battery, a Belt-Driven Starter Generator (BSG), and a Low Voltage DC/DC Converter (LDC). The BSG replaces the traditional alternator, enabling energy recuperation during deceleration and providing electric torque assistance during acceleration[1]. Hyundai's system can reduce fuel consumption by up to 7% in real-world driving conditions[2]. The company has also introduced a Continuously Variable Valve Duration (CVVD) technology, which works in tandem with the mild hybrid system to further optimize engine efficiency[3].

Strengths: Seamless integration with existing powertrains, significant fuel economy improvements, and enhanced performance. Weaknesses: Higher initial cost compared to conventional powertrains, and limited electric-only driving range.

General Motors LLC

Technical Solution: General Motors has developed a sophisticated 48V mild hybrid system called eAssist. This system features a compact lithium-ion battery and a Belt-Alternator-Starter (BAS) motor. The BAS motor provides electric torque assistance during acceleration and enables regenerative braking to recapture energy during deceleration[4]. GM's eAssist technology can improve fuel efficiency by up to 15% in city driving conditions[5]. The system also incorporates advanced start-stop functionality, which can shut off the engine when the vehicle is stationary and restart it seamlessly when needed. GM has integrated this technology across various vehicle platforms, from compact cars to full-size SUVs, demonstrating its scalability and versatility[6].

Strengths: Significant fuel efficiency improvements, wide range of vehicle applications, and enhanced start-stop functionality. Weaknesses: Added complexity to the powertrain system and potential long-term reliability concerns.

Core Innovations

Hybrid vehicle

PatentWO2018054772A1

Innovation

- A hybrid vehicle with a simplified transmission system that integrates an electric machine, energy storage device, and main control via a data bus, allowing the main transmission control to manage all components, reducing complexity and enhancing reliability, and using a mild hybrid configuration with a 12V or 24V electrical system to eliminate the need for alternators and reduce battery size.

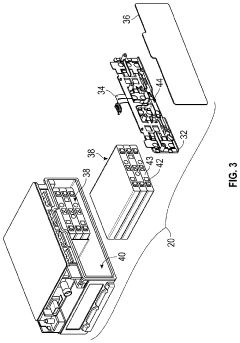

Bus bar assembly having a temperature sensing interface, battery moudle including the bus bar assembly, and method of manufacturing the battery module

PatentPendingUS20220238926A1

Innovation

- A bus bar assembly with a flex circuit and temperature sensor welding tab is used, where the welding tab is soldered to the flex circuit and welded to the terminal end of the electrochemical cell, creating a robust mechanical joint that facilitates accurate temperature sensing and withstands mechanical tests like vibration and shock.

Emissions Regulations

Emissions regulations have become increasingly stringent worldwide, driving the automotive industry towards more sustainable and environmentally friendly technologies. Mild hybrid systems have emerged as a crucial enabler for future mobility solutions, offering a cost-effective approach to meeting these regulations while improving fuel efficiency and reducing emissions.

The European Union has set ambitious targets for reducing CO2 emissions from new passenger cars and light commercial vehicles. By 2030, the EU aims to reduce CO2 emissions by 37.5% for cars and 31% for vans, compared to 2021 levels. These regulations have prompted automakers to invest heavily in electrification technologies, including mild hybrid systems, to comply with the new standards.

In the United States, the Corporate Average Fuel Economy (CAFE) standards require manufacturers to achieve increasingly higher fleet-wide fuel efficiency. The Biden administration has proposed new standards that would require an industry-wide fleet average of approximately 49 mpg for passenger cars and light trucks by 2026. Mild hybrid systems play a significant role in helping automakers meet these stringent requirements.

China, the world's largest automotive market, has also implemented strict emissions regulations. The China 6 standard, which came into effect in 2020, is one of the most stringent emission standards globally. Additionally, China has set ambitious targets for new energy vehicles (NEVs), including hybrid and electric vehicles, to account for 20% of all vehicle sales by 2025.

Mild hybrid systems offer a practical solution for automakers to comply with these regulations. By integrating a small electric motor and battery with a conventional internal combustion engine, mild hybrids can reduce fuel consumption and CO2 emissions by up to 15%. This technology allows for engine shut-off during coasting, regenerative braking, and electric boost during acceleration, all contributing to improved efficiency and reduced emissions.

Furthermore, mild hybrid systems provide a stepping stone towards full electrification. As battery technology continues to advance and costs decrease, mild hybrid systems can be easily upgraded to full hybrid or plug-in hybrid configurations, allowing automakers to gradually transition their product lines to meet future emissions targets.

The adoption of mild hybrid systems is expected to grow significantly in the coming years, driven by these stringent emissions regulations. According to market research, the global mild hybrid market is projected to reach $20 billion by 2025, with a compound annual growth rate of over 15%. This growth demonstrates the critical role that mild hybrid systems will play in enabling future mobility solutions and helping automakers comply with increasingly strict emissions standards worldwide.

The European Union has set ambitious targets for reducing CO2 emissions from new passenger cars and light commercial vehicles. By 2030, the EU aims to reduce CO2 emissions by 37.5% for cars and 31% for vans, compared to 2021 levels. These regulations have prompted automakers to invest heavily in electrification technologies, including mild hybrid systems, to comply with the new standards.

In the United States, the Corporate Average Fuel Economy (CAFE) standards require manufacturers to achieve increasingly higher fleet-wide fuel efficiency. The Biden administration has proposed new standards that would require an industry-wide fleet average of approximately 49 mpg for passenger cars and light trucks by 2026. Mild hybrid systems play a significant role in helping automakers meet these stringent requirements.

China, the world's largest automotive market, has also implemented strict emissions regulations. The China 6 standard, which came into effect in 2020, is one of the most stringent emission standards globally. Additionally, China has set ambitious targets for new energy vehicles (NEVs), including hybrid and electric vehicles, to account for 20% of all vehicle sales by 2025.

Mild hybrid systems offer a practical solution for automakers to comply with these regulations. By integrating a small electric motor and battery with a conventional internal combustion engine, mild hybrids can reduce fuel consumption and CO2 emissions by up to 15%. This technology allows for engine shut-off during coasting, regenerative braking, and electric boost during acceleration, all contributing to improved efficiency and reduced emissions.

Furthermore, mild hybrid systems provide a stepping stone towards full electrification. As battery technology continues to advance and costs decrease, mild hybrid systems can be easily upgraded to full hybrid or plug-in hybrid configurations, allowing automakers to gradually transition their product lines to meet future emissions targets.

The adoption of mild hybrid systems is expected to grow significantly in the coming years, driven by these stringent emissions regulations. According to market research, the global mild hybrid market is projected to reach $20 billion by 2025, with a compound annual growth rate of over 15%. This growth demonstrates the critical role that mild hybrid systems will play in enabling future mobility solutions and helping automakers comply with increasingly strict emissions standards worldwide.

Cost-Benefit Analysis

The cost-benefit analysis of mild hybrid systems as enablers of future mobility solutions reveals a complex interplay of economic, environmental, and technological factors. From a financial perspective, the initial investment in mild hybrid technology is relatively modest compared to full hybrid or electric vehicles, making it an attractive option for automakers and consumers alike.

One of the primary benefits is the significant improvement in fuel efficiency, typically ranging from 10% to 15% in urban driving conditions. This translates to substantial cost savings for vehicle owners over the lifetime of the vehicle, particularly in regions with high fuel prices. Moreover, the reduced fuel consumption directly correlates with lower CO2 emissions, aligning with increasingly stringent environmental regulations and consumer preferences for greener transportation options.

The simplicity of mild hybrid systems, which can be integrated into existing vehicle architectures with minimal modifications, offers a cost-effective solution for manufacturers. This adaptability allows for faster market penetration and economies of scale, potentially reducing production costs over time. Additionally, the technology's compatibility with both gasoline and diesel engines provides flexibility in meeting diverse market demands.

However, the benefits of mild hybrid systems must be weighed against certain limitations. The fuel economy improvements, while significant, are less pronounced than those offered by full hybrid or electric vehicles. This may impact long-term competitiveness as more advanced electrification technologies become mainstream. Furthermore, the added components of mild hybrid systems, such as the electric motor and battery, introduce new maintenance considerations and potential repair costs.

From a broader perspective, mild hybrid technology serves as a bridge between conventional internal combustion engines and fully electrified powertrains. This transitional role offers valuable time for infrastructure development and consumer adaptation to electrification, potentially smoothing the path towards more sustainable mobility solutions. However, this intermediary position also raises questions about the long-term viability of mild hybrid systems as stricter emissions standards may eventually favor fully electric solutions.

In conclusion, the cost-benefit analysis of mild hybrid systems reveals a generally positive outlook in the short to medium term. The technology offers a balanced approach to improving fuel efficiency and reducing emissions without requiring radical changes in vehicle design or consumer behavior. However, the long-term benefits may diminish as more advanced electrification technologies mature and become more cost-competitive.

One of the primary benefits is the significant improvement in fuel efficiency, typically ranging from 10% to 15% in urban driving conditions. This translates to substantial cost savings for vehicle owners over the lifetime of the vehicle, particularly in regions with high fuel prices. Moreover, the reduced fuel consumption directly correlates with lower CO2 emissions, aligning with increasingly stringent environmental regulations and consumer preferences for greener transportation options.

The simplicity of mild hybrid systems, which can be integrated into existing vehicle architectures with minimal modifications, offers a cost-effective solution for manufacturers. This adaptability allows for faster market penetration and economies of scale, potentially reducing production costs over time. Additionally, the technology's compatibility with both gasoline and diesel engines provides flexibility in meeting diverse market demands.

However, the benefits of mild hybrid systems must be weighed against certain limitations. The fuel economy improvements, while significant, are less pronounced than those offered by full hybrid or electric vehicles. This may impact long-term competitiveness as more advanced electrification technologies become mainstream. Furthermore, the added components of mild hybrid systems, such as the electric motor and battery, introduce new maintenance considerations and potential repair costs.

From a broader perspective, mild hybrid technology serves as a bridge between conventional internal combustion engines and fully electrified powertrains. This transitional role offers valuable time for infrastructure development and consumer adaptation to electrification, potentially smoothing the path towards more sustainable mobility solutions. However, this intermediary position also raises questions about the long-term viability of mild hybrid systems as stricter emissions standards may eventually favor fully electric solutions.

In conclusion, the cost-benefit analysis of mild hybrid systems reveals a generally positive outlook in the short to medium term. The technology offers a balanced approach to improving fuel efficiency and reducing emissions without requiring radical changes in vehicle design or consumer behavior. However, the long-term benefits may diminish as more advanced electrification technologies mature and become more cost-competitive.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!