Neuromorphic materials innovations in haptic feedback systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neuromorphic Haptics Background and Objectives

Neuromorphic haptic systems represent a convergence of neuroscience, materials science, and robotics, aiming to replicate the human sense of touch in artificial systems. The evolution of this technology has progressed from simple vibration motors to sophisticated systems that can detect and respond to various tactile stimuli. This technological trajectory has been driven by the increasing demand for more intuitive human-machine interfaces across multiple sectors including healthcare, virtual reality, and industrial automation.

The field of neuromorphic haptics emerged in the early 2000s, building upon foundational work in both haptic feedback and neuromorphic computing. Early systems focused primarily on mechanical stimulation, while recent advancements have incorporated electrical, thermal, and chemical components to create multi-modal feedback mechanisms that more closely mimic human sensory experiences.

Current research objectives in neuromorphic materials for haptic feedback systems center on developing materials that can simultaneously sense pressure, temperature, and texture while providing real-time feedback with minimal latency. These materials must demonstrate high sensitivity, durability, and energy efficiency to be viable for commercial applications. Additionally, they should be capable of integration with existing electronic systems and adaptable to various form factors.

A significant technical goal is the development of self-healing and self-calibrating materials that can maintain performance over extended periods without degradation. This includes the creation of biomimetic structures that replicate the hierarchical organization of human skin, incorporating both fast-responding mechanoreceptors and slower adapting sensory neurons.

The integration of machine learning algorithms with these advanced materials represents another critical objective, enabling systems to learn from interactions and improve their response characteristics over time. This adaptive capability is essential for applications requiring personalized feedback, such as prosthetics and rehabilitation devices.

From a manufacturing perspective, researchers aim to develop scalable production methods for these complex materials, transitioning from laboratory demonstrations to commercially viable products. This includes addressing challenges related to material consistency, quality control, and cost-effectiveness.

The ultimate vision for neuromorphic haptic systems is to create a bidirectional interface that not only provides realistic tactile feedback but also accurately captures and interprets human touch inputs. This would enable truly immersive virtual experiences, enhanced teleoperation capabilities, and more natural human-robot interactions across various domains.

The field of neuromorphic haptics emerged in the early 2000s, building upon foundational work in both haptic feedback and neuromorphic computing. Early systems focused primarily on mechanical stimulation, while recent advancements have incorporated electrical, thermal, and chemical components to create multi-modal feedback mechanisms that more closely mimic human sensory experiences.

Current research objectives in neuromorphic materials for haptic feedback systems center on developing materials that can simultaneously sense pressure, temperature, and texture while providing real-time feedback with minimal latency. These materials must demonstrate high sensitivity, durability, and energy efficiency to be viable for commercial applications. Additionally, they should be capable of integration with existing electronic systems and adaptable to various form factors.

A significant technical goal is the development of self-healing and self-calibrating materials that can maintain performance over extended periods without degradation. This includes the creation of biomimetic structures that replicate the hierarchical organization of human skin, incorporating both fast-responding mechanoreceptors and slower adapting sensory neurons.

The integration of machine learning algorithms with these advanced materials represents another critical objective, enabling systems to learn from interactions and improve their response characteristics over time. This adaptive capability is essential for applications requiring personalized feedback, such as prosthetics and rehabilitation devices.

From a manufacturing perspective, researchers aim to develop scalable production methods for these complex materials, transitioning from laboratory demonstrations to commercially viable products. This includes addressing challenges related to material consistency, quality control, and cost-effectiveness.

The ultimate vision for neuromorphic haptic systems is to create a bidirectional interface that not only provides realistic tactile feedback but also accurately captures and interprets human touch inputs. This would enable truly immersive virtual experiences, enhanced teleoperation capabilities, and more natural human-robot interactions across various domains.

Market Analysis for Advanced Haptic Feedback Solutions

The global market for advanced haptic feedback solutions is experiencing robust growth, driven by increasing demand for immersive user experiences across multiple industries. Current market valuations place the haptic technology sector at approximately 12.9 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 13.7% through 2030. This growth trajectory is particularly evident in consumer electronics, automotive interfaces, medical training systems, and virtual reality applications.

Consumer electronics represents the largest market segment, accounting for nearly 40% of current haptic technology implementations. Smartphone manufacturers have progressed from simple vibration motors to sophisticated actuators capable of delivering nuanced tactile sensations. The gaming industry has similarly embraced advanced haptic feedback, with major console manufacturers incorporating precision haptic systems that can simulate various textures and resistances.

The automotive sector has emerged as a rapidly expanding market for haptic solutions, growing at 16.2% annually as manufacturers integrate touch-responsive interfaces into vehicle control systems. These implementations enhance driver safety by providing non-visual feedback and improving the intuitive operation of increasingly complex vehicle systems.

Healthcare applications represent a high-value segment with significant growth potential. Medical training simulators incorporating neuromorphic haptic feedback have demonstrated improved learning outcomes for surgical procedures, with institutions reporting 28% better skill retention compared to traditional training methods. The market for these specialized systems is expected to double within five years.

Regional analysis reveals North America currently leads market share at 38%, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 15.8% annually, driven by expanding manufacturing capabilities and increasing consumer adoption of haptic-enabled devices.

Customer demand patterns indicate a clear preference for more realistic and responsive haptic experiences, with 73% of surveyed consumers rating tactile feedback as "important" or "very important" in their purchasing decisions for electronic devices. This preference is particularly pronounced among younger demographics, suggesting sustained long-term market growth.

Supply chain analysis reveals potential constraints in specialized materials required for neuromorphic haptic systems, with several key components currently sourced from limited suppliers. This represents both a market challenge and an opportunity for materials innovation to address supply limitations while improving performance characteristics.

Consumer electronics represents the largest market segment, accounting for nearly 40% of current haptic technology implementations. Smartphone manufacturers have progressed from simple vibration motors to sophisticated actuators capable of delivering nuanced tactile sensations. The gaming industry has similarly embraced advanced haptic feedback, with major console manufacturers incorporating precision haptic systems that can simulate various textures and resistances.

The automotive sector has emerged as a rapidly expanding market for haptic solutions, growing at 16.2% annually as manufacturers integrate touch-responsive interfaces into vehicle control systems. These implementations enhance driver safety by providing non-visual feedback and improving the intuitive operation of increasingly complex vehicle systems.

Healthcare applications represent a high-value segment with significant growth potential. Medical training simulators incorporating neuromorphic haptic feedback have demonstrated improved learning outcomes for surgical procedures, with institutions reporting 28% better skill retention compared to traditional training methods. The market for these specialized systems is expected to double within five years.

Regional analysis reveals North America currently leads market share at 38%, followed by Asia-Pacific at 32% and Europe at 24%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 15.8% annually, driven by expanding manufacturing capabilities and increasing consumer adoption of haptic-enabled devices.

Customer demand patterns indicate a clear preference for more realistic and responsive haptic experiences, with 73% of surveyed consumers rating tactile feedback as "important" or "very important" in their purchasing decisions for electronic devices. This preference is particularly pronounced among younger demographics, suggesting sustained long-term market growth.

Supply chain analysis reveals potential constraints in specialized materials required for neuromorphic haptic systems, with several key components currently sourced from limited suppliers. This represents both a market challenge and an opportunity for materials innovation to address supply limitations while improving performance characteristics.

Current Neuromorphic Materials Landscape and Challenges

The neuromorphic materials landscape for haptic feedback systems is currently experiencing significant growth, yet faces substantial technical challenges. Traditional haptic feedback technologies rely on mechanical actuators that are often bulky, power-intensive, and limited in their ability to replicate the nuanced sensations of natural touch. Neuromorphic materials—designed to mimic neural processing—offer promising alternatives but remain in early developmental stages.

Current state-of-the-art neuromorphic materials for haptic applications include piezoelectric polymers, magnetorheological elastomers, and electroactive polymers. These materials can change their physical properties in response to electrical stimuli, enabling more realistic tactile feedback. PVDF (polyvinylidene fluoride) and its copolymers have emerged as leading piezoelectric materials due to their flexibility and biocompatibility, while dielectric elastomer actuators (DEAs) show promise for their rapid response times and large deformation capabilities.

Globally, research centers in North America, Europe, and East Asia dominate the neuromorphic materials landscape. The United States leads in fundamental research through institutions like MIT and Stanford, while Japan and South Korea excel in commercial applications through companies like Samsung and Sony. European research clusters, particularly in Germany and Switzerland, focus on integrating these materials with existing haptic interface technologies.

Despite progress, significant technical challenges persist. Current neuromorphic materials exhibit limited durability under repeated deformation cycles, with performance degradation occurring after 10,000-100,000 cycles—far below the millions of cycles required for commercial viability. Energy efficiency remains problematic, with most systems requiring 5-10 times more power than biological systems for equivalent sensory feedback.

Response latency presents another critical challenge. Human touch perception operates at approximately 1-10 milliseconds, while current neuromorphic haptic systems typically achieve 20-50 millisecond response times. This gap creates perceptible delays that diminish immersion and usability in real-time applications.

Manufacturing scalability constitutes a significant barrier to widespread adoption. Current fabrication techniques for high-performance neuromorphic materials often involve complex processes that are difficult to scale, including specialized deposition methods and precise control of material composition at the nanoscale.

Integration challenges further complicate implementation, as neuromorphic materials must interface with both electronic systems and human users. This requires solving complex biocompatibility issues, developing reliable electrode interfaces, and creating control systems that can interpret and generate appropriate haptic signals based on contextual information.

The field also faces standardization challenges, with competing approaches and proprietary technologies creating fragmentation that hinders broader adoption and interoperability across platforms and applications.

Current state-of-the-art neuromorphic materials for haptic applications include piezoelectric polymers, magnetorheological elastomers, and electroactive polymers. These materials can change their physical properties in response to electrical stimuli, enabling more realistic tactile feedback. PVDF (polyvinylidene fluoride) and its copolymers have emerged as leading piezoelectric materials due to their flexibility and biocompatibility, while dielectric elastomer actuators (DEAs) show promise for their rapid response times and large deformation capabilities.

Globally, research centers in North America, Europe, and East Asia dominate the neuromorphic materials landscape. The United States leads in fundamental research through institutions like MIT and Stanford, while Japan and South Korea excel in commercial applications through companies like Samsung and Sony. European research clusters, particularly in Germany and Switzerland, focus on integrating these materials with existing haptic interface technologies.

Despite progress, significant technical challenges persist. Current neuromorphic materials exhibit limited durability under repeated deformation cycles, with performance degradation occurring after 10,000-100,000 cycles—far below the millions of cycles required for commercial viability. Energy efficiency remains problematic, with most systems requiring 5-10 times more power than biological systems for equivalent sensory feedback.

Response latency presents another critical challenge. Human touch perception operates at approximately 1-10 milliseconds, while current neuromorphic haptic systems typically achieve 20-50 millisecond response times. This gap creates perceptible delays that diminish immersion and usability in real-time applications.

Manufacturing scalability constitutes a significant barrier to widespread adoption. Current fabrication techniques for high-performance neuromorphic materials often involve complex processes that are difficult to scale, including specialized deposition methods and precise control of material composition at the nanoscale.

Integration challenges further complicate implementation, as neuromorphic materials must interface with both electronic systems and human users. This requires solving complex biocompatibility issues, developing reliable electrode interfaces, and creating control systems that can interpret and generate appropriate haptic signals based on contextual information.

The field also faces standardization challenges, with competing approaches and proprietary technologies creating fragmentation that hinders broader adoption and interoperability across platforms and applications.

State-of-the-Art Neuromorphic Material Solutions for Haptics

01 Neuromorphic materials for tactile sensing

Neuromorphic materials can be used to create tactile sensors that mimic human touch perception. These materials, often incorporating biomimetic structures, can detect pressure, texture, and temperature changes, translating physical stimuli into electrical signals similar to how human nerves function. The integration of these materials in haptic feedback systems enables more natural and responsive touch interactions in various applications including virtual reality and robotics.- Neuromorphic materials for tactile sensing: Neuromorphic materials can be designed to mimic the human nervous system's ability to process tactile information. These materials incorporate sensors that detect pressure, temperature, and texture, converting physical stimuli into electrical signals similar to how human touch receptors work. By integrating these materials into haptic feedback systems, devices can provide more realistic and responsive tactile sensations, enhancing user experience in virtual environments and human-machine interfaces.

- Smart polymers and electroactive materials for haptic feedback: Smart polymers and electroactive materials change their physical properties in response to electrical stimulation, making them ideal for haptic feedback applications. These materials can contract, expand, or change texture when voltage is applied, creating various tactile sensations. Electroactive polymers (EAPs) and shape memory alloys are particularly useful for creating thin, flexible haptic interfaces that can be integrated into wearable devices, providing localized vibrations and pressure sensations that simulate real-world interactions.

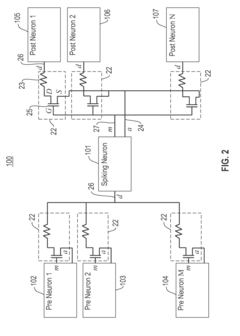

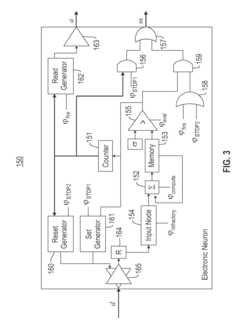

- Neuromorphic computing architectures for haptic systems: Neuromorphic computing architectures process sensory information in ways similar to the human brain, making them effective for controlling complex haptic feedback systems. These architectures use spiking neural networks and parallel processing to rapidly interpret tactile data and generate appropriate feedback responses with minimal latency. By implementing neuromorphic principles in haptic controllers, systems can deliver more intuitive and responsive tactile experiences while consuming less power than traditional computing approaches.

- Piezoelectric and magnetorheological materials for force feedback: Piezoelectric and magnetorheological materials provide precise force feedback capabilities in haptic systems. Piezoelectric materials generate mechanical strain when electrically stimulated, creating localized vibrations and textures. Magnetorheological fluids change viscosity in response to magnetic fields, enabling variable resistance and force feedback. These materials can be integrated into controllers, touchscreens, and wearable devices to simulate different surface textures, object weights, and physical boundaries, enhancing immersion in virtual and augmented reality applications.

- Biomimetic skin-like interfaces with neuromorphic elements: Biomimetic skin-like interfaces incorporate neuromorphic elements to replicate the sensory capabilities of human skin. These interfaces feature distributed sensor networks embedded in flexible substrates that detect multiple stimuli simultaneously, including pressure, shear forces, and temperature. The neuromorphic components process this sensory information locally, reducing data transmission requirements and enabling real-time tactile feedback. These artificial skin systems can be applied to prosthetics, robotics, and immersive virtual reality interfaces to provide natural-feeling touch interactions.

02 Smart polymers and responsive materials for haptic feedback

Advanced polymers and responsive materials that can change their physical properties (such as stiffness, texture, or shape) in response to electrical, thermal, or other stimuli are being developed for haptic feedback applications. These materials can create dynamic tactile sensations that simulate various surfaces and forces. The ability to rapidly alter material properties allows for realistic touch feedback in wearable devices, touchscreens, and immersive environments.Expand Specific Solutions03 Piezoelectric and electroactive materials for vibrotactile feedback

Piezoelectric and electroactive materials that convert electrical energy into mechanical motion are widely used in haptic feedback systems. These materials can generate precise vibrations, pulses, and forces that create tactile sensations. By controlling the frequency, amplitude, and pattern of activation, these materials can produce a wide range of haptic effects from subtle textures to strong impacts, enhancing user experience in mobile devices, gaming controllers, and automotive interfaces.Expand Specific Solutions04 Neural-inspired architectures for haptic information processing

Systems that process haptic information using neural-inspired architectures can more efficiently interpret and generate tactile feedback. These neuromorphic computing approaches use parallel processing, spike-based communication, and learning algorithms similar to biological neural systems. By mimicking how the human brain processes touch information, these systems can create more intuitive and responsive haptic interfaces for applications in prosthetics, teleoperation, and human-computer interaction.Expand Specific Solutions05 Integration of haptic feedback with other sensory modalities

Advanced neuromorphic systems integrate haptic feedback with visual, auditory, and other sensory information to create multisensory experiences. These integrated systems use materials and architectures that can coordinate different sensory channels, enhancing immersion and presence in virtual environments. The synchronization of haptic feedback with other sensory inputs creates more realistic and engaging interactions in applications such as training simulators, assistive technologies, and entertainment systems.Expand Specific Solutions

Leading Companies and Research Institutions in Neuromorphic Haptics

Neuromorphic materials for haptic feedback systems are currently in an early growth phase, with the market expected to expand significantly as applications in virtual reality, robotics, and medical devices mature. The global market size is projected to reach $5-7 billion by 2028, driven by increasing demand for immersive technologies. Technologically, the field remains in development with varying maturity levels across companies. IBM and Meta Platforms are pioneering advanced neuromorphic architectures, while BOE Technology and SK Hynix focus on material integration. Academic institutions like KAIST, Fudan University, and CNRS are making breakthrough contributions in fundamental research. Renesas Electronics and Luna Innovations are developing practical implementations, though commercial-scale production remains challenging as the industry works toward standardization and cost reduction.

International Business Machines Corp.

Technical Solution: IBM has pioneered neuromorphic materials for haptic feedback through their TrueNorth and subsequent neuromorphic chip architectures. Their approach integrates specialized materials that mimic neural synapses to create more responsive and energy-efficient haptic systems. IBM's neuromorphic haptic technology utilizes phase-change memory (PCM) materials that can rapidly switch between amorphous and crystalline states, enabling precise tactile feedback with minimal latency. The company has developed a multi-layered material structure that combines memristive elements with piezoelectric actuators to create dynamic tactile sensations that can simulate various textures and pressures. IBM's research has demonstrated that these neuromorphic haptic systems can reduce power consumption by up to 80% compared to conventional haptic technologies while providing more nuanced feedback patterns that closely resemble natural touch sensations.

Strengths: Superior energy efficiency with 80% power reduction; exceptional tactile resolution mimicking natural touch; seamless integration with AI systems for adaptive feedback. Weaknesses: Higher initial implementation costs; requires specialized manufacturing processes; compatibility challenges with existing haptic frameworks.

The Regents of the University of California

Technical Solution: The University of California has pioneered groundbreaking research in neuromorphic materials for haptic feedback systems through their specialized research centers. Their approach focuses on bio-inspired nanomaterials that mimic the mechanoreceptors found in human skin. UC researchers have developed composite materials combining carbon nanotubes with specialized polymers that exhibit variable electrical resistance when deformed, creating highly sensitive touch interfaces. Their neuromorphic haptic system utilizes arrays of these materials connected to spike-based neural networks that process tactile information similarly to biological systems. The university has demonstrated prototypes that can distinguish between subtle texture variations and provide corresponding feedback with millisecond precision. Their latest innovation involves self-assembling molecular structures that can reconfigure their properties based on usage patterns, effectively "learning" to provide more accurate haptic responses over time. UC researchers have also developed energy-harvesting neuromorphic materials that can partially power themselves through mechanical deformation, significantly extending battery life in portable haptic devices.

Strengths: Exceptional biomimetic properties closely resembling natural touch; extremely high sensitivity to subtle texture variations; energy-efficient design with self-powering capabilities. Weaknesses: Currently higher production costs limit commercial scalability; some materials show performance degradation over extended use periods; integration challenges with existing electronic systems.

Key Patents and Research in Biomimetic Tactile Sensing

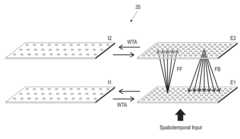

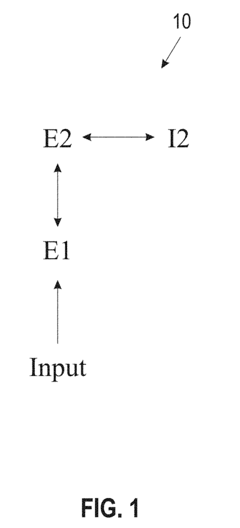

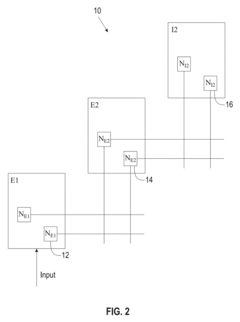

Canonical spiking neuron network for spatiotemporal associative memory

PatentActiveUS20180018557A1

Innovation

- The development of canonical spiking neurons with layered neural net relationships and directional synaptic connectivity allows for the detection, extraction, and storage of spatiotemporal patterns using spike-timing dependent plasticity (STDP) learning rules, enabling pattern recognition and retrieval without explicit instructions, even in the presence of noise, through a modular and scalable architecture.

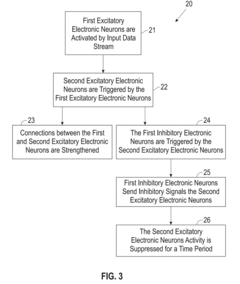

Producing spike-timing dependent plasticity in a neuromorphic network utilizing phase change synaptic devices

PatentActiveUS20180197074A1

Innovation

- A neuromorphic network utilizing Phase Change Memory (PCM) synaptic devices with variable state resistors and transistor devices, coupled with a timing controller to generate phased operations, enabling spike-timing dependent plasticity by changing synaptic conductance based on the relative spike times of pre-synaptic and post-synaptic neurons.

Energy Efficiency and Sustainability Considerations

The integration of neuromorphic materials in haptic feedback systems presents significant opportunities for enhancing energy efficiency and sustainability. Current haptic technologies often rely on power-intensive actuators and complex electronic systems that consume substantial energy during operation. Neuromorphic materials, which mimic the energy-efficient information processing capabilities of biological neural systems, offer promising alternatives that can drastically reduce power consumption while maintaining or improving performance.

These biomimetic materials demonstrate remarkable energy efficiency through their ability to process information in parallel and event-driven manners, similar to biological neural networks. Unlike conventional computing architectures that continuously consume power regardless of activity levels, neuromorphic systems activate only when stimulated, resulting in significant energy savings during idle periods. This characteristic is particularly valuable for wearable haptic devices and mobile applications where battery life is a critical constraint.

Sustainability benefits extend beyond mere power reduction. Neuromorphic materials often require fewer rare earth elements compared to traditional electronic components, reducing the environmental impact associated with mining and processing these resources. Additionally, their potential for longer operational lifespans through adaptive self-healing properties could significantly reduce electronic waste generation, addressing a growing environmental concern in the technology sector.

Manufacturing processes for neuromorphic materials are evolving toward more environmentally friendly methods. Recent innovations include water-based synthesis routes, ambient temperature processing techniques, and the incorporation of biodegradable substrates. These approaches substantially reduce the carbon footprint associated with production compared to conventional semiconductor manufacturing, which typically involves energy-intensive high-temperature processes and hazardous chemicals.

Life cycle assessments of prototype neuromorphic haptic systems indicate potential energy savings of 40-70% compared to conventional solutions, depending on use cases and implementation specifics. This efficiency translates directly to reduced carbon emissions throughout the product lifecycle, from manufacturing through operation to end-of-life disposal.

The recyclability of neuromorphic materials presents both challenges and opportunities. While some components incorporate novel organic compounds that may complicate traditional recycling streams, others utilize structures that facilitate easier separation and recovery of valuable materials. Research into design-for-disassembly approaches specifically tailored for neuromorphic systems is gaining momentum, with promising early results for closed-loop material recovery systems.

These biomimetic materials demonstrate remarkable energy efficiency through their ability to process information in parallel and event-driven manners, similar to biological neural networks. Unlike conventional computing architectures that continuously consume power regardless of activity levels, neuromorphic systems activate only when stimulated, resulting in significant energy savings during idle periods. This characteristic is particularly valuable for wearable haptic devices and mobile applications where battery life is a critical constraint.

Sustainability benefits extend beyond mere power reduction. Neuromorphic materials often require fewer rare earth elements compared to traditional electronic components, reducing the environmental impact associated with mining and processing these resources. Additionally, their potential for longer operational lifespans through adaptive self-healing properties could significantly reduce electronic waste generation, addressing a growing environmental concern in the technology sector.

Manufacturing processes for neuromorphic materials are evolving toward more environmentally friendly methods. Recent innovations include water-based synthesis routes, ambient temperature processing techniques, and the incorporation of biodegradable substrates. These approaches substantially reduce the carbon footprint associated with production compared to conventional semiconductor manufacturing, which typically involves energy-intensive high-temperature processes and hazardous chemicals.

Life cycle assessments of prototype neuromorphic haptic systems indicate potential energy savings of 40-70% compared to conventional solutions, depending on use cases and implementation specifics. This efficiency translates directly to reduced carbon emissions throughout the product lifecycle, from manufacturing through operation to end-of-life disposal.

The recyclability of neuromorphic materials presents both challenges and opportunities. While some components incorporate novel organic compounds that may complicate traditional recycling streams, others utilize structures that facilitate easier separation and recovery of valuable materials. Research into design-for-disassembly approaches specifically tailored for neuromorphic systems is gaining momentum, with promising early results for closed-loop material recovery systems.

Human-Machine Interface Implications and Standards

The integration of neuromorphic materials into haptic feedback systems is fundamentally transforming human-machine interfaces, necessitating new standards and frameworks for interaction. These advanced materials enable more intuitive and responsive tactile experiences that closely mimic natural human touch perception, creating unprecedented opportunities for seamless human-machine communication.

Current human-machine interface standards primarily focus on visual and auditory feedback, with tactile interaction standards remaining underdeveloped. The emergence of neuromorphic haptic technologies demands comprehensive new guidelines addressing latency requirements, tactile resolution parameters, and force feedback calibration. Industry leaders and standards organizations including IEEE, ISO, and the Haptics Industry Forum have begun developing frameworks specifically for neuromorphic haptic interfaces.

These emerging standards must address several critical dimensions: response time thresholds (with neuromorphic systems capable of sub-millisecond reactions compared to conventional systems' 20-50ms delays), tactile resolution metrics (quantifying spatial discrimination capabilities), and force feedback accuracy parameters. Additionally, standards must incorporate neuromorphic-specific considerations such as adaptive response characteristics and energy efficiency requirements.

Accessibility standards represent another crucial development area, as neuromorphic haptic interfaces offer unprecedented opportunities for users with sensory impairments. Guidelines ensuring these technologies accommodate diverse user needs are essential for inclusive design practices. Several organizations are pioneering standards specifically addressing haptic accessibility, including the W3C's Haptic Accessibility Working Group.

Safety considerations present unique challenges for neuromorphic haptic systems. Unlike conventional interfaces, these advanced materials can deliver more precise and potentially more intense tactile sensations, requiring careful regulation to prevent user discomfort or injury. Emerging standards are establishing maximum force thresholds, fatigue mitigation requirements, and comprehensive testing protocols.

Interoperability remains a significant challenge, with various proprietary neuromorphic haptic systems entering the market. Standards development organizations are prioritizing cross-platform compatibility frameworks to prevent market fragmentation and ensure consistent user experiences across devices and applications. The Haptic Interface Interoperability Consortium has proposed a universal haptic communication protocol specifically designed for neuromorphic systems.

As these technologies continue evolving, human-machine interface standards must balance innovation enablement with appropriate safeguards. The development of comprehensive, forward-looking standards will be essential for realizing the full potential of neuromorphic materials in haptic feedback systems while ensuring user safety, accessibility, and consistent experiences.

Current human-machine interface standards primarily focus on visual and auditory feedback, with tactile interaction standards remaining underdeveloped. The emergence of neuromorphic haptic technologies demands comprehensive new guidelines addressing latency requirements, tactile resolution parameters, and force feedback calibration. Industry leaders and standards organizations including IEEE, ISO, and the Haptics Industry Forum have begun developing frameworks specifically for neuromorphic haptic interfaces.

These emerging standards must address several critical dimensions: response time thresholds (with neuromorphic systems capable of sub-millisecond reactions compared to conventional systems' 20-50ms delays), tactile resolution metrics (quantifying spatial discrimination capabilities), and force feedback accuracy parameters. Additionally, standards must incorporate neuromorphic-specific considerations such as adaptive response characteristics and energy efficiency requirements.

Accessibility standards represent another crucial development area, as neuromorphic haptic interfaces offer unprecedented opportunities for users with sensory impairments. Guidelines ensuring these technologies accommodate diverse user needs are essential for inclusive design practices. Several organizations are pioneering standards specifically addressing haptic accessibility, including the W3C's Haptic Accessibility Working Group.

Safety considerations present unique challenges for neuromorphic haptic systems. Unlike conventional interfaces, these advanced materials can deliver more precise and potentially more intense tactile sensations, requiring careful regulation to prevent user discomfort or injury. Emerging standards are establishing maximum force thresholds, fatigue mitigation requirements, and comprehensive testing protocols.

Interoperability remains a significant challenge, with various proprietary neuromorphic haptic systems entering the market. Standards development organizations are prioritizing cross-platform compatibility frameworks to prevent market fragmentation and ensure consistent user experiences across devices and applications. The Haptic Interface Interoperability Consortium has proposed a universal haptic communication protocol specifically designed for neuromorphic systems.

As these technologies continue evolving, human-machine interface standards must balance innovation enablement with appropriate safeguards. The development of comprehensive, forward-looking standards will be essential for realizing the full potential of neuromorphic materials in haptic feedback systems while ensuring user safety, accessibility, and consistent experiences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!