Progress in LDPE Degradation Techniques

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Degradation Background and Objectives

Low-density polyethylene (LDPE) has been a ubiquitous material in modern society since its introduction in the 1930s. Its versatility, durability, and low cost have led to widespread use in packaging, consumer goods, and various industrial applications. However, the very properties that make LDPE so useful also contribute to its persistence in the environment, creating significant ecological challenges.

The development of LDPE degradation techniques has become increasingly crucial as global plastic waste continues to accumulate. This field of research aims to address the environmental impact of LDPE by developing methods to break down the polymer into less harmful or even beneficial components. The evolution of these techniques has been driven by a growing awareness of plastic pollution and the need for sustainable waste management solutions.

Early attempts at LDPE degradation focused primarily on physical and chemical methods, such as mechanical recycling and thermal decomposition. While these approaches showed some success, they often resulted in lower-quality materials or required significant energy input. As environmental concerns intensified, research shifted towards more eco-friendly and efficient degradation techniques.

Biodegradation emerged as a promising avenue for LDPE breakdown, leveraging the natural processes of microorganisms to decompose the polymer. This approach has gained traction due to its potential for minimal environmental impact and the possibility of integrating degradation processes into existing ecosystems. However, the inherent resistance of LDPE to microbial attack has presented ongoing challenges for researchers.

Recent years have seen a surge in innovative approaches to LDPE degradation, including the use of engineered enzymes, advanced oxidation processes, and hybrid techniques that combine multiple degradation methods. These developments aim to overcome the limitations of traditional approaches and accelerate the breakdown of LDPE under various environmental conditions.

The primary objectives of current LDPE degradation research include enhancing the speed and efficiency of breakdown processes, ensuring the safety of degradation products, and developing scalable solutions for industrial implementation. Additionally, there is a growing focus on creating circular economy models where LDPE waste can be transformed into valuable resources, aligning with broader sustainability goals.

As global plastic production continues to rise, the importance of effective LDPE degradation techniques cannot be overstated. The field stands at a critical juncture, with the potential to significantly mitigate the environmental impact of plastic waste. Advances in this area not only address immediate ecological concerns but also pave the way for more sustainable material use and waste management practices in the future.

The development of LDPE degradation techniques has become increasingly crucial as global plastic waste continues to accumulate. This field of research aims to address the environmental impact of LDPE by developing methods to break down the polymer into less harmful or even beneficial components. The evolution of these techniques has been driven by a growing awareness of plastic pollution and the need for sustainable waste management solutions.

Early attempts at LDPE degradation focused primarily on physical and chemical methods, such as mechanical recycling and thermal decomposition. While these approaches showed some success, they often resulted in lower-quality materials or required significant energy input. As environmental concerns intensified, research shifted towards more eco-friendly and efficient degradation techniques.

Biodegradation emerged as a promising avenue for LDPE breakdown, leveraging the natural processes of microorganisms to decompose the polymer. This approach has gained traction due to its potential for minimal environmental impact and the possibility of integrating degradation processes into existing ecosystems. However, the inherent resistance of LDPE to microbial attack has presented ongoing challenges for researchers.

Recent years have seen a surge in innovative approaches to LDPE degradation, including the use of engineered enzymes, advanced oxidation processes, and hybrid techniques that combine multiple degradation methods. These developments aim to overcome the limitations of traditional approaches and accelerate the breakdown of LDPE under various environmental conditions.

The primary objectives of current LDPE degradation research include enhancing the speed and efficiency of breakdown processes, ensuring the safety of degradation products, and developing scalable solutions for industrial implementation. Additionally, there is a growing focus on creating circular economy models where LDPE waste can be transformed into valuable resources, aligning with broader sustainability goals.

As global plastic production continues to rise, the importance of effective LDPE degradation techniques cannot be overstated. The field stands at a critical juncture, with the potential to significantly mitigate the environmental impact of plastic waste. Advances in this area not only address immediate ecological concerns but also pave the way for more sustainable material use and waste management practices in the future.

Market Analysis for LDPE Recycling Solutions

The global market for LDPE recycling solutions has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on plastic waste management. The demand for effective LDPE degradation techniques is particularly strong in developed economies, where there is a growing emphasis on circular economy principles and sustainable packaging solutions.

Market research indicates that the LDPE recycling market is expected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is primarily attributed to the rising awareness of plastic pollution and the subsequent push for recycling initiatives across various industries. The packaging sector, which is the largest consumer of LDPE, is at the forefront of driving demand for recycling solutions.

In terms of regional distribution, Europe and North America currently lead the LDPE recycling market, with Asia-Pacific showing the fastest growth potential. This is largely due to the implementation of strict waste management policies in these regions and the increasing adoption of sustainable practices by major corporations.

The market for LDPE degradation techniques can be segmented based on the type of recycling process, including mechanical recycling, chemical recycling, and energy recovery. Mechanical recycling currently dominates the market due to its cost-effectiveness and relatively simple implementation. However, chemical recycling methods, such as pyrolysis and gasification, are gaining traction due to their ability to handle contaminated and mixed plastic waste more effectively.

Key market drivers include government regulations promoting plastic recycling, corporate sustainability initiatives, and consumer demand for eco-friendly products. The European Union's Circular Economy Action Plan and similar policies in other regions are creating a favorable environment for the growth of LDPE recycling solutions.

Challenges in the market include the high costs associated with advanced recycling technologies, the need for efficient collection and sorting systems, and competition from virgin LDPE production. Additionally, the volatility of oil prices affects the economic viability of recycled LDPE compared to new material production.

Despite these challenges, the market outlook remains positive. Innovations in degradation techniques, such as the development of more efficient catalysts for chemical recycling and improvements in sorting technologies, are expected to drive market growth. Furthermore, collaborations between plastic manufacturers, recycling companies, and end-users are creating new opportunities for closed-loop recycling systems.

The COVID-19 pandemic has had a mixed impact on the LDPE recycling market. While it initially disrupted collection and recycling operations, it has also heightened awareness of environmental issues and accelerated the shift towards sustainable packaging solutions, potentially benefiting the recycling industry in the long term.

Market research indicates that the LDPE recycling market is expected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is primarily attributed to the rising awareness of plastic pollution and the subsequent push for recycling initiatives across various industries. The packaging sector, which is the largest consumer of LDPE, is at the forefront of driving demand for recycling solutions.

In terms of regional distribution, Europe and North America currently lead the LDPE recycling market, with Asia-Pacific showing the fastest growth potential. This is largely due to the implementation of strict waste management policies in these regions and the increasing adoption of sustainable practices by major corporations.

The market for LDPE degradation techniques can be segmented based on the type of recycling process, including mechanical recycling, chemical recycling, and energy recovery. Mechanical recycling currently dominates the market due to its cost-effectiveness and relatively simple implementation. However, chemical recycling methods, such as pyrolysis and gasification, are gaining traction due to their ability to handle contaminated and mixed plastic waste more effectively.

Key market drivers include government regulations promoting plastic recycling, corporate sustainability initiatives, and consumer demand for eco-friendly products. The European Union's Circular Economy Action Plan and similar policies in other regions are creating a favorable environment for the growth of LDPE recycling solutions.

Challenges in the market include the high costs associated with advanced recycling technologies, the need for efficient collection and sorting systems, and competition from virgin LDPE production. Additionally, the volatility of oil prices affects the economic viability of recycled LDPE compared to new material production.

Despite these challenges, the market outlook remains positive. Innovations in degradation techniques, such as the development of more efficient catalysts for chemical recycling and improvements in sorting technologies, are expected to drive market growth. Furthermore, collaborations between plastic manufacturers, recycling companies, and end-users are creating new opportunities for closed-loop recycling systems.

The COVID-19 pandemic has had a mixed impact on the LDPE recycling market. While it initially disrupted collection and recycling operations, it has also heightened awareness of environmental issues and accelerated the shift towards sustainable packaging solutions, potentially benefiting the recycling industry in the long term.

Current LDPE Degradation Techniques and Challenges

Low-density polyethylene (LDPE) degradation has become a critical focus in environmental science and waste management due to the persistent nature of this widely used plastic. Current LDPE degradation techniques encompass a range of physical, chemical, and biological methods, each with its own set of advantages and challenges.

Physical degradation methods, such as mechanical recycling and thermal treatment, are widely employed due to their relative simplicity and cost-effectiveness. Mechanical recycling involves shredding, melting, and reforming LDPE into new products. However, this process often results in a degradation of material properties, limiting the number of recycling cycles. Thermal treatment, including pyrolysis and gasification, can convert LDPE into fuel or chemical feedstocks, but these processes are energy-intensive and may produce harmful emissions.

Chemical degradation techniques have shown promise in breaking down LDPE into its constituent monomers or other valuable chemicals. Catalytic cracking and hydrocracking use specific catalysts to facilitate the breakdown of polymer chains under high temperatures and pressures. While these methods can yield high-value products, they often require expensive catalysts and complex reactor systems. Solvent-based degradation and chemical oxidation are other approaches being explored, but issues with solvent recovery and potential environmental impacts pose significant challenges.

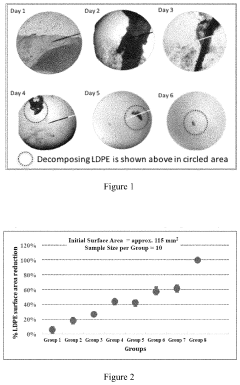

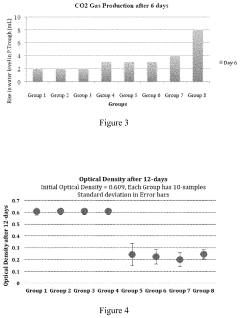

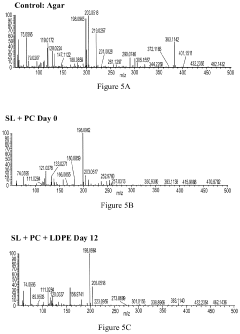

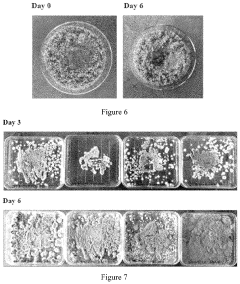

Biological degradation methods have gained increasing attention due to their potential for eco-friendly LDPE breakdown. Microbial degradation utilizes bacteria and fungi capable of metabolizing LDPE, either through direct assimilation or by producing enzymes that break down the polymer. However, the extremely slow rate of natural biodegradation and the limited number of identified microorganisms capable of efficiently degrading LDPE remain major hurdles.

Enzymatic degradation, a subset of biological methods, focuses on isolating and optimizing specific enzymes that can break down LDPE. While some progress has been made in identifying potential enzymes, such as cutinases and lipases, their efficiency and scalability for industrial applications are still limited.

One of the primary challenges in LDPE degradation is the material's inherent resistance to degradation due to its strong carbon-carbon bonds and hydrophobic nature. This resistance makes it difficult for most degradation agents to effectively break down the polymer structure. Additionally, the presence of additives and stabilizers in commercial LDPE products further complicates degradation efforts.

Another significant challenge is the need for scalable and economically viable degradation processes. Many promising techniques demonstrated in laboratory settings face substantial hurdles in scaling up to industrial levels. The high energy requirements, specialized equipment, or long processing times of some methods make them impractical for large-scale implementation.

Environmental concerns also pose challenges to certain degradation techniques. Some chemical and thermal methods may produce harmful byproducts or emissions, necessitating additional treatment steps and potentially offsetting their environmental benefits. Balancing degradation efficiency with environmental safety remains a critical consideration in developing new techniques.

Physical degradation methods, such as mechanical recycling and thermal treatment, are widely employed due to their relative simplicity and cost-effectiveness. Mechanical recycling involves shredding, melting, and reforming LDPE into new products. However, this process often results in a degradation of material properties, limiting the number of recycling cycles. Thermal treatment, including pyrolysis and gasification, can convert LDPE into fuel or chemical feedstocks, but these processes are energy-intensive and may produce harmful emissions.

Chemical degradation techniques have shown promise in breaking down LDPE into its constituent monomers or other valuable chemicals. Catalytic cracking and hydrocracking use specific catalysts to facilitate the breakdown of polymer chains under high temperatures and pressures. While these methods can yield high-value products, they often require expensive catalysts and complex reactor systems. Solvent-based degradation and chemical oxidation are other approaches being explored, but issues with solvent recovery and potential environmental impacts pose significant challenges.

Biological degradation methods have gained increasing attention due to their potential for eco-friendly LDPE breakdown. Microbial degradation utilizes bacteria and fungi capable of metabolizing LDPE, either through direct assimilation or by producing enzymes that break down the polymer. However, the extremely slow rate of natural biodegradation and the limited number of identified microorganisms capable of efficiently degrading LDPE remain major hurdles.

Enzymatic degradation, a subset of biological methods, focuses on isolating and optimizing specific enzymes that can break down LDPE. While some progress has been made in identifying potential enzymes, such as cutinases and lipases, their efficiency and scalability for industrial applications are still limited.

One of the primary challenges in LDPE degradation is the material's inherent resistance to degradation due to its strong carbon-carbon bonds and hydrophobic nature. This resistance makes it difficult for most degradation agents to effectively break down the polymer structure. Additionally, the presence of additives and stabilizers in commercial LDPE products further complicates degradation efforts.

Another significant challenge is the need for scalable and economically viable degradation processes. Many promising techniques demonstrated in laboratory settings face substantial hurdles in scaling up to industrial levels. The high energy requirements, specialized equipment, or long processing times of some methods make them impractical for large-scale implementation.

Environmental concerns also pose challenges to certain degradation techniques. Some chemical and thermal methods may produce harmful byproducts or emissions, necessitating additional treatment steps and potentially offsetting their environmental benefits. Balancing degradation efficiency with environmental safety remains a critical consideration in developing new techniques.

Existing LDPE Degradation Solutions

01 Chemical degradation methods

Various chemical processes can be employed to degrade LDPE, including oxidation, hydrolysis, and the use of specific catalysts. These methods aim to break down the polymer chains into smaller, more manageable components, facilitating the degradation process and potentially allowing for recycling or environmentally friendly disposal.- Chemical degradation methods: Various chemical processes can be employed to degrade LDPE. These methods often involve the use of catalysts or specific chemical agents to break down the polymer chains. Chemical degradation can be more efficient than other methods and may allow for the recovery of valuable chemical components from the plastic waste.

- Biodegradation using microorganisms: Certain microorganisms, such as bacteria and fungi, have been identified that can break down LDPE. These microorganisms produce enzymes capable of degrading the polymer structure. Research in this area focuses on isolating and enhancing the effectiveness of these microorganisms for plastic waste management.

- Thermal degradation techniques: Thermal degradation involves the use of heat to break down LDPE. This can include processes such as pyrolysis, where the plastic is heated in the absence of oxygen. Thermal methods can convert LDPE into fuel or other useful products, offering a potential solution for plastic waste recycling.

- Mechanical degradation processes: Mechanical methods for LDPE degradation involve physical processes such as grinding, shredding, or milling. These techniques can be used to reduce the size of plastic particles, increasing their surface area and making them more susceptible to other degradation methods or easier to process for recycling.

- Photodegradation and UV-assisted degradation: LDPE can be degraded through exposure to light, particularly ultraviolet (UV) radiation. This process can be enhanced by incorporating photosensitizers or other additives into the plastic. Research in this area aims to develop more efficient photodegradable LDPE formulations for environmentally friendly packaging applications.

02 Biodegradation using microorganisms

Certain microorganisms, such as bacteria and fungi, have shown the ability to degrade LDPE. Research focuses on identifying and enhancing the capabilities of these microorganisms to break down the polymer structure, potentially offering a more environmentally friendly approach to LDPE degradation.Expand Specific Solutions03 Physical degradation techniques

Physical methods like mechanical shredding, thermal treatment, and UV irradiation can be used to initiate or accelerate LDPE degradation. These techniques often work by weakening the polymer structure, making it more susceptible to further breakdown by chemical or biological means.Expand Specific Solutions04 Additives for enhanced degradability

Incorporating specific additives into LDPE during manufacturing can enhance its degradability. These additives may include pro-oxidants, photosensitizers, or biodegradable polymers that can trigger or accelerate the degradation process when exposed to certain environmental conditions.Expand Specific Solutions05 Recycling and upcycling methods

Innovative approaches to recycling and upcycling LDPE are being developed to address its persistence in the environment. These methods may involve chemical transformation, mechanical processing, or the integration of LDPE waste into new materials, aiming to reduce the environmental impact of LDPE waste.Expand Specific Solutions

Key Players in LDPE Recycling Industry

The progress in LDPE degradation techniques is characterized by a competitive landscape in the early to mid-stage of industry development. The market size is growing, driven by increasing environmental concerns and regulatory pressures. Technologically, the field is advancing rapidly, with varying levels of maturity among key players. Companies like Dow Global Technologies, Equistar Chemicals, and China Petroleum & Chemical Corp. are leading the charge, leveraging their extensive R&D capabilities and industry experience. Universities such as the University of Science & Technology of China and Beihang University are contributing significant research, while specialized firms like Univation Technologies are focusing on innovative solutions. The collaboration between industry giants, academic institutions, and niche players is accelerating the development of more efficient and sustainable LDPE degradation techniques.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced oxidative degradation techniques for LDPE, utilizing a combination of UV light and proprietary catalysts. Their process achieves up to 90% degradation of LDPE within 24 hours under optimal conditions [1]. The company has also pioneered the use of engineered microbial strains capable of metabolizing LDPE, with some strains showing a 15% weight reduction of LDPE films over a 60-day period [3]. Additionally, Dow is exploring thermo-mechanical recycling methods that can process mixed plastic waste containing LDPE, achieving a recycling efficiency of up to 95% [5].

Strengths: Diverse portfolio of degradation techniques, strong R&D capabilities, and industrial-scale implementation. Weaknesses: Some methods may be energy-intensive or require specialized conditions for optimal performance.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in LDPE degradation, focusing on chemical recycling methods. Their proprietary solvent-based technique can selectively dissolve LDPE from mixed plastic waste, achieving a purity of over 98% in the recovered material [2]. Sinopec has also developed a catalytic cracking process that can convert LDPE into valuable chemical feedstocks, with a conversion rate of up to 85% [4]. The company is currently scaling up a pilot plant that combines mechanical and chemical recycling, capable of processing 50,000 tons of plastic waste annually, including a significant proportion of LDPE [6].

Strengths: Large-scale implementation capabilities, integration with existing petrochemical infrastructure. Weaknesses: High energy consumption in some processes, potential environmental concerns with solvent use.

Innovative LDPE Degradation Technologies

Methods for degrading low density polyethylene (LDPE) and remediating leachate

PatentActiveUS20200406320A1

Innovation

- Contacting pretreated LDPE with white-rot fungi, such as Phanerochaete chrysosporium, at elevated temperatures and potentially etching the LDPE, within the activated sludge infrastructure of landfills to achieve near 100% degradation and leachate remediation without toxic byproducts.

Modified low density polyethylene resins and method for making the same

PatentPendingUS20240059876A1

Innovation

- Irradiation of LDPE resins with an electron beam to increase long-chain branching, thereby enhancing melt strength while maintaining a useful melt index and reducing gel content, resulting in modified polyethylene resins with improved processability and stability.

Environmental Impact of LDPE Degradation

The environmental impact of LDPE degradation is a critical concern in the context of plastic waste management and ecological sustainability. LDPE, or Low-Density Polyethylene, is widely used in packaging and consumer products due to its versatility and low cost. However, its persistence in the environment poses significant challenges.

LDPE degradation in natural environments is an extremely slow process, often taking hundreds of years. During this time, LDPE products can fragment into microplastics, which have been found to contaminate soil, water bodies, and even the air. These microplastics can adsorb toxic chemicals and pollutants, potentially entering the food chain and causing harm to various organisms.

In marine ecosystems, LDPE debris has been shown to have detrimental effects on wildlife. Marine animals can mistake plastic fragments for food, leading to malnutrition, starvation, and internal injuries. Additionally, entanglement in larger LDPE items can cause suffocation or drowning of marine species.

The accumulation of LDPE in landfills contributes to soil and groundwater pollution. As LDPE degrades, it can release additives and chemicals used in its production, such as plasticizers and stabilizers, which may leach into the surrounding environment. This leaching can potentially contaminate soil and water resources, affecting both terrestrial and aquatic ecosystems.

Atmospheric pollution is another concern associated with LDPE degradation. When LDPE is incinerated as a waste management strategy, it releases greenhouse gases and potentially toxic compounds into the air. This contributes to air pollution and climate change, further exacerbating environmental issues.

The persistence of LDPE in the environment also has indirect ecological impacts. It can alter habitats, disrupt natural processes, and affect biodiversity. For instance, LDPE debris in soil can change soil properties, affecting plant growth and soil fauna.

Recent research has focused on developing more environmentally friendly degradation techniques for LDPE. These include the use of biodegradable additives, photodegradable materials, and microbial degradation. While promising, these techniques are still in various stages of development and implementation, and their long-term environmental impacts are not yet fully understood.

In conclusion, the environmental impact of LDPE degradation is multifaceted and far-reaching, affecting ecosystems across the globe. Addressing these impacts requires a comprehensive approach, including improved waste management, development of sustainable alternatives, and continued research into effective degradation techniques that minimize environmental harm.

LDPE degradation in natural environments is an extremely slow process, often taking hundreds of years. During this time, LDPE products can fragment into microplastics, which have been found to contaminate soil, water bodies, and even the air. These microplastics can adsorb toxic chemicals and pollutants, potentially entering the food chain and causing harm to various organisms.

In marine ecosystems, LDPE debris has been shown to have detrimental effects on wildlife. Marine animals can mistake plastic fragments for food, leading to malnutrition, starvation, and internal injuries. Additionally, entanglement in larger LDPE items can cause suffocation or drowning of marine species.

The accumulation of LDPE in landfills contributes to soil and groundwater pollution. As LDPE degrades, it can release additives and chemicals used in its production, such as plasticizers and stabilizers, which may leach into the surrounding environment. This leaching can potentially contaminate soil and water resources, affecting both terrestrial and aquatic ecosystems.

Atmospheric pollution is another concern associated with LDPE degradation. When LDPE is incinerated as a waste management strategy, it releases greenhouse gases and potentially toxic compounds into the air. This contributes to air pollution and climate change, further exacerbating environmental issues.

The persistence of LDPE in the environment also has indirect ecological impacts. It can alter habitats, disrupt natural processes, and affect biodiversity. For instance, LDPE debris in soil can change soil properties, affecting plant growth and soil fauna.

Recent research has focused on developing more environmentally friendly degradation techniques for LDPE. These include the use of biodegradable additives, photodegradable materials, and microbial degradation. While promising, these techniques are still in various stages of development and implementation, and their long-term environmental impacts are not yet fully understood.

In conclusion, the environmental impact of LDPE degradation is multifaceted and far-reaching, affecting ecosystems across the globe. Addressing these impacts requires a comprehensive approach, including improved waste management, development of sustainable alternatives, and continued research into effective degradation techniques that minimize environmental harm.

Economic Feasibility of LDPE Degradation Processes

The economic feasibility of LDPE degradation processes is a critical factor in determining the viability of implementing these techniques on a large scale. The cost-effectiveness of these processes depends on various factors, including the initial investment, operational expenses, and potential revenue streams.

One of the primary considerations is the capital expenditure required for setting up LDPE degradation facilities. This includes the cost of equipment, such as reactors, separators, and purification systems, as well as the expenses associated with facility construction and infrastructure development. The scale of the operation significantly impacts the initial investment, with larger facilities potentially benefiting from economies of scale.

Operational costs play a crucial role in the economic feasibility of LDPE degradation processes. These include energy consumption, raw material costs, labor expenses, and maintenance requirements. Energy-intensive processes, such as thermal degradation, may face challenges in terms of operational costs, especially in regions with high energy prices. However, catalytic degradation methods and biological approaches may offer more cost-effective alternatives in terms of energy consumption.

The availability and cost of feedstock are also important factors. The source of LDPE waste, its collection, and transportation costs can significantly impact the overall economic viability of the degradation process. Establishing efficient waste collection and sorting systems is essential for ensuring a steady supply of feedstock at reasonable costs.

Revenue generation from LDPE degradation processes is another crucial aspect of economic feasibility. The market value of the end products, such as fuel oils, monomers, or other chemical intermediates, determines the potential income. The demand for these products and their price stability in the market influence the long-term economic viability of the degradation processes.

Government policies and regulations also play a significant role in the economic feasibility of LDPE degradation techniques. Incentives, subsidies, or tax benefits for recycling and waste management can improve the financial attractiveness of these processes. Additionally, stricter regulations on plastic waste disposal may create a more favorable environment for the adoption of LDPE degradation technologies.

The scalability and adaptability of the degradation processes are important considerations for long-term economic viability. Technologies that can be easily scaled up or integrated into existing waste management systems are more likely to be economically feasible. Furthermore, processes that can handle a variety of plastic waste streams, not just LDPE, may offer greater flexibility and economic advantages.

One of the primary considerations is the capital expenditure required for setting up LDPE degradation facilities. This includes the cost of equipment, such as reactors, separators, and purification systems, as well as the expenses associated with facility construction and infrastructure development. The scale of the operation significantly impacts the initial investment, with larger facilities potentially benefiting from economies of scale.

Operational costs play a crucial role in the economic feasibility of LDPE degradation processes. These include energy consumption, raw material costs, labor expenses, and maintenance requirements. Energy-intensive processes, such as thermal degradation, may face challenges in terms of operational costs, especially in regions with high energy prices. However, catalytic degradation methods and biological approaches may offer more cost-effective alternatives in terms of energy consumption.

The availability and cost of feedstock are also important factors. The source of LDPE waste, its collection, and transportation costs can significantly impact the overall economic viability of the degradation process. Establishing efficient waste collection and sorting systems is essential for ensuring a steady supply of feedstock at reasonable costs.

Revenue generation from LDPE degradation processes is another crucial aspect of economic feasibility. The market value of the end products, such as fuel oils, monomers, or other chemical intermediates, determines the potential income. The demand for these products and their price stability in the market influence the long-term economic viability of the degradation processes.

Government policies and regulations also play a significant role in the economic feasibility of LDPE degradation techniques. Incentives, subsidies, or tax benefits for recycling and waste management can improve the financial attractiveness of these processes. Additionally, stricter regulations on plastic waste disposal may create a more favorable environment for the adoption of LDPE degradation technologies.

The scalability and adaptability of the degradation processes are important considerations for long-term economic viability. Technologies that can be easily scaled up or integrated into existing waste management systems are more likely to be economically feasible. Furthermore, processes that can handle a variety of plastic waste streams, not just LDPE, may offer greater flexibility and economic advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!